| Pages:

1

2 |

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

DIY acid washed sand changed color unexpectedly

A bit ago I cleaned some extra sand I got from Home Depot with the intention of being able to use it for chemistry (sand baths, prevent bumping, maybe

filtering, etc), and to do so, I processed it like so:

Froth wash (to get rid of anything that would easily float when agitated)

demagnetized it pretty well using a series of strong magnets

passed it through some screens to get a specific mesh size

acid washed it multiple times (with concentrated HCl)

dried it in the oven

And it worked pretty well, the sand seems nice and clean, not really dusty when I pour/scoop some out, it's all mostly a very consistent size, etc.

However, the other day I was using it as a sand bath to dehydrate some sodium acetate with this setup:

So that's a large porcelain dish with the sand, then a smaller porcelain dish sitting in the center, on top of the sand.

You can see the thermocouple is in the sodium acetate which is in the smaller dish, and that never got over 220C.

After the dehydration, when I took out the center porcelain dish, I could see the sand under it seemed to have changed color, darkening slightly,

maybe even turning a little red:

Another picture with flash enabled:

My first thought was maybe there was some iron that got oxidized into iron oxide, but if that was the case, I would think the sand that was exposed to

oxygen would have gotten oxidized while the sand under the porcelain dish wouldn't have gotten oxidized, right? (less oxygen available under the dish,

so slightly anaerobic environment?) Not to mention I thought the acid wash would have gotten rid of any iron contaminants to begin with.

Also, when I dried the sand in the oven in the process listed above, it got way over 220C, and it never turned this color.

My goal is to make this sand as clean and inert as possible, so maybe I should have done some other washing steps? Maybe concentrated NaOH wash and/or

a concentrated H2SO4 wash, possibly with H2O2? I've read a few documents on preparing sand for laboratory

use, and one of the steps is washing it with piranha solution, which I didn't do, but may end up doing.

What compounds could have been created when it was heated like that without oxygen, and what could they be washed away with?

Thanks in advance for any input.

[Edited on 26-10-2020 by SuperOxide]

[Edited on 26-10-2020 by SuperOxide]

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

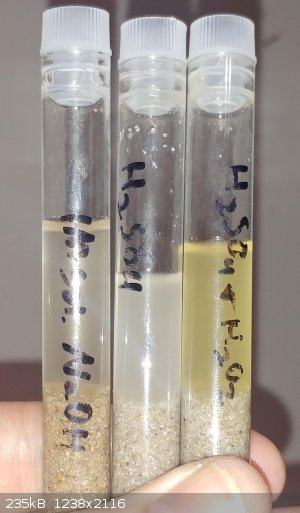

P.S. - This isn't necessarily related to the above question, but shows I may have some work to do in terms of cleaning it up a little more.

I did a small scale test of washing small 5g samples with NaOH, conc. H2SO4, and piranha solution:

(I know the NaOH on the left says 1M solution, but I ended up adding more NaOH so it ended up being more concentrated than that)

Here's the picture of the results:

It looks like the NaOH had virtually no change in appearance, the H2SO4 seems to be lighter, and the H2SO4

with H2O2 maybe even cleaner than that (but not by much - though if you look at the picture of them in test tubes, it's evident

that it did more just by the color of the solution).

I'm heating some sand up right now in an anaerobic environment to see if it gets darker - and if it does, I may run the same test I ran here on that

sand to see what happens.

[Edited on 26-10-2020 by SuperOxide]

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

NaOH will react with the sand to make sodium silicates (soluble in water), if there are metal impurities you'll precipitate insoluble metal silicates

while dissolving the sand. You are cleaning the impurities from the sand XD

[Edited on 26-10-2020 by Ubya]

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by Ubya  | NaOH will react with the sand to make sodium silicates (soluble in water), if there are metal impurities you'll precipitate insoluble metal silicates

while dissolving the sand. You are cleaning the impurities from the sand XD

[Edited on 26-10-2020 by Ubya] |

lol. I figured if there was alumina oxide or something like that in the sand, then the NaOH would react with it to make sodium aluminate which could

be washed away. That was only a small scale test any ways (5g).

I know that highly concentrated NaOH at very high temperatures can etch/dissolve glass, but I don't think it would in the concentration or

temperatures I'm using.

Also, the sand that changed colors in the first post wasn't treated with NaOH, only concentrated HCl.

[Edited on 26-10-2020 by SuperOxide]

|

|

|

MidLifeChemist

Hazard to Others

Posts: 192

Registered: 4-7-2019

Location: West Coast USA

Member Is Offline

Mood: precipitatory

|

|

Yeah, dissolving sand in NaOH is not easy. Takes a long time in hot, concentrated NaOH.

Btw, I did a few minutes of quick research, and it looks like it is very hard to remove Iron impurities from sand. Good luck!

https://patents.google.com/patent/US4405588A/en

[Edited on 26-10-2020 by MidLifeChemist]

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Right, that's definitely not what I was trying to do.

Yeah, that's for sure. But do you think that's what the color change is? It's just such a clear color change that I doubt its entirely because of iron

impurities. I did 3 washes with concentrated HCl (heating it quite a bit, then letting it sit for a few days, stirring and heating it intermittently),

so I know I got a lot of iron out. On the last wash, the HCl wasn't as yellow as the first two washings (which is what happens with iron gets

dissolved in it).

And again, if it was iron being oxidized under higher temperatures, then one would think that the sand that wasn't exposed to the oxygen wouldn't have

been oxidized, but it was the opposite.

So I doubt its iron contaminants that's the culprit.

[Edited on 27-10-2020 by SuperOxide]

|

|

|

clearly_not_atara

International Hazard

Posts: 2799

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Your sand looks greenish, that suggests iron or nickel chlorides. If there is some kind of alkali in the porcelain it could convert to the oxide and

lose the green tint. Consistently the sand in the NaOH looks kind of reddish, like the sand under the dish. The red of course suggests iron.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by clearly_not_atara  | | Your sand looks greenish, that suggests iron or nickel chlorides. If there is some kind of alkali in the porcelain it could convert to the oxide and

lose the green tint. Consistently the sand in the NaOH looks kind of reddish, like the sand under the dish. The red of course suggests iron.

|

I agree that the sand treated with NaOH does seem a little red as well, but I don't see any green at all. I think maybe the lighting in the first

picture might look greenish perhaps? But if you look at the one right after it, with flash enabled, you'll see there's no green.

Also, if the red was due to iron, wouldn't all of the heated sand turn red? Not just the sand immediately under the porcelain dish? I

would think that the iron in the sand that was exposed to the oxygen would turn red as well, but it doesn't seem so.

I think I should do some more HCl washes anyways though.. I'm doing a test run on 400g of the sand and like 150mL of 31% HCl (but obviously added an

appropriate amount of water, making sure it covered all the sand). I just started it and it's emitting some odd smell.. not exactly like chlorine,

more like some poopy smelling sulfur compound, but can't be sure (I hesitate saying it smells like a poopy sulfur compound because I can't imagine how

sulfur got in there, and I would think I would have smelled it before, but maybe wearing a mask masked the smell.)

[Edited on 27-10-2020 by SuperOxide]

[Edited on 27-10-2020 by SuperOxide]

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

You might try a nitric acid or aqua regia soak and rinse.

My plan for washing a bag of sand is:

Float rinse to remove light stuff.

Magnetic removal of iron and nickel.

Pan to leave behind heavy stuff (mostly black sand that isn't magnetic, trace amounts of gold and silver can show up).

Treat with acetic acid first to remove carbonates (most of the contaminants).

30% H2O2 + close to glacial acetic acid soak will dissolve almost anything, using a little (1%) concentrated nitric acid to activate it converts it

to peracetic acid.

The exception is silver acetate is not super soluble and platinum group metals do not fully react.

Rinse well.

Then treat with nitric acid (will dissolve silver and mercury compounds).

If you suspect remaining platinum group metal contamination treat with aqua regia.

Then several long soaks with HCl to remove iron contamination (iron is the worst because it is high concentration).

Several other compounds that can show up red.

Mercury, Silver and Lead are not soluble in HCl.

All three can form complexes or compounds that are red.

Other platimun group metals will not dissolve in HCl under normal conditions.

Even metal oxides can be slow to dissolve. Particularly calcined oxides.

A good question is the actual source of the sand.

Sometimes it is just mining tailings that are deemed 'safe for resale'.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by macckone  | You might try a nitric acid or aqua regia soak and rinse.

My plan for washing a bag of sand is:

Float rinse to remove light stuff.

Magnetic removal of iron and nickel.

Pan to leave behind heavy stuff (mostly black sand that isn't magnetic, trace amounts of gold and silver can show up).

Treat with acetic acid first to remove carbonates (most of the contaminants).

30% H2O2 + close to glacial acetic acid soak will dissolve almost anything, using a little (1%) concentrated nitric acid to activate it converts it

to peracetic acid.

The exception is silver acetate is not super soluble and platinum group metals do not fully react.

Rinse well.

Then treat with nitric acid (will dissolve silver and mercury compounds).

If you suspect remaining platinum group metal contamination treat with aqua regia.

Then several long soaks with HCl to remove iron contamination (iron is the worst because it is high concentration).

Several other compounds that can show up red.

Mercury, Silver and Lead are not soluble in HCl.

All three can form complexes or compounds that are red.

Other platimun group metals will not dissolve in HCl under normal conditions.

Even metal oxides can be slow to dissolve. Particularly calcined oxides.

A good question is the actual source of the sand.

Sometimes it is just mining tailings that are deemed 'safe for resale'.

|

Wow, thanks for such a detailed response!

I follow some of those steps (froth/float wash, magnetic removal, HCl, etc). The hematite gets left behind because it's not magnetic (which I didn't

realize initially), so I hoped the concentrated HCl wash would help with that, but maybe it wasn't enough.

Do you by any chance have a picture of the before and after? Curious to see how pretty looking it is (I know... it's just sand, but still, lol).

I haven't tried nitric or acetic acid, or H2O2, but I think I will give that a shot. Thanks!

|

|

|

DraconicAcid

International Hazard

Posts: 4356

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

Washing with acid is only going to get iron off the surface. If your sand particles are contaminated with iron oxides all the way through, acid won't

take it off, but heat can still change the colour.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

MidLifeChemist

Hazard to Others

Posts: 192

Registered: 4-7-2019

Location: West Coast USA

Member Is Offline

Mood: precipitatory

|

|

Quote: Originally posted by DraconicAcid  | | Washing with acid is only going to get iron off the surface. If your sand particles are contaminated with iron oxides all the way through, acid won't

take it off, but heat can still change the colour. |

Yes, this is what I was alluding to in my previous post on this topic, I don't washing with acid is going to remove the Iron, it may be embedded in

the structure of the minerals used to form the sand - e.g. part of the chemical formula.

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

Draconic acid is correct, you can only remove the surface contaminants without turning it into sodium silicate and then reconstituting the silica,

which will be much finer than the original sand. Of course you can also crush glass and the only contaminants of significant amount will be sodium,

potassium and calcium.

Processing sand is a pain in the butt.

However, it is cheaper than buying high grade silica sand of a specific grit which is surprisingly expensive.

Really pure silica can be obtained by first converting to sodium silicate and then reacting with HCl.

Followed by dissolving the cleaned hydrosilic acid precipitate with ammonia fluoride or bifluoride then precipitating silica with ammonia.

Patent US5266289 for the ammonium fluoride process

This gives fine powdered silica rather than sand though.

|

|

|

chornedsnorkack

National Hazard

Posts: 564

Registered: 16-2-2012

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by macckone  | | Draconic acid is correct, you can only remove the surface contaminants without turning it into sodium silicate and then reconstituting the silica,

which will be much finer than the original sand. Of course you can also crush glass and the only contaminants of significant amount will be sodium,

potassium and calcium. |

Most window glasses that look clear when seen across a few mm thickness are green when looked edge on. Due to contamination of iron.

And crushing glass gives you sand of, well, glass, not of quartz.

Quote: Originally posted by macckone  |

Processing sand is a pain in the butt.

However, it is cheaper than buying high grade silica sand of a specific grit which is surprisingly expensive.

Really pure silica can be obtained by first converting to sodium silicate and then reacting with HCl.

Followed by dissolving the cleaned hydrosilic acid precipitate with ammonia fluoride or bifluoride then precipitating silica with ammonia.

Patent US5266289 for the ammonium fluoride process

This gives fine powdered silica rather than sand though. |

So how do you then grow your quartz into crystals of desired size?

Silica solubility increases in either alkaline solution or acid fluoride solution. How do you get fine silica to undergo rapid Ostwald ripening, like

in agitated fluoride solution?

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by DraconicAcid  | | Washing with acid is only going to get iron off the surface. If your sand particles are contaminated with iron oxides all the way through, acid won't

take it off, but heat can still change the colour. |

I see, so even using something like nitric acid wouldn't be that much better, because the acid may not even reach the iron oxides...

Quote: Originally posted by macckone  | Draconic acid is correct, you can only remove the surface contaminants without turning it into sodium silicate and then reconstituting the silica,

which will be much finer than the original sand. Of course you can also crush glass and the only contaminants of significant amount will be sodium,

potassium and calcium.

Processing sand is a pain in the butt.

However, it is cheaper than buying high grade silica sand of a specific grit which is surprisingly expensive. |

Yep, this is why I'm trying to do it myself (also just so I can learn the process and get my hands dirty with some chemistry..)

Quote: Originally posted by macckone  | Really pure silica can be obtained by first converting to sodium silicate and then reacting with HCl.

Followed by dissolving the cleaned hydrosilic acid precipitate with ammonia fluoride or bifluoride then precipitating silica with ammonia.

Patent US5266289 for the ammonium fluoride process

This gives fine powdered silica rather than sand though. |

Yeah, I see the process for converting it to powdered silica, and I may do that as a means to get powdered silica, but I also need some actual sand

grain as well.

Some examples of what I would like to use the sand for is:

Sand bath for high temp experiments

a layer at the top and bottom of small chromotography column

prevent bumping in some high temp reactions

layer of sand for filters (thus needs to be as inert as it can get)

So without converting sand all the way to silicone dioxide powder, is there a decent way to accomplish this?

[Edited on 28-10-2020 by SuperOxide]

|

|

|

MidLifeChemist

Hazard to Others

Posts: 192

Registered: 4-7-2019

Location: West Coast USA

Member Is Offline

Mood: precipitatory

|

|

SuperOxide,

Based on what you what to use the sand for, I'll bet it is fine just the way after you processed it with a froth wash and HCl wash. But that is just

my speculation, I'm not a sand expert.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by MidLifeChemist  | SuperOxide,

Based on what you what to use the sand for, I'll bet it is fine just the way after you processed it with a froth wash and HCl wash. But that is just

my speculation, I'm not a sand expert. |

Yeah I think it should be ok. Just the color changing caught me off

guard I suppose.

I do wish it was a little lighter in color. Also, I see some black specs still in it, and they aren't magnetic, so they must be hematite.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Heres a bit of a closer picture, so you can see there definitely is some extra contaminants. I get that HCl can't get to all of the iron

oxides, but I would think some of these particles that are seemingly mostly not silicone dioxide would be easily processed.

I think it was macckone that suggested I try nitric acid, and I may give that a shot.

|

|

|

phlogiston

International Hazard

Posts: 1379

Registered: 26-4-2008

Location: Neon Thorium Erbium Lanthanum Neodymium Sulphur

Member Is Offline

Mood: pyrophoric

|

|

If the impurities don't leach out after all of these different extreme treatments, it seems unlikely to me it's going to leach out and interfere when

you use it for filtering, anti-bumping material, etc.

Maybe you're also doing this for the challenge though, which I can appreciate.

In my country, hardware stores sell an exceptionally clean variety of sand locally known as 'zilverzand', which literally translates as 'silver sand'.

It looks perfectly white to the eye and it said to be quite pure SiO2. It is used for mortar and to cover the floor of bird cages.

Can you get something like that in your country? It seems to me that would be a much more suitable starting material.

-----

"If a rocket goes up, who cares where it comes down, that's not my concern said Wernher von Braun" - Tom Lehrer |

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by phlogiston  | | If the impurities don't leach out after all of these different extreme treatments, it seems unlikely to me it's going to leach out and interfere when

you use it for filtering, anti-bumping material, etc. |

This may be true, but if I use the sand for whatever

reason in some reaction, and the reaction has some weird failure, I'd like to be a little more confident that it wasn't due to some impurity

introduced by the sand that was used as boiling stones (or filter, or whatever).

Ok, yeah. That's definitely a

factor, lol.

Quote: Originally posted by phlogiston  | In my country, hardware stores sell an exceptionally clean variety of sand locally known as 'zilverzand', which literally translates as 'silver sand'.

It looks perfectly white to the eye and it said to be quite pure SiO2. It is used for mortar and to cover the floor of bird cages.

Can you get something like that in your country? It seems to me that would be a much more suitable starting material. |

zilverzand.. I've never heard of that before. I'll look around to see if I can get my hand on some. From what I can tell it certainly looks pretty

clean.

I re-read these two documents:

Iron and Aluminium Removal from Algerian Silica Sand by Acid Leaching

Impurity removal process for high-purity silica production by acid leaching

And saw some details that were suggested here, such as washing with HCl:HNO3 and even H2SO4:H2O2, so I may give that a try, and then I can be

satisfied that it's as inert as I want it to be - and pretty... it has to look pretty.. lol

[Edited on 29-10-2020 by SuperOxide]

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quick question - I don't have any HNO3 on hand so I plan on making some tomorrow, but not sure how much I will make (limited time and KNO3 on hand).

In some of the literature it suggests using just HNO3, some suggest using HCl:HNO3, and I think I will eventually do a some testing on different

batches to see which one has a better result, but if I only have enough nitric acid for a small amount what do you guys think I should try? Just

nitric acid, or aqua regia (which I admit I've never used before, but I will definitely read up on some SDS docs and other safety procedures first).

Is there any reason that using HNO3 would yield a better result than HNO3:HCl? Or should I just skip right to the HNO3:HCl? I get that aqua regia

isn't some specific acid, but rather a mixture of acids, so my intuition says there isn't anything that HNO3 can do on its own that aqua regia can't,

but I wanted to get some of your input.

Thanks

[Edited on 29-10-2020 by SuperOxide]

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

HNO3 is superior for silver, mercury and lead.

HNO3:HCl is superior for other platinum group metals.

HCl causes silver, mercury and lead to precipitate chlorides.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by macckone  | HNO3 is superior for silver, mercury and lead.

HNO3:HCl is superior for other platinum group metals.

HCl causes silver, mercury and lead to precipitate chlorides. |

Right, I get that, and I'm not sure how many platinum group metals or silver/mercury/lead is in the sand (I doubt very much, if any at all), but I

know it can be used to clean other metal contaminants.

In the PDF document in my previous post in section 2, it states: | Quote: | | The silica used in this work is a natural one from the region of Siliana in Tunisia. In first time of purification, a silica was dipped for a few

minutes in an acids mixture solution HCl:HNO3 with volume proportion of (2:1) to remove metallic impurities located at the surface of silica grains.

Then it was abundantly rinsed with deionized water and dried under vacuum in an oven at a temperature of about 120°C. |

And a similar procedure is listed in other documents too in addition to other acids such as sulfuric acid, phosphoric acid and oxalic acid. Some of

them even suggest using HF, which seems odd as that would dissolve the silicone dioxide itself, as opposed to the impurities - wouldn't it? I'll

probably do a small scale test to see what works best, which I plan on carrying out later today. I will update yall on my results :-)

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

The level of silver/mercury/lead contamination is probably low, but it is non-zero.

Just as other contaminants are non-zero. Beach sand is going to be lower in lead but could be higher in mercury if it is from the great lakes. If it

is mine tailings they are supposed to be below a certain limit of mercury and lead to be resold. But that isn't necessarily true and a number of

countries use gold amalgamation extraction and sell the crushed tailings as sand.

The hydrofluoric method does result in a loss of silica. But the impurities are removed to low levels.

The method I provided actually solubilizes the silica with ammonium fluoride/bifluoride and produces fine silica.

Someone mentioned that crushed glass is glass not quartz, for the most part there isn't a difference unless trace amounts of iron, sodium or boron are

a problem. And by trace I mean much less than in the particles of play sand.

Obviously all of this depends on the end use. Mine is as a dispersion medium for making nitric acid via birkeland eyde method. The sand helps break

up the bubbles and increases absorption. But it needs to be as pure as possible and have a certain grain size. Crushed glass works but it is hard to

get a good grain size. It tends to form chuncks and powder. The chunks are fine for boiling stones since they are generally the same composition as

the glass distilling container. Back to the sand, the biggest impurity in mine was calcium carbonate, the second was various forms of iron. The

third was aluminum oxide which I did not separate and for most uses, it doesn't matter. Glass making would obviously be a different matter. If you

were using it as a reagent then converting it to sodium silicate and then using the ammonium fluoride process makes more sense.

[Edited on 29-10-2020 by macckone]

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by macckone  | The hydrofluoric method does result in a loss of silica. But the impurities are removed to low levels.

The method I provided actually solubilizes the silica with ammonium fluoride/bifluoride and produces fine silica. |

Interesting.... I may try to use Whink Rust Stain Remover to see if that works. Jeri Ellsworth (one of my fave YouTubers ... and nerd crush) has

a video on safe glass etching using this product, so it may suffice as a low HF source.

[Edited on 29-10-2020 by SuperOxide]

|

|

|

| Pages:

1

2 |