| Pages:

1

2

3

4

5

6

..

19 |

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by smuv  | Also, the reason why these acids work, and carboxylic acids like acetic acid don't, is that formic and chloroacetic acid are strong enough to

protonate the alkene, giving a carbocation which is vulnerable for attack by the formed carboxylate. Trifluoroacetic acid works in the same way, but

it is way overkill, acetic acid on the other hand, just is not acidic enough to protonate the alkene.

All this being said, it is possible that if you reflux the stuff in glacial acetic acid, with a catalytic amount of H2SO4, you may get addition to the

double bond.

[Edited on 3-4-2011 by smuv] |

The Wiki entry on alpha-pinene states explicitly that alpha-terpineol acetate is obtained from refluxing pinene with glacial acetic acid.

And a paper linked to above points to efficient conversion of pinene to terpineol with dilute sulphuric acid in an excess of acetone (refluxing).

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

That's from pinene though, with a strained ring. In

USA, pine turpentine is very cheap, and might be more reasonable starting material than limonene. If you want to start with limonene:

http://www.scielo.br/scielo.php?script=sci_arttext&pid=S...

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

The sulfuric acid method would be simpler, if it works. The problem is sometimes these things undergo dehydration even with very dilute acids, which

is why often the ester is formed and then hydrolyzed. But since you have a reference for this specific case it is worth a shot.

About, the conversion of alpha-pinene to alpha-terpineol acetate, I can't comment about the wiki ref, but comparing the ring opening of a cyclobutane

to the addition of a carboxylic acid to a double bond, is not exactly comparing apples to apples.

Anyways, I hope everything works out. Might be the first terpene synth on this forum.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Eclectic and smuv:

Decisions, decisions, eh? Both pine turpentine and orange oil are highly OTC (although trichloroacetic acid is less so). I’m surprised no one on the

organics board hasn’t tried these synths yet. There’s a first time for everything, I guess…

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by blogfast25  | Thanks to ScienceSquirrel and IPN over at the potassium thread:

http://www.sciencemadness.org/talk/viewthread.php?tid=14970&...

… another useful idea has emerged: synth. of the tertiary alcohol α-terpineol: http://en.wikipedia.org/wiki/Terpineol

Acc. several literature references hydration of α-pinene in excess acetone in the presence of dilute sulphuric acid at 80-85 C oil bath leads to

terpineol being formed. The excellent *.pdf unearthed by IPN (first link above) gives several examples. One example cited involves 2 g of turpentine

oil (source of pinenes and VERY OTC), 4 ml of a 15 v/v% H2SO4 solution in an excess of 25 ml of acetone, with maximum conversion of pinenes to

terpineols occurring at about 4 h at 80-85 C.

Ideas for work up (essentially elimination of the excess acetone) of the terpineol from organic wizzkids here would be much appreciated…

|

I'm working on a process to isolate alpha-terpineol fom turpentine, basically following the procedure laid out in the paper. This will be my first

foray into organic chemistry, so sorry if the following questions are naieve:

1) I assume 'turpentine oil' is the same thing as standard turpentine? Specifically, "Klean-Strip 100% Pure Gum Spirits Turpentine" is what's

available here and that's what I'd like to use.

2) At the end of the reaction, could you not eliminate the extra acetone by simple heating? Terpineol boils at over 200C, so the acetone and any water

should boil off much sooner for easy separation.

Basically, the plan is to follow the procedure outlined above in the paper, neutralize the product solution with a base (baking soda or NaOH), and

heat it to boil off the acetone.

Any help would be greatly appreciated!

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Thanks MrHomeChemist for wanting to help out here. I was going to run a test today using the same procedure but something’s popped up. Hopefully

tomorrow, then we can ‘compare notes’?

Your questions:

1) I bought turpentine paint stripper/thinner and made sure it was ‘the real deal’ by smelling it. If it smells strongly of pine oil, it should

contain about 70 %+ of alfa-pinene (acc. info on turpentine in google) and be fit for purpose.

2) As regards the work up of the final product, like you said, firstly neutralise the mix with weak NaOH. I’m assuming the reaction product mix will

be a two phase system (two layers), one the alcohol (and other by-products), the other acetone/water and some sodium sulphate (and some other acetone

soluble by-products). I believe the alcohol phase will be the bottom one (but won’t put my hand in the fire on that: acetone has a lower density

than alfa-terpineol but the acetone phase also contains some (heavier) water). If I’m right on this, then separate the phases and wash the alcohol

phase a few times with clean water, this will leach out any remaining acetone (which is highly soluble in water). Then dry the product with some

crushed anhydrous MgSO4 or dry Na2CO3.

But, but, but. If no two separate phases are present then distilling off the acetone will be needed. Use steam distillation for this: it’s very

safe, low temperature and because acetone is both very volatile and soluble in water it should get rid of the acetone real easily. Then dry the

product with some crushed anhydrous MgSO4 or dry Na2CO3.

The end product should be a flagrance with an odour quite different from turpentine: alfa-terpineol is used in perfumery for instance.

You can also check the tertiary alcohol nature of the product by means of potassium dichromate: tertiary alcohols like alfa-terpineol CANNOT be

oxidised by it, see here:

http://www.chemguide.co.uk/organicprops/alcohols/oxidation.h...

I think this is an interesting first organic experience for anyone...

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by blogfast25  | | Thanks MrHomeChemist for wanting to help out here. I was going to run a test today using the same procedure but something’s popped up. Hopefully

tomorrow, then we can ‘compare notes’? |

Definitely. I just ordered some 24/40 glassware from "DrBob" from over in the reagents acquisition section, so I'm hoping that will arrive early next

week. In the meantime I can try to rig something up with my non-jointed liebig as a refluxer to do some preliminary runs.

Thanks for answering my questions. If the product is two phase that would simplify things greatly. Your plan for the workup sounds good to me. I've

got some CaCl2 as a drying agent too, as I'd have to dehydrate MgSO4 (Epsom salt) in my oven. I'm always wary of getting chemicals anywhere near the

kitchen, even if they seem innocuous.

Quote: Originally posted by blogfast25  | | But, but, but. If no two separate phases are present then distilling off the acetone will be needed. Use steam distillation for this: it’s very

safe, low temperature and because acetone is both very volatile and soluble in water it should get rid of the acetone real easily. Then dry the

product with some crushed anhydrous MgSO4 or dry Na2CO3. |

Steam distillation is something I haven't done either, but I looked around a bit and it seems pretty straightforward. Any reason I couldn't use a

standard distillation (i.e. oil bath or heating the flask directly)?

Perfect, I have some dichromate already and I was wondering how I'd be able to check my results. I had also thought of the smell test, as you

mentioned - turpentine has that pine scent, and alpha-terpineol "has a pleasant odor similar to lilac" according to the wiki.

Thanks for the link too, that site has a lot of really useful information. Looking forward to trying this!

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Well, direct distillation has the disadvantage that when the acetone content gets low, the BP of the stuff gets naturally close to that of the

remaining component (the alfa-terpineol), so rather high. But it may be possible to get rid of most of the acetone by straight distillation, then

switch to steam distillation when the boiler temperature is getting too high for comfort... It depends a bit on your set up.

By steam distillation here can simply be understood: add some water to the mix and some boiling stones (low boiling mixtures tend to boil rather

bumpily, not w/o danger). Now you start distilling off gently and the steam that passes through the product mix carries with it most of the volatiles,

including the acetone, while the alcohol is condensed in your column. When little water is left, separate the phases and dry the product unless you

can still smell acetone in there.

I will have a first run tomorrow.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

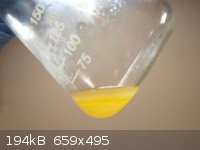

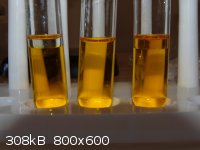

Well, that first run wasn’t successful because my refluxer couldn’t take the flow and reagent mixture was spitting out at the top. Using a demoted

graduated pipette (top and bottom clipped off) the new refluxer now works fine. This is the setup: 100 ml round flask (62 ml total charge), electrical

submersion heater (but manual temp. control, ON - OFF), and refluxer:

Turps and the mixture of acetone/dilute H2SO4 form a two phase system with turps floating on top:

All ready for a run tomorrow…

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

I came across US Patent 2432556 in an unrelated search, which claims that terpene alcohols are produced in superior yield from terpenes using sulfamic acid

instead of sulfuric acid as catalyst. The improvement is not vast but sulfamic acid is also easier to handle and may be more readily available in some

places than sulfuric acid.

PGP Key and corresponding e-mail address

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Thank you, Polverone!

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Very interesting find Polverone! Thanks for passing it along. I'm going to try to replicate the paper's method first, and if I can get that to work

then sulfamic acid is definitely something to try for comparison. They let their reaction run at a lower temperature but for a much longer period,

though. Four hours is plenty long enough for me

I rigged up an acceptable reflux apparatus last night, so hopefully I'll be able to do a run tonight. I'll start by only going for 2 hours just to see

if it works, and this should give me a decent yield according to the paper.

edit: @Blogfast: So that second picture was before you did any reaction, correct? That's promising that it already shows two layers.

[Edited on 3-25-2011 by MrHomeScientist]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Yes, it was before refluxing. The alcohol may be better soluble in acetone than pinene itself though: only one way to find out. alfa-terpineol is

listed as soluble in ethanol, for instance.

That pinene floats on the acetone/H2So4 mix is good because the boiling bottom phase will constanty agitate the pinene!

Good luck with your run. I had to postpone again. Hopefully tomorrow

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

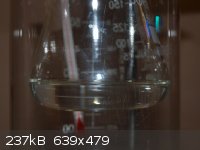

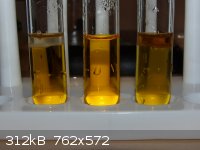

First Run

I did my first run of this tonight, and it seems to have gone well. I haven't tested the product yet, but here's a photo of the results to whet your

appetite:

This was after neutralizing with NaOH. There's two layers there, but it's hazy so I'm letting it settle overnight. The bottom layer is oily, and the

top is aqueous. My starting solution also had two layers, but was completely clear. The color change was surprising.

Just wanted to post a quick update. It's late, so I'll finish up and post the full details tomorrow.

[Edited on 3-26-2011 by MrHomeScientist]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Lookin' good!

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Here’s the writeup for my first run of the terpineol synthesis. I tried to follow the method outlined in the paper. It’s a bit long, and I’ve

got even more photos if something isn’t clear.

A 150mL flask was used as the reaction vessel, and into this was mixed:

4g Crude Turpentine (4.6mL – this was chosen by assuming turpentine is 50% a-pinene)

1.6mL 4.4M Sulfuric Acid

25mL Acetone

The mix was biphasic with turpentine floating on top, as seen by blogfast25.

This was immersed in a water bath, and connected to a liebig condenser using Teflon tape to afford a better seal. Additional cooling was not used.

The water was heated to the 80 – 85C range and held there for 2 hours. I only went for two hours because Figure 2 in the original paper shows that

around 70% of the terpineol should be produced at this point. The maximum yield would be at 4 hours. Sometimes it creeped up to 90C, because my

hotplate isn’t great, so tweaking was necessary every so often.

Shortly after reaching about 70C, the mix started changing color to yellowish and the volume began decreasing. This is likely the acetone boiling away

and escaping the condenser due to insufficient cooling. Throughout the reaction, reflux was observed so at least some of the acetone survived. I’ll

fix this in the next run.

After 2 hours, heating was stopped and the apparatus disassembled. A strong scent of turpentine and acetone was detected. The mix had separated into

two layers, both orange-yellow colored.

I neutralized the acid with 0.5g NaOH in 3mL water, which evolved considerable heat. This was when the picture in my post above was taken. After

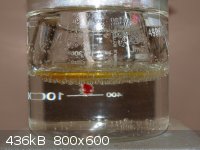

letting it settle overnight, this is what it turned into:

The colors flipped! It almost looks like there are 3 layers there, but I never found a third in subsequent steps so I think that's an illusion. The

layers were then separated, and the bottom layer turned out to be fairly clear while the top layer was orange. I assumed the bottom was the oil layer,

so I tried to wash this with 2mL of water. Turns out, this was the aqueous layer! It was miscible with my wash water.

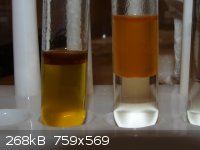

I then prepared a test solution of a few mg of potassium dichromate in 9mL water, acidified with about 10 drops of 4.4M sulfuric acid. This was split

into 3 test tubes, and combined with 0.5mL of the following solutions (from left to right):

Test tube A: original, raw turpentine (the control)

Test tube B: lower layer

Test tube C: upper layer

A & C separated into layers, while B was miscible with the dichromate solution.

These were placed in a warm water bath for a few moments, with no changes observed at the time. The heat was turned off, and I left for about an hour.

When I came back, the tubes looked like this:

It’s a little hard to see, but A had become a light olive green, B had not changed, and C had become a darker green with the oil layer darkening

significantly.

This is when I realized the original upper layer must have been the organic, so I took that and shook it with 2mL of water to remove soluble

contaminants. I then repeated the dichromate test, and ended up with a bit darker green solution.

After heating:

EDIT: After letting this sit while I wrote up this post, this solution has become an even darker green, which looks like a positive test for a

tertiary alcohol!

Conclusions

It probably worked! The darker green color of the upper layer of my product seems to mean that some terpineol was produced, so more was available for

the dichromate to reduce.

One source of error was insufficient cooling, which allowed almost all of the acetone solvent to evaporate and escape. In the next run I’ll use

water cooling on my condenser, which should solve this problem.

If anyone has any suggestions on how to improve, please let me know. As I’ve said, this is my first experience with organic chemistry so there’s

likely some basic things I’m unaware of. I really enjoyed doing it though!

[Edited on 3-27-2011 by MrHomeScientist]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Good write up!

A few comments so far, maybe some more later on.

Cooling: the easiest way is to wrap your refluxer in kitchen towel (absorbent paper), wetted with iced water. My own refluxer which is very much the

same size as yours is cooled that way and can handle (easily) twice the amount of boiler charge (I’ll be basing everything on 4 ml turps, not 2).

Then occasionally (say every 10 minutes) you need to pipette some more iced water on your cooler…

There is one glaring error in your write up though: as I indicated above, potassium dichromate CANNOT oxidise t-alcohols, a ‘negative’ test result

would thus indicate no primary or secondary alcohols are present in the end mix. Clearly there are but that’s probably quite normal: if you look at

the article, final analysis shows it to be quite a witches’ brew! For the purposes of a catalyst for K synth. these minor constituents probably

won't harm...

http://www.chemguide.co.uk/organicprops/alcohols/oxidation.h...

For your next run I’d suggest to use ethanol or methanol (or ‘methylated spirits’) as a control: that would allow you to compare intensity of

colour and speed of oxidation.

Did you get to smell the organic phase at all?

Good work though!

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Whoops! You're right of course, I got my dichromate test results backwards. I looked at the paper again and there's definitely a lot going on in the

products. Can the dichromate test even tell us anything then? All I can conclude from mine is that turpentine contains some reducible material, the

aqueous product phase does not, and the organic product phase appears to contain more than the turpentine. The latter may be because I only went for 2

hours, and so the product ratios will be different.

Using methanol as a control is a great idea. I think because there's so many extra products hanging around, the speed of oxidation will be what we

want to look at. The higher the concentration of a-terpineol, the slower it should change colors I would think.

For cooling, I found an old fish tank pump and I'll try to use the condenser as it was meant to be used - with ice water flowing through the jacket.

The paper towel suggestion is good though, if this pump doesn't still work.

I did smell the products, but it was all a turpentine/acetone scent. I imagine the lilac smell of terpineol is easily overwhelmed by turpentine's

strong pine scent. It might be more evident, had I gone the full 4 hours. That will be the best test I think, since the dichromate test is iffy.

Thanks for the encouragement, and I really appreciate the comments and advice! I'll see if I can do another run today.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Regards the cooler, sorry, I didn’t see it was a proper Liebig with cooling mantle. Don’t pump too much or it will affect the temperature of the

refluxed liquid.

One of the reaction products mentioned is fenchyl alcohol (fenchol), that’s a seconday alcohol and would be affected by dichromate (I think). To get

a clear negative would probably only work with pure terpineol, which is why a comparison with a readily oxidisable substance is more appropriate

here…

Your set up should also easily be capable of dealing with 2 - 3 the paper recipe quantities.

I’ve just distilled off some acetone today and my first run will definitely be tomorrow.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Sigh… another teething problem occurred: refluxer flooding. This is where the upward vapour flow exceeds the downward liquid flow and

liquid starts building up in the refluxer column. Once initiated it just gets worse and worse, with more vapour condensing in the held-up liquid: I

ended up with a column full of liquid!

The main cause here was too narrow a diameter of the ‘bottom’ of the modified pipette (the column), but thankfully nothing taking off another bit

of glass off that part couldn’t solve. By then it was too late to achieve a full run of 4 h, so instead I ran some useful tests. Latest set up:

The BP of the reagent mix was about 62 - 63 C, in line with an acetone phase laced with a bit of dilute H2SO4. In principle that means that under

total reflux the water bath temperature should be of no importance: the temp. of the reboiler being always it’s constant BP. In practice the bath

temp. does affect the boiling rate, as the heat per unit of time transferred from bath to reboiler is directly proportional to the temp. difference

between the bath and the reboiler. The boiling rate could then be calculated by dividing the transferred heat (per unit of time) by the molar heat of

evaporation of the boiler liquid (acetone, basically). The difference in reboiling rates was palpably visible while toggling manually between 80 and

85 C bath temperature.

But if the run tomorrow is successful and yields a K-synth. useful product, I’ll be making the product using my trusted acetone still (of much

larger capacity) and a plain steam bath at 100 C bath temp.

The power of the submersion heating coil is about 280 W (measured) and about right for the job of manually regulating bath temp. The ‘paper towel

cooling mantle’ also worked fine, with no acetone vapours escaping at the top but it needs regular addition of iced water.

After about an hour or so of putting the thing through its paces the turpentine phase (top) had turned a light yellow, as did MrHomeScientist’s:

The acetone/H2SO4 phase was turbid. I could have sworn the mix also smelled differently after the test but that may just be wishful thinking…

[Edited on 28-3-2011 by blogfast25]

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Nice! Your upper layer looks exactly like the color I found at about that time in the reaction. Nice to get confirmation  Sorry to hear about your refluxer problems though, at least you got some preliminary

results. Sorry to hear about your refluxer problems though, at least you got some preliminary

results.

How much acetone are you using? It looks like much more than what I have. That could be due to different container sizes though.

I've noticed the same thing with boiling rate as you have. I ran a second test Sunday night, this time with cooling water running through the liebig.

Everything was going great until my hotplate started to get away from me. I saw no change in volume until about 1.5 hours in, when my hotplate creeped

up around 90C. It seems that as long as bath temperature stays in the 80-85C range (like the paper uses) things are fine, but above that vapors begin

to escape my system. I let it run to 2.5 hours, but by then practically all of the acetone was gone and I was down to about the same volume as my

first run. Darn. I really need to babysit my system apparantly.

I was busy yesterday so I didn't test my product yet, but it does have a somewhat lighter color. Still smells like turpentine/acetone though. I'll try

and get to that tonight or tomorrow, and post more photos.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

MrHomeScientist:

I used twice the amount of the recipe, so about 62 ml. During refluxing, I could see vapour/liquid getting dangerously close to the top of the

refluxer when bath temp. was 85 C. Our refluxers must be operating similarly!

After about 2 ½ h, I noticed that the boiling behaviour started to change: it seemed to reboil less… And after 3 ½ hours the liquid refused to

boil at all, so I stopped.

The cause was soon found: the content of the flask was about 86 g at the end of the run, presumably because of cooling water infiltration! How this

affects the conversion is of course unknown but of course it increases the BP! The next, much larger test will be done with my acetone still.

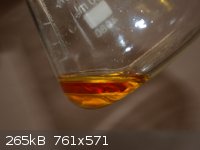

The two phase system was then neutralised with 5 % NaOH which made the acetone/water phase cloud over. The two phases are now being allowed to

separate to the fullest extent possible, overnight:

One thing is striking: the transformation of the odour. The treated product mix has a flagrance that is almost completely different from the starting

mix. The new flagrance is extremely pleasant, very ‘clean’ and ‘citrussy’, reminiscent of some lemon flavoured toilet cleaners, with perhaps

overtones of pine. Something has been brewed in there. If only I had access to FT-IR!

Update:

After standing overnight the cloudiness had coalesced into the kind of dross you find in your bath water! Draining off the watery/acetone phase and

replacing it with clean water still didn’t get rid of it. But the oily phase filtered well to a clear, light yellow and very flagrant liquid (1 - 2

ml):

For now I’ll just call it hydrated pine oil. I’ll desist from drying and further attempts at characterising it (only IR could

conclusively tell what it is anyway) because I’m running another batch, this time 4 times the recipe quantities (and no cooling water

infiltration!!). But the ‘finished’ product smells like I described it: so nice I’d gladly put some of it behind my ears!

[Edited on 30-3-2011 by blogfast25]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Today a run with 4 times the quantities the paper called for, using a home made still that I use to recycle acetone with. Above the water cooled still

column head is paper cooled corrugated flexible hose (not shown), normally used for cooling and directing the distillate into a distillate flask. On

this occasion it was clamped into vertical position to provide the cooler:

Yesterday I distilled some 125 g of acetone (it came over at 56.1 - 56.3 C) w/o problems but today the damn thing had decided to leak a little from

the joint to holds the column and still head together. But only a little and it was remedied by topping up the acetone level through the cooler a

couple of times. Total run time just over 3 hours.

Two phases existed in the boiler liquid at all times. The cooled reaction mix was then neutralised and spilt into three phases:

You don’t see that everyday! But the mystery of the third, bottom phase was soon revealed when on standing crystals began to appear: these are

Na2SO4 which salted out the acetone-water phase into Na2SO4-water and acetone (mainly).

The top, ‘oily’ phase was then decanted off and washed with some clean water. Tomorrow it will be filtered and dried. It looks amberish

and smells like yesterday’s product.

$$^&%^**_)_)+

During the three hours of babysitting yesterday’s pine oil hydrate was subjected to a K2Cr2O7 oxidation test.

100 ml of 0.1 M K2Cr2O7 solution in 1 M H2SO4 was prepared. Here’s 10 ml of it:

To it was added an excess of methylated spirits (about 0.5 ml) and this was heated om steam bath. Predictably it turned blue-green (from Cr3+). This

is a control.

To another 10 ml of the solution was then added drop by drop some methylated spirits, heating in between additions, to achieve the same colour as the

control above. It took 8 drops to get colour matching.

To two test tubes both with the dichromate was added respectfully 8 drops of the hydrated pine oil (HPO) obtained yesterday and 8 drops of turpentine.

In both cases the dichromate oxidised something: the HPO t5ube went dark to brownish but not green/blue. The turpentine control also reacted

slightly, darkening the dichromate solution.

[Edited on 1-4-2011 by blogfast25]

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Very interesting results! The smell you describe is the most striking thing. My products have so far all smelled of turpentine/acetone, but somewhat

less strong than the original turpentine. Perhaps I need to run it longer to further get rid of it. Like I said before, I imagine that pine scent is

strong enough to overwhelm the more pleasent scent of the real product.

I've never seen 3 phases in mine before! You said the top was the oil and bottom was water/acetone - what was the middle, milky layer?

I've unfortunately been busy this week every day after work, so I haven't had time to work on my own runs. I've neutralized my product and let it sit,

and it's settled out to be very similar to my first run. I'm betting since most of my solvent ended up evaporating away this batch will be nearly the

same as the first batch. I might have to add more acetone, like you did. I've just been trying to stick to the paper's formula to make sure I can

replicate it before I started making any changes, but your results really look promising. I'll try and do more work this weekend, and maybe get to try

out my fancy new glassware! Keep it up!

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Hi!

The three phases appeared after neutralising the acid, the bottom one of them splitting into two. Turned out that the bottom shown in the photo was

water + Na2SO4 (which crystallised and made a general nuisance of itself in the outlet of the separating funnel). The milky middle phase was

mainly acetone: the sodium sulphate had salted it out of the water phase. Top was the ‘oily’ phase, presumably holding the alcohol(s).

The characteristic odour is what kind of gives me hope that there’s alfa terpineol in there. Unfortunately I’ve no real means of assaying the

product. But if this really is ‘hydrated pine oil’ then I can see why some would want to produce and trade it…

The real test will be to try and use it in the K-synth!

[Edited on 1-4-2011 by blogfast25]

|

|

|

| Pages:

1

2

3

4

5

6

..

19 |