August 21, 2014

By ParadoxChem126

Introduction

Chlorobenzene is a useful chemical in organic syntheses. It dissolves a wide range of organic compounds, making it an effective high-boiling solvent.

It also has numerous applications as a reagent. For example, it is a direct precursor to phenylmagnesium chloride, a valuable Grignard reagent that

can be used to produce a variety of compounds (e.g. benzene, triphenylmethanol, etc.).

The most common laboratory preparation of chlorobenzene involves the direct chlorination of benzene using a Lewis acid catalyst. This preparation is

considerably hazardous, as it involves the use of very toxic and carcinogenic chemicals. For home chemists, a safer method of preparing chlorobenzene

is the use of the Sandmeyer reaction. This reaction entails the diazotization of aniline to a phenyldiazonium salt, followed by the catalytic

decomposition of that salt with copper(I) chloride. The main resultant product is chlorobenzene.

In this experiment, chlorobenzene will be prepared from aniline via the Sandmeyer reaction, as detailed above. This is a slightly modified,

scaled-down version of the preparation found on page 577 of Vogel’s Textbook of Practical Organic Chemistry, Second Edition.

Experimental

Combine 20 mL of aniline and 57 mL of distilled water in a 600 mL beaker. Place the beaker on a magnetic stirrer, and slowly add 57 mL of 37%

hydrochloric acid to the beaker in small portions. Small amounts of white fumes are evolved.

Addition of hydrochloric acid to the reaction mixture

Once the fumes subside, place the beaker in a salt-ice bath and wait for the temperature to drop to 0°C or below. A white precipitate of aniline

hydrochloride is observed at this low temperature.

Once the mixture reaches the desired temperature, begin to add a solution of 16g of sodium nitrite in 33 mL of distilled water using an addition

funnel. This forms nitrous acid in situ. Add the sodium nitrite solution dropwise to ensure that the temperature stays as low as possible.

Do not let the temperature rise above 5°C, as the sensitive phenyldiazonium chloride would decompose. If the temperature gets too high, brown-orange

nitrogen dioxide gas will be released. Keep the magnetic stirrer stirring and use the salt-ice bath for cooling throughout the entire addition. The

white precipitate of aniline hydrochloride dissolves as it reacts with the nitrous acid.

Addition of sodium nitrite solution to the reaction mixture

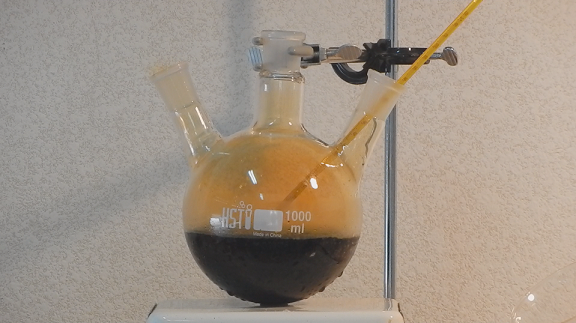

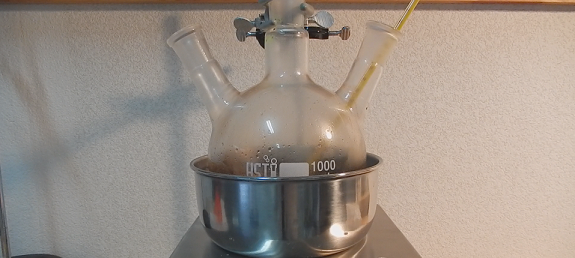

Meanwhile, dissolve 27.72g of copper(I) chloride in 113 mL of 37% hydrochloric acid in a 1 L three neck round-bottom flask. The resulting solution is

dark green to black. Place the flask in a salt-ice bath on top of a magnetic stirrer. Allow the temperature to drop to 0°C or below.

When the sodium nitrite addition is complete, allow the mixture to finish reacting for a few minutes. Use the salt-ice bath to keep the temperature

as low as possible. Then, begin to slowly add the phenyldiazonium chloride solution to the copper(I) chloride solution in small portions. Keep the

phenyldiazonium chloride cold between additions.

Addition of the phenyldiazonium chloride to the copper(I) chloride

The mixture thickens due to the separation of an addition product between the diazonium salt and the copper(I) chloride. During the addition of the

diazonium salt, small amounts of brown-orange nitrogen dioxide gas are released. Once all of the diazonium salt has been added, remove the cooling

bath and allow the mixture to come to room temperature without external heating. The mixture becomes less viscous as it warms up. During this step,

nitrogen dioxide gas is released, so it is necessary to do this outside or under a fume hood.

Evolution of nitrogen dioxide gas

As the mixture warms up, effervescence is observed as nitrogen gas (N2) is released. By the time the reaction reaches room temperature,

the evolution of brown-orange nitrogen dioxide will have stopped. Once the mixture reaches room temperature, a hot water bath is applied to slowly

bring the reaction up to 60°C. Magnetic stirring is continued throughout the heating process. The release of nitrogen gas continues for several

minutes.

Heating the reaction mixture on a hot water bath

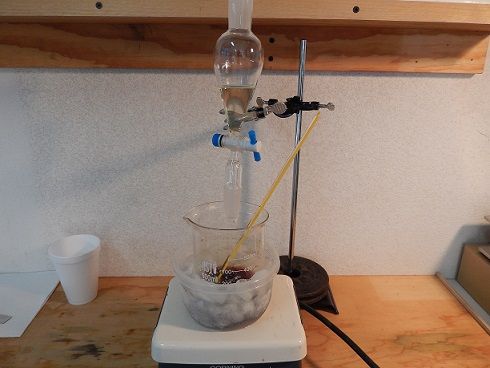

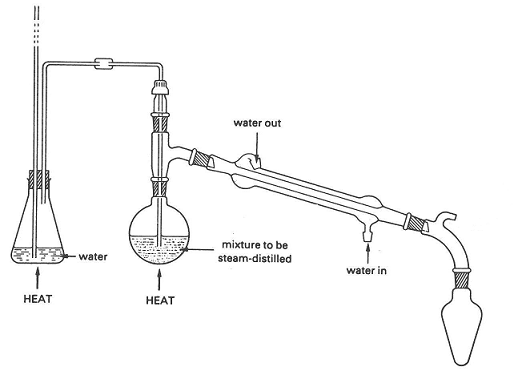

Once no more nitrogen is evolved, set up for steam distillation using the following (or similar) apparatus:

Apparatus for steam distillation

The leftmost flask contains distilled water that is boiled to generate steam. The steam travels up the tube and bubbles through the reaction mixture.

The resulting steam/vapor mixture is condensed in the condenser and the distillate is stored in the rightmost flask. It is important to note that

the reaction flask must be heated; otherwise, the steam will simply condense upon contact with the cooler reaction mixture.

As the distillation commences, drops of yellow oil will appear in the distillate. This oil is the crude chlorobenzene. Continue the distillation

until no more oily drops are present in the distillate.

Steam distillation to separate the crude chlorobenzene

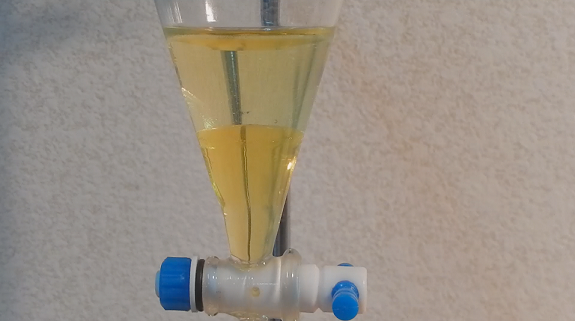

The distillate was given time to form two layers. Then, it was transferred to a separatory funnel and the layers were separated. Discard the upper

aqueous layer and keep the lower chlorobenzene layer. Transfer the chlorobenzene back to the separatory funnel and wash it twice consecutively with

solutions of 2.5g of sodium hydroxide in 25 mL of water. The sodium hydroxide solution helps to remove phenol and other side products. Wash the

chlorobenzene one more time with 30 mL of distilled water.

Chlorobenzene (bottom) and water (top) after distilled water wash

Transfer the chlorobenzene to a 50 mL Erlenmeyer flask and add enough anhydrous calcium chloride until the CaCl2 is free-flowing without

clumps. This removes any traces of water from the chlorobenzene. Place the flask on a magnetic stirrer and stir it for about 30 minutes to complete

the drying process.

Decant the chlorobenzene into a 100 mL round-bottom flask. Rinse the Erlenmeyer flask and calcium chloride with a total of 35 mL of dry

dichloromethane in small portions. Add all of the dichloromethane rinses to the 100 mL round-bottom flask. Rinsing with dichloromethane ensures that

none of the chlorobenzene is lost on the desiccant.

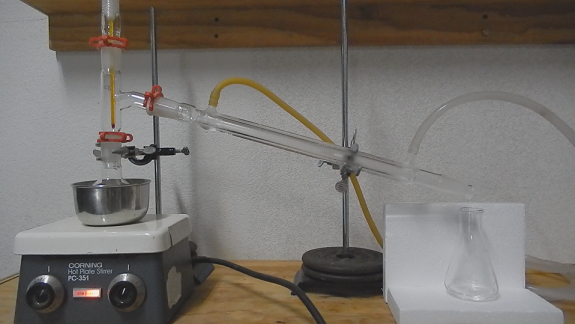

Distillation of the dichloromethane/chlorobenzene mixture

Set up for simple distillation and distill off all but about 1 mL of liquid. The distillate is a colorless mixture of dichloromethane and

chlorobenzene. The distillate, contained in a 125 mL round-bottom flask, is placed on a hotplate set to very low heat. The goal is not to boil the

solution; it is to only provide enough heat to aid in evaporation. Once the schlieren due to dichloromethane vapor are no longer visible, continue to

heat for another 20 minutes to ensure that all dichloromethane has evaporated. Alternatively, heat the liquid until it stops losing mass. Once all

of the dichloromethane has been evaporated, transfer the pure, colorless chlorobenzene to a suitable bottle for storage.

Final product in storage bottle

Discussion of Results

9.98 grams (roughly 9 mL) of pure chlorobenzene were collected. This corresponds to a 40% yield based on aniline. The following factors may be

responsible for this relatively low yield:

• This is a relatively small scale of this reaction. Dealing with such a small amount of material causes more loss during workup (e.g. separatory

funnel washes, transfers between containers, etc.).

• Appreciable loss occurred during steam distillation. The distillation was stopped when distillate began to come over extremely slowly. Perhaps if

the reaction flask was heated more intensely, less steam would have condensed prematurely. This would allow the distillation to be continued longer,

likely yielding more chlorobenzene.

• A small amount of chlorobenzene is lost to evaporation during the removal of dichloromethane.

Attachment: Chlorobenzene from Aniline via the Sandmeyer Reaction-2.pdf (513kB)

This file has been downloaded 2356 times