| Pages:

1

2

3

4

5 |

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Halogen in his post of 24-9-15 above suggested that the amide may contain short chain oligomers capped with ammonia (he means amide groups I presume).

I think this is probably very likely but I couldn't see how to test it at the time. Having thought about it further and in the light of my results

trying to test for amides with sodium hydroxide I think that one way to test it may be to heat some of the "amide" with strong (say 15-20%) aqueous

ammonia to about 100 C in my newly acquired autoclave for 10-15 minutes. My idea is that the pure amide is rather resistant to further hydrolysis by

ammonia but any uncleaved ester linkages will hydrolyse, some to amides and some to the ammonium salt, the latter are water soluble so the presence of

water soluble ammonia salts in the aqueous phase is indicative of unhydrolysed ester linkages, ie there are residual oligomers.

@Romix, the solubility of normal sodium terephthalate is about 14g of salt per 100ml of saturated solution or about 15g of salt per 100ml of water

based on my own experience and this is almost independant of temperature ie you can't recrystallise the sodium salt from water by simply cooling a hot

saturated solution. Other sodium salts, particularly NaOH, greatly reduce its solubility so the salt can be precipitated by adding 60% NaOH solution

until the concntration of NaOH in the terephthalate solution is about 15% but beware! The resulting slurry is impossible to filter with paper filters

and is very fine grained and so washes through all but the finest glass frits. Both bases of terephthalic acid are stronger than carbonic acid and so

CO2 will not precipitate terephthalic acid. Terephthalic acid is almost insoluble in water (about 10 milligrams per litre!), the only workable solvent

for terephthalic acid appears to be dimethylformamide, solubility 7g per 100ml of solvent at room temperature.

I just peel off the labels from the bottles, this leaves small dabs of glue but these do not cause problems with such aggressive conditions so I don't

try to remove them with expensive solvents.

I have also discovered a few more very basic transformation that PET will go through under modestly amateur friendly conditions: PET can be

transesterified to dimethyl terephthalate with methanol and alkali (see US pat 3321510) and that this compound (solid Mp 142 C) can be half hydrolysed

to methyl 4-amidobenzoate by alcoholic ammonia. According to another patent I found aqueous ammonia in an autoclave at 180-190 C causes complete

hydrolysis to ammonium terephthalate.

|

|

|

Romix

Hazard to Others (Literally)

Posts: 483

Registered: 19-6-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Boffis  | Halogen in his post of 24-9-15 above suggested that the amide may contain short chain oligomers capped with ammonia (he means amide groups I presume).

I think this is probably very likely but I couldn't see how to test it at the time. Having thought about it further and in the light of my results

trying to test for amides with sodium hydroxide I think that one way to test it may be to heat some of the "amide" with strong (say 15-20%) aqueous

ammonia to about 100 C in my newly acquired autoclave for 10-15 minutes. My idea is that the pure amide is rather resistant to further hydrolysis by

ammonia but any uncleaved ester linkages will hydrolyse, some to amides and some to the ammonium salt, the latter are water soluble so the presence of

water soluble ammonia salts in the aqueous phase is indicative of unhydrolysed ester linkages, ie there are residual oligomers.

@Romix, the solubility of normal sodium terephthalate is about 14g of salt per 100ml of saturated solution or about 15g of salt per 100ml of water

based on my own experience and this is almost independant of temperature ie you can't recrystallise the sodium salt from water by simply cooling a hot

saturated solution. Other sodium salts, particularly NaOH, greatly reduce its solubility so the salt can be precipitated by adding 60% NaOH solution

until the concntration of NaOH in the terephthalate solution is about 15% but beware! The resulting slurry is impossible to filter with paper filters

and is very fine grained and so washes through all but the finest glass frits. Both bases of terephthalic acid are stronger than carbonic acid and so

CO2 will not precipitate terephthalic acid. Terephthalic acid is almost insoluble in water (about 10 milligrams per litre!), the only workable solvent

for terephthalic acid appears to be dimethylformamide, solubility 7g per 100ml of solvent at room temperature.

I just peel off the labels from the bottles, this leaves small dabs of glue but these do not cause problems with such aggressive conditions so I don't

try to remove them with expensive solvents.

I have also discovered a few more very basic transformation that PET will go through under modestly amateur friendly conditions: PET can be

transesterified to dimethyl terephthalate with methanol and alkali (see US pat 3321510) and that this compound (solid Mp 142 C) can be half hydrolysed

to methyl 4-amidobenzoate by alcoholic ammonia. According to another patent I found aqueous ammonia in an autoclave at 180-190 C causes complete

hydrolysis to ammonium terephthalate. |

Something precipitated on cooling, more like sodium carbonate.

[Edited on 4-4-2016 by Romix]

|

|

|

Romix

Hazard to Others (Literally)

Posts: 483

Registered: 19-6-2015

Member Is Offline

Mood: No Mood

|

|

Boiled it down to 350ml. Something precipitating. White crystals.

Solution yellow. Glue might be the cause of colour change.

I let it sit for night. And then weigh a sample of precipitate and try decompose it at about 1000c+.

If it's therephtalate salt, there be decrease in weight. If not it's NaCO3.

Or simply be adding few drops of acid.

|

|

|

Romix

Hazard to Others (Literally)

Posts: 483

Registered: 19-6-2015

Member Is Offline

Mood: No Mood

|

|

Crystals of IPA + NaOH that were difficult to scrape off.

Were dissolved in water. And PET bottle that were damaged by it.

Were cutten into squares and left in solution.

2 days sitting there. Noticeable cracks and holes every.

Ipa alone, doesn't react with PET.

Base does but very, very slow.

[Edited on 5-4-2016 by Romix]

|

|

|

Romix

Hazard to Others (Literally)

Posts: 483

Registered: 19-6-2015

Member Is Offline

Mood: No Mood

|

|

Every time I check, there's more and more cracks and holes, on PET pieces soaked. IPA + NaOH= + H2O + PET

As what it goes into solution, any ideas dear colleagues?

|

|

|

Romix

Hazard to Others (Literally)

Posts: 483

Registered: 19-6-2015

Member Is Offline

Mood: No Mood

|

|

Solution completly lost alchocholic smell. And turned yellow in colour after a week standing.

Wait few more months, see how it goes.

Sample that been boiled in sodium hydroxide, yellow too.

[Edited on 14-4-2016 by Romix]

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Is the IPA smell lost? Strange. Because it has a strong, characteristic odor.

Although there is a process (trans-esterification) of vegetable oils catalysed by NaOH (or another strong base) in methanol what yields biodiesel, but

you wrote that you added some extra water to the mix. And water is bad for that trans-esterification, it works against you (at least against the

equilibrium). So I'm puzzled, I'm going to cut up some pet-bottles now and try to repeat this IPA-PET-Base "mystery". :-)

|

|

|

Romix

Hazard to Others (Literally)

Posts: 483

Registered: 19-6-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Pumukli  | Is the IPA smell lost? Strange. Because it has a strong, characteristic odor.

Although there is a process (trans-esterification) of vegetable oils catalysed by NaOH (or another strong base) in methanol what yields biodiesel, but

you wrote that you added some extra water to the mix. And water is bad for that trans-esterification, it works against you (at least against the

equilibrium). So I'm puzzled, I'm going to cut up some pet-bottles now and try to repeat this IPA-PET-Base "mystery". :-) |

Yes.

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

I put 24.4g PET-slices and 2.4g NaOH (lentil-like half spheres) into a 250 ml FBF. Then I realized that all my chemistry equipment is in a

transitional state in boxes and I could not locate the IPA bottle. :-)

Found some methanol so I used this instead of isopropanol. I poured 46 g methanol into that FBF and closed it.

The NaOH is still slowly dissolving in the flask, some of it is jammed between the PET slices above the methanol and has a really hard time

dissolving. I think it will take a few days - if ever. :-) The solution is turbid by the way.

The flask is in my would-be laboratory, no heating in that building so the temperature is around 12 Celsius right now.

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

After 24 hours I can say that something is going on.

The methanol solution has small, white particles floating and is not transparent anymore. Not so white like e.g. milk yet but in another 24 hours it

probably will look much like that. :-)

On the other hand there are no holes or cracks on my PET slices anywhere - which is sad, because I expected them. They have a thin, whitish (dust

like) coating though - probably the same thing that is floating in the methanol.

I will take some pictures tomorrow and post them together with the yesterday made ones to show you the "before" and "after" states.

Maybe Romix has a different kind of PET with different additives over there (in the US?) and it may explain the cracks and holes he encountered during

his experiment.

Or IPA is the real culprit, it maybe does something what methanol can not do under the same (khmm, at least very similar) conditions.

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

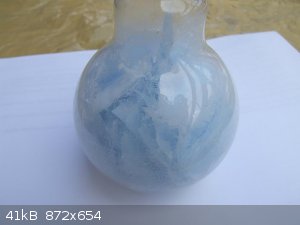

The original state, right after I closed the flask two days ago.

Now, after the processes had 48 hours to run:

[Edited on 17-4-2016 by Pumukli]

Another view from the bottom of the flask. You can see the white precipitate better from this angle:

[Edited on 17-4-2016 by Pumukli]

There are no cracks or holes on the PET slices. The mixture does not seem to get yellow(ish) either, just forms that white precipitate. (The original

PET bottle I cut up was a mineral water bottle, so the PET should be high quality (food grade), not recycled one. The slices originally had a

light-blue hue.)

[Edited on 17-4-2016 by Pumukli]

|

|

|

Romix

Hazard to Others (Literally)

Posts: 483

Registered: 19-6-2015

Member Is Offline

Mood: No Mood

|

|

Crystals of Methanol reacted with base?

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Crystals of methanol?

My methanol does not have crystals, it is just the simple, free-flowing liquid. :-)

The white spots (crystals?) on the first picture are NaOH half-spheres. They dissolved very slowly in methanol at first giving a just slightly turbid

solution. Since then that white precipitate formed. I think it is either terephtalic acid sodium salt or methyl ester of terephtalic acid.

I will check it later, in a few weeks, after the process has advanced and produced more of this compound (or consumed more of the original PET or

NaOH, whichever happens sooner.)

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@Pumukli, thats interesting. It would be interesting to recover some of the white precipitate and see if it is water soluble or not. Sodium

terephthalate is pretty soluble in water but dimethyl terephthalate is not and melts at 142 C if I remember correctly. This tell us whether sodium

hydroxide in methanol causes transesterification or hydrolysis. If the methanol is dry I think you should get mainly the dimethyl ester which would be

another useful starting material for synthesis.

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

I can't check the melting point (or just could provide a crude estimate of it) because I don't have a melting point apparatus (yet). But I will do my

best. :-)

The water content of methanol is unknown, I just opened a (few) decades old bottle and used that. :-) It was originally "for synthesis" grade, I hope

it is still in the "not too bad for amateurs" category.

I decidedly used 1/10th mass of NaOH to PET ratio because I was also curious whether it would transesterify or hydrolize the PET. I thought that

1/10th mass may mean "catalytic ammount", although it may be a bit overkill for that purpose due to the very different molar masses. Next time I will

use less. :-)

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Actually Pumukli, if the precipitate melts easily and cleanly I think that's good evidence that its the methyl ester, if it melt with difficulty and

decomposition then you have probably got the Na salt. I did some experiments with transesterification of phthalate esters some time back and it may be

worth looking at:

http://www.sciencemadness.org/talk/viewthread.php?tid=23943#...

In this thread Nicodem posted an interesting reference in German that I have yet to try which is a sort of transesterification in the presence of urea

to get phthalimide from phthalate esters. The idea has now occurred to me that this might be another route to terephthalamide via a similar route

directly from PET.

I did some reading into transesterification in biodiesel production at that time and you are right that you only need trace amounts of strong base.

This is the nice'n easy to follow home recipe, it formed the basis of my experiments in the referenced thread:

Attachment: Transesterification - Make Biodiesel (online) A M Helmensteine 2013.docx (68kB)

This file has been downloaded 610 times

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Yesterday evening I filtered the precipitate from the PET-slices - methanol mixture becasue it was hard to see if it was still forming or the reaction

ended.

Filtering was a pain.

I have only a glass fritt filter which fits my vacuum bottle and although the filtrate was crystal clear but the filtering took ages (well, more

minutes than I expected or wanted to waste on this thing). I got a nice, voluminous white precipitate.

I checked its water solubility. Based on that what I got is not the transesterified PET but the hydrolized terephtalic acid sodium salt. :-( It

dissolves in water fairly well and upon acidification with 2N HCl it immediately gives a dense, white precipitate. (Terephtalic acid)

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@Pumukli, it does sound like you got hydrolysis rather than transesterification. I wonder if it is possible to transesterify a polymer? I thought I

had a paper specifically about transesterification of PET in methanol but i can't find it and I can't find any other applicable examples. There are

several patents from various countries about a similar process but most seem to use high temperature and therefore pressures rather than a catalyst.

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

I agree, I could find only high temperature / high pressure methods for transesterification.

This low-temp method for hydrolysis is also not too good, I found a patent which uses fairly strong (approx. 90%) sulfuric acid for hydrolysis and

according to that paper it takes around 10 minutes when PET is boiled in that acid. (Although it may take longer with pet slices instead of granules.)

|

|

|

Texium

|

Thread Split

12-5-2016 at 06:06 |

Romix

Hazard to Others (Literally)

Posts: 483

Registered: 19-6-2015

Member Is Offline

Mood: No Mood

|

|

What are decomposition products of Terephthalic acid?

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@Romix, can you be more specific. Decompose under what conditions? It is remarkably stable but thermal decomposition of the silver salt has been

referenced above, I suggest you check out the reference. The whole essence of this thread is the conversion of terephthalic acid into other compounds,

any of these reaction may be deemed a decomposition by some.

|

|

|

Eddygp

National Hazard

Posts: 858

Registered: 31-3-2012

Location: University of York, UK

Member Is Offline

Mood: Organometallic

|

|

Has the product been identified as terephthalamide? As in, has anyone actually checked IR, NMR or at least melting point?

there may be bugs in gfind

[ˌɛdidʒiˈpiː] IPA pronunciation for my Username |

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Hi Eddygp, I don't have access to IR or NMR so no, The melting point is higher than I can measure (about 280 C). For various reasons I think that the

terephthalamide is impure and contains a significant amount of short chain partial hydrolysis products. I intend to test this idea in the near future

as part of my on-going work on terephthalic acid derivatives. I have observed that these partial hydrolysis products are suceptable to further

hydrolysis giving a mixture of terephthalic acid and its monoamide and hope to be able to test the amount of each but I am still working on way to

separate the two acids.

|

|

|

Eddygp

National Hazard

Posts: 858

Registered: 31-3-2012

Location: University of York, UK

Member Is Offline

Mood: Organometallic

|

|

Quote: Originally posted by Boffis  | | Hi Eddygp, I don't have access to IR or NMR so no, The melting point is higher than I can measure (about 280 C). For various reasons I think that the

terephthalamide is impure and contains a significant amount of short chain partial hydrolysis products. I intend to test this idea in the near future

as part of my on-going work on terephthalic acid derivatives. I have observed that these partial hydrolysis products are suceptable to further

hydrolysis giving a mixture of terephthalic acid and its monoamide and hope to be able to test the amount of each but I am still working on way to

separate the two acids. |

Good. I'm trying to come up with an old school way to quantify the amount of terephthalic acid/monoamide there.

Maybe a reaction with the carboxylic acid taking advantage of its more reactive nature, to then quantify the amount of reagent that reacted away and

give an estimate of the total number of carboxylic acid groups... oh well, this is when you realise how much merit the work of pre-IR/NMR/MS/...

chemists has!

there may be bugs in gfind

[ˌɛdidʒiˈpiː] IPA pronunciation for my Username |

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Boffis  | Halogen in his post of 24-9-15 above suggested that the amide may contain short chain oligomers capped with ammonia (he means amide groups I presume).

I think this is probably very likely but I couldn't see how to test it at the time. Having thought about it further and in the light of my results

trying to test for amides with sodium hydroxide I think that one way to test it may be to heat some of the "amide" with strong (say 15-20%) aqueous

ammonia to about 100 C in my newly acquired autoclave for 10-15 minutes. My idea is that the pure amide is rather resistant to further hydrolysis by

ammonia but any uncleaved ester linkages will hydrolyse, some to amides and some to the ammonium salt, the latter are water soluble so the presence of

water soluble ammonia salts in the aqueous phase is indicative of unhydrolysed ester linkages, ie there are residual oligomers.

|

I have now done some more experiments on the ammoniolysis products of PET plastic and it is fairly clear that hydrolysis is incomplete even in the

alkali soluble fractions. I carried out the tests by reacting the various materials with 28% ammonia solution in my 50ml autoclave for an hour or so

at about 100 C. The resulting solutions were acidified and the acid filtered off. A small, accurately weighed, sample of the dried acid was dissolved

in a known volume of standard 0.2M sodium hydroxide (actually 0.2025M) and the excess alkali titrated against standard hydrochloric acid.

The white acid recovered from the large scale ammoniolysis experiment described above had a neutralization value that fell outside that of a mixture

of terephthalic acid and its monoamide, almost certainly due to the presence of partial hydrolysis products. After "pressure cooking" with ammonia

solution this value fell within the range for a mixture of terephthalic acid and its monoamide. In fact the results would appear to indicate that the

new product is about 92% terephthalic acid monoamide and about 8% free terephthalic acid.

A similar experiment was carried out on the "terephthalamide" counterpart and after pressure cooking for an hour the ammonia soluble fraction was

filtered off, acidified and filtered. The insoluble acid was subjected to analysis as described above and gave 83.7% terephthalic monoamide and 16.3%

terephthalic acid.

The direct pressure cooking of new PET chips with excess ammonia solution under the same conditions resulted in only partial hydrolysis but the

ammonia soluble portion gave 93.2% terephthalic monoamide and 6.8% free acid.

|

|

|

| Pages:

1

2

3

4

5 |