| Pages:

1

2

3 |

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

I was looking for a wee bit more procedural detail, not that I don't appreciate your thoughtfulness,

Such as, concentrated H2SO4 or what dilution?

What % H2O2? 6%, or 30%?

Any aprticular order of addn?

These little details are nice to know, and I'd just as soon read them as have to work them all out for myself. Merck referres one to Gmelin's Iron,

which I do not have, and Brauer was unhelpful.

In the end, I can always just buy it from Alfa, or maybe from the Ozzies, if they have it, or Carlo Erba, or Panreac.

|

|

|

Xenoid

National Hazard

Posts: 776

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Good grief! This is a forum for amateur experimentalism.

There aren't too many possible combinations. Look at the stoichiometry of the reaction.

The strength of the H2O2 doesn't matter just add the right amount.

Try it with what you have got! It's a no brainer. I have seen this reaction described in a 1950's childrens home experimental chemistry book!

This isn't a complex organic preparation!

Regards, Xenoid

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

And I'm a trained chemist not a sous-chef.

If I am going to spend time boiling off a lot of excess water, then I'm going to start with as concentrated materials as possible (that are at hand)

consistent with safety and good practice.

I have conc H2SO4 18M

H2O2 30%

So we need 2 mols of FeSO4 heptahydrate, so that's 304 g plus 252 g water of hydration so 556 g FeSO4.7H2O

I mol conc H2SO4 is about 55 ml so clearly, the acid should be slowly and cautiously added to the ferrous sulfate, which will heat up and the water of

hydration dilutes the acid. Adding the solid to the acid would be stupid. Could splatter.

1 mol of 30% H2O2 is c.100 ml. That goes in last dropwise w/stirring.

The resulting mixture ought to now be warm and weigh about 750 g. According to Xenoid, boil it till negative to ferrous ferricyanide (no blue on rxn

w/ potassium ferricyanide) and then concentrate (remove water) till a whitish mas ppts. And this gets worked up. Ought to be 400 g plus 162 g of water

of hydration or 562 g of hygroscopic Fe2(SO4)3.9H2O

The implication being that only 200 ml water needs to be taken off.

I suspect that we might be better off starting with 110 ml 50% acid and 200 ml 15% H2O2 so we then have some more water to remove.

Just the sort of uncertainty that I'd rather remove by reading a published procedure first.

[Edited on 4-9-2007 by Sauron]

|

|

|

chloric1

International Hazard

Posts: 1158

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Sauron,

Yes a proceedure would be nice. But you know it might be impossible to find. This forum allows us amatuers a unique opportunity to communicate. You

may find yourself writing a proceedure. I would like to see at what temperature ferric sulfate dehydrates. Wonder if Ferric Ammonium Sulfate would

be easier to work with, or if it would be reduced to SO2 by the ammonium ion.

Fellow molecular manipulator

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

It's just that I have a vast respect for the literature of chemistry. It's out there, somewhere.

The online encyclopedia was slightly helpful. It says ferric sulfate is prepared by adding nitric acid to a hot solution of ferrous sulphate

containing sulfuric acid, then concentrating the result. Colorless crystals obtained.

That at least confirms the order of addition, and clearly nitric acid is functioning as an exidizer just as H2O2 does.

Wilkepedia has no entry for iron (III) sulfate - just iron (II).

My library (thus far) is primarily organic and rather spotty on inorganic. ACS search was thus far no help, likewise Google.

----------

Roscoe & Schorlemmer came through, with same reaction described in the 1911 Encyclopedia, and correct stoichiometry, on page 101 of the volume

containing chapter on iron. (Attached.)

Concentration of the yellow-brown solution gives a syrupy liquid, which deposits crystals on standing. Adding H2SO4 to the syrup precipitates the

anhydrous salt.

Likewise, treating equimolar amounts of FeSO4.7H2O with boiling sulfuric acid gives the same salt Fe2(SO4)3

The salt is extremely hygroscopic. I'd store it in a dessicator over conc sulfuric acid.

[Edited on 4-9-2007 by Sauron]

Attachment: Pages from a_treatise_on_chemistry_2ii.pdf (1.4MB)

This file has been downloaded 777 times

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Ferric sulfate is available very cheaply for water treatment.

It's a coagulant, and removes H2S, while also precipitating heavy metals.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Thanks. One of my reagent suppliers localls, sells industrial chemicals as well including water treatment chemicals so they ought to have it in 25 Kg

sacks.

And now we know that rather than having to roast it dry, conc sulfuric acid will take up the water of hydration and ppt the anhydrous ferric sulfate.

Obviously, there won't be any need to rigoroushly remove the acid, since the anhydrous ferric chloride will be used directly to make oleum and the

small amount of acid will be driven off first anyway.

The filtration will need to be done in the glove box to keep the cake from picking up moisture. A nice dry atmosphere will prevent that.

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

Aluminium sulfate, as Al2(SO4)3.18H2O, so-called "alum", appears to be the coagulant of choice for water treatment, though. Ferric sulfate is liable

to cause staining, and may corrode metals more electropositive than Fe with which it is in contact, e.g. the Zn and Al plating of "galvanized" tanks

and pipes.

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

I think the ferric sulfate is more for industrial wastewater treatment, mine tailing effluent, that sort of thing.

(Unless the municipal water source has H2S or heavy metal contamination that needs to be removed.)

I think it's available as the monohydrate in poly bags.

[Edited on 9-4-2007 by Eclectic]

|

|

|

chloric1

International Hazard

Posts: 1158

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Information

Suaron you are an avid sleuther. I think I downloaded the treatice on Chemistry from Google books. I need to look through it more.

I am glad it is so simple. I now have a use for partially oxidized copperas  As

far as needing a ferrous sulfate looks like I need to get some steel bars and electrolytically reducing the brown cake I have. :/ Oh well it is all

in the name of chemistry fun As

far as needing a ferrous sulfate looks like I need to get some steel bars and electrolytically reducing the brown cake I have. :/ Oh well it is all

in the name of chemistry fun

Fellow molecular manipulator

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Seven volumes of A Treatise on Chemistry are in the forum library - 3 on organic, three on inorganic, and one on organometallic. All gotten from

Gallica vis S.C.Wack. Why muck around with Google Books?

|

|

|

Aqua_Fortis_100%

Hazard to Others

Posts: 302

Registered: 24-12-2006

Location: Brazil

Member Is Offline

Mood: †

|

|

catalytic properties of Fe2O3

| Quote: | Originally posted by S.C. Wack

The author in Mellor was probably just trying to keep it simple, it was already long known that a basic sulfate was an intermediate from the

monohydrate. Some recent investigation into this (and with a basic sulfate identified under the conditions used) and also the differences in heating

the different sulfates of iron and other metals can be found (in German of course) here.

[Edited on 3-9-2007 by S.C. Wack] |

Yes...

Your book (Mellor - 57) gave very useful information on catalytic properties of iron oxide (from sulfate formation) according with the following :

| Quote: | pag 338:

The action of ferric oxide as a catalyst is perceptible at 400°; below 600°, the ferric oxide has only a slight activity, and

above 620°, the activity decreased. The optimum temp, is between 600° and

620° ; and there is then approximately a 70 per cent, conversion. In practice,

however, a conversion of 40 per cent, with a burner gas containing 5-7 per cent,

of sulphur dioxide is considered to be a good result; but, according to F. Haber,

it is doubtful if the equilibrium yield has ever been attained because a long contact

with the catalyst is needed for equilibrium. G. Keppeler and J. d'Ans found the

optimum temp, to be 629° for a mixture containing 2 per cent, of SO2, and there

was a 72-5 per cent, yield ; with 3 per cent. S02, the optimum temp, was 640° ;

with 4 per cent., 650°; and with 7 per cent., 665°. The yields in the last two cases

were respectively 65-0 and 53-2 per cent. A number of attempts have been made

to improve the catalytic activity of ferric oxide. Thus, K. Albert heated a mixture

of ferric oxide with oxide of barium or strontium. The catalysis begins at 400°,

and gives a 94 per cent, conversion at 450° ; nor is the product so sensitive to

moisture as ferric oxide alone.

The catalytic action of ferric oxide has been explained by assuming that ferric

sulphate or a basic ferric sulphate is alternately formed and decomposed, since

ferric sulphate decomposes in the same temp, range as ferric oxide is active as a

catalyst:

2Fe2O3+6SO2+3O2 ---> 2Fe2(SO4)3 ;

Fe2(S04)3 ---> Fe2O3+3SO3.

(...)

|

So, in practice, maybe , for economy , worth a try any of these .. both Fe2(SO4)3 or Fe2O3 , placed in a tube with strong heat and a flow of dried and

already mixed SO2 (from a Sulfur Burner ) and dried air (from e.g. an aquarium pump passing the air through dissecant agents).. The 'waste' SO2 rich gases, after cooled and

bubbled in conc H2SO4 for oleum, can be caught by several scrubbers or something similar..

another thought :

| Quote: | pag 332:

(...)F. Wohler, and ¥. Mahla observed that the oxides of chromium and copper, at a

dull red-heat, oxidized sulphur dioxide mixed with air to form sulphur trioxide.

The contact catalyst employed is not known. |

So , copper sulfate , copper oxide, anything of these would probably work for home setup

for copper sulfate/oxide, maybe the catalytic reactions are quite similar , comparing with iron sulfate/oxide:

CuO + SO2 + 1/2O2 ----> CuSO4

CuSO4 -----> CuO + SO3

Can anyone tell me if some of this is wrong?

thanks... good thread

"The secret of freedom lies in educating people, whereas the secret of tyranny is in keeping them ignorant."

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

@aqua_fortis, we aren't employing ferric sulfate as a catalyst, we are decomposing it to SO3. And we aren't oxidizing SO2 in any sort of contact

process. That is the subject of an entirely seperate thread. Q.v. Anyway the contact catalyst is V2O5.

There's an entire brand new volume on sulfuric acid manufacture on the industrial scale posted in References in the New Books (Inorganic) thread.

I am quite sure that the performance of oxides of Cu and Fe is inferior to that of vanadium, else, V2O5 would not have been the preferred catalyst for

the last century and more.

But you are right, Mellor is always interesting.

|

|

|

jimmyboy

Hazard to Others

Posts: 235

Registered: 1-3-2004

Location: Texas

Member Is Offline

Mood: No Mood

|

|

I think many sulfates decompose to sulfur dioxide at high temperatures -- I was looking for a table which shows their decomposition temps - no dice -

I think sodium bisulfate (easily bought) is the lowest.. not sure

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

SO3 is always produced. SO3 gas comes to equilibrium with SO2 + 1/2 O2 variously at high temperatures, reducing yield.

Decomposing a hotter-burning sulfate in a retort would give the perfect feedstock for the contact process, of course.

Tim

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Concerning FeSO4 to Fe2(SO4)3, I remember FeSO4 needs to be kept with a certain amouts of H2SO4 for it to be stable.

I remeber looking at a potential/pH graph for FeSO4, and above a certain pH (between 3 or 5 IIRC), Fe2+ is oxidized to Fe3+ by mere O2. Having SO4

ions from Na2SO4 or a similar unreactive sulfate would possibly furnish the needed SO4 2- anion. I guess in the absence of exces sulfates, it must

partially dismute to some oxide. I'll try and find the potential/pH diagram again.

This could diminish the water amount to be evaporated, and bubbling air through a solution overnight (or maybe much less time) would be such a hassle.

I don't think Na2So4 would interfer with the SO3 production although that is just an unfouded presumtion.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

I think we have abandoned ferrous sulfate, as ferric sulfate hydrate is supposed to be available in bulk and cheap. So no need to make it. But thanks.

If someone does want to make it from ferrous sulphate, then the simplest method is to boil ferrous sulphate in conc H2SO4, till anhydrous ferric

sulfate ppts.

Almost as simple, treat the stoichiometric amount of ferrous sulfate with 50% H2SO4, then add stoichiometric amount of either conc nitric acid, or

hydrogen peroxide, and boil till the yellow-brown solution fails to give a blue color with potassium ferricyanide. Then concentrate, till syrupy. Add

conc H2SO4 and the anhydrous ferric sulfate ppts out.

The equations are available upthread for both oxidizers.

The first, simpler method involves the hazard of boiling concentrated H2SO4. Exercise caution and protect yourself.

|

|

|

chloric1

International Hazard

Posts: 1158

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Given if the amatueur has ready access to battery acid, the process can be continuous. Andhydrous Ferric sulfate leaves ferric oxide or basic

sulfate. This is dissolved in sufuric acid with much stirring and heat reforming ferric sulfate. Some battery acid is retained to make concentrated

sulfuric acid s.p. 1.84 and this is added to the ferric sulfate.

Problems that may occur. I have noticed it past attempts ferric oxide is not easily soluble in acids especially if was heated. So a different

process may be needed. Maybe the oxide mixed with hot oxalic acid to affect solution followed by decomposition of said oxalate complexs with hot

H2SO4

Fellow molecular manipulator

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Look, chances are that ferric sulfate tech grade in 50 lb sacks or whatever costs maybe $1/lb or less. How much blood sweat & tears do you want to

invest in turning this into a continuous process by recovering your waste oxide?

It will not be worth the time. The big savings is in what one is making and not trying to squeeze a few cents out of the raw material.

|

|

|

chloric1

International Hazard

Posts: 1158

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Well there is one supplier I know of for ferric sulfate but before I order that I am going to use what I already have. What I have is partially

oxidized copperas. I will be able to make Ferric Sulfate and ferrous sulfate. The oxide recovery is kinda a brain fart but i usually do well to

reuse what I can. Not only for economic reasons but for accessability reasons.

Fellow molecular manipulator

|

|

|

Ozone

International Hazard

Posts: 1269

Registered: 28-7-2005

Location: Good Olde USA

Member Is Offline

Mood: Integrated

|

|

Just a little bit of anectodotal information:

In sugar mills (outside of the US) they use sulfitation to produce a white sugar product directly from cane. It is known in that industry that if too

much O2 enters the sulfur stove (burner) that the piping is eaten out at a (scarefully) uneconomical rate. This is attributed to stoicheometric

conversion to SO3 (and, with water, H2SO4 in the pipes).

In this industry, the sulfur burner is a horizontally mounted cylinder which is open to air. The rising heat pulls in the air through a baffle to

facilitate (the correct) stoicheometric combustion. A guy stands there and shovels in S8 from a wheelbarrow.

It burns this really neat, almost UV purple color when it is making pure SO2 (don't know about what it looks like if making SO3, because they try very

hard to avoid this).

How about a sulfur stove with an O2 feed line?

What the hell,

O3

-Anyone who never made a mistake never tried anything new.

--Albert Einstein

|

|

|

Xenoid

National Hazard

Posts: 776

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Another reference just for the sake of completeness and all the girls out there!

Are there any girls out there?

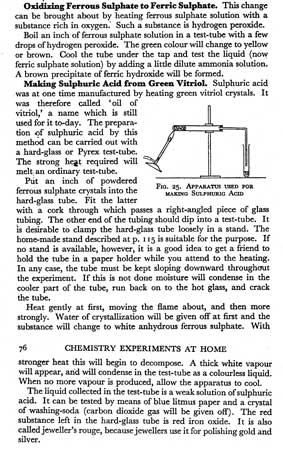

Heyes, H.L. 1949 : Chemistry Experiments At Home For Boys and Girls. Chapter (IV) pp 75-76. George G. Harrap & Co. Ltd. Ed. 1957.

Regards, Xenoid

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Thanks @Xenoid.

Let's keep in mind that ferric sulfate is more productive of SO3 than ferrous sulfate, and apparently about as available and economical.

And aluminum sulfate might be competitive with ferrous sulfate though not in the ferric sulfate class. It also is on the threshold of being doable in

pyrex unlike either of the iron sulfates - regardless of your old clipping. Aluminum sulfate is the only one that will go at 500 C which is th upper

limit of pyrex and similar borosilicate glasses. They anneal at 550 C.

It is not an accident that high temp Glas Col mantles top out to 450 C. They are designed to heat pyrex.

But again, thanks.

|

|

|

ciscosdad

Hazard to Self

Posts: 76

Registered: 6-2-2007

Member Is Offline

Mood: Curious

|

|

Temperature control

From my limited understanding of the topic, it seems that there is a rather restricted range of useful temperatures to get this to work. 750 Deg C max

to keep the SO3 intact and whatever temp is required to decompose the selected sulfate.

Obviously if a temp comtrolled muffle furnace was used, then the problem would be solved, but what about some improvised method for use by amateurs? I

like the idea of using charcoal as the heating method, but temp control is quite iffy. What about some sort of "double boiler" type arrangement but

using a liquid metal as the heat transfer medium? Aluminum comes to mind if an operating temp approximating its MP was used (630C?). Use the presence

of solid AL metal as an indication of the temp being at the MP. That would be comfortably under the magic 750 and over the published decomposition

temps.

I realise it would not be as strightforward as all that, but is it worth considering?

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Quite a few of us (forum members) have tube furnaces. I've posted pics of mine; see the SO3 contact process thread for another from same maker

(Thermolyne). I got mine for $100 on LabX. They usually top out at 1000-1200 C and have thermocouple controls.

|

|

|

| Pages:

1

2

3 |