| Pages:

1

..

11

12

13 |

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Tomorrow, NurdRage is uploading his video on his new technique for making sodium. I can hardly wait.

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

Woohoo!

I think I will buy a few hundred grams of Mg in readiness!

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

And, If I am not mistaken, I think this is the definitive work.

https://www.youtube.com/watch?v=jCrFFVVcPUI

Kudos to Nurdrage for his efforts. This really is the most promising thing I have seen in... well ever. It looks so much tidier than electrolysis of

molten NaOH or any other methods I have seen.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Definitely very cool. I am going to have to make some dioxane when I get my fume hood built.

|

|

|

tsathoggua1

Hazard to Others

Posts: 335

Registered: 8-1-2017

Location: Beyond the pale

Member Is Offline

Mood: Phosphorescent

|

|

Likewise, JJ. Although I'll work outside for it instead and wear hazmat gear in place of the hood, for this, considering that the initiation of the

magnesiothermic reduction is not something one would want indoors. Happen to have plenty antifreeze that was going to be used for making perc, during

a time when no chlorocarbons were available, but now plenty dichlor is to hand when needed, less can go on to be chlorinated w/ Zn/HCl, trying

Nurdrage's dioxane method for Na separation (and will try with KOH also), got everything needed to make a go at it, just as long as the antifreeze is

ethylene glycol rather than DEG as is sometimes to be found. Although I think I picked up some EG specifically, about a gallon of the stuff.

This is a great discovery, my compliments to Nurdrage for this. Looks like it beats the absolute piss out of the various rather touchy electrolytic

processes.

How prone is 1,4-dioxane to peroxidation compared with diethyl ether, diisopropyl ether, and THF? for longer term storage of a quantity of dioxane

that would be dedicated to this particular purpose, storage over sodium after argon sparging and degassing under vacuum, followed by an argon blanket

over any headspace in the 1,4-dioxane ought to reduce and eliminate peroxides as formed should it not? so if stored over a few nuggets of Na, can the

dioxane not be continually recycled, since refluxing over Na (and the dioxane batch being dedicated specifically to magnesiothermic Na or K

production), it would get regular treatment for peroxides as essentially a side bonus of the process itself taking care of any formed peroxides should

it not?

And two other questions-what is the shelf-life of 1,4-dioxane inhibited with a little BHT or BHA, with or without sodium? And uninhibited dioxane if

not otherwise treated, how long does significant peroxidation take, roughly?

Have you considered, after first pre-drying the dioxane, using an argon blanket over the liquid 1,4-dioxane and storage under Ar to increase shelf

life?

And when using Mg powder (mine is, IIRC 400 mesh, possibly 500) how manageable is the reaction in comparison with that using Mg swarf/turnings? does

the fine grain size not result in a dramatically faster, more energetic reduction of the caustic? I'd sooner nnt have any rapid deflagration/flashover

when attempting this.

I noticed, nurdrage, that he distilled the dioxane to dryness. This is something that I have always had drilled into me, as something never to do with

ethers, does this apply to freshly treated (immediately before use) ethers, when treated for peroxides and distilled under a current of inert gas.

Ordinarily distilling ethers to dryness is or can be dangerous because any peroxides formed already are concentrated and can pose a significant hazard

if present, since once concentrated down there is much less solvent to peroxide ratio, increasing the potential for a big mess that one really

wouldn't want occurring in one's glassware, and less still doing so whilst the experimenter is within range of flying razor sharp glass fragments.

|

|

|

Elemental Phosphorus

Hazard to Others

Posts: 185

Registered: 11-11-2016

Location: Is everything

Member Is Offline

Mood: No Mood

|

|

I honestly can say that the risk if peroxides is almost zero if the peroxides are stored over a small amount of sodium and kept in a tightly sealed

bottle. I use Boston round bottles (from Dr.Bob, no less!) to store the relatively small amount of peroxide I have, but really any airtight bottle

should work. As for the speed of the reduction, once I tried burning sodium hydroxide with magnalium (before the whole NurdRage sodium process came

out) and using 200-325 mesh magnalium and coarse to medium hydroxide, and it burnt hot and even after cooling, reacted vigorously with water.

Therefore, I think that with very fine magnesium and powdered sodium, you will boil off some of your yield.

|

|

|

zed

International Hazard

Posts: 2283

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

This, no doubt, has been posted elsewhere.

Nurdrage has moved on, to an even more do-able Sodium Synthesis.

Not a thermite type reaction!

Just prolonged heating and stirring, with Magnesium, NaOH, a catalyst, and Baby oil.

https://www.youtube.com/watch?v=oiZf-O6vvbE

Kudos!

|

|

|

oberkarteufel

Harmless

Posts: 47

Registered: 11-12-2018

Member Is Offline

Mood: Mayonesium sulfate

|

|

Carry on with active metals...

Some time ago I have tried the thermite-type reaction to produce some sodium.

Some notes for the ones that would want to attempt this also:

- make sure that your reaction vessel will not melt, as a lot of heat is generated.

- make sure that you have a proper fire extinguishing equipment ready, just in case (additional pile of dry sand will also be handy, you can't be too

careful).

- it's a good idea to dig your reaction vessel into the ground to prevent it from tipping over.

- sparklers should be enough to initiate the reaction.

- cover the vessel immediately with a heavy "lid". A brick should be fine.

- a huge fireball may happen anyway, so take away all flammable things from the reaction spot, including yourself.

- SERIOUSLY, DON'T EVEN THINK OF DOING IT INSIDE.

- bigger, un-crushed chunks of "slag" will decrease the yield. Dioxane separation requires small particles.

- it's a good idea to mix the dioxane with NaOH, let it sit for some time, destroy the peroxides and finally distill it. Ja=ust to make sure that it

doesn't contain lots of water eager to decrese your yield further.

- it's also a good idea to dehydrate the oil you plan to store your sodium in.

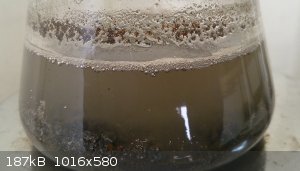

And here are some coalescing sodium droplets:

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

what if you decompose sodium azide in mineral oil since decomposition of sodium azide yields sodium metal as seen in a video by dbx labs.

https://www.youtube.com/watch?v=gZSfroJ1FJE&t=155s

seems a bit pointless since making sodium azide is not easy but still it may work

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

some guy succesfully made sodium metal using sodium azide decomposition under mineral oil from this vid

https://www.youtube.com/watch?v=GMSzXdmTeBM

I predicted som1 would be mad enough to try this!!!

|

|

|

Jome

Hazard to Others

Posts: 154

Registered: 10-6-2004

Location: Soutwest sweden

Member Is Offline

Mood: desiccated

|

|

I wonder if anyone has tried Nurdrages menthol-method but in a metal container, like stainless steel. There would of course be no glassware corrosion,

and the whole thing could be built so that even if it does catch fire, nothing happens. It just needs to keep 200 or so degrees for 20-30 hours...

[Edited on 4-5-2022 by Jome]

[Edited on 4-5-2022 by Jome]

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

There is no glass corrosion when you jump start the reaction with a bit of sodium. No water == no corrosion

|

|

|

clearly_not_atara

International Hazard

Posts: 2786

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Sodium metal will probably corrode other metals by intercalation.

|

|

|

BAV Chem

Harmless

Posts: 28

Registered: 9-5-2021

Location: In the middle of nowhere

Member Is Offline

Mood: Thoroughly confused

|

|

Electrolysis of molten sodium formate

Reading through this thread there was at one point the idea of electrolyzing molten carboxylic acid salts of sodium. Aparrently this doesn't work with

acetates or longer chain salts as those form some weird organic gunk.

However who said formate won't work? Ideally it would just loose the formate as CO(2) and water and deposit sodium on the cathode.

Long story short I tried that and it might just have worked. I used a graphite anode and an iron nail as the cathode. Now I didn't see actual metallic

globules of sodium floating around but there were some yellow sparks close to the cathode every now and then. Unfortunately I couldn't quite keep the

melt hot enough and my sodium formate definitely wasn't dry enough.

The solid that was stuck to the cathode also released quite a bit of H2 gas upon throwing it in water. This definitely looks promising to

me so ig I'll try to optimize it a little this weekend.

|

|

|

BAV Chem

Harmless

Posts: 28

Registered: 9-5-2021

Location: In the middle of nowhere

Member Is Offline

Mood: Thoroughly confused

|

|

Well that didn't work. Some traces of sodium are produced but it seems to quickly react with the formate to give hydrogen and sodium carbonate. The

carbonate quickly builds up on the cathode and stops the electrolysis. Also it's quite hard to keep the formate nice and molten without decomposing it

to oxalate and hydrogen gas.

|

|

|

Texium

|

Thread Moved

19-11-2023 at 09:53 |

| Pages:

1

..

11

12

13 |