| Pages:

1

2

3

4

5

..

7 |

FrankRizzo

Hazard to Others

Posts: 204

Registered: 9-2-2004

Member Is Offline

Mood: No Mood

|

|

US line voltage is supposed to be 115V@60Hz, but it can vary within +/- 5-6%. The monitoring software for the UPS connected to my PC is saying the

input voltage is currently 121V.

[Edited on 30-12-2004 by FrankRizzo]

|

|

|

rift valley

Hazard to Others

Posts: 103

Registered: 24-7-2004

Location: NH

Member Is Offline

Mood: semiconducting

|

|

Well my birthday is next week and since I don't trust my knowledge of electrics I bought a nice little power regulator, for eighty bucks. I know

it isn't in the spirit of science madness, but I am afraid starting an electrical fire, or getting electrocuted. The Kanthal D wire is on its

way, I already have the refractory, all I need is some tubing and a container. Speaking of which would anyone have any ingenious ideas for a

container, I think I might just use metal ducting intended for a home furnace. Midterms next week, to bad I have a feeling that I won't be

studying

P.S. Axehandle have you only used your furnace for the melting of metal, or have you used it for any experiments. Recently I have been thinking that

an electrical furnace would be perfect for a phosphorus synth. or will it not get hot enough?

|

|

|

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

| Quote: |

P.S. Axehandle have you only used your furnace for the melting of metal, or have you used it for any experiments.

|

I've molten KCl in it, and tried converting NaHSO<SUB>4</SUB> to

Na<SUB>2</SUB>S<SUB>2</SUB>O<SUB>7</SUB>. In the latter case I "overcooked" it, making a small cloud of

SO<SUB>3</SUB> which made me flee in terror... it's not easy maintaining an exact temperature without a thermostat, heh.

EDIT: Btw, rift valley, do you have a link to some info about the power controller you've ordered?

PS

I think it's "madscience" enough building your own furnace from almost scratch, without building the power controller yourself. Even I,

reckless as I am, would hesitate to construct the power controller myself. There are so many things that could go wrong, and it's better IMHO to

use an off-the-shelf power controller rather than to roll your own and then having to babysit the furnace for every second while it's in use...

[Edited on 2005-1-8 by axehandle]

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

rift valley

Hazard to Others

Posts: 103

Registered: 24-7-2004

Location: NH

Member Is Offline

Mood: semiconducting

|

|

http://www.heatersplus.com/18tbp.htm This is the model I bought, but it is more expensive on this website, I found it for like $82. I am very

pleased with the unit so far. It is smaller then I expected (6x6 cm). I do need to rig a heat sink for it or put a CPU fan on it. I of course bought

the 120 volt model.

|

|

|

jimwig

Hazard to Others

Posts: 215

Registered: 17-5-2003

Location: the sunny south

Member Is Offline

Mood: No Mood

|

|

try to think of a temperature controller (like Redlion) using a thermocouple.

they are digital and control and programming are great.

i think K type TC are good to 1800F.

[Edited on 8-1-2005 by jimwig]

|

|

|

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

rift valley, that power controller looks very good, even having a dial going from 0 to 100. I have to make something similar for my power controller

From the specs it seems to be good up to 15A. Just as you said, adding a fan in addition to the built-in heatsink is probably necessary, especially

since you're going to use it at the top of its rating, I believe you mentioned 14A at 110V.

Please tell us of your progress with the furnace ---- it's very interesting, and although the web has lots of pictures and plans of and for home

built furnaces, they are typically all gas fired.

Incidentally, I'm in the "acquiring parts stage" for another, <b>much</b> bigger electrical furnace. It will be capable of

melting aluminum, brass, silver, zink etcetera, firing pottery and serving as muffle furnace for chemical processes. Perhaps cooking pot roasts as

well, although that might be overkill. This time I got some off-the-shelf industrial grade insulation, a 7 meter roll of SuperWool 607 ceramic blanket

(less unhealthy alternative to Kaowool, specs at http://www.607max.com).

I intend to include a thermostat this time. The thermocouple won't be cheap though *shudder*.

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

evilgecko

Harmless

Posts: 36

Registered: 2-1-2005

Member Is Offline

Mood: Decomposing

|

|

Oh man I can only get 10A from sockets over here, and I learnt that the hard way. Still, 10A would be enough to melt aluminium wouldn't it?

|

|

|

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

The temperature of the furnace chamber isn't limited by the current but by the temperature of the heating coil. A very thin heating wire will

become yellow hot with a small current, a thicker will require a higher current for the same temperature.

The main factor is the refractory. As long as the power dissipation through the refractory remains below the power input of the heater, the furnace

chamber will -- eventually - reach the same temperature as that of the heating coil.

All else being equal, a higher current will allow you to melt a batch faster than with a lower current, there are no other differences. If you have

two coils, one with R1=25Ω and the other with R2=50Ω, the coils will reach the same temperature, but coil 1 will consume twice as much power

as coil 2.

EDIT: A good analogy would be a water boiler. Two water boilers, one 1000W and one 2000W, will both heat water to 100 degrees C, but the 2kW once will

make it boil in half the time it will take the 1kW one.

[Edited on 2005-1-8 by axehandle]

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

evilgecko

Harmless

Posts: 36

Registered: 2-1-2005

Member Is Offline

Mood: Decomposing

|

|

Aaaaaaaaahhhhhhhhh...I get it know. Hmmmm...now of hunting for a cheap power regulator.

|

|

|

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

| Quote: |

Oh man I can only get 10A from sockets over here

...

|

The stove in the apartment/house is probably hooked up to its own, separate 16A fuse. I know mine is, at least. You may be able to steal power from

it, although you'll probably be unable to cook while using the furnace.

On a side note, and yes, I'm blabbering -- I may just have located a source for Kanthal-A1 wire. Maximum temp 1400C as opposed to 1300 for

Kanthal-D. Could be useful... although the thinnest one they carry is 1.1mm. Incidentally, if max current is 9A, and the coil diameter is 8mm, the

number of turns needed is, according to my calculations, 666 (!). Weird. Get it? 666. Fire. Hell. Pretty funny.

[Edited on 2005-1-10 by axehandle]

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

evilgecko

Harmless

Posts: 36

Registered: 2-1-2005

Member Is Offline

Mood: Decomposing

|

|

Axehandle I think that wire must be made for you. Or maybe its a omen warning you against using it? Ok this ain't a phycoligy (sp,sp,sp) forum.

Back on track. I don't think my parents would like me mucking around with the oven, but yes, it has a 15A fuse instead of 10A. It also has huge

wires coming out of it.

|

|

|

rift valley

Hazard to Others

Posts: 103

Registered: 24-7-2004

Location: NH

Member Is Offline

Mood: semiconducting

|

|

My wire finally arrived, technically its for my birthday (tomarrow) but I managed to cut off a little piece to test it out. My mom thinks I ask for

the oddest things for my birthday, "What do you need all that wire for? You're not making a bomb are you?" I swear sentence my mom

speaks to me ends with "You're not making a bomb are you?" I got close to five hundred feet of the wire so I think that I'm set

for now. (If any members want a piece send me a U2U) Here are a couple of pictures.

|

|

|

rift valley

Hazard to Others

Posts: 103

Registered: 24-7-2004

Location: NH

Member Is Offline

Mood: semiconducting

|

|

Is it possible to place more then one attachment on to a post? Here is the other photograph.

EDIT: just got into college, now I can abandon school work and focus on this project

[Edited on 12-1-2005 by rift valley]

|

|

|

rift valley

Hazard to Others

Posts: 103

Registered: 24-7-2004

Location: NH

Member Is Offline

Mood: semiconducting

|

|

Here is my long overdue electrical resistance furnace. The first thing I noticed is how much easier this furnace it to operate then my old POS

charcoal blast furnace. I would like to thank Axehandle, his furnace was a great model to build off of. Also the refractory composisition was

fantastic to work with (Silica sand, Portland cement, Perlite and bentonite clay). Thank you also for helping me along with the electrical aspect

since I have never been taught any of the electrical laws. The pictures might be a little decieving since there is nothing to guage the size of the

furnace with. It is a rather small furnace about 15 inches tall, the body is made out of two 5 quart cans for painting I found at home depot. My only

regret is that I made the lid a little too thick IMO but that is just a little detail. It is surprising how efficent this furnace it, it helps that

the air/gases are not constantly being replaced like in a propane/charcoal furnace. If I grow some balls maybe I will attempt some phosphorus

extraction ideas that I have been having. The winters are long in New England so I really will not be able to give this thing a run for its money

until spring comes, although I could run this indoors but I don't want to burn my house down (had a close call once but thats a different story).

Well I'm babbeling again so I'll just show you the pictures.

This is just a picture of the completed system as a whole

I ripped the guts out of the power controller I bought and created a new housing for it with a fan (although at this time it isn't powered)

This is the inside of the beast, when drying it out i got some cracks but fortunatly they did not seem to weaken the structure that much.

Is this what hell looks like? Just a picture of the furnace when its heated up. I melted a piece of copper in it so I know it gets up to at least

1100C/2000F unfortunatly I didn't take a picture because I was afraid of frying my dads camera, I wish I did though it looked mean.

Thanks again Axehandle and the whole sciencemadness community, if it wasn't for this website I'd still be the kewl I once was.

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

Nice work!

How did your furnace look after your first run? Many cracks? How long did it take to take on red heat inside, i.e. the the walls of the furnace inside

would glow?

Re. the copper - did it truly melt, or just become soft? Where did you place it inside the furnace? I am wondering due to my own experiences, it would

have to be white heat inside (correct me if wrong) for it to reach 1100 deg C. In the pic it didnt look like it though

I am just curious because with my charcoal i did melt stainless steel, but only in small places, and only when it directly contacted the brightly

white glowing coal, but not elsewhere.

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

rift valley

Hazard to Others

Posts: 103

Registered: 24-7-2004

Location: NH

Member Is Offline

Mood: semiconducting

|

|

Thanks, that picture posted is not of the furnace when I was melting the copper, I'm not positive how long it took to get up to melting temp

because I just cranked it up to like 90% and came back like 1/2-1 hour later and put a little snippet of copper pipe through the top hole the furnace

was at a yellowish/white heat it was an amazing sight. It turned out not to be the smartest thing to do because without the little fan working my

controller got hot but luckily it is very cold outside so nothing bad happened. As soon as I get the fan powered I will redo a small copper melt and

take plenty of pictures. If you managed to melt stainless steel copper should be a breeze (unless the alloying metals drop the melting point

drastically in SS) Currently the cracks are miniscule and if they worsen i will buy some ceramic coating for them (ITC-100 perhaps) but it sells for

like 50 bucks per pint, but on the plus side it reflects something like 98% of the heat allowing the furnace to come to heat much faster. Once I get

the cooling sorted out for my electrical controller I'll post some more pics.

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

Or make your own ITC 100 type stuff.

I was doing I bit of reseach on it- it uses zirconia, but zircon might work also and it is cheap from the pottery store. I'll post more info if

anyone is interested.

So this was using axehandle's mix with portland cement etc and there was no fluxing/melting/glazing of the refractory on the inside, even at

yellow/white temps?

|

|

|

BrAiNFeVeR

Harmless

Posts: 42

Registered: 23-5-2002

Location: Belgium

Member Is Offline

Mood: busy

|

|

I going to make my own heating applications after these 2 wonderfull examples of what experimentialism can accomplish.

In place of spending alot of hard earned cash on an expensive power regulator, I made my own. Capable of regulating 16 Amperes (3.5 KW on 240 V), it

will suffice for most things.

It can be made with under 10€ electronic parts.

Schematic:

First tests with it seem very promising.

A RBF heating mantle will be my first project

|

|

|

BrAiNFeVeR

Harmless

Posts: 42

Registered: 23-5-2002

Location: Belgium

Member Is Offline

Mood: busy

|

|

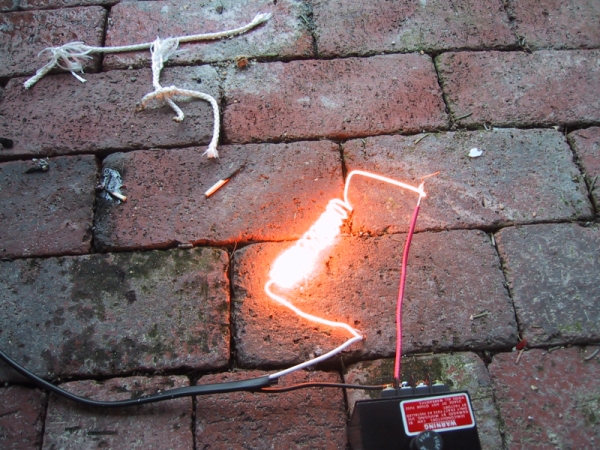

An action shot of the above construction:

Notice the old cpu cooler the BT139 triac is mounted on.

The setup is mounted on a simple piece of wood now, but this is only to show the simplicity and size of the cirquit.

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

And the BR100 and BT139 thyristors (??) are some we can buy from any electronics supply?

Just to point out, www.conrad.de sells power regulators for cheap too. But I like the idea of making one yourself. Nonetheless, I think the ultimate quest of making

your own electrical furnace is that of ensuring proper insulation, proper heat-wire selection, and proper design. Not to put you down at all - please

understand that priorities in this forum lie within the chemistry, material chemistry, and so on; rather than electrics and electronics, or

electrotechnics.

Please post though where you get those thyristors from (just searched Conrad, but couldnt find them). It's definitley cheaper than buying a

full-scale power regulator altogether.

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

BrAiNFeVeR

Harmless

Posts: 42

Registered: 23-5-2002

Location: Belgium

Member Is Offline

Mood: busy

|

|

Any electronics shop should have these components.

I got mine from a Velleman shop.

Most components are dirt cheap (a few cents), only the printboard, variable resistor and BT139 triac where a bit more expensive.

About €3 for the print, €2 for the varistor and €2 for the triac. The rest of the part cost is less then €1.

The complexity for the scheme is low enough to be feasable to make for amateurs in the electronic science, and can (as you see) make a big difference

in price.

Money that could be better spent on some quality glassware

|

|

|

BrAiNFeVeR

Harmless

Posts: 42

Registered: 23-5-2002

Location: Belgium

Member Is Offline

Mood: busy

|

|

Conrad has them too:

Clicky: conrad site BT139

Though they are more expensive then the shop I went to ...

Datasheets can be found on Datasheetarchive.

[Edited on 5-3-2005 by BrAiNFeVeR]

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

I have been thinking of building a small furnace recently. I got this (to state what it says on the case) "variable transformer" that

weighs around 15 lbs out of my university junkheap. It is rated for an input of 120V and an output of 0-140V at 7.5 A. It has an 8A fuse built in. I

tested it on a lamp and it works to dim it(just checking to make sure it is still operable). Will this work as a power regulator for a small furnace?

If it does then by v=IR, R=V/I=140V/7.5A (am I using the right amperage here? the rated one of the supply and not what the electrical 120V line is

rated for?) R=18.6666666ohms needed in the coil.

Assuming 0.5410mm kanthal D wire resistance is 5.8936 ohms per meter, then I need 3.17m of wire.

Of course I could use much less wire if I wanted a very small "furnace" for the heating of a small crucible, and just never turn the power

relulator to full, right? Just never exceed a maximum voltage on the regulator based on calculations from the length of the wire?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Your calculation and assumptions seem right to me, although I have never built a furnace. The max power would be 7.5 x 140 = 1050w. Does that agree

with the nameplate max wattage?

I believe for most wires resistance goes up with temperature so a cold wire should draw the most amps & power.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Mr. Wizard

International Hazard

Posts: 1042

Registered: 30-3-2003

Member Is Offline

Mood: No Mood

|

|

The variable autotransformer is also called a variactor, and they were very popular before solid state controllers, and switching power supplies

became cheap and popular. The weak link in the variactor is the limit on how many watts you can pull out of it, and the sliding contact may get hot,

burned or otherwise screwed up, especially under heavy loads; like furnace heating elements. Keep your nose near the unit and if it starts to smell

hot, turn it off. The solid state stuff is really better for this. If you use a variable auto transformer, don't use it near it's upper

power limit. I have a 5KW unit as big as a car wheel, and someone had toasted the sliding contacts before I got it!

|

|

|

| Pages:

1

2

3

4

5

..

7 |