| Pages:

1

2

3

..

7 |

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

Electrical Furnace Contruction - My design and implementation

I made a new topic because the old, "Metal melting <b>propane</b> furnace contruction" didn't fit anymore after I decided

to fork it by going electrical and thereby avoid the hassles of propane.

The furnace is finished, and here is the preliminary contruction log:

http://species8472.dyndns.org/tools/el_furnace/el_furnace.ht...

This topic is a continuation of the thread

http://www.sciencemadness.org/talk/viewthread.php?tid=1968

Edit1: Woot! Look at this glory hole, this is HELLFIRE!!!!! :

[Edited on 2004-6-16 by axehandle]

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

nice!

That furnace light is awesome! It looks like white heat. Do you have an estimate of your maximum temperature? Also, do have a way of regulating the

temperature? It seems this might well be used as a muffle furnace as well as a foundry implement.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Esplosivo

Hazard to Others

Posts: 491

Registered: 7-2-2004

Location: Mediterranean

Member Is Offline

Mood: Quantized

|

|

Congratulations axehandle! Just wanted to ask, have you any idea on what is the power consumption of your furnace? Thanks.

Theory guides, experiment decides.

|

|

|

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

It's adjustable from 0 to 15A, using 220V AC. The power regulator can be seen in the contruction log, you lazy bastard...

The current coil (which I'll replace with one with lower resistance once I hotwire the power supply to the stove) has a resistance of 27 ohm.

Using U=IR, that gives a maximum current of 8.7A. Using P=UI, that gives Pmax=1914W.

I don't think I've exceeded 6..7A in the dehydration step.

The maximum temperature should be close to the maximum temperature of the heating wire, 1300 degrees C, about 100 degrees lower than the MP of iron.

Edit1: As soon as I can afford a Pt/Rh thermocouple, I'll build a temperature display + thermostat circuit for integration.

[Edited on 2004-6-17 by axehandle]

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

At what temperature does it have a resistance of 27 Ohms?

|

|

|

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

At room temperature, at it's maximum allowed working temperature, 1300 degrees C, the resistance is approximately 1.08 times the room temperature

resistance.

The wire is designed to deviate very little in resistance, regardless of the temperature.

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

rikkitikkitavi

Hazard to Others

Posts: 192

Registered: 17-6-2002

Member Is Offline

Mood: No Mood

|

|

I think you will have problems with teh electrical connection to the wire-electrodes since the latter will oxidize heavily at 1000 C.

all electrical ovens I have seen the wire is connected externaly , i e the wire continues out through the oven wall. By spiraling the wire inside,

and keeping a straight wire as a connector heatload will be less on the straight wire part, so that it will not be so hot (i e white hot)

I will try to take some pics of my 2,7 kW electrical oven, if I can borrow a camera.

otherwise I have to practise my Paintskillz...

/rickard

|

|

|

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

Good idea, I didn't know that. If the connections fail, I can simple yank out the electrodes and do like you described.

Here is an interesting picture of a clay pot I fired in the furnace yesterday. It doesn't look very artistic, but that's beside the point.

The point is that this particular clay is a white-burning one that is fired at 1200..1250 degrees C, and that it's, well, fired  . It has turned white, and goes *clink* *clink* like porcelain when I knock on it. . It has turned white, and goes *clink* *clink* like porcelain when I knock on it.

Tonight, I will melt some brass in it.

[Edited on 2004-6-18 by axehandle]

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

Molten Al

Some scrap Al in a pot, slowly cooling down... beautiful.

[Edited on 2004-7-13 by axehandle]

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

Saerynide

National Hazard

Posts: 954

Registered: 17-11-2003

Location: The Void

Member Is Offline

Mood: Ionic

|

|

I thought molten aluminum doesnt change colour and stays metallic silver

"Microsoft reserves the right at all times to monitor communications on the Service and disclose any information Microsoft deems necessary to...

satisfy any applicable law, regulation or legal process"

|

|

|

Nick F

Hazard to Others

Posts: 439

Registered: 7-9-2002

Member Is Offline

Mood: No Mood

|

|

All objects that are at the same temperature emit the same light.

Whether or not the molten Al is silvery, or bright orange, or whatever, depends on how hot it is.

That's looking pretty nice btw. I'm going to have to hurry up and get what I need for insulation, so I can document my metal melting

microwave furnace!

[Edited on 13-7-2004 by Nick F]

|

|

|

Nevermore

Hazard to Others

Posts: 140

Registered: 3-5-2003

Location: China at the moment

Member Is Offline

Mood: shopping businessman

|

|

| Quote: | Originally posted by axehandle

At room temperature, at it's maximum allowed working temperature, 1300 degrees C, the resistance is approximately 1.08 times the room temperature

resistance.

The wire is designed to deviate very little in resistance, regardless of the temperature. |

axehandle did u think about using an electromagnetic device to raise the temp up to melting iron? I've made a small device that by magnetic

coupling brings a cutter to red heat in a couple of seconds.

If u can realize in bigger and use the coil to preheat the mix could be great..however i think that molten iron won't react anymore with the

magnetic field.

Nevermore!

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

Are you talking about an induction furnace? I read somewhere that with a bare 15kW one could achieve temperatures of 3400 deg C!

Yes, I was thinking this would make an interesting project

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

Axehandle, are you using that clay crucible you described earlier? How is it holding up? I have a vague distrust of porcelain, and metal casting

books say that fireclay crucibles (similar to what you are using) will not stand up to repeated uses in a furnace.

Nick F, pretty soon we are going to need a category just for furnaces.

|

|

|

Nevermore

Hazard to Others

Posts: 140

Registered: 3-5-2003

Location: China at the moment

Member Is Offline

Mood: shopping businessman

|

|

| Quote: | Originally posted by chemoleo

Are you talking about an induction furnace? I read somewhere that with a bare 15kW one could achieve temperatures of 3400 deg C!

Yes, I was thinking this would make an interesting project

|

yes i made an induction furnace, but the power i have is small, around 200W, enuf to bring a cutter blade to glow red, but can't go more..so the

piece should be preheated, and the induction assembly should be pumped up at least to 700-900W..

Nevermore!

|

|

|

IvX

Hazard to Others

Posts: 112

Registered: 14-4-2004

Member Is Offline

Mood: No Mood

|

|

Very true about the fire clay, had some bad experiance in my attempt at making a metal copper laser.First few runs the (induction)furnace did'nt

have enough power to vaporise the copper and then it cracked and started a nasty fire killing one crow(just as well though since at that time I

did'nt know yet how to discharge into the plasma  ) )

[Edited on 23-7-2004 by IvX]

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

How did the fire kill a crow? Do you mean a crow as in a bird? I must be

missing something. I must be

missing something.

I need a crucible for my furnace, and my thought is that if I use an iron pipe and endcap, it will melt under the heat, if I use fireclay/ any other

kind of clay, it will crack at high temperatures, and I cannot use a SiC or C crucible, that would not be DIY. Ok, I might have to if there are no other options. Ok, I might have to if there are no other options.

By the way, charcoal furnaces burn coals, coals are partially graphite. Graphite crucibles are graphite. Why will the crucible not burn?

Maybe the fireclay binder helps. Aha, to make a graphite crucible could I just mix fireclay and graphite dust? That is too easy!

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

Nevermore would you like to post your design on your induction furnace?

Who knows this maybe warrants a new thread... we should then have nearly all types of furnaces covered

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

IvX

Hazard to Others

Posts: 112

Registered: 14-4-2004

Member Is Offline

Mood: No Mood

|

|

Yes it was a bird(started a not-so-small fire-the crow must have been old anyway  ). ).

Nice idea about your crucible unless the graphite/charcoal cathces fire.

|

|

|

Nevermore

Hazard to Others

Posts: 140

Registered: 3-5-2003

Location: China at the moment

Member Is Offline

Mood: shopping businessman

|

|

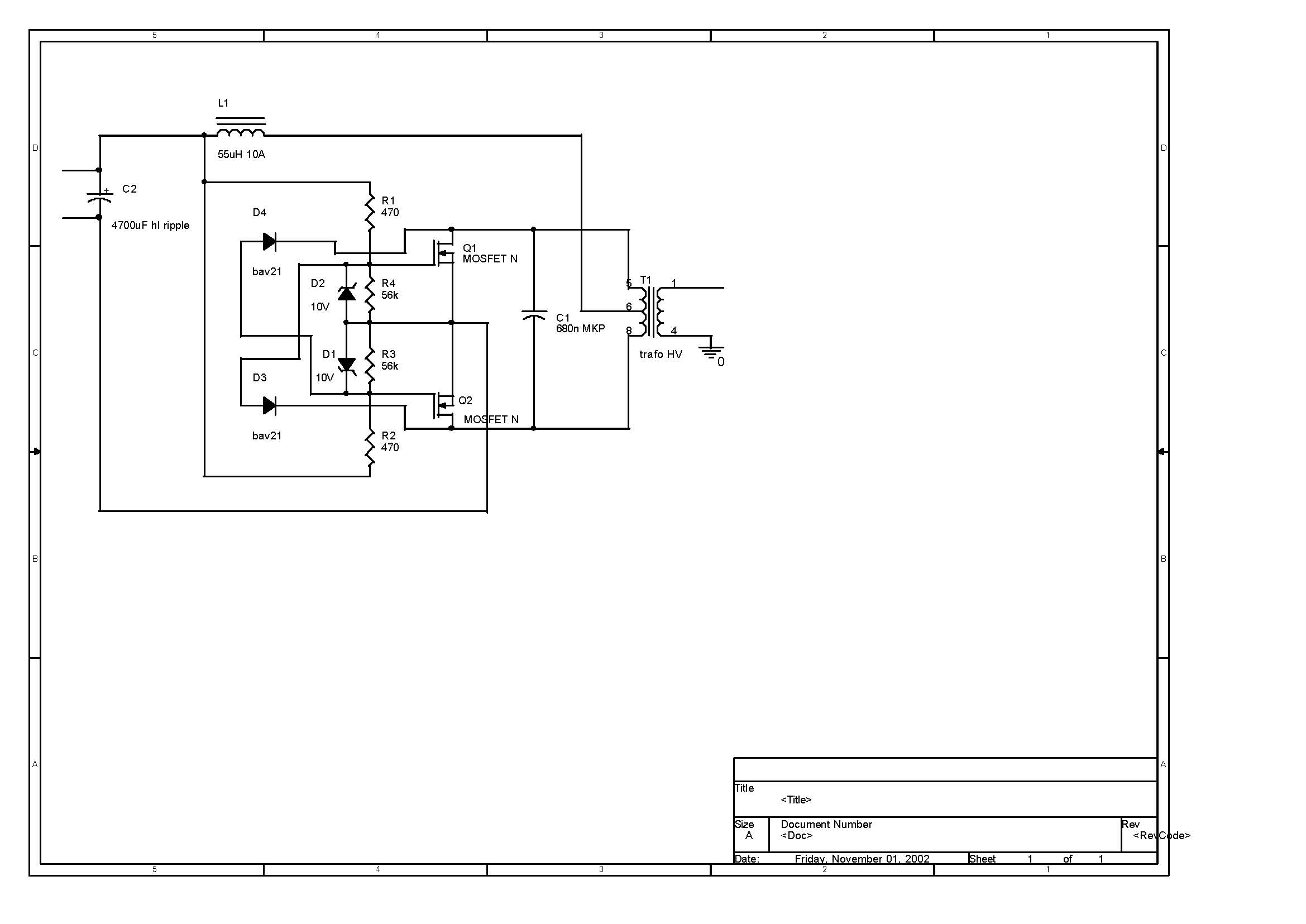

ok here it is the design circuit, on the left you should put the power supply, DC from 12 to 30V at least capable of giving out 20A, the T1 should be

removed and on its place two coils of thich copper wire should be used, i used 5 rounds of 4mm copper on a diameter of 10cm, the thightest the better

but then the mosfet will start to get too hot and eventually die, also care that the magnetic dipole generated are opposite (that means if you make a

coil turning on the right, the second should be turning on the left), that's it..the connection from mosfet to the capacitor MKP should be as

short as possible also the connection to the induction coil should be short too. the induction coil should be put on top of each other, even better

if they are winded together in order to concentrate the magnetic field.

If well made it drains lotsa power from the power supply BUT the mosfet remains almost cold, if they get hot something is wrong!

the circuit was not made by me, the original idea is of Vlad Mazzilli.

This circuit can use also IGBT, that will make peak current far higher, so more power, but the oscillating freq will drop alot with them, so still

need to be tested (should be VERY effective too and also more reliable).

I have this circuit in working order right now, so if there is any prob ask me and i'll tell you what's wrong.

Nevermore!

|

|

|

Nevermore

Hazard to Others

Posts: 140

Registered: 3-5-2003

Location: China at the moment

Member Is Offline

Mood: shopping businessman

|

|

| Quote: | Originally posted by Cyrus

How did the fire kill a crow? Do you mean a crow as in a bird? I must be

missing something. I must be

missing something.

I need a crucible for my furnace, and my thought is that if I use an iron pipe and endcap, it will melt under the heat, if I use fireclay/ any other

kind of clay, it will crack at high temperatures, and I cannot use a SiC or C crucible, that would not be DIY. Ok, I might have to if there are no other options. Ok, I might have to if there are no other options.

By the way, charcoal furnaces burn coals, coals are partially graphite. Graphite crucibles are graphite. Why will the crucible not burn?

Maybe the fireclay binder helps. Aha, to make a graphite crucible could I just mix fireclay and graphite dust? That is too easy!

|

did u try using porcelain?

a coffee cup (the small one) should make an excellent job, remember the thinner the better, since is less likely there is air bubbles trapped in

Nevermore!

|

|

|

IvX

Hazard to Others

Posts: 112

Registered: 14-4-2004

Member Is Offline

Mood: No Mood

|

|

Found a link about how steel is madeLink: It's about how steel is made in a factory.

|

|

|

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

| Quote: |

Axehandle, are you using that clay crucible you described earlier? How is it holding up? I have a vague distrust of porcelain, and metal casting books

say that fireclay crucibles (similar to what you are using) will not stand up to repeated uses in a furnace.

|

I've only used it a couple of times, for "test melts". As far as I can see, it's holding up. I fired it before using it, first at

approx. 400C for a couple of hours, then for approx. 4 hours at about 1100C. It goes "clink clink" like porcelain when I knock it. It's

made from a fine-grained expensive kaolin-containing white burning clay I got at my trusty pottery supplier -- definitely not flower pot clay!

| Quote: |

Maybe the fireclay binder helps. Aha, to make a graphite crucible could I just mix fireclay and graphite dust? That is too easy!

|

Make a crucible out of pure platinum. It will last forever.

(Has anyone noticed that I have a particular fondness for Pt?)

[Edited on 2004-7-24 by axehandle]

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

Nevermore, I thought about subjecting one of my tea cups/mugs to 1500C, but I have 3 objections.

1- I'm not that mean, I like my porcelainware in one piece.

2-If that actually works, why don't any books/websites/etc. say "instead of buying a $50 SiC crucible, you can use a tea cup" ?

3- If you look closely, the things crack after a while, just from coffee and tea, let alone molten aluminum.

I have never tried though, have you?

Axehandle, thanks for the suggestion about Pt. You are very helpful. Let me hack up one of my Pt bricks and melt it in my furnace and crucible so

that I can cast it into a crucible.  Nobody has noticed that you have a fetish

for metals, notably Pt. Not at all. Nobody has noticed that you have a fetish

for metals, notably Pt. Not at all.

I just got some fireclay and some firebrick sealant to seal all of the cracks in my furnace.

Does anyone know why graphite crucibles don't burn?

According to a foundry book I read, the graphite/fireclay crucibles CANNOT be made at home. That makes me all the more determined.

|

|

|

Nevermore

Hazard to Others

Posts: 140

Registered: 3-5-2003

Location: China at the moment

Member Is Offline

Mood: shopping businessman

|

|

hello, pure porcelain and thin should rexist up to molten al temp..a mug is not good for that, is not porcelain and is not thin at all, porcelain is

white and transparent so that u can see the shadow of ur hand behind..

i have tried to melt low temp metals, such as bismuth and lead..

but i used a very good quality china porcelain, thin around 2mm and very transparent, vitreous i must say.

Nevermore!

|

|

|

| Pages:

1

2

3

..

7 |