| Pages:

1

2 |

Pok

potassium Prometheus

Posts: 176

Registered: 5-12-2010

Member Is Offline

|

|

It seems that the addition of NaOH is not needed, when the concentrations are not too high and when Na2SO3 is used as a reducing agent. The original

source is a patent. Attachment: Patent DE000000055152A.pdf (194kB)

This file has been downloaded 394 times

It says "In order to avoid further exposure of the copper cyanide to the 6 molecules of sulphuric acid formed, either work in a highly diluted

solution or neutralize most of the free sulphuric acid formed by adding alkali, unless you prefer to use a sulphite from the outset."

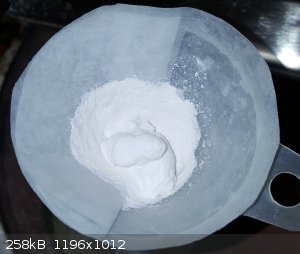

I used about a 10 % solution of copper sulphate, heated it nearly to the boiling point and added a solution of about 10 % sodium sulfite/ferrocyanide

very slowly with stirring. According to the patent a slight excess of copper sulfate is required to avoid the formation of a iron-rich precipitate.

Maybe that's the brown stuff? So I used a 10 % excess of copper and about 10-15 minutes after the whole mixture was added, the precipitate has turned

almost pure white. (I made a few q&d tests before including NaOH, Cu(OH)2 and so on and the products turned brown very fast and contained

noticable amouns of iron.)

I washed the precipitate with pure water and pressed it between filter paper. My sample is drying now and looks similar to your last picture, but

rather with a gray tint than pink. Some small pieces are already dry and look off-white. I'm still afraid it could be contaminated with iron. I will

check that later.

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

There you go, your question answered!

Is the presence of iron a big issue? I suspect that it is present either as a ferric oxide hydrate or as a copper cyanoferrate complex, niether of

which should be a problem in organic chemistry.

|

|

|

Bedlasky

International Hazard

Posts: 1239

Registered: 15-4-2019

Location: Period 5, group 6

Member Is Offline

Mood: Volatile

|

|

Nice preparation!

May I asked what did you do with filtrate? I know that it probably containted only very small amount of free cyanide ions but still there were present

in it. Did you add bleach in it to oxidised cyanide in to cyanate?

Btw CuCN can be also used for hydrocyanation of alkynes to make unsaturated nitriles. See: http://organicreactions.org/index.php?title=Hydrocyanation_o...

|

|

|

Pok

potassium Prometheus

Posts: 176

Registered: 5-12-2010

Member Is Offline

|

|

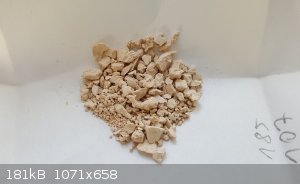

I prefer pure compounds.  My goal is to make KCN from it and iron impurities could

be a problem. My goal is to make KCN from it and iron impurities could

be a problem.

Unfortunately, my dry product is not as white as shown in the second picture. Better washing could have helped. Or maybe the colour only comes from

tiny Fe impurities. I will test for iron soon. My yield is only about 90 %. Maybe it still was too acidic and some HCN escaped. But a single addition

of some NaOH just after adding all the K4Fe(CN)6 should be enough I think. I will make further tests.

I didn't throw away the solution yet. It still contains some copper. I will probably add bleach and a precipitation agent for the copper.

[Edited on 19-5-2020 by Pok]

|

|

|

Bedlasky

International Hazard

Posts: 1239

Registered: 15-4-2019

Location: Period 5, group 6

Member Is Offline

Mood: Volatile

|

|

How did you convert CuCN in to KCN? I firstly think about double displacement between CuCN and KI because corresponding Ag salt is less soluble than

AgCN. But I found solubility product of CuCN and CuI and CuCN is much less soluble than CuI.

Another way which comes to my mind is reaction between CuCN and Mg or Zn to make magnesium or zinc cyanide and copper. Than heating with potassium

carbonate to form KCN and insoluble basic carbonate.

[Edited on 20-5-2020 by Bedlasky]

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Does anyone have a reference to an example of the use of cuprous cyanide to prepare a nitrile by halogen displacement either aliphatic or aromatic? I

have found a few using alkali cyanides but I was wondering if Cu-1 cyanide can be used as a substitute? anomalous in his orginal post indicates that

it work in the case of some aromatic cyanations of haloaromatic compounds, presumably reactive ones like nitrobromobenzenes etc.

I have a few details for Sandmeyer type diazo reactions to give aromatic nitriles but its not the same.

[Edited on 20-5-2020 by Boffis]

|

|

|

DavidJR

National Hazard

Posts: 908

Registered: 1-1-2018

Location: Scotland

Member Is Offline

Mood: Tired

|

|

That looks great.

|

|

|

Pok

potassium Prometheus

Posts: 176

Registered: 5-12-2010

Member Is Offline

|

|

Quote: Originally posted by Bedlasky  | How did you convert CuCN in to KCN? I firstly think about double displacement between CuCN and KI because corresponding Ag salt is less soluble than

AgCN. But I found solubility product of CuCN and CuI and CuCN is much less soluble than CuI.

Another way which comes to my mind is reaction between CuCN and Mg or Zn to make magnesium or zinc cyanide and copper. |

I planned to convert the CuCN (which was a bit brown after drying)

to Copper(I) oxide with KOH. Unfortunately, it turned out that a complex copper potassium cyanide is formed, which doesn't get further attacked by

KOH. After mixing a small amount of CuCN with a solution of KOH in excess, everything seemed to work. Yellow hydrated Cu2O formed with a colourless

solution above (not visible in the following picture because the whole mixture was stirred)

After heating the precipitate became brown (water-free Cu2O) and crystals appeared during cooling, which seem to be not very soluble in water.

There are many different complexes of CuCN and KCN and this one doesn't seem to be very usefull. After letting it sit for 1-2 days under the

colourless liquit it became a mixture of a black compound (probably CuO) and a green compound (some basic copper salt).

The liquid above didn't decolorize a copper tetrammine solution.

The CuCN seems to be quite pure. Only very small amounts of iron seem to be present. I also tried to convert it to Mg(CN)2. 250 mg of CuCN were

suspended in about 2-3 ml water and 150 mg (or so) Mg powder was added. The mixture became quite warm and some gas was produced. After a few hours a

brown solid (Cu + remaining Mg) and a clear solution was visible. Again, this solution didn't decolorize a copper tetrammine solution.

I don't see an easy way to convert CuCN to KCN. Silver cyanide should offer a much better way.

[Edited on 23-5-2020 by Pok]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Has anyone considered that the precipitate is cuprous ferrocyanide when white (and the basis for Williams' "bullshit" method for quantifying

ferrocyanide) and cupric ferrocyanide when red-brown?

|

|

|

Bedlasky

International Hazard

Posts: 1239

Registered: 15-4-2019

Location: Period 5, group 6

Member Is Offline

Mood: Volatile

|

|

Quote: Originally posted by Pok  |

The CuCN seems to be quite pure. Only very small amounts of iron seem to be present. I also tried to convert it to Mg(CN)2. 250 mg of CuCN were

suspended in about 2-3 ml water and 150 mg (or so) Mg powder was added. The mixture became quite warm and some gas was produced. After a few hours a

brown solid (Cu + remaining Mg) and a clear solution was visible. Again, this solution didn't decolorize a copper tetrammine solution.

|

Dissolve in your cyanide solution huge excess of sodium thiosulfate. Than add some ferric salt. Upon acidification with dilute acid you should obtain

red solution (with some sulfur from thiosulfate decomposition). Cyanides reacts with thiosulfate or sulfur to form thiocyanate which form with ferric

ions red complex. Be sure that acid which you use doesn't contain iron (test it with thiocyanate, salicylic acid or other iron sensitive reagent).

From my expirience vinegar is good choice - commercial HCl or battery acid contain lots of iron (especially battery acid).

Another good test is mixing your solution with Fe(II)+Fe(III) solution. If cyanide is present, there is a formation of prussian blue.

Quote: Originally posted by S.C. Wack  | | Has anyone considered that the precipitate is cuprous ferrocyanide when white (and the basis for Williams' "bullshit" method for quantifying

ferrocyanide) and cupric ferrocyanide when red-brown? |

I didn't find any mention about Cu(I) ferrocyanide. But I was thinking about this few days ago. I made few calculations for silver cyanide formation

and in theory it shouldn't work, because silver ferrocyanide is more insoluble than silver cyanide. But reaction takes place in hot acidic solution.

At these conditions HCN should form which can react with Cu(I) or Ag(I) to form CuCN or AgCN.

[Edited on 24-5-2020 by Bedlasky]

|

|

|

Pok

potassium Prometheus

Posts: 176

Registered: 5-12-2010

Member Is Offline

|

|

Regarding the solubility: AgCN is less soluble than AgCl. But you can make HCN from AgCN by letting it react with HCl!

Probably some complexes are formed which make this reaction possible.

@S.C. Wack: it's not cuprous ferrocyanide. The compound doesn't contain considerable amounts of iron!

I also tried to make HCN from CuCN by letting it react with HCl (formation of sparingly soluble CuCl). But this didn't work. The CuCN dissolved in the

concentrated HCl. This is typical for CuCN.

[Edited on 24-5-2020 by Pok]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Was there any distillation of that?

Has anyone compared their cyanide from ferrocyanide to cyanide from cyanide?

[Edited on 24-5-2020 by S.C. Wack]

|

|

|

kmno4

International Hazard

Posts: 1497

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

| Quote: |

Has anyone compared their cyanide from ferrocyanide to cyanide from cyanide?

|

I did. CuCN from ferrocyanide is slightly darker than CuCN from KCN, but all tests I made gave the same results (but Fe contamination).

Besides, white Cu4Fe[(CN)6] is described in legendary "Chemistry of cyanogen compounds" by Williams.

I still dare to claim, that the simplest and cheapest method utilizes CuCl solution prepared in situ from CuSO4, NaCl and Cu.

Anyway, obtained CuCN is pretty useless, however its preparation from FeCy6 is interesting and surprising.

At least one question is explained: influence of Cu(I) on acidolysis of K4Fe[(CN)6].

Слава Україні !

Героям слава !

|

|

|

Fery

International Hazard

Posts: 1015

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Quote: Originally posted by Boffis  | | Does anyone have a reference to an example of the use of cuprous cyanide to prepare a nitrile by halogen displacement either aliphatic or aromatic? I

have found a few using alkali cyanides but I was wondering if Cu-1 cyanide can be used as a substitute? anomalous in his orginal post indicates that

it work in the case of some aromatic cyanations of haloaromatic compounds, presumably reactive ones like nitrobromobenzenes etc.

|

1-bromonaphthalene + CuCN + pyridine -> 1-naphthonitrile = 1-cyanonaphthalene

you can also use 1-chloronaphthalene just the reaction time is slightly longer and temperature higher (15 hours 220 C for bromo, 24 hours 245-250 for

chloro)

https://pubs.acs.org/doi/pdf/10.1021/ja01290a507

https://sci-hub.se/https://pubs.acs.org/doi/pdf/10.1021/ja01...

Attachment: newman1937.pdf (124kB)

This file has been downloaded 16 times

I rather posted something more "exothic" to synthesize as you can obtain benzonitrile from cheap benzoic acid + sulfamic acid

https://www.sciencemadness.org/whisper/viewthread.php?tid=16...

|

|

|

clearly_not_atara

International Hazard

Posts: 2787

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

For the reaction of aliphatic halides with transition metal cyanides:

| Quote: | The ratio of isocyanide to nitrile depends largely on the nature of the metal cyanide employed. Guillemard

(231), in an extensive study of different metal cyanides, showed that the heavier metal cyanides such as those of

silver gave isocyanides exclusively, while with other metals the following percentages of isocyanide were in the

mixture resulting from the reaction with ethyl iodide: cuprous copper, 56 per cent; cadmium, 11 per cent;

nickel, 8 per cent; zinc, 2.6 per cent. Sodium and potassium cyanides gave only minor amounts of isocyanides. The

temperature of reaction was also found to play an important role in the amount of isocyanide produced. All of the

metallic cyanides gave normal nitriles if the reaction were conducted above 150°C. Lower temperatures favored

isocyanide formation. |

So for the rxn of CuCN with aliphatic halides, temperatures above 150 C are advisable, since the isocyanide is famously noxious. DMF refluxes at 153 C

and seems like it could be an ideal medium for the preparation of heavy aliphatic nitriles. For lighter nitriles, the dehydration of amides over

alumina or vanadium-hydrotalcite seems preferable. But benzyl bromide (bp 198 C) is already a reasonable candidate for this method.

Mowry, D.T. The Preparation of Nitriles, 1948, attached.

Attachment: mowry1948.pdf (5.2MB)

This file has been downloaded 14 times

|

|

|

Fery

International Hazard

Posts: 1015

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Nitrobenzene, DMF, pyridine are suitable solvents.

https://sci-hub.se/https://doi.org/10.1016/S0040-4039(01)02168-2

| Quote: | The Rosenmund-von Braun reaction has been known for almost the same length of time, which gives rise to aryl nitriles from the coupling of copper

cyanide (CuCN) with aryl halides. This reaction is usually carried out in polar solvents such as nitrobenzene, DMF and pyridine using excess of CuCN

at 150-250°C. The product isolation is a tedious process, involving washings with water followed by extensive silica gel column chromatography.

...

We initially set out to investigate the feasibility of using ionic liquids, especially 1-n-butyl-3-methylimidazolium halides (bmiX, X=I, Br, Cl) as

reaction media to replace DMF and pyridine in the Rosenmund-von Braun reaction. We reasoned that because of the nonvolatility of ionic liquids, the

products could be distilled directly from the reaction mixture. On the other hand, owing to the limited solubility of these ionic liquids in certain

organic solvents such as hexanes, ethyl acetate and toluene, isolation of products could be achieved directly via simple extraction using common

organic solvents. |

DMF (cca 10 EUR per 1 liter) is cheapest from all the 3 above solvents, but it is hard to dry, best method is sequential drying with 3A molecular

sieves

https://www.tesble.com/10.1021/jo00414a038

|

|

|

| Pages:

1

2 |