| Pages:

1

2

3 |

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

so... hurray! I appear to have succeeded.

Bad news? I seem to have a problem cleaning my buchner funnel. The frit is contaminated with minute amounts of NHN and since I am putting sodium

hydroxide through it to neutralize it, it is turning green from nickel oxide... Is my buchner funnel done for? I planned on giving it away for someone

to use to make food grade stuff. I figure it is kinda useless now for that purpose?

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

nah, it's fine just wash it with sodium hydroxide then hydrochloric acid, the hydrochloric acid cleans off any nickel oxide

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

That's good to know. How dilute does the HCl need to be?

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

maybe 10-5% it doesn’t matter much, just enough to dissolve the small amount of nickel oxide

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

OK, so my HCl is around 31.5%, so to 1 part of that, add 2.5 parts of water. simple enough.

[Edited on 15-12-2021 by ManyInterests]

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

yea, it's not an exact science, anywhere between 15% and 5% would probably work

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

Here is my end result! 8 grams (wow! I wasn't expecting that much!) of clay like NHN. I did burn the filter paper and I did hear the snap and crackle

that is characteristic of small NHN deflageration.

That being said. It seems like I added too little dextrin to the nickel nitrate, or the dextrin should have been added to the hydrazine. At any rate.

I will need to very carefully grind them up with a rubber spatula, just like the documentation said.

Edit: After grinding I had apparently lost 0.2 grams (enough for a cap!) that got stuck to the containers.

I hate to throw them away. But after this... well, I'm soaking them in sodium hydroxide solution to neutralize the NHN. I will throw the water after

and throw them in the trash. I can always get more glass baking pans.

[Edited on 17-12-2021 by ManyInterests]

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

Yea, you’ll always lose a bit to mechanical loses, but 8g is a very nice amount, enough for 40 detonators which should last a very long time, in

confinement does the NHN strongly detonate? (Don’t test to much, I usually use remote detonator for my first test or two, just to get a feel of how

much I can test at a time)

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

40 detonators? That's quite a lot. I was thinking around 16. The reason is I was using the improvised munitions manual as a guide on making improvised

detonators.

They recommend 1 gram of a booster (RDX, picric acid, or ETN/PETN) combined with anything from 3 grams of lead picrate to one gram of TACC, 0.5 grams

of DDNP, or 0.75 grams of mercury fulminate, HMTD, or double salts.

I mentioned it several times before that I am using a pen body for a detonator casing. How much ETN and NHN should I put in? How much black powder for

the ignition mix? ( I will be using an electric match. I will seal the other end with hot glue.

Edit: I was planning on usnig 0.5 grams of NHN, using the same amount as DDNP (albeit NHN has a det velocity of 7000mps, while DDNP is around 5500).

[Edited on 18-12-2021 by ManyInterests]

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

I use about 200mg NHN to set off ETN, so long as the ETN is dry and medium/low density 200mg is fine and ~>90 explosive yield compared to using

500mg NHN, since ETN is quite easy to set off, how much explosive you want to use depends on what you want to set off, you won’t need any more than

a gram for nearly all secondarys, between 1g and 10g is needed for tertiarys, although all this depends on what explosive you use, DDNP would be fine

for a detonator, not sure how much NHN you would need though, maybe 500mg would be required for it, although 0.5g of DDNP might not be sufficient for

all secondarys (something like nitrourea which is arguably a tertiary explosive might not be set off)

3g lead picrate is not ideal and you only need that much since lead picrate sucks, if you use a stronger primary like NHN, CHP, AgNTZ, CuNTZ,

Ni(NTZ)NO3 etc then you will only need max 500mg (depending on the booster you chose) , but all that depends on what you want to set off, but I would

recommend increasing the amount of booster rather than the amount of primary if you want to set off more insensitive explosives since you can separate

the primary and the secondary prior to detonations so as to reduce the danger (dealing with 1g primary + 10g secondary separated is much safer than

10g primary + 1g secondary separated or either mix on their own)

For a NHN/ETN pen detonator the amount of black powder is not super crucial, maybe ~1cm worth, just enough to get it all to burn at the same time, for

initiating ETN you only need 200mg NHN lightly compressed (LIGHTLY being an important stipulation) ontop of 200mg powdered ETN and however much cast

ETN you want depending on what you need the detonator for (minimum 500mg for secondary up to maybe 5g maximum for setting off tertarys, but take that

with a grain of salt as I don’t work with tertiarys)

[Edited on 18-12-2021 by fredsci93]

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

That sounds good. Detonators are an interesting thing. The reason why lead picrate and the other stuff is use is because the improvised munitions

manual was written in 1969 and back then things were a little different... on top of that, the laws regarding obtaining reagents was very different

back then, and the manual assumes the munitions maker has no chemistry equipment.

The reason why they made the detonator so strong (I believe) is that they wanted to make a detonator that could set off almost all explosives, like

dunnite (ammonium picrate, a very stable explosive) or composition B or TNT, which require a booster like tetryl, RDX, or picric acid in order to

detonate in addition to the primary.

But right now I'm not really looking to set anything off other than the detonator. So I guess I'll make a few with various compositions... or maybe

make them just before I know I will get an opportunity to set them off. I don't think it's a good idea to have blasting caps lying around, especially

with the electric match inserted.

When I do get around to setting stuff off I will be making a plasticized ETN/RDX mix (I would have that now, but as you know, my K6/RDX synth went

awry) as well as a cheddite explosive (potassium chlorate mixed with petroleum jelly in a 9:1 mixture).

I also made a system of getting the energetic powder into my pen body before pressing.

https://www.youtube.com/watch?v=62kPi5kpbcg&list=WL&...

This video makes a very nice cone that fits well into the inner diameter of my pen but also flares up that it makes loading quite easy. I will be hand

pressing, but I will put the pen body in my 5 gallon, sawdust filled bucket with a pair of needle-nosed pliers (away from my hand) and press with the

wooden dowel that I will also hold with a pair of pliers.

I won't press too hard. I will gently increase pressure but not give it a ram. No tamping either.

My black powder I believe will work. But maybe in the future I might want to attempt to make faster burning black powder. I tried the wet method

(using alcohol and trying to cake and grate the grains) but it didn't work well. The powder still burns well when I put an electric match in it, but

it doesn't react when I use a barbique lighter. It's weird that way. So I need to make sure that when I insert the electric match, the match must be

enveloped in the black powder to insure ignition.

|

|

|

Gargamel

Hazard to Others

Posts: 166

Registered: 9-3-2013

Member Is Offline

Mood: No Mood

|

|

@fredsci93

| Quote: |

I use about 200mg NHN to set off ETN, so long as the ETN is dry and medium/low density 200mg is fine |

What confinement was used in this case?

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

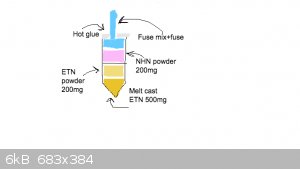

The NHN is lightly pressed into a PP tube and takes up ~5mm of the tube, a fuse mix is added above it with a fuse inserted, this assembly is then

sealed with hot glue and electrical tape.

So the confinement is a PP tube with a hot glue lid, the NHN sits directly ontop the ETN (except for a thin layer of cling film to stop the ETN mixing

with the NHN)

|

|

|

B(a)P

International Hazard

Posts: 1139

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

Quote: Originally posted by fredsci93  | The NHN is lightly pressed into a PP tube and takes up ~5mm of the tube, a fuse mix is added above it with a fuse inserted, this assembly is then

sealed with hot glue and electrical tape.

So the confinement is a PP tube with a hot glue lid, the NHN sits directly ontop the ETN (except for a thin layer of cling film to stop the ETN mixing

with the NHN) |

Have you tested this? I would be surprised if lightly pressed 200 mg of NHN would reliably set of ETN.

|

|

|

Gargamel

Hazard to Others

Posts: 166

Registered: 9-3-2013

Member Is Offline

Mood: No Mood

|

|

Now I'm even more suspicious

What does the witnessplate say to this?

Just a bang or at least a dent?

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1385

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

For reliable DDT, respectively for DDT segment with low density was necessary do mix ETN /NHN 1:1. A like two dry powders, respectively

grains ETN + fine powder NHN. And it even in solid steel cavity. Thats my experiences. Output segment of course cast ETN or high pressed ETN. This

described mix is pressed on 5 Kg in cavity 6 mm. With central bridge wire in mix. As plug can be used warm plastic glue. The assemble cast ETN +

slightly pressed NHN only, can be not reliable always. Especially in plast cavity.

300 mg high pressed ETN as output segment must deflorate 2 mm steel plate of diameter minimal 6 mm, usually 7 mm.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

I haven’t extensively tested it (I did a couple detonations, 3 with one misfire where the NHN wasn’t defligrated/detonated due to a bad fuse + I

detonated some ETN with the cap), it's not the greatest design, I'll look at improving it I've just not had a burning need to have a high yield

detonator cap right now so the potentially poor explosive yield and overall power has never phased me enough to look into it, but it sounds like it's

sub optimal

below is a diagram (not the greatest quality, but you get the idea)

[Edited on 20-12-2021 by fredsci93]

|

|

|

Gargamel

Hazard to Others

Posts: 166

Registered: 9-3-2013

Member Is Offline

Mood: No Mood

|

|

| Quote: |

I haven’t extensively tested it (I did a couple detonations |

Can you explain these "detonations"? Did you set anything of with you cap or was it just the caps itself?

Like Doc Liptakov wrote, can you punch through metal?

If the cast ETN is set of properly, that should be no problem. If it is blasted to pieces the whole assembly can still make a hell of a bang but it

will initiate nothing.

But thank you for sharing your synthesis, like others, I got frustrated with the sulfate. But I happen to have some dichloride I got as a gift a long

time ago and never bothered since

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

I didn’t test with any metal plates, I have done 3 detonations with just the cap underground and one with the cap and ETN (10g), all but one showed

subjectivity good results based off what I expected from prior detonations, the one bad result being one cap which didn’t get properly initated for

some reason, I should have tested it's penetrating power on some aluminium or steel, maybe next time I suppose.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1385

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Witness plate test is necessary for confirmation. All others are only speculations. CHP works a like primary - secondary energetic material.

[Edited on 20-12-2021 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

When I test energetics for performance, I use the following setup:

- 1.000 +- 0.002 g of the material is pressed into a brass tube of 8mm OD and 0.5 mm wall thickness. The tube is bottomless to avoid errors from

varying material thickness. The pressure used is substantial, but unmeasured - I use a vice or my small hydraulic press, so around 100 kg, or 570 psi.

- 0.300 +- 0.002 g of PETN is pressed directly on top by hand.

- The charge is glued into a 3D-printed flange which is then glued onto a piece of 20 +- 0.005 mm thick aluminum bar taken from the same stock to

avoid alloy variations. The point of the 3D-printed piece is to ensure an absolutely flush and square contact between the charge and the witness

block.

- It is set off using a small 3D-printed cap that fits inside the tube, and contains a wad of fluffy NC. The cap is then closed at one end with a

putty made of aminoguanidine nickel perchlorate and NC dissolved in acetone. The other end is closed by design, except for a hole which fits the wire

I use. A 20 cm piece of wire is cut off and inserted into the hole (I've designed it to be an interference fit).

- The assembly is placed in a thermobox (ca. 30 liters) filled with crumb rubber in place of coarse sawdust, and initiated electrically using a cheap

(1 dollar) boost converter which produces an arc across the end of the wire inside the cap, igniting the fluffy NC.

The dent that the explosion makes in the aluminum block is then measured using a dial indicator as the difference in height between the flat upper

surface and the lowest point of the dent. This is then compared to the values I obtained for picric acid, PETN, RDX and HMX, in the same setup.

Not all energetics perform as well as they might under this protocol. Aminotetrazolium nitrate for instance, places between picric acid and PETN. This

might well be caused by under initiating or by too little distance to accelerate but this reflects what I require from energetics, since I usually

work at the ~1 g scale.

[Edited on 21-12-2021 by Microtek]

|

|

|

katyushaslab

Hazard to Self

Posts: 81

Registered: 19-1-2021

Member Is Offline

Mood: precipitating

|

|

Microtek: that is a *very* interesting setup, I might have to borrow some ideas from it. How well does it do with regards noise reduction? I'd imagine

it muffles the sound a fair bit?

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Yes, my family doesn't notice the difference between me hitting something with a hammer in my workshop (located below the main floor) and a detonation

in my thermobox. I'm sure that coarse sawdust will muffle the noise just as well as crumb rubber, but the rubber is less flammable.

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

After doing a touch of work with making black powder filled caps (only black powder) and experimenting slightly with the NHN I made I came to the

following.

When pressing the ETN and NHN it must be pressed very gently. Not because of the sensitivity, but one thing I noticed is that if I press something too

hard into a cap it won't even burn. I've had black powder fizzle, potassium chlorate/nitrocellulose pop well when not super pressed, but fail to do

anything when heavily pressed.

Also I realize that NHN is so flame sensitive that it does not an igniter like black powder. Besides... the match head I used on my electric match

will produce all the flame needed to set off NHN. Given how unbelievably flame sensitive this stuff is!

Seriously. I took like a tiny pinch of NHN (My scale couldn't measure how much because of how little I put) and the flash it made after the flame so

much as licked it was shocking. I was momentarily stunned by its power! My first successful batch was a fine batch indeed!

One other thing is that I apparently am terrible at making christmas light e-matches. I'd better stick to my own design. They need more power to set

off, but a 9V battery made of 6 AA is quite small and I noticed will still ignite my match that is set at the end of 3 meters worth of wire. I will

test it with a soldered battery pack made of 6 AAAs. But that is just out of curosity.

|

|

|

Brightthermite

Hazard to Others

Posts: 133

Registered: 26-6-2019

Member Is Offline

|

|

@Microtek Id love some photos of the 3D printed caps your using and your box! Can you point me in the direction of some info regarding that primarily

putty, it sounds interesting.

@ManyInterests its called dead pressing. Good to know the NHN can be dead pressed though, Im sure that will save someone a headache.

|

|

|

| Pages:

1

2

3 |