| Pages:

1

2

3 |

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

Quantitative NHN synthesis without Hydrazine hydrate

NHN or Nickel hydrazine nitrate is a very powerful primary with high storage stability and low sensitivity. The traditional synthesis utilises

Hydrazine hydrate or hydrazine sulphate, the former being difficult to obtain and the prior producing inconsistent results, with some members

reporting good yields via calcium and barium hydroxide and some members having no success at all with hydrazine sulphate.

Last week I decided to attempt the synthesis with hydrazine dihydrochloride and I was amazed by the results, the yield on my first run was 75% due to

a poor hydrazine freebasing technique, these results were still promising so I repeated the synthesis using this technique bellow.

To 24.25g hydrazine dihydrochloride in 50ml ethanol a total of 18.5g of sodium hydroxide was added in portions over ice with stirring, the resulting

slurry was mixed for 20 minutes and let sit for 10 minutes, the slurry didn’t separate well so I opted to filter, I gravity filtered it and washed

the resulting solids with a total of 50ml ethanol over 2 washes.

A solution of nickel nitrate hexahydrate was prepared by dissolving 14g of nickel nitrate hexahydrate in ~100ml water.

The filtrate was stirred and it's temperature was raised to approximately 60-65C, the nickel nitrate hexahydrate solution was added quickly in 10ml

portions yielding a thick slurry of purple precipitate which was stirred for a minute at 60-65C before being hot filtered through two coffee filters

which gave a colourless solution and a purple filter cake. The filter cake was not washed as I deemed it unnecessary (however I may be wrong and I

only didn’t wash it because the filtrate was so clean), The filter cake was dried over paper towels before being totally desiccated over a steam

bath for 4h This yielded 12.9g of product (96% yield)

The yield was more or less quantitative with the losses being mostly due to mechanical losses

The product was able to detonate in small quantities when confined and deflagrates when not confined, it has a moderate sensitivity towards impact,

somewhere between lead azide and ETN.

Note 1: it is very important to add the nickel to the hydrazine, otherwise a blue compound seems to form in addition to the NHN, the blue compound is

totally non-energetic and likely a hydroxide of nickel

Note 2: I did not dextrinate the compound since I don’t have any dextrin, the sensitivity is alright without any dextrin

Note 3: The compound tends to clump when drying, these clumps can be safely broken up in 0.5g portions with light compression

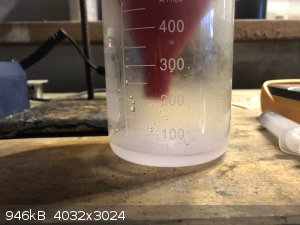

Image 1: Slurry formed by hydrazine free basing

Image 2: Hydrazine solution on hot plate

Image 3: NHN filtrate

Image 4: NHN filter cake

Image 5: Steam bath setup

Image 6: NHN drying

Image 7: NHN directly after formation

[Edited on 2-12-2021 by fredsci93]

|

|

|

Brightthermite

Hazard to Others

Posts: 133

Registered: 26-6-2019

Member Is Offline

|

|

Cant wait to give this a shot, what was your source for hydrazine dihydrochloride?

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

The hydrazine dihydrochloride and nickel nitrate hexahydrate were both from chemcraft (https://chemcraft.su/product/23119) (https://chemcraft.su/product/24044)

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

I'm going to be making some very soon. I already have hydrazine sulfate, I just need to make a bit more and make nickel nitrate.

I know your method would probably be better, but I really want to make my stuff from scratch.

[Edited on 5-12-2021 by ManyInterests]

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

You may want to convert your hydrazine sulfate to hydrazine monochloride with calcium chloride (http://www.sciencemadness.org/smwiki/index.php/Hydrazine_hyd...). Hydrazine sulfate on it's own can work for NHN but from what I've seen it's very

particular and has a tendency to just form inert nickel hydroxides.

Homemade nickel nitrate and hydrazine sulfate should work just fine, so long as the reagents are pure enough, since sulphate ions in the reaction

mixture will destabilise the complex.

|

|

|

Brightthermite

Hazard to Others

Posts: 133

Registered: 26-6-2019

Member Is Offline

|

|

Also question regarding safety, other then gloves and good air flow is there any other precautions I should specifically take when handling hydrazine?

I hear it is nasty stuff and I have yet to work with it so Id like to be prepared.

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

I kept a bottle of calcium hypochlorite solution to spray in case of spills and to degassify the air if I feel like any fumes were out.

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

Keep all hydrazine solutions covered with glad wrap at all times, maintain good air flow, keep hydrazine solutions far from your face and nose, wear

eye and hand protection. Also be very careful with the NHN, it's a very powerful explosive and should be handled with care and respect, it's power

decreases exponentially as you add water to it it so for long storage you may want to add 5% water to desensitise it.

I second what Manyinterests said, calcium hypochlorite for treating spills is very important, if there were to be a spill my best advice it to spray

the affected area with the hypochlorite and leave for a couple hours, lowering the exposure time is key to safely dealing with any spill.

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

If you are going to freebase the hydrazine anyway, what's the point of converting it to the chloride first?

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

Hydrazine produced from hydrazine sulfate + NaOH seems to be much less suitable for NHN synthesis since some sulfate ions will come over and

destabilise the complex, converting to the hydrochloride beforehand removes all sulfate ions which would result in a cleaner hydrazine, if you free

base with calcium or barium hydroxide that would also remove all sulfate contamination, either method would work well, I am somewhat stipulating on

some of the methods as I have not synthesised NHN with hydrazine sulfate and I am going off other reports, it is possible that hydrazine sulfate +

NaOH works well and other people who failed the synthesis were doing something wrong with their methodology, so take everything I say regarding using

hydrazine sulfate for NHN with a grain of salt.

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

Quote: Originally posted by fredsci93  | | Hydrazine produced from hydrazine sulfate + NaOH seems to be much less suitable for NHN synthesis since some sulfate ions will come over and

destabilise the complex, converting to the hydrochloride beforehand removes all sulfate ions which would result in a cleaner hydrazine, if you free

base with calcium or barium hydroxide that would also remove all sulfate contamination, either method would work well, I am somewhat stipulating on

some of the methods as I have not synthesised NHN with hydrazine sulfate and I am going off other reports, it is possible that hydrazine sulfate +

NaOH works well and other people who failed the synthesis were doing something wrong with their methodology, so take everything I say regarding using

hydrazine sulfate for NHN with a grain of salt. |

I've seen people get decent yields with both hydrazine hydrate (hydrazine sulfate + sodium hydroxide) and azeotropic hydrazine (64%). Pyrotechnical

Science on youtube got rather small yields from both, while others got a decent yield. I believe in order to get the best, you do need a touch of

dextrine (1% volume of the nickle nitrate you are using) and to make sure the entire thing is done at 65C and not above, maybe a little below, but 65C

is the accepted temperature the hydrazine solution should be at.

Your mention of calcium hydroxide sounds interesting, but I have no access to it right now, or at least I don't know exactly where to get it. I do

have plenty of sodium hydroxide and I will be using it out of convenience at the moment. If I get a yield of 3 grams I would consider that a good

yield.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

This would be problematic in alcohol with cooling and the sulfate.

Shaking with a bunch of small glass beads might help in that case.

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

| Quote: | | This would be problematic in alcohol with cooling and the sulfate. |

What if we kept the denatured ethanol in the freezer for a while to keep it super cold?

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

What I think is, that all the accounts which were created years ago but were dormant for 1.5+ years before suddenly becoming active with many posts

for a time, have more than that in common.

It was shocking to see that L. Lerner agrees with me...saying that yield of hydrazine in alcohol with base suffers when the sulfate is used. Inorg Syn

gives directions for making the hydrochloride from the sulfate with little loss...via the benzalazine...if one happens to have spare benzaldehyde. (or

other similar molecules)

[Edited on 8-12-2021 by S.C. Wack]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1386

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

I find in patents this: Abstract

A process is provided, applicable to the production of hydrazine, which assures a continuous and constant production of azines without the need for

detailed control of the working solution. According to the invention, azines are synthesized from oxygenated water, ammonia, and a reactant having a

carbonyl group, by the following steps. The reactants are contacted with a working solution in order to obtain azine. The working solution is

separated from the azine and possibly from the excess amount of reactant having a carbonyl group. All or part of the working solution is brought to a

temperature above 130{degree}C, the water of reaction being eliminated before, after, or simultaneously. The working solution is then recycled to the

first step. A product capable of maintaining azine production is introduced into the working solution at some point in the preceding stages. This

product is preferably chosen from among acetic acid, ammonium acetate, and acetonitrile. The azines are hydrolyzed in order to obtain hydrazine

hydrate. 1 fig.

link: https://www.osti.gov/etdeweb/biblio/6084367

Oxygenated water is what? Introduction ozone gas into water? Thus mixing ammonia water + acetic acid + ozone = hydrazine hydrate production?

Without next catalyseur? So easy? ... In this process will sure some problem. In this process will sure some problem.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I think the "oxygenated water" is hydrogen peroxide. I found that US6605265 is very similar to what is described here (and it seems to be the same

authors).

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1386

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Not, I finded different between oxygenated water and peroxide. Is it not the same. Oxygenated water is only oxygen dissolved in water.

Thus H2O + O2. Peroxide is H2O2, thus some a like aqueous acid. It are two different solutions. Any way, if works both, is it pretty interesting.

Production ozone is (or can be) easily than H2O2. Bigger problem can be mixing next compounds for sucessful result. According patent it seems, that

destillation column is necessary.

Maybe try easy attempt, mixing Ammonia water + acetic acid + H2O2 is closure solid container. (ratios unknown yet) And heated it on 100 C. Cooling

after 2 hours. And try adding Ni(NO3)2 solution. If arise pink NHN powder, works it.

[Edited on 9-12-2021 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I know what hydrogen peroxide is, I just think that the correct term has been lost in translation. If you look closely, you can see that the abstract

you referenced is from a patent application in French, specifically Canadian patent number CA 2017358. The original French abstract is:

| Quote: |

L'invention concerne dans un procédé continu de synthèse d'azines à partir d'eau oxygénée, d'ammoniac et d'un réactif portant un groupe CO...

|

The term "d'eau oxygénée" might be literally translated as oxygenated water, but a translation such as:

The invention relates to a continuous process for the synthesis of azines from hydrogen peroxide, ammonia and a reagent bearing a CO group.

would be more correct. The patent also exists in english versions, but if you need it, the original can be found at:

https://www.ic.gc.ca/opic-cipo/cpd/eng/patent/2017358/summar...

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1386

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Oh yes, patent use hydrogen peroxide, others is wrong in translation. The point is to try it.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

I just want to report what happened in my first attempt at making Nickel Nitrate... it was very much a cartoon event! Thankfully I escaped unharmed

and none of the equipment was harmed and I cleaned the spill.

I added 20 grams of nickel metal (cut into chips) and added around 6 ml of 35% hydrogen peroxide... but I didn't realize just what an effect adding

the nitric acid to it would have (I used 30ml of 70%)... I had a small fountain of nitric acid fumes and liquid. I quickly put the thing down in my

balcony and immediately poured large amounts of bicarbonate water. I had to wipe a lot of the spill by hand after and tried to collect as much of the

nickel metal chips as I could. This was quite an event, but my only real loss is that I didn't have much nitric acid left. I had enough for one more

synthesis of this kind. I had some more nickel metal chopped up and ready, so I used them. I added the nitric acid first, and I carefully put it below

my reflux column first BEFORE (drop wise) adding around 2 or 3 ml of hydrogen peroxide. I nearly had another fountain event, but I quickly put it in

the column and no spill occured.

Damn that was something! I put the small (100ml) boiling flask that I am using for this and putting that in a 1000ml beaker full of boiling water at

100C. It's not refluxing yet, but I hope it will. making nickel nitrate is an adventure!

I don't know how long it needs to be doing that in the hot water, but I hope I will be good in four hours or so.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

FWIW the original lit says "Im Porzellantiegel erhitzt, explodiert die Substanz aufserordentlich heftig unter heller Lichterscheinung."

(goes boom when heated)

It was made in a different way of course...the total amount of water present gave a 10% concentration of nitrate (w/v) and hydrazine hydrate (v/v) at

mixing. The product was digested hot for a time, washed, and dried...just one of many nickel and other metal salts with hydrazine that they made.

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by S.C. Wack  |

FWIW the original lit says "Im Porzellantiegel erhitzt, explodiert die Substanz aufserordentlich heftig unter heller Lichterscheinung."

(goes boom when heated)

|

I haven’t tested it as well as I assume they have, however I know that in DIRECT flame it simply deflagrates even in >200mg amounts, however

possibly in indirect heat it's more likely to detonate, I can’t remember well, if I get around to testing it later, I'll inform you

I have tested it in confinement though and it's incredibly powerful and impressive, it's nearly as powerful as a secondary with the DDT of a primary

(by which I mean the ability to explode in high yields even in small amounts)

One thing I should note as an unrelated point of information is that NHN has an excellent heat sensitivity and can be brought to very high

temperatures without any decomposition >100C

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

219C is a temperature which has been given for it to explode. It's also supposed to be not insensitive to electricity; good news I guess for certain

detonators, bad news for winter static.

[Edited on 12-12-2021 by S.C. Wack]

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

Out of curosity. I've seen videos were NHN was synthesized when putting in the nickel nitrate into the hydrazine hydrate, but also the other way

around. Is it safe to heat up hydrazine hydrate in an erlenmeyer flask to 65C and not risk the fumes? I could of course cover it. But I need to put

the thermometer through in order to accurately measure the temperature.

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

Yea, it’s fine so long as the beaker is mostly covered (as shown in the photos)

|

|

|

| Pages:

1

2

3 |