| Pages:

1

2 |

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

That is an interesting product.

Yeah, HF preferentially removes the areas of the sand grains with the most impurities.

It also increases the surface area and 'activates' the silica to some extent.

It is used as a pretreatment in making catalysts

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by macckone  | That is an interesting product.

Yeah, HF preferentially removes the areas of the sand grains with the most impurities.

It also increases the surface area and 'activates' the silica to some extent.

It is used as a pretreatment in making catalysts |

Awesome. Well that rust stain remover hopefully would

suffice, if not, I'm not going to risk dealing with any other higher concentration of HF (I am still a chemical newbie, after all, and this is just

sand, lol).

Will update you after I do the HNO3[:HCl] leaches. Thanks for the replies everybody! These forums are awesome :-)

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

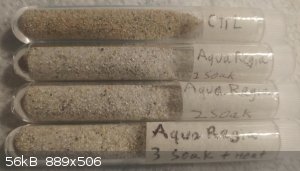

Just some updates - The aqua regia wash definitely whitened it up quite a bit, even more so than the

H2SO4:H2O2 wash did.

Here's a photo of the difference:

(full size image here, or here for same image with flash enabled)

The control sand (you can see how it's a little a little brownish or even reddish

First wash with decently concentrated aqua regia (soaked for at least 4 or 5 days)

Second wash with aqua regia for just as long, not much of a difference from the first wash

Third wash with aqua regia, this time I even applied heat for some time (not quite boiling, but 80C or so for a while)

Here's a link to the Imgur image gallery (which contains the other acid/base washes as well for comparison).

The sand is clearly much cleaner looking than the control, so that's a big plus, but even after 3 long washes with concentrated aqua regia, it still

has some black bits in it (presumably hematite), any idea what might take care of that? The only two acids I haven't tried yet are HF and glacial

acetic acid, and I'm not positive that either of those would work for it, but I think I'll give it a shot on a small scale.

I'm going to wash the rest of the sand with aqua regia as well since it clearly makes it much cleaner, but id like to figure out a good solution for

the black sand that persists through multiple HCl washes, conc. sulfuric acid, piranha solution, conc. nitric acid, aqua regia and sodium hydroxide.

They're invincible!

[Edited on 29-11-2020 by SuperOxide]

|

|

|

CharlieA

National Hazard

Posts: 646

Registered: 11-8-2015

Location: Missouri, USA

Member Is Offline

Mood: No Mood

|

|

Have you checked the black particles to see if they are magnetic? I'm thinking that magnetite may be a possibility.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by CharlieA  | | Have you checked the black particles to see if they are magnetic? I'm thinking that magnetite may be a possibility. |

I have, and I used a series of neodymium magnets to remove all of the magnetic particles in there (which I should have mentioned that was the first

thing I did, I apologize).

Here's a picture of me holding the test tube with the acid washed sand in it next to a relatively large neodymium magnet, you can see that nothing is

jumping over to it:

Full size image here

The hematite is usually either not magnetic or very weakly magnetic, and that seems to match what I'm seeing here, but if that's the case, I'm

surprised that the repeated concentrated HCl washes and even repeated aqua regia hasn't gotten to them (though they still had an overall positive

effect, just not the expected/intended result, lol).

|

|

|

B(a)P

International Hazard

Posts: 1139

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

Have you had a look with a hand lens. The dark minerals may also be biotite or amphibole, though the treatments you subjected the sand to would likely

remove biotite.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by B(a)P  | | Have you had a look with a hand lens. The dark minerals may also be biotite or amphibole, though the treatments you subjected the sand to would likely

remove biotite. |

I have, pretty sure thats not what they are.

However, quick update, I ran everything through my new (very fine) screen to separate out the silt from the sand, and the silt seems to contain much

more black particulate than the larger sand particles (or perhaps it's just because they were heavier and made it to the screen easier).

Out of curiosity, I put some of the silt in a test tube with some more concentrated aqua regia. Every day I would shake the test tube up a bit, and

that was about a week ago. And it appears that there's a red layer settling out above the sand, which I presume to be iron oxide from the black

particulate...

Here are two photos, one w/o flash and one w/ flash.

And here are some other photos.

So perhaps I just either need to re-wash the same sand, but in much more concentrated aqua regia for even longer (which is surprising, because I

thought it was decently concentrated before, but I suppose I was just skimping out on using my precious HNO3).

|

|

|

RustyShackleford

Hazard to Others

Posts: 200

Registered: 10-12-2020

Location: Northern Europe

Member Is Offline

|

|

I think its very likely to be iron contamination. If you are ever in need of fine extra pure sand, get some hamster sand (almost pure white) and heat

that in HCl for a couple hours. probably the best purity you can get outside very complicated procedures or actual laboratory sand from a lab

supplier.

|

|

|

Morgan

International Hazard

Posts: 1705

Registered: 28-12-2010

Member Is Offline

Mood: No Mood

|

|

There's a fair amount of mostly quartz sand where I live. It's a fine sand and it squeaks or chirps when you walk on it. In spots it looks like snow

almost. Like this example someone posted.

https://wandareddish.wordpress.com/2011/12/24/pensacola-beac...

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by RustyShackleford  | | I think its very likely to be iron contamination. If you are ever in need of fine extra pure sand, get some hamster sand (almost pure white) and heat

that in HCl for a couple hours. probably the best purity you can get outside very complicated procedures or actual laboratory sand from a lab

supplier. |

hamster sand, I've never heard of that... I will check it out. Thanks!

And I think I agree about it being iron contaminants... I suppose I just skimped on the use of HNO3 since I only have like 400mL of azeotropic. I was

mostly just doing this for the analytical experience and the challenge to see if I could get it very pure (without actually reacting it with NaOH then

converting it back to pure silicone dioxide, since I do plan to use the granulated sand itself).

Yeah I saw someone mention that. That's pretty awesome, I don't think I've ever seen anything that white in a natural setting such as a beach... Lucky

you!

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

A lot of really white sand contains large amounts of calcium carbonate.

It is a major impurity in a lot of sands.

Some sands even contain titanium dioxide which gives a whiter color.

Titanium dioxide is very inert and would require real effort to remove.

The calcium carbonate comes out with vinegar.

As for the black impurity, it is likely something black in a silica matrix.

If it was pure hematite it would have dissolved in aqua regia.

You could try a round of gravity separation, ie. panning the sand.

Density separation is used extensively in the mining industry as well as the hazardous waste clean up industry.

The orange color is likely iron oxychloride of variable composition.

That would indicate the black impurity is hematite in a silica matrix.

One trick that might help is heating the sand to 200C then dropping it in ice water slowly to avoid too much boiling and steam. This will cause the

impure particles to shatter while the pure silica will remain in one piece. If you are going for a particular particle size this has the added

benefit that the smaller particles will be the impure stuff.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

I did react some with some [nearly] glacial acetic acid, and that seemed to yield no difference at all (in weight or appearance). I figured that would

happen considering it's already had a few acid washes, but since it was in the sand purification documents I looked at, I just wanted to rule it out.

Quote: Originally posted by macckone  | As for the black impurity, it is likely something black in a silica matrix.

If it was pure hematite it would have dissolved in aqua regia. |

I think I agree with you on this. However

maybe the aqua regia with sand in suspension should have been heated for longer - I did 3 AR washes, each time it set for at least 4 days, sometimes a

week, but I only heated the last batch, and it didn't get to a boil, but rather just kept it at around 80C for like an hour. Maybe that wasn't enough.

Quote: Originally posted by macckone  | You could try a round of gravity separation, ie. panning the sand.

Density separation is used extensively in the mining industry as well as the hazardous waste clean up industry. |

Yeah, I don't have a gold panning pan thingy, so I'll have to figure something out (I'm sure it's not too difficult). When I have

the sand in a test tube with some acid on it, and I shake it around, I often notice that the black particulates will concentrate in some spot and form

a band mostly at the same level. So perhaps I should have given this a shot before. I just assumed that the acid washes would take care of it better,

but I guessed wrong.

Quote: Originally posted by macckone  | The orange color is likely iron oxychloride of variable composition.

That would indicate the black impurity is hematite in a silica matrix. |

Iron oxychloride,

interesting. The photos with the red/orange particles in suspension was a _very_ concentrated solution of AR, so I may neutralize it and see how that

looks. If it has a noticeable difference, then I may use the same process on the rest.

Quote: Originally posted by macckone  | | One trick that might help is heating the sand to 200C then dropping it in ice water slowly to avoid too much boiling and steam. This will cause the

impure particles to shatter while the pure silica will remain in one piece. If you are going for a particular particle size this has the added

benefit that the smaller particles will be the impure stuff. |

Now that's a hell of an idea.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by macckone  | If it was pure hematite it would have dissolved in aqua regia.

You could try a round of gravity separation, ie. panning the sand.

Density separation is used extensively in the mining industry as well as the hazardous waste clean up industry. |

I put some silt (that was just filtered off from the sand with a very fine screen) in a flask with some acid, shook it up, and look at the blatantly

obvious line it formed...

So I think what this all boils down to is my shitty gravity separation techniques and trying to over-compensate for it with use of acids.

I don't have a panning thing that I can use, but I'm sure I can come up with something. Since it's decently pure sand all of similar grade, maybe it

can pass through a sep funnel even... I'll test that out on a small scale. Or even just put it in a jar and shake it with some water, then put it on

the side, and the lip will hold in the lower layers as I pour it out (think I'll try that first before clogging up my sep funnels).

[Edited on 22-12-2020 by SuperOxide]

|

|

|

MidLifeChemist

Hazard to Others

Posts: 192

Registered: 4-7-2019

Location: West Coast USA

Member Is Offline

Mood: precipitatory

|

|

Your dedication to this project amazes me!

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Haha, thanks. I know it's a bit of a silly project to be so interested in, but I thought it would be a fun experimental exercise.... Get some sand,

test various cleaning processes on it and see which ones yield the best results. Plus it's not like it's a full on days work in each step, some of

them are just letting it sit in acid for a few days, then wash it and analyze it a bit.

|

|

|

VeritasC&E

Hazard to Others

Posts: 176

Registered: 29-1-2018

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by SuperOxide  |

Haha, thanks. I know it's a bit of a silly project to be so interested in, but I thought it would be a fun experimental exercise.... Get some sand,

test various cleaning processes on it and see which ones yield the best results. Plus it's not like it's a full on days work in each step, some of

them are just letting it sit in acid for a few days, then wash it and analyze it a bit. |

Given the many applications of pure SiO2 I feel this is a super interesting project and I look forward to reading up on future updates.

Have you maybe thought of starting off with automated physical separation techniques before the leaching steps?

Along the way of:

Gravitational: Shaking the sand on a purely vertical axis inside of a metal cylinder ending up with a cone at the bottom (with help of a simple

electric motor). The shaking amplitude and frequency should be such that all the sand inside the cylinder is freely suspended in air for some time at

each cycle, without coming in contact with the cylinder's upper lid. You'd simply pour in some sand from the top (maybe 1kg at a time or more if you

have a large enough cylinder with a powerful enough motor), put the power on, power it off after a while and emptying the cylinder from the bottom

cone by fractions (with increasingly small fraction sizes at the beginning and end of the sand batch inside). When emptying the cylinder you could put

it on a scale to know where you're at. Any contamination from the metal cylinder will dissolve before anything else in the later acid washes.

Magnetic: I'm not sure how the magnetic step was carried out but it could be easily automated as well by making a simple electric rotary tumbler a

putting the sand inside by 5Kg batches or so together with the neodymium magnet. The magnet being cleared from particles at exponentially increasing

intervals.

[Edited on 30-12-2020 by VeritasC&E]

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by VeritasC&E  |

Given the many applications of pure SiO2 I feel this is a super interesting project and I look forward to reading up on future updates.

|

I agree! However keep in mind that if it was just the pure SiO2 that I was after, then there's a method to go about getting that which involves doing

some basic purification techniques such as separating out the magnetite/hematite from the sand, then heat the sand up with molten NaOH, then a few

other steps.

There are a few good videos on YT about that as well (eg: videos by Vibzz lab and The Canadian Chemist), but the end results there are a pure SiO2 powder, which isn't the same as pure SiO2 sand. The sand granules are actually

what make the substance quite useful to me (and I think most others).

If I can get it to where it's mostly SiO2 still contained in sand granules, then that would be a win, however I know thats not 100% possible, as the

individual granules aren't just one substance (eg: SiO2 on the outside, but maybe some iron oxide on the inside, etc).

I've thought about it, and once I get the process down, then maybe that would be the way to go. I'm actually mostly a tech nerd, and chemistry is just

a recently acquired passion of mine. So I think automating the process with an Arduino or RaspberryPi would be a fun thing to do when I know i have

the underlying process down to pat. Or perhaps that would be overkill, not sure, lol.

Quote: Originally posted by VeritasC&E  |

Gravitational: Shaking the sand on a purely vertical axis inside of a metal cylinder ending up with a cone at the bottom (with help of a simple

electric motor). The shaking amplitude and frequency should be such that all the sand inside the cylinder is freely suspended in air for some time at

each cycle, without coming in contact with the cylinder's upper lid. You'd simply pour in some sand from the top (maybe 1kg at a time or more if you

have a large enough cylinder with a powerful enough motor), put the power on, power it off after a while and emptying the cylinder from the bottom

cone by fractions (with increasingly small fraction sizes at the beginning and end of the sand batch inside). When emptying the cylinder you could put

it on a scale to know where you're at. Any contamination from the metal cylinder will dissolve before anything else in the later acid washes.

|

So that's a yes and a no.... I thought I did some decent gravitational separation, but I'm now realizing that I just sucked at it. I didn't have a

gold panning pan thing, so I just used a saucer with a lip on the end, but that clearly didn't work as well as I thought. I did get a lot of the heavy

particles (magnetite and hematite) out, enough that I was convinced that I did a good job, but clearly I was wrong. This is definitely the step I need

to go back and reassess (I'm just wasting my precious acids on this step when all it needs is some mechanical work done by yours truly).

Quote: Originally posted by VeritasC&E  |

Magnetic: I'm not sure how the magnetic step was carried out but it could be easily automated as well by making a simple electric rotary tumbler a

putting the sand inside by 5Kg batches or so together with the neodymium magnet. The magnet being cleared from particles at exponentially increasing

intervals.

|

Yep! This step I'm 100% sure I got right. I have a series of very powerful neodymium magnets, and the sand I have now, I can throw the magnets in

there, shake it around, and when I pull them out they have literally nothing on them. However the black particles are still in the sand, so they must

be hematite (since hematite is weakly magnetic if magnetic at all). This is what I need to work on getting out by the gravity separation.

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

Based on the photo with the clear line, gravity separation is the way to go.

Something like this would make an excellent riffle mat.

https://www.amazon.com/Mini-Ice-Cube-Trays-Food-Grade/dp/B01...

They also sell them but they cost more:

https://www.amazon.com/Sluice-Fox-Rubberized-Pocket-Prospect...

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Using an ice cube tray as a riffle mat... genius. I just looked in my kitchen and I think the tray I have would work even better, actually.

|

|

|

| Pages:

1

2 |