| Pages:

1

2 |

anomolous

Harmless

Posts: 23

Registered: 12-3-2013

Location: USA

Member Is Offline

Mood: No Mood

|

|

Silver and Copper Cyanide from Potassium Ferrocyanide

KCN, NaCN, and pretty much any other cyanide is hard to find in the US. Methods used to make these compounds are mostly difficult and dangerous and

offer poor results. In some cases, though, for example, in the cyanation of aromatic halides, copper cyanide will work nearly as well as alkali

cyanides. This is why I was so excited to find the Bergman Process in "The Cyanide Industry: Theoretically and Practically Considered" (1906), which

can be downloaded free from google books. On page 94 begins the following:

| Quote: |

This process, which is one of little practical value, and which produces only the cyanides of copper and silver, is a wet method. It consists in

heating a solution of ferrocyanide in the presence of a copper or a silver salt, in sufficient quantity to effect the total union of the cyanide of

the prussiate with the copper or the silver. The mixture should contain a certain proportion of free acid, which, producing the decomposition of the

ferrocyanide, causes the formation of prussic acid, which unites with the silver or with the copper to form cyanides of these metals. In the case of

the cyanide of silver the reaction is as follows: 6NO3Ag + FeCy6K4 = 6CyAg + 4NO3K + (NO3)2Fe. 422 parts by weight of crystallized ferrocyanide of

potassium are dissolved in 50 times its weight of water, to which is added a 2% solution of 1020 parts of nitrate of silver. After slightly acidifying

with sulphuric acid, the solution is brought to a boil until the whole of the precipitate of ferrocyanide of silver which is first formed is

completely transformed into cyanide of silver by absorbing the whole of the silver remaining in excess. This cyanide is separated by decantation and

washings. In the case of the copper cyanide the reaction may be expressed thus: 6SO4Cu + FeCy6K4 + 3SO2 + 6H2O = CuCy2 + 2SO4K2 + SO4Fe + 6SO4H2. In

order to avoid a too excessive action of the 6 molecules of free sulphuric acid which are formed in the course of the reaction it is well to operate

in very dilute solution, or to neutralize the acid as fast as it is formed by the addition of alkali. Likewise a sulphite may be used from the

beginning. At first a reddish-brown precipitate of ferrocyanide of copper is formed, which under the action of heat is gradually transformed into a

white, flucculent cyanide of copper. The cyanide of copper thus obtained furnishes very interesting double cyanides when digested in the cold with an

alkaline sulphide. |

I intend to give the copper cyanide method a try soon. I'm hoping for input on how others here would proceed. I'm confused as to the purpose of the

sulfur dioxide and exactly how this would be added to the reaction mixture. Should I simply dissolve SO2 in water? Also, I'm assumung the formula for

cuprous cyanide is a typo as it is written CuCy2, which, I think, does not exist. Thanks in advance for you help. If anyone else tries this please let

us know how it went.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

The only role for the SO2 that I can think of is the reduction of cupric to cuprous cations, the latter which then would form the insoluble CuCN.

Since as everything else maintains its oxidation state that must be what's happening and 'CuCy2' must be a typo.

This is assuming the general idea is even valid: hexacyanoferrates are very 'complete' complexes: in solution neither show typical reactions of

Fe2+ or Fe3+ cations and the (III) version is even used in food preparation.

[Edited on 23-6-2013 by blogfast25]

|

|

|

cyanureeves

National Hazard

Posts: 744

Registered: 29-8-2010

Location: Mars

Member Is Offline

Mood: No Mood

|

|

this is almost the method i use to make silver plating solution although i didnt know about what all goes on just that it works.i was told to boil

with carbonate also and to use silver chloride instead of nitrate but again it was to make silver plating solution.this process you write about is to

extract potassium cyanide free from silver contamination?the sediment in the silver cyanate solution i make also is a rusty color and figured it was

the ferro and always thought it was not a real cyanate solution.talking to plante1999 after he sent me that book remarked that cyanide only disolves

noble metals so iron doesnt really contaminate cyanides.up until then i never understood how cyanide was heated to high heat in iron pots and not

pickup cross contamination.oddly my "inferior"silver cyanate solution plates silver that does not tarnish black like @ogers and sons silver plate.of

course @gers and sons is better and shinier.

[Edited on 6-23-2013 by cyanureeves]

|

|

|

anomolous

Harmless

Posts: 23

Registered: 12-3-2013

Location: USA

Member Is Offline

Mood: No Mood

|

|

| Quote: |

The only role for the SO2 that I can think of is the reduction of cupric to cuprous cations, the latter which then would form the insoluble CuCN.

Since as everything else maintains its oxidation state that must be what's happening and 'CuCy2' must be a typo. |

blogfast, I think you are right on about the purpose of the SO2. SO2 is often used to reduce cupric chloride to cuprous chloride. I don't see why else

it would be necessary. It may be easier to skip the SO2, filter the CuCN2, and then heat it to decompose, as CuCN2 decomposes to CuCN. What do you

think? If not, how would you go about getting the SO2 into the reaction mixture? Burn some sulfur and bubble the smoke into water until it gains the

proper amount of weight? Or is their some other way?

cyanureeves, No, the idea is to make CuCN from potassium ferrocyanide. The usual method of making KCN from the ferrocyanide involves the evolution of

deadly HCN and dissolving this into KOH or heating it intensely. As mentioned above, CuCN can be used in place of K or NaCN in some cases and this

reaction appears to be mostly safe and easy. I'll test it out soon and post my results. But please, if you have any ideas on how this reaction would

look in your lab, tell me. The more brain-power behind my attempt the more likely it will succeed.

[Edited on 23-6-2013 by blogfast25][/rquote]

[Edited on 23-6-2013 by anomolous]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by anomolous  |

| Quote: |

The only role for the SO2 that I can think of is the reduction of cupric to cuprous cations, the latter which then would form the insoluble CuCN.

Since as everything else maintains its oxidation state that must be what's happening and 'CuCy2' must be a typo. |

It may be easier to skip the SO2, filter the CuCN2, and then heat it to decompose, as CuCN2 decomposes to CuCN. What do you think? If not, how would

you go about getting the SO2 into the reaction mixture? Burn some sulfur and bubble the smoke into water until it gains the proper amount of weight?

Or is their some other way?

[Edited on 23-6-2013 by anomolous] |

It's Cu(CN)2, not CuCN2. Cu(CN)2 is unlikely to decompose to CuCN, as far as I know.

SO2 can be made in various ways. Sulphites + strong acid = SO2 for example. It can also be provided in situ by sodium metabisulphite for instance but

I'm not sure that would work here.

[Edited on 23-6-2013 by blogfast25]

|

|

|

anomolous

Harmless

Posts: 23

Registered: 12-3-2013

Location: USA

Member Is Offline

Mood: No Mood

|

|

| Quote: |

It's Cu(CN)2, not CuCN2. Cu(CN)2 is unlikely to decompose to CuCN, as far as I know. |

I wasn't sure about this either so I looked it up. According to Modern Inorganic Chemistry, Butterworth (1975), "...copper (II) cyanide rapidly

decomposes at room temperature, to give copper (I) cyanide and cyanogen (CN)2." This also fits with the description given of the substance in the

quote above, "At first a reddish-brown precipitate of ferrocyanide of copper is formed, which under the action of heat is gradually transformed into a

white, flucculent cyanide of copper." Cu(CN)2 is a blue-green powder while CuCN is off-white. The SO2 must serve to reduce the Cu4[Fe(CN)6] formed.

The reaction of K4[Fe(CN)6] + CuSO4 = Cu4[Fe(CN)6 + K2SO4.

| Quote: |

SO2 can be made in various ways. Sulphites + strong acid = SO2 for example. It can also be provided in situ by sodium metabisulphite for instance but

I'm not sure that would work here. |

That is a very interesting idea. I will definitely try it but first I think I'll generate the SO2 using NaHSO3 which I have a bunch of. I'm going to

use a lot of water to keep the free acid generated diluted as recommended. Otherwise I may add some base (Na2CO3 or NaOH) to neutralize it, but I'm

scared these may screw with the CuCN formed.

Please feel free to make more suggestions. If you were to repeat this experiment what exactly would you do? I should get the K4[Fe(CN)6] next week and

then I'll get started.

|

|

|

woelen

Super Administrator

Posts: 8082

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

For getting SO2 I simply would add some sodium metabisulfite or potassium metabisulfite. These compounds can be obtained from beer-making or

wine-making companies (so-called campden tablets or powder contain K2S2O5 in pure form). Probably you should not add all of this at once, but in small

portions during the conversion of the red cupric ferrocyanide to cuprous cyanide.

I definitely would add some reductor, otherwise you'll get cyanogen gas. This gas is as toxic as HCN. Having SO2 around is not pleasant, but it is

much less toxic than cyanogen. The latter easily kills you. So, although this method of making cyanides is less dangerous than making HCN and

neutralizing that with KOH, it still is not without risk.

This type of reactions is possible only for highly insoluble cyanides. These cyanides are in equilibrium with ferrocyanide and apparently their

solubility is so low that they precipitate and hence take cyanide out of the equilibrium system.

|

|

|

anomolous

Harmless

Posts: 23

Registered: 12-3-2013

Location: USA

Member Is Offline

Mood: No Mood

|

|

Here is a basic outline of how I plan on doing this reaction. Please feel free to chime in with recommended improvements. I will probably do it on a

smaller scale than described but following the same general procedure.

General Process: An SO2 generator is prepared consisting of sodium metabisulfite and an addition funnel with H2SO4. 3 mol of CuSO4

(750 g, hexahydrate) is dissolved into 3 L of dH2O in a 5 L flask equipped for reflux, with an addition funnel, an overhead stirrer, and SO2 gas

inlet. 0.5 mol of potassium ferrocyanide (211 g, trihydrate) is dissolved into 1 L of dH2O. The CuSO4 sol. is brought to a reflux and the K4[Fe(CN)6]

sol. is added dropwise with stirring. Once the red-brown Cu[Fe(CN)6] is finished precipitating the flask is weighed and recorded. SO2 is then bubbled

into the water until 1.5 moles is added (an increase of about 98 g) or all of the red-brown precipitate has changed to an off-white. The mixture is

cooled, the CuCN vacuum filtered, rinsed with cold water, dried and stored into an air-tight container.

woelen, in the second run, instead of bubbling the SO2 into the mixture, I will attempt to generate it in-situ as you described.

Do you guys think that waiting until after the Cu[Fe(CN)6] has formed to add the SO2 is a good idea?

|

|

|

anomolous

Harmless

Posts: 23

Registered: 12-3-2013

Location: USA

Member Is Offline

Mood: No Mood

|

|

Here is a similar reaction for making Copper (I) Chloride from "Handbook of Preparative Inorganic Chemistry" (1965) p 1005 that may be useful:

2CuSO4 + 2NaCl + SO2 + H2O = 2CuCl + Na2SO4 + 2H2O

"Gaseous SO2 is bubbled through an aqueous solution of 50 g of CuSO4-5H2O and 24 g of NaCl at 60-70C until CuCl ceases to precipitate. The product is

suction filtered..." etc.

I'm thinking our reaction occurs in three or four steps. First, the K4[Fe(CN)6] is converted to Cu2[Fe(CN)6), then the Cu2[Fe(CN)6] is decomposed by

H2SO4 and/or SO2, releasing HCN and forming Cu(CN)2, which is immediately decomposed by the heat and/or SO2 to form CuCN. Something like this:

2CuSO4 + K4[Fe(CN)6] = Cu2[Fe(CN)6] + 2K2SO4

Cu2[Fe(CN)6] + 3H2SO4 = 2CuSO4 + 6HCN + Fe(SO4)

3CuSO4 + 6HCN = 3Cu(CN)2 + H2SO4

6Cu(CN)2 + SO2 =HEAT> 6CuCN + 3(CN)2

Our guide gives this equation:

6CuSO4 + K4[Fe(CN)6 + 3SO2 + 6H2O = CuCN + K2SO4 + FeSO4 + 6H2SO4 (Note: The actual product is written as "CuCN2" which is assumed to be a typo.)

And says, "The mixture should contain a certain proportion of free acid, which, producing the decomposition of the ferrocyanide, causes the formation

of prussic acid, which unites with the silver or with the copper to form cyanides of these metals."

I'm unsure whether or not a small amount of sulfuric must be added to get the reaction started. An equilibrium reaction occurs between the excess

CuSO4 and SO2 as follows: CuSO4 + SO2 + H2O <=> Cu + H2SO4 which may be sufficient. I guess if the reaction doesn't seem to be going forward I

can always add H2SO4 drop-wise to get it started.

I know I haven't balanced this but its the best I could do.

[Edited on 25-6-2013 by anomolous]

|

|

|

Random

International Hazard

Posts: 1120

Registered: 7-5-2010

Location: In ur closet

Member Is Offline

Mood: Energetic

|

|

Anomolous, isn't that too much cyanogen right there? Is it even possible to do it safely?

|

|

|

anomolous

Harmless

Posts: 23

Registered: 12-3-2013

Location: USA

Member Is Offline

Mood: No Mood

|

|

I believe nearly anything can be done safely. This reaction, obviously, should be done under a fume hood or outdoors. The cyanogen evolved is a

problem but not one that is insurmountable. I'm thinking of running the evolved gasses into conc. HCl to hydrolyze the cyanogen.

(CN)2 + H2O = CONH2 + H2O = COONH4

But I'm open to suggestions.

|

|

|

anomolous

Harmless

Posts: 23

Registered: 12-3-2013

Location: USA

Member Is Offline

Mood: No Mood

|

|

Well, I tried it out and its not quite as simple as I thought it would be. Here are the results.

Experimental 1: 0.6 mol of copper sulfate hexahydrate (150 g) was dissolved into about 1 L of water in a 3000 mL flask equipped with a three-neck

adapter, reflux column, SO2 gas inlet, and addition funnel. The reflux column was stoppered and fitted with tubing which guided the evolved gases

outside. An SO2 generator was prepared containing 110 g sodium metabisulfite and 120 mL of 31% HCl. 0.1 mol of potassium ferrocyanide trihydrate (42

g) was dissolved into 700 mL of water and poured into the addition funnel. The oilbath temp was brought to 100C, the SO2 generator was started, and

the K4[Fe(CN)6] sol. was added. The red-brown Cu2[Fe(CN)6] formed immediately and after all the K4[Fe(CN)6] sol. was added about 5 mL of H2SO4 was

added. The mixture grew increasingly light and after about 2 hours white specks could be seen in the red-brown mixture. The SO2 generator was heated

to force more SO2 into the reaction and the oilbath temp was increased to about 110C . It probably would have been better to start the SO2 generator

after the K4[Fe(CN)6] sol. was added because the generator sputtered out before the reaction had finished. Or to just use more sodium metabisulfite

and HCl. I added another 2 tblsps of NaHSO3 and another splash of HCl to the generator. The mixture was quite thick and may have clogged the inlet

tube if no gas was flowing through it. In spite of this the heating was continued. When the reaction was complete the liquid was clear, with a purple

tint, and afinely divided grey precipitate remained. The heat was turned off and the mixture allowed to cool. The grey precipitate was vacuum

filtered, rinsed with water, then dried. It had the appearance of ash.

Experimental 2: 0.6 mol of copper sulfate hexahydrate (150 g) was dissolved into about 1 L of water in a 3000 mL flask equipped with a three-neck

adapter, reflux column, and SO2 gas inlet. The reflux column was stoppered and fitted with tubing which guided the evolved gases outside. An SO2

generator was prepared containing 150 g sodium metabisulfite and 150 mL of 31% HCl. 0.1 mol of potassium ferrocyanide trihydrate (42 g) was dissolved

into 1000 mL of water and mixed with the CuSO4 sol immediately forming a the red-brown Cu2[Fe(CN)6]. More water was added, filling the flask. About 50

mL of H2SO4 was added, the flask was shaken, heating was begun, and the SO2 generator started. After the oilbath temp reached anout 110C a fluffy,

light, white precipitate began to form which floated on top of the mixture. The reaction mixture sucked back into the SO2 generator and, by the time

the CuCN seemed to actually form, the generator was almost done. After the SO2 generator was spent no more precipitate formed. Heating was continued

none-the-less to no avail. A small amount of sodium metabisulfate was added resulting in an overflow and nasty fumes.

INSIGHTS: Mixing the CuSO4 and K4[Fe(CN)6] first seems to be the way to go. The mixture needs to be brought to reflux before beginning to generate SO2

and the SO2 generation must be continued until the reaction is complete. The reaction does not occur without continuous SO2. It seems the the 50mL

H2SO4 benefited the reaction. Perhaps more would be even more effective.

Experimental 3: 0.3 mol of copper sulfate hexahydrate (75 g) was dissolved into about 1 L of water in a 3000 mL flask equipped with a three-neck

adapter and reflux column. A stopper was placed into the neck that held the SO2 inlet in previous experimentals. I intended to insert after the

mixture began refluxing. The reflux column was stoppered and fitted with tubing which guided the evolved gases outside. The SO2 generator was prepared

containing 185 g sodium metabisulfite and 185 mL of 31% HCl. 0.05 mol of potassium ferrocyanide trihydrate (21 g) was dissolved into 1000 mL of water

and mixed with the CuSO4 sol immediately forming a the red-brown Cu2[Fe(CN)6] precipitate. More water was added and I accidently filled the flask too

much so I dumped maybe 200 mL out but the flask was full. 50 mL of H2SO4 was added, the flask was shaken and heating was begun. Once the mixture was

refluxing the SO2 inlet was inserted and gas generating started. After an hour the mixture was not as dark but no white precipitate was seen. FAILED

|

|

|

kmno4

International Hazard

Posts: 1517

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

These results are very interesting.

However "copper sulfate hexahydrate" is rather pentahydrate.

I think main problem is too acidic solution. In the end of reaction I would add some Na2CO3 or something like this, to neutralize H2SO4.

Your "ash" is probably CuCN.

My CuCN is grey powder, very easily picking up static when dry.

EDIT

This reaction really works

But I did it in a slightly different way - I used Cu (wire) as reductor.

Precipitate of red-brown Cu2[Fe(CN)6] slowly reduces its volume, becomes brighter and brighter and water phase turns green (Fe(II)).

This is much clearer and cheaper comparing to SO2 method.

Amazing.....

[Edited on 13-7-2013 by kmno4]

Слава Україні !

Героям слава !

|

|

|

kmno4

International Hazard

Posts: 1517

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

I have made few experiments on 7,5g CuSO4•5H2O scale and Cu wire as reductor.

Reaction goes on hot, but takes several hours of boiling.

I have found not expensive catalyst, called it WKC(=wundebar kmno4's catalyst) which speeds up reaction.

With WKC, reaction is completed in less than 10h, with magnetical stirring without heating.

Brown-red slurry of starting Cu2[Fe(CN)6] slowny turns white-grey-brown in the end of reaction.

Remaining Cu was removed and mixture filtered.

In most cases, residue on filter changes its colour to more brown, but sometimes remains unchanged.

I think it is caused by Cu(I) oxidation with air.

Additionally, it seems that colour of the product depends on molar ratio of substrates.

In each run 5,8-6,2 g of colored powder is obtained (theory 5,4g for CuCN).

It seems to be poor quality contaminated CuCN.

However, the use of WKC (~1g) makes the synthesis more friendly.

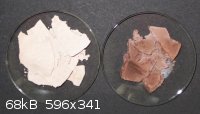

Foto - output "powders".

Слава Україні !

Героям слава !

|

|

|

AndersHoveland

Hazard to Other Members, due to repeated speculation and posting of untested highly dangerous procedures!

Posts: 1986

Registered: 2-3-2011

Member Is Offline

Mood: No Mood

|

|

Just for if anyone was not aware, the cyanides of silver and copper normally exist in the form of the Cu(CN)2‒ ion.

That is why solutions of cyanide can so easily dissolve Cu/Ag/Au in the presence of air.

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by anomolous  |

I believe nearly anything can be done safely. This reaction, obviously, should be done under a fume hood or outdoors. The cyanogen evolved is a

problem but not one that is insurmountable. I'm thinking of running the evolved gasses into conc. HCl to hydrolyze the cyanogen.

(CN)2 + H2O = CONH2 + H2O = COONH4

But I'm open to suggestions. |

Actually, the suggested process is very akin to a Wikipedia cited path to Cyanogen. To quote (link: http://en.wikipedia.org/wiki/%28CN%292 ):

"Alternatively, one can combine solutions of copper(II) salts (such as copper(II) sulfate) with cyanides, an unstable copper(II) cyanide is formed

which rapidly decomposes into copper(I) cyanide and cyanogen.[7]

2 CuSO4 + 4 KCN → (CN)2 + 2 CuCN + 2 K2SO4 "

While not really recommending this preparation method for copper(I) cyanide, I note the following. First, per this source ( see http://copper.atomistry.com/cuprous_cyanide.html ), to quote:

"The best method for its preparation [of CuCN] is to mix cold aqueous solutions of potassium cyanide (65 grams) and cupric sulphate (130 grams), and

expel cyanogen by warming the mixture under an efficient air-extractor. After settling, the cuprous cyanide is decanted, and washed with water,

alcohol, and ether."

Also, per this link ( http://carbon.atomistry.com/cyanogen.html ) to quote:

"Its reaction [referring to Cyanogen] with sulphurous acid, though slower than, is similar to, that of the halogens: (CN)2 + H2SO3 + H2O = 2HCN +

H2SO4.

Moreover, just as chlorine reacts with dilute alkali to form chloride and hypochlorite, so cyanogen yields cyanide and cyanate, thus:

(CN)2 + 2KOH = KCN + KCNO + H2O"

And lastly, per this link http://copper.atomistry.com/cupric_cyanide.html :

"The Cupric cyanide, Cu(CN)2, is obtained as a brownish-yellow precipitate by the interaction of solutions of potassium cyanide and cupric sulphate,

but it is very unstable, decomposing at ordinary temperatures into cupric cuprous cyanide, Cu[Cu(CN)2]2,5H2O, with evolution of cyanogen. On heating,

it is converted into cuprous cyanide."

Based on the above comments, I have two ideas to reduce the risk of Cyanogen exposure. First, use agitation and time for SO2 to remove some of the

(CN)2. Second, add Cu(OH)2 to the reaction mixture (or a copper mineral such as CuSO4.2Cu(OH)2 or CuSO4.3Cu(OH)2 ) for a speculated reaction (which is

possibly slow as well and best performed at, or less than, room temperature based on the hydrolysis of (CN)2 ):

2 (CN)2 + 2 Cu(OH)2 --> Cu(CN)2 + Cu(CNO)2 + 2 H2O

Or, separately capture the (CN)2 and treat it with a cold solution of Cu(OH)2. Being unstable, any formed Cupric cyanide's decomposes into cupric

cuprous cyanide, Cu[Cu(CN)2]2.5H2O and more (CN)2 which can react with more Cu(OH)2, ....This may increase the yield of CuCN and reduce possible

exposure to Cyanogen gas.

[Edited on 1-8-2013 by AJKOER]

|

|

|

anomolous

Harmless

Posts: 23

Registered: 12-3-2013

Location: USA

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by kmno4  | I have made few experiments on 7,5g CuSO4•5H2O scale and Cu wire as reductor.

Reaction goes on hot, but takes several hours of boiling.

I have found not expensive catalyst, called it WKC(=wundebar kmno4's catalyst) which speeds up reaction.

With WKC, reaction is completed in less than 10h, with magnetical stirring without heating.

Brown-red slurry of starting Cu2[Fe(CN)6] slowny turns white-grey-brown in the end of reaction.

Remaining Cu was removed and mixture filtered.

In most cases, residue on filter changes its colour to more brown, but sometimes remains unchanged.

I think it is caused by Cu(I) oxidation with air.

Additionally, it seems that colour of the product depends on molar ratio of substrates.

In each run 5,8-6,2 g of colored powder is obtained (theory 5,4g for CuCN).

It seems to be poor quality contaminated CuCN.

However, the use of WKC (~1g) makes the synthesis more friendly.

Foto - output "powders". |

You really think that brown powder is copper (I) cyanide? I still have doubts. I made some copper (I) cyanide by HCN addition to cupric acetate

solution followed by addition of sodium metabisulfite and it was very bright white and fluffy (though it became tinted slightly yellow after a week).

It looked very different from the brown powder obtained by this reaction and even had a different consistency. If it is CuCN it is very impure. Have

you had any luck purifying the product? How can we verify that it is CuCN? I'll see what I can figure out, too.

Thanks for following up on the post. Good work!

|

|

|

kmno4

International Hazard

Posts: 1517

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

According to XRF analyser, my powders contain ~8% Fe and ~92% Cu (as a sum of heavy metals). This is average value, all powders were combined and

mixed together.

It seems to be not very interesting mixture of CuCN and some cyanoferrate. It is inert to water, concentrated NaCl solution and acetic acid solution.

Acetic acid sol. initially gives some weak green-blue solution, but another washing gives clear solution and the powder after filtration looks like

input one - pale brown, very fluffy powder. It also gives orange fluorescence under UV light, my pure CuCN sample does not give such a fluorescence.

I did also experiment with K4[Fe(CN)6] sol. and CuCl (as solution in conc. NaCl sol.)

I got white jelly suspension at the very begining, becoming slightly violet for a moment and becoming almost white sediment. Unfortunately, this white

sediment (after washing) becomes pale brown powder, looking exactly like earlier products.

Слава Україні !

Героям слава !

|

|

|

Boffis

International Hazard

Posts: 1897

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Some thoughts on Cuprous Cyanide

In anomalous' initial post he alluded to the potential use cuprous cyanide in organic synthesis either in its own right or as a substitute for an

alkali cyanide. However, cuprous cyanide can also be used as a source of cyanogen through its reaction with ferric chloride solution (see Brauer vI,

p661 (SM library)). Cyanogen is the starting material for a whole range of syntheses, its reaction with hydrogen azide give rise to tetrazole

derivatives while its reaction hydrogen sulphide give rise to thioxamide derivatives. Dithioxamide (rubeanic acid) reacts with hydroxylamine to give

diaminoglyoxime and hence provides an alternative route to diaminofurzane and its derivatives (see the various posts by Axt particularly in the SM

Prepublication section).

Cyanogen is also available through the thermal decomposition of silver cyanide which is available by a similar means to cuprous cyanide (see

anomalous' initial post for the reference) or by heating dried potassium ferrocyanide with mercuric chloride (see Cyanogen Compounds, their chemistry,

detection and estimation; Herbert E. Williams 2nd ed 1947 or 1st ed 1923) however, this last technique suffer from the evolution of much mercury

vapour.

I am not going to consider either the preparation or the uses of cyanogen further in this post. The purpose of this offering is a critical

considertion of the technique described in the original post and the reason for the failures experience by those members who have tried the reaction.

In the book cited in the original post the author states that sodium sulphite may also be used as a reducing agent but anomalous tried the reaction

using sulphur dioxide without neutralisation. Consider the following equations:

6CuSO4(H2O)5 + K4Fe(CN)6(H2O)3 + 3SO2 -> 6CuCN + FeSO4 + 2K2SO4 + 6H2SO4 + 27H2O

6CuSO4(H2O)5 + K4Fe(CN)6(H2O)3 + 3Na2SO3 -> 6CuCN + FeSO4 + 3Na2SO4 + 2K2SO4 + 3H2SO4 + 30H2O

In the first example using sulphur dioxide as the reductant much free sulphuric acid is produced and even highly insoluble cyanide such as cuprous

cyanide are eventually hydrolysed to an ammonium salt and carbon dioxide by boiling under these conditions. In the second reaction much less sulphuric

acid is generated and since there is a molar excess of alkali sulphates the sulphuric acid will tend to give rise to bisulphate ions which are much

less acid. I would contend that even if kept cool this would be close to the limiting acidity condition under which even cuprous cyanide can survive

and that further neutralization of the acid is desirable. Total neutralization must be avoided or the ferrous sulphate will hydrolyse, particularly if

there is any oxygen present (highly likely). The high concentration of sulphate salts will help to reduce the tendency to hydrolyse the ferrous ions

but it will still be necessary to maintained slightly acid conditions; a feature referred to in anomalous' original quotation.

An alternative strategy might be neutralise part of the resulting acid and then add a complexing agent that will prevent the precipitation of the iron

while not interferring with the desired reaction; trisodium citrate would seem to be a good candidate as it acts both as a complexing agent for iron

and also a pH buffer (it is used for this purpose in soft drinks and as a result it is cheap and easily available). Other complexing agents such as

triethanolamine or sodium tartrate might also work.

One further point is that commercial sodium sulphite is usually a hydrate (7H2O if I recall correctly) and unless its composition is known it while

require drying before weighing. Alternatively the more readily available anhydrous sodium metabisulphite may be used with a commensurate increase in

the amount of neutralising agent, say NaOH.

The fully neutralised reaction would thus be:

12CuSO4(H2O)5 + 2K4Fe(CN)6(H2O)3 + 3Na2S2O5 + 18NaOH ->

12CuCN + 2FeSO4 + 12Na2SO4 + 4K2SO4 + 75H2O

Theoretically this would require for one Mole of copper sulphate pentahydrate (249.7g):

Copper sulphate pentahydrate 249.7g

Potassium ferrocyanide 3H2O 70.4g

Sodium metabisulphite 47.5g

Sodium hydroxide 60.0g

To yield 89.5g of cuprous cyanide.

In practice I would recommend the use of a slight excess of sodium metabisulphite to inhibit oxidation of the ferrous ions and a little less sodium

hydroxide which would hopefully negate the need for sodium citrate or similar.

My proposed experimental procedure is as follows:

Dissolve 25g of copper sulphate pentahydrate in 250ml of hot water. Into a 1L beaker place 350ml of water, 7g of potassium ferrocyanide and 5g of

sodium metabisulphite and place on a hotplate and stir until the salts have dissolved. Make up a solution of 5g of sodium hydroxide in 50ml of water.

Heat the ferrocyanide solution almost to boiling and commence the addition of the copper sulphate solution while stirring continuously. Periodically

check the pH with a meter or Congo red paper (pH 3 to 5) if the solution becomes acid to Congo red (paper turns blue) add sodium hydroxide until the

excess acidity is just neutralised (pH 5) the solution should remain acid to litmus paper all of the time. Once all of the copper sulphate solution

has been added maintain the heat until the brown colour is discharges, cool and filter. It is preferable to filter with a vacuum pump and buchner

funnel as the precipitate is likely to be very fine and will filter slowly by gravity alone. Wash with cold water and dry. You SHOULD end up with

about 9g of white powder.

I'll try this over the coming week and report back.

[Edited on 13-8-2013 by Boffis]

|

|

|

kmno4

International Hazard

Posts: 1517

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Another experiments, this time with good results (at least I think so).

On the same scale as written earlier, but with additional 1g of H2SO4** and boiling.

Some foto in attachment (see bookmarks panel):

p_1: CuSO4 + K4[Fe(CN)6]

The mixture was warmed, added Cu, WKC, H2SO4, stoppered with a glass cork and put on magnetic stirrer.

After ~2h I got nice white suspension in pale blue liquid (p_2). This is not CuCN, because it is getting brown on contact with air (brown sediment on

upper part of flask).

I had not time, mixture p_2 was left for _12 h without stirring (p_3)

P_3 was heated to very slow boiling (short air cooler + cotton plug): colour of liquid was changing from blue to green, sediment reduced its volume

and changed coloud to white-grey and became inert to air (p_4 and p_5)

After ~3h, precipitate was filered, washed with water and dried (p_6)

Two runs gave similar product: soft, more or less grey powder. Weights are 5,4g and 5,3g - much better agreemnent with theory than earlier "browns".

I am going to do XRF analysis of these powders but in a few days.

** possibly 1g of H2SO4 is even too much, but it gave less than 1% concentration in mixture....

Attachment: Binder1.pdf (191kB)

This file has been downloaded 829 times

Слава Україні !

Героям слава !

|

|

|

Boffis

International Hazard

Posts: 1897

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@kmno4

I have just tried this preperation too, as I described above. I used slightly less NaOH that expected because using more precipitates green ferrous

hydroxide. I ended up with a white suspension which I filtered and washed with 0.5% bisulphite/citrate and then de-ionised water. Curiously when I

washed the ppt with water it started to turn flesh pink. I basically got the same results as you seem to have done, white precipitate with a pale

green blue supernatant liquid (ferrous sulphate). I am waiting for the ppt to dried so I can report the yield but it look promising. I'll post the

detail in full later.

By the way are you going to tell us what WKC is?

|

|

|

kmno4

International Hazard

Posts: 1517

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

XRF analysis of my grey powders gave 3% Fe and 97% Cu.

Still contaminated with Fe but much less than earlier. Possibly decomposition of "Cu4Fe[(CN)6]" is very slow process and mixture should be boiled for

some longer period to strip all Fe from it.

The formula of WCK costs 100 USD, payment via PP.

However it can be deduced from earlier postst (0 USD).

Hint: WCK helps in oxidation of Cu(0) with Cu(II).

Just easy chemical riddle for interested

Слава Україні !

Героям слава !

|

|

|

Boffis

International Hazard

Posts: 1897

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

In my post above I outlined my proposed method for the preparation of cuprous cyanide from a ferrocyanide now I will detail the actual results of my

attempts to carry out this conversion. I used 1/10th scale for the first two experiments and then 1/4 scale for the "production" run.

1st Attempt

25.10g of copper sulphate pentahydrate were dissolved in 250ml of hot water in a 500ml beaker while 7.10g of potassium ferrocyanide trihydrate and

4.94g of sodium metabisulphite were dissolved in 350ml of hot water in a 1L beaker. The neutralising solution was prepared by dissolving 5.0g of

sodium hydroxide in 50ml of cold water.

The potassium ferrocyanide solution was placed on a hot plate and warmed while the copper sulphate solution was addd slowly with good stirring causing

a dark brown precipitate to form. Periodically the suspension was tested with Congo Red paper (pH3-5) and if the solution tested acid sodium hydroxide

solution was added until it was no longer acid to Congo Red but was to Litmus and then the addition of copper sulphate continued. Each addition of

sodium hydroxide caused the precipitate to become paler in colour. Once all of the copper sulphate had been added a final pH adjustment was made and

then the suspension heated almost to boiling and cooled.

The cooling suspension The cooling suspension

The pale flesh pink precipitate was filter off at the pump using a 9cm buchner funnel . The precipitate filters easily with gentle suction. Before the

cake was sucked completely dry it was washed with 100ml of a solution containing 0.5g of sodium metabisulphite and 1g of tri-sodium citrate per 100ml,

this cause the precipitate to become almost white. After a final wash with 50ml of water the filter cake was sucked as dry as possible, this however,

caused the precipitate to turn deep flesh pink and as the cake was dried overnight it turn brown. The discolouration started at the surface and

migrated inwards and so is due to atmospheric oxidation.

The greenish blue ferrous iron rich filtrate The greenish blue ferrous iron rich filtrate

The filter cake was dried at about 35° C overnight when the dried dark brown precipitate weighed 9.60g. It was ground to a powder and dispersed into

200ml of 2% sodium metabisulphite solution and boiled for a few minute but this did not return the colour to its original pale flesh pink.

2nd Attempt

This was carried out in the same manner using slightly more ferrocyanide to ensure a slight excess. 24.93g of CuSO4.5H2O; 7.44g of K4Fe(CN)6.3H2O and

4.93g of sodium metabisulphite were used in the same volumes of water as before. The reaction was carried as before to the final neutralization when a

little extra sodium hydroxide was added but maintaining the solution acid to Litmus paper Note 2) and then the suspension simmered for 30 minutes and

cooled overnight.

The dense almost white precipitate settled quickly and filtered easily and darkened only very slightly when dried. The filter cake was dried at 35° C

as before for about 16 hours to give 9.32g of a slightly pinkish powder (after grinding).

The precipitates from 2nd and 1st attempts; note the paler 2nd product (left side) The precipitates from 2nd and 1st attempts; note the paler 2nd product (left side)

3rd Attempt at a "preparation" scale

100g of copper sulphate pentahydrate were dissolved in 1l of hot water in a 2l beaker on a hotplate. While this was dissolving 15g of sodium hydroxide

were dissolved in 90ml of cold water in a second beaker and in a third beaker 28.41g of potassium ferrocyanide trihydrate plus 19.80g sodium

metabisulphite were dissolved in 400ml of warm water.

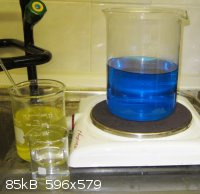

The solutions before mixing The solutions before mixing

Half the sodium hydroxide solution was added to the ferrocyanide solution and this then stirred into the copper sulphate solution (Note 1). The

initial dark brown precipitate rapidly became paler and eventually almost white. As before the pH was monitored with Congo Red paper and if the

suspension became acid (paper turned purple or blue) more sodium hydroxide was added but it is important to maintain the suspension acid to litmus,

the ideal pH is probably about 5.5.

Initial precipitate Initial precipitate

Precipitate after about 5minutes Precipitate after about 5minutes

The suspension was simmered for 1 hour and then left to cool overnight. The precipitate settles rapidly leaving a clear greenish blue solution. Most

of the clear solution could be decanted and only the last 400ml or so of suspension filtered through a 12.5cm buchner funnel. The precipitate was

washed with 200ml of water only and then sucked as dry as possible, healing any desiccation cracks that formed with a spatula until the cake was

friable. The cake was turned out onto a large watch glass and dried at about 35° C as before for 24 hours. The almost white cake turned pale pink on

drying and weighed 36.70g which is slightly more than 100% indicating that the precipitate may not be completely dry but the yield is clearly almost

quantitative with respect of copper sulphate.

Precipitate after 1 hours heating Precipitate after 1 hours heating

The final product The final product

Notes

1: This is the reverse of the addition used previously and it was found that the initial dark precipitate was slow to completely decolourise; some of

the flocculent aggregates maintained darker cores presumably due to a protective effect necessitating the longer simmering. It appears to be better to

add the copper sulphate to the ferrocyanide/metabisulphite solution.

2: The reaction mixture must not become alkaline to litmus or green ferrous hydroxide precipitates and quickly turns brown and is then difficult to

re-dissolve.

|

|

|

Pok

potassium Prometheus

Posts: 176

Registered: 5-12-2010

Member Is Offline

|

|

Very interesting procedure. But this part seems quite complicated:

Quote: Originally posted by Boffis  | As before the pH was monitored with Congo Red paper and if the suspension became acid (paper turned purple or blue) more sodium hydroxide was added

but it is important to maintain the suspension acid to litmus, the ideal pH is probably about 5.5.

|

Isn't there a way to do it in a simple "one step" procedure?

The complete equation for the procedure (using sodium sulfite) is:

6 CuSO4 + K4Fe(CN)6 + 3 Na2SO3 + 6 NaOH -> 6 CuCN + 2 K2SO4 +

FeSO4 + 6 Na2SO4 + 3 H2O

So it should be possible to convert half of the CuSO4 to Cu(OH)2 before and add this slurry-like 1:1 mixture of

Cu(OH)2 and CuSO4 to the K4Fe(CN)6/Na2SO3 solution:

3 CuSO4 + 3 Cu(OH)2 + K4Fe(CN)6 + 3 Na2SO3 -> 6 CuCN + 2

K2SO4 + FeSO4 + 3 Na2SO4 + 3 H2O

In your case (using sodium metabisulfite) it would be necessary to convert 3/4 of the CuSO4 to Cu(OH)2 and add this 1:3 mixture

to the boiling ferrocyanide/metabisulfite solution:

3 CuSO4 + 9 Cu(OH)2 + 2 K4Fe(CN)6 + 3 Na2S2O5 = 12 CuCN + 4

K2SO4 + 2 FeSO4 + 3 Na2SO4 + 9 H2O

If this works, it would be much easier than neutralising the developing sulfuric acid from time to time.

Is the CuCN shown in the last picture pure? What did you do with it? Did you try to convert it to KCN or so?

[Edited on 18-5-2020 by Pok]

|

|

|

Boffis

International Hazard

Posts: 1897

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Try it and let us know! Its already a one pot process, how much simpler do you want it?

From experience if the reaction mixture becomes too alkaline ferrous hydroxide is formed which rapidly converts to hydrated ferric oxide, which once

formed is hard to redissolve. So it needs to be kept acid but not too acid. It may be possible to buffer the reaction mixture or add a ferrous iron

specific complexing agent but this sounds way too complex for such a simple process.

The last photo above is of a pale flesh pink product so it is not completely pure or it would be white but its good enough for organic synths

|

|

|

| Pages:

1

2 |