| Pages:

1

..

5

6

7

8 |

Picric-A

National Hazard

Posts: 796

Registered: 1-5-2008

Location: England

Member Is Offline

Mood: Fuming

|

|

If you dont have the equiptment to make SO3/Oleum then you certainly dont have the equiptment to use/store it safely SO DONT!

|

|

|

D S2 A

Harmless

Posts: 16

Registered: 7-1-2010

Location: Brazil

Member Is Offline

Mood: No Mood

|

|

I simply do not have equipment suitable to very high temperatures or pressurise the reaction vessel, Picric-A. The oleum shall be stored only for a

day. The stumbling block for me is just related to elevated temperatures like 600 ºC.

Best regards, Dúlio.

Do not compare you to others but with the best that yourself can do.

|

|

|

Picric-A

National Hazard

Posts: 796

Registered: 1-5-2008

Location: England

Member Is Offline

Mood: Fuming

|

|

600 can easily be reached by a bunsen burner... or any gas burner for that matter.

Learn to walk before you can run.

|

|

|

D S2 A

Harmless

Posts: 16

Registered: 7-1-2010

Location: Brazil

Member Is Offline

Mood: No Mood

|

|

Even a candle goes above 1.000 ºC, Picric-A. The matter for me is how to build a reaction vessel able to resist such temperatures.

If it not bothers you, add me on MSN.

Best regards, Dúlio.

[Edited on 7-1-2010 by D S2 A]

Do not compare you to others but with the best that yourself can do.

|

|

|

Picric-A

National Hazard

Posts: 796

Registered: 1-5-2008

Location: England

Member Is Offline

Mood: Fuming

|

|

True.. but i would like to see you try heating half a gram of (say...) sand to 1000 degC with a candle...

Ps. I cannot go on MSN here (it is blocked by the school grr.) so if you want to contact me use U2U)

[Edited on 7-1-2010 by Picric-A]

|

|

|

D S2 A

Harmless

Posts: 16

Registered: 7-1-2010

Location: Brazil

Member Is Offline

Mood: No Mood

|

|

It is just an example, Picric-A.

Best regards, Dúlio.

Do not compare you to others but with the best that yourself can do.

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

This may be of interest.

http://www.google.com/patents?hl=en&lr=&vid=USPAT391...

In section 4 the patentee states that, by electrolysis, the concentration of dilute H2SO4 can be brought to 100% and above.

It is presumed that above 100% means oleum. . .

The downside is that platinum electrodes work best.

|

|

|

D S2 A

Harmless

Posts: 16

Registered: 7-1-2010

Location: Brazil

Member Is Offline

Mood: No Mood

|

|

Unfortunately I do not have either equipment nor knowledge do deal with electrolysis. Any other idea?

Best regards, Dúlio.

Do not compare you to others but with the best that yourself can do.

|

|

|

matt

Harmless

Posts: 2

Registered: 15-12-2011

Member Is Offline

Mood: No Mood

|

|

Stoichiometric Magnesium Sulfate and Sodium Pyrosulfate

Hi, this is my first post on this site. The process was carried out some 6 months ago, and I've since lost the photos and product.

1 mole (or proportion) of anhydrous Sodium Pyrosulfate (Na2S2O7) {prepared by thermal decomposition of Sodium Persulfate (Na2S2O8)} and 1 mole (or

proportion) of anhydrous Magnesium Sulfate (MgSO4) {prepared by heating Epsom Salts (MgSO4.7H2O) at c. 250'C for several hours} were finely ground and

mixed using mortar and pestle and the resulting white powder placed in a small retort. Heating over LPG burner flame resulted in a gradual rising,

swelling and a change in colour to a metallic grey (similar to lead (a little whiter) or many amalgamated metals). Up to this point no fumes or

condensation were observed. After effectively total conversion to this spongy-appearing, grey form, a clear liquid began to distill off and was

collected in concentrated Sulfuric Acid (H2SO4). A weight gain corresponding to 0.8 mole (or proportion) of sulfur trioxide (SO3) was measured at the

completion of the distillation run. When the receiver was removed from the end of the condenser, white fumes with an acrid smell developed from the

clear liquid present at the end of both joints.

(The amounts involved in the run I describe correspond to an actual yield of 16g SO3 out of a theoretical 20g, I wont specify the weights of starting

materials as I would be extrapolating, however I remember the yield values very clearly. The vessel was a 125ml retort [just like a retort is meant to

look] with the condenser mounted in a 2 liter plastic bottle full of ice water [refreshed at about room temperature] and the burner was an LPG

hotplate burner such as sold in camping stores for connection to a 9kg LPG or propane bottle.)

This is it for the moment, an attempt to convert to Thionyl Chloride failed and I lost what I had left. The system I was working with reaches a

maximum internal temperature in the high 400'Cs as best i know and the late onset of distillation suggests to me the absence of any unrecognised water

of crystallisation. I found this procedure to be accessible and productive to an extent beyond the others I came by in this forum. Owing to the fact

that it remains merely an interpretation of the vague procedures outlined in the German patents already referenced in this thread, I felt that this

was the right place to share this. I hope this is useful to somebody, even if I have misinterpreted the results.

This is only the beginning of a response to the stimulus I have gained from the pages of ScienceMadness and I will endeavour to share more of the

developments which lead on specifically from ideas which arose out of this forum.

Thanks, Matt.

[Edited on 15-12-2011 by matt]

|

|

|

AndersHoveland

Hazard to Other Members, due to repeated speculation and posting of untested highly dangerous procedures!

Posts: 1986

Registered: 2-3-2011

Member Is Offline

Mood: No Mood

|

|

Sulphur trioxide reacts with nitrogen pentoxide in carbon-tetrachloride solution, with the formation of a crystalline precipitate melting at 124° to

128° C., which is probably (SO3)4.N2O5:

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Quote: Originally posted by matt  | | 1 mole (or proportion) of anhydrous Sodium Pyrosulfate (Na2S2O7) {prepared by thermal decomposition of Sodium Persulfate (Na2S2O8)} and 1 mole (or

proportion) of anhydrous Magnesium Sulfate (MgSO4) {prepared by heating Epsom Salts (MgSO4.7H2O) at c. 250'C for several hours} were finely ground and

mixed using mortar and pestle and the resulting white powder placed in a small retort. Heating over LPG burner flame resulted in a gradual rising,

swelling and a change in colour to a metallic grey (similar to lead (a little whiter) or many amalgamated metals).[Edited on 15-12-2011 by matt]

|

A metal? There's only one metal in that mix as far as I can tell, and I don't think it'd form this easily.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

madscientist

National Hazard

Posts: 962

Registered: 19-5-2002

Location: American Midwest

Member Is Offline

Mood: pyrophoric

|

|

Quote: Originally posted by AndersHoveland  | Sulphur trioxide reacts with nitrogen pentoxide in carbon-tetrachloride solution, with the formation of a crystalline precipitate melting at 124° to

128° C., which is probably (SO3)4.N2O5:

|

The addition of sulfur trioxide to carbon tetrachloride is one of the early phosgene preparations.

I weep at the sight of flaming acetic anhydride.

|

|

|

matt

Harmless

Posts: 2

Registered: 15-12-2011

Member Is Offline

Mood: No Mood

|

|

Yes, I recently repeated this procedure, on a larger scale (1 molar), this time only getting a 50% yield although on the upside my glassware didn't

crack from the heat. The metallic color, I believe, is carbonisation of impurities in the pool chemical grade reagents I used, the melt returned to

white on continued heating although I'm not sure if that contradicts my idea of carbonised impurities. IIRC, the article which listed results for

various alkali and alkaline earth metal pyrosulfates nominated lithium as the most easily thermally decomposed. Large amounts of Lithium Sulfate might

require some effort to arrange, but hopefully the Lithium itself could be recovered from post-reaction by-products by some sort of metathesis. From my

understanding of pyrosulfates, an anhydrous lithium pyrosulfate would probably be more difficult to obtain than the oleum to be produced from the

combination of Na2S2O7 and Li2SO4. This is the direction I hope to take it in next as neither 50% yields nor one-time sacrificial glassware seem

efficient enough to me to consider oleum as a first choice where other reagents are suitable.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Quote: Originally posted by matt  | | IIRC, the article which listed results for various alkali and alkaline earth metal pyrosulfates nominated lithium as the most easily thermally

decomposed. |

Just last week I looked up the abstract for the lithium pyrosulfate -> SO3 temp. article by Spitsyn IIRC, CA 20435 (1960)...the long abstract gave

the impression that Gmelin's may have taken the figure out of context, not surprising considering the quoted temp...there may be measurable losses....

|

|

|

halogen

Hazard to Others

Posts: 372

Registered: 18-4-2004

Member Is Offline

Mood: No Mood

|

|

"Bismuth sulfate (Bi2(S04)3) is found in the form of white hygroscopic

crystals, which readily decompose in water to give basic subsulfate and

dissolve without decomposition in aqueous sulfuric acid. Above 465°C, it is

converted to the oxide under the liberation of sulfur trioxide."

Organic Bismuth Chemistry Hitomi Suzuki

TYPO?

|

|

|

Agricola

Harmless

Posts: 42

Registered: 28-10-2013

Location: Brazil

Member Is Offline

Mood: No Mood

|

|

For a preparation of SO3 from P4O10 and H2SO4, see the attached paper by Evans. Notice Evans calls SO3 and P4O10 "anhydrous sulfuric acid" and

"anhydrous phosphoric acid". Today we would call them acid anhydrides not anhydrous acids.

Attachment: sulfur_trioxide_evans1848.pdf (358kB)

This file has been downloaded 1043 times

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

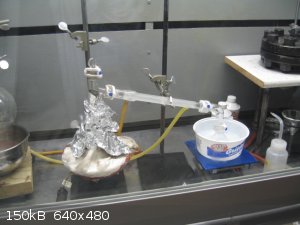

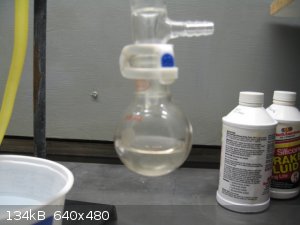

Today I made 2-3ml of oleum using the procedure of CD-ROM-LAUFWERK as presented by garage chemist. This is an extremely facile method. Phosphoric

acid is first dewatered to metaphosphoric acid (HPO3) under strong heat. This then dewaters the H2SO4 to SO3.

The hot phosphoric acid severely corrodes the 100 mL rbf but garage chemist says NaOH will remove this.

[Edited on 27-9-2017 by Magpie]

[Edited on 27-9-2017 by Magpie]

[Edited on 27-9-2017 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

| Quote: | | Phosphoric acid is first dewatered to metaphophoric acid (HPO3) under strong heat. This is then dewatered to SO3. |

Didn't know (HPO3) was such a strong desiccant, tbh, but NaOH will further corrode your already damaged RBF.

|

|

|

Melgar

Anti-Spam Agent

Posts: 2004

Registered: 23-2-2010

Location: Connecticut

Member Is Offline

Mood: Estrified

|

|

I've been using KOH a lot lately, since I've been able to get it for about the same price as NaOH. Although it's a stronger base, it has

significantly less of a corrosive effect on glass compared to NaOH. Potassium salts are also much better than sodium salts for salting out an aqueous

layer. There seems to be very little that potassium salts dissolve significantly in besides water.

The first step in the process of learning something is admitting that you don't know it already.

I'm givin' the spam shields max power at full warp, but they just dinna have the power! We're gonna have to evacuate to new forum software!

|

|

|

clearly_not_atara

International Hazard

Posts: 2789

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

I don't think anything can actually reverse the damage metaphosphoric acid does to glass... you can remove the phosphate, at least, with

alkali. In the future consider preparing your HPO3 in stainless steel.

Pretty cool that metaphosphoric acid can make oleum, though. Chlorosulfonic acid and tosyl chloride become OTC, if only you can find a way to contain

the rxn mixture. Come to think of it, it might be possible to go all the way to TsCl in situ by starting with a mixture of H2SO4 and TsOH,

adding HPO3, and gassing with HCl. If produced successfully, tosyl chloride (s.g. 1.3) will float on top of the rxn mixture (s.g. ~1.8).

[Edited on 27-9-2017 by clearly_not_atara]

|

|

|

Melgar

Anti-Spam Agent

Posts: 2004

Registered: 23-2-2010

Location: Connecticut

Member Is Offline

Mood: Estrified

|

|

Is tosyl chloride the same thing as para-toluenesulfonyl chloride? Because I'm pretty sure that's available on Amazon if anyone needs any.

The first step in the process of learning something is admitting that you don't know it already.

I'm givin' the spam shields max power at full warp, but they just dinna have the power! We're gonna have to evacuate to new forum software!

|

|

|

amaming

Harmless

Posts: 5

Registered: 8-9-2017

Member Is Offline

Mood: No Mood

|

|

the grit left on my flask after dehydrating the phosphoric acid stayed on despite me bombarding it with everything I could to try and clean it. If you

want to do the meta phosphoric acid method to oleum, get yourself a 3" copper endcap or a flask you dont mind losing.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I was able to remove the grit by refluxing with concentrated KOH solution for a few hours.

edit: No, this did not work. See pictures below:

[Edited on 29-9-2017 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Today I made another batch of oleum, this time at 4X scale. I used a 600mL beaker for preparing the HPO3 and a 250mL flask for making the oleum. The

yield was excellent at 29.6g vs an estimated 2-3g for the 1X scale.

I should caution that my ground glass joints leaked profusely. Therefore a good fume hood is mandatory.

2 pictures will be posted as soon as I figure out how with my new computer.

[Edited on 29-9-2017 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

The NaOH did Not remove the corrosion product from my flasks. See above picture.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

| Pages:

1

..

5

6

7

8 |