| Pages:

1

2

3

4 |

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

Please remind me, wasn't there a thread recently with excellent pictures on some manganese oxide derivative, which was used for oxidative purposes?

I'll happily delete this post once it's clarified.

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by chemoleo

Please remind me, wasn't there a thread recently with excellent pictures on some manganese oxide derivative, which was used for oxidative purposes?

I'll happily delete this post once it's clarified. |

Yeah , the other manganic alum reducing reagent thread is

https://sciencemadness.org/talk/viewthread.php?tid=6882#pid7...

maybe even the threads should merge ?

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

Hilski, thanks first of all for your excellent contributions.

I merged this thread with the previous one on this matter.

Please send me a U2U if you aren't happy with the title.

I'd like to keep similar threads together because it will make searching for it so much easier, and it'll keep the forum more condensed.

PS Perhaps the info/pics on ammonium manganic alum should be written together for the pre-puplication forum?

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Just a bit of additional information which could be relevant and useful in strategies for original preparation of a manganic alum oxidation reagent ,

for adjustment / correction of the initial oxidation state , as well as an alternative chemical means for regeneration of

the spent reagent .

Potassium permanganate can be used to oxidize the

other manganous compounds present to the manganic

form . Of course by using additional manganate in the

form of permanganate , your quantity of regenerated

reagent will grow and accumulate . But this would provide a quick means of regeneration , in the case where time may be an issue and it is

inconvenient to wait for perhaps days for an electrolytic regeneration to complete .

The proportions would have to be worked out , as applies

to the manganous alums regeneration , and the additional materials of ammonium or potassium donors needed to maintain the alum composition for the

reagent ,

producible by such a chemical regeneration via permanganate .

Attached is a patent which shows how this proceeds

in the preparation / regeneration of a similar manganic

oxidation reagent . This may be of interest and adaptable to the alums as well .

Attachment: US837777 Usefulness of Permanganate for regenerating Manganous to Manganic reagent.pdf (236kB)

This file has been downloaded 1304 times

|

|

|

Hilski

Hazard to Others

Posts: 197

Registered: 13-9-2006

Member Is Offline

Mood: No Mood

|

|

Thanks for that post, Roscoe.

I had been thinking about ways one could go about regenerating the oxidizer in a more expedient manner. KMNO4 had came to mind, but I have no idea

how to go about calculating proper proportions. I also wondered how adding another element (K) would effect the behavior of the oxidizer both during

the reaction with toluene, and during electrolytic regeneration.

Perhaps a small specific amount of the permanganate could be used in addition to the electrolytic process to say, cut regeneration times in half. I

also wonder if something like ammonium or potassium persulfate could be used to achieve the same results?

I guess seeing as how I already have about 2 liters of the alum prepared and fully functional, that I should be the one answering these questions

instead of asking them. But what fun is that?

\"They that can give up essential liberty

to obtain a little temporary safety

deserve neither liberty nor safety. \"

- Benjamin Franklin

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I have wondered if even hydrogen peroxide , or

perhaps acetone peroxide , or MEKP could be used for regeneration of the manganous alum to the manganic alum . It sure would save hours of

electrolysis to be able to stir in the stuff and boil off the inert byproduct .

Yeah I would think that the persulfates should also

work the same way with their respective potassium

or ammonium alums . You would have to keep an

inventory of your reaction mixture content with the

desired proportions of the respective ions , and

work out the amounts of what you add during regeneration , so that you keep the composition

of the reagent consistent with its proper stoichiometric proportions for the desired alum formation .

I haven't done the math , so I am not sure how the

numbers crunch on this idea ....it just looked like an

interesting possibility , particularly on the initial formulation of the potassium alum ....it looked like

that making the reagent in the manganic form ready

for use without electrolyzing for the first run , could

be done by forming some of the potassium sulfate and

manganic sulfate content from potassium permanganate

plus H2SO4 , eliminating or reducing the need for the

electrolysis . I think there is even some surplus oxidizing

capability there for oxidizing the bulk manganous sulfate

to the manganic state . So it appeared to be a way of shortcutting the workup for the initial alum ....if nothing else . What would be the economy

of this as compared

with just using electrolysis alone on the manganous sulfate alum is another matter which could make it not worthwhile .

BTW I found an analogous process is possible for chromium also , as is used here for manganese compounds ....but of course the chromium reagent

would be a way more expensive method .

I am still inclined to believe that the ferrous salt and

its alums would also work for this process , and also

other polyvalent metal salts .....although my interest

would be focused on the cheap ones like manganese

and iron

|

|

|

Organikum

resurrected

Posts: 2342

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

Vanadium is told to work with H2O2 even in situ with no need for transferring something from one cell to another. The article should be in the toluene

to b-dehyde thread.

/ORG

|

|

|

Hilski

Hazard to Others

Posts: 197

Registered: 13-9-2006

Member Is Offline

Mood: No Mood

|

|

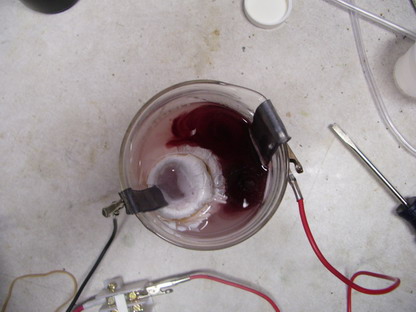

I guess all in all, passing current through a non-divided cell for 24 hours isn't really all that bad. Unless one needs to regenerate the oxidizer

like RIGHT NOW, then there just isn't a more economical way to do so. Here are a couple of pictures of the electrolytic cell regenerating the MAA

recently. 4 amps have been passing through the cell for about 10-12 hours in the photos. I think it was still needing about 10-12 more to be fully

regenerated. You can see the large quantity of yellow precipitate (MAS) still sitting at the bottom of the jar. This is because I have crammed so

much oxidizer into this jar with not enough acid that the mag stirrer has a hard time keeping it all in suspension. A little poking around with a

glass rod gets everything mixed up again though, so it really isn't a problem. If you look at the second picture, you can see a brown substance

floating on top, in the center of the jar. This is mostly benzoic acid floating on top of the saturated acid solution. It is due to left over

toluene and/or benzaldehyde from a previous reaction. It's hard to get every last little bit of organic material out of the mix, but it really

doesn't affect anything. It just smells REALLY strong once too much builds up in the cell.

| Quote: | Vanadium is told to work with H2O2 even in situ with no need for transferring something from one cell to another. The article should be in the toluene

to b-dehyde thread.

/ORG

|

I recall seeing something about venadium sulfate (I think) being used for this purpose with H2O2. Not having to transfer anything back and forth is

always a plus. That's one reason I like this MAA oxidizer so much. Once the oxidation is complete, and the aldehyde has been extracted, just drop in

two electrodes and turn on the PSU. No membrane, or other special apparatus required.

[Edited on 26-1-2007 by Hilski]

\"They that can give up essential liberty

to obtain a little temporary safety

deserve neither liberty nor safety. \"

- Benjamin Franklin

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

@Organikum

As I think I understand this process so far .....

That patent which I posted above , US837777 , is directly related .....but superior to

the " neograviton method " which you posted early on the Benzaldehyde from Toluene thread .

The earlier patent US780404 , by the same inventor Max Bazlen , is a patent which you listed among others in the other thread . The yield of

benzaldehyde from toluene by oxidation with manganese (IV) sulfate , manganese persulfate , is reported as nearly quantitative , which generally means

>95% , with no byproduct benzoic acid

from any overoxidation .

The subsequent patent US837777 simply advances the

same process using Potassium Permanganate for generating the dark brown colored

Manganese ( IV ) "per"sulfate , Mg(SO4)2 .

The (IV) valency variant is a yet still more active oxidizer than the also useful *green* colored Manganese ( III ) analogue , or Mangan " ic "

Sulfate , Mg2(SO4)3 .

Reduction of the (IV) and/or the (III) compound during oxidation of toluene to benzaldehyde produces

the fully reduced Manganese ( II ) Mangan " ous " Sulfate , MgSO4 as the spent reagent , which is regenerated ,

by electrolytic oxidation , stepped back up to its (III) and

further to its original (IV) oxidation state for reuse .

CRC gives a range of colorations from pink through red for the ( II ) manganous sulfates depending upon the level of hydration , including the alum

with ammonium sulfate , which BTW is a hexahydrate .

Oxidation to the ( III ) state is described as producing a

green color for the pure manganese(III) or mangan" ic "

sulfate .

I am thinking that the mixing of the green in with the incompletely regenerated red is what gives the darkening towards brown .....it could even pass

through a tar black color first and then lighten slightly to more distinct brown for the final transition to the brown coloration of the manganese (

IV ) sulfate , manganese persulfate . IIRC the persulfate is only quasi-stable and only in a range of fairly concentrated H2SO4 .

Anyway I suppose the advantage realized for any

"hyper-regeneration" being applied chemically using permanganate , or perhaps peroxide if possible , or by electrolysis of the manganic sulfate to

the even higher (IV) persulfate is that an additional amount of toluene may be converted to benzaldehyde by the same quantity of Manganese ion present

, if its oxidation state is at maximum , which is the persulfate .

I haven't gone back and checked the details on the

regenerations by electrolysis which have been pictured

and described , to see if anyone allowed the regeneration

to keep running longer than required to produce the pink

or red material , even where the alum double salt is being

used ......to see if it will continue to oxidize further to the

solid brown color as would indicate the persulfate .

Edit: I just went back and reviewed this thread , and it looks like the ammonium alum manganese sulfate follows the US808095 patent description

nicely , with regards to color

changes , and other details . Whether or not the yield or

the volume efficiency for this method could be improved by running the regeneration electrolysis longer , might be a worthwhile experiment . It might

be necessary to have some

additional amount of manganese sulfate present which is

beyond that amount which will form the alum in combination with the ammonium sulfate present . The alum itself may be limiting with respect to

formation of the persulfate .....and

of course the acid concentration would have to be within the allowable range also in order to permit its formation from

any added time of electrolysis . Color change and gas evolution from the anode would tell the tale on whether

this effort is worthwhile , along with of course comparison of the yield and how much toluene may be reacted with a given quantity of the regenerated

oxidation reagent .

But the typical yield for the alum Mn(III) process is 80% , compared with >95% reported for the non-alum Mn(IV)

process , which should also have a better volume yield ,

although it would depend on the volume of acid ( I haven't checked this to be sure ) . So it would seem that using the

Bazlen patent method based on the Mn (IV) sulfate would be superior .

Quantitative yield is as good as it gets

[Edited on 26-1-2007 by Rosco Bodine]

|

|

|

Hilski

Hazard to Others

Posts: 197

Registered: 13-9-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | to see if anyone allowed the regeneration

to keep running longer than required to produce the pink

or red material , even where the alum double salt is being

used ......to see if it will continue to oxidize further to the

solid brown color as would indicate the persulfate . |

I have let it go longer than required, and a brownish solution does result, although I didn't know why the brown color was present. I haven't

distilled the the aldehyde from the reaction with the brown(ish) oxidizer yet, so I don't know how it might have affected yields.

\"They that can give up essential liberty

to obtain a little temporary safety

deserve neither liberty nor safety. \"

- Benjamin Franklin

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The brown material is precisely what you want for maximum yield . And you can use more toluene

also .....I haven't done the math , but offhand

maybe 50% more toluene per reaction with the same amount of " hyper" regenerated brown reagent ....

I'll have to check the math on this to be certain .

Attached is the original Bazlen patent US780404

concerning near quantitative yield of benzaldehyde from toluene via oxidation by manganese (IV) sulfate ,

manganese persulfate , which may be regenerated

by electrolysis .

[Edited on 27-1-2007 by Rosco Bodine]

Attachment: US780404 Manganic(IV) Sulfate electrolysis regenerated.pdf (173kB)

This file has been downloaded 1530 times

|

|

|

Hilski

Hazard to Others

Posts: 197

Registered: 13-9-2006

Member Is Offline

Mood: No Mood

|

|

Some experiments

As I mentioned in another thread, I would like to set up a functional electrolytic cell that would produce Manganese(IV) sulfate aka (MnSO4)2 from

MnSO4 in 55% H2SO4. I loosely followed the guidelines from This Patent to know what reagents/ratios etc to use. Also, one of my goals was to find out whether Tyvek (a commonly available material

manufactured by Dupont) would make a sufficient membrane for a divided electrolytic cell. The following are some details and a few pictures of what

I've come up with so far.

Chemicals and materials:

Anolyte:

MnSO4 - 50 grams disolved in 504 grams H2SO4 (55%)

Catholyte:

55% H2SO4

Cell construction:

Cathode compartment: A small HDPE container with holes drilled in the sides. Inside the HDPE container is placed a Tyvek bag which acts as a

microporous membrane to allow for ion echange. The cathode is 0.5 inches wide X 6 inches long and is made of lead sheet. The compartment is filled

with 55% H2SO4 and placed inside the glass beaker which will serve as the anode compartment.

Anode compartment: A 600ml Kimax beaker was used as the anode compartment. A lead anode, 1 inch wide X 6 inches long was placed in the compartment

along with a solution of 50 grams MnSO4 dissolved in 504 grams 55%H2SO4. This compartment is where (hopefully) a solution of Manganese(IV) sulfate

will be produced electrolytically.

The empty cell:

The cell after the pink MnSO4/H2SO4 solution has been added:

I hooked up the computer power supply I used for this project, and set the voltage to 5 volts. I chose this voltage because it's what I had used in

the past to regenerate the manganous ammonium alum, and it has worked well. I switched on the power, and a dark red color, similar to that of the

aforementioned alum, poured off of the anode.

I didn't use any kind of magnetic or mechanical stirring for this project, but if I decide to scale it up, I will definately add that to make the

process a lot faster and more efficient. For this small cell I just used a glass rod to stir things up occasionally.

Here is the cell after about 10 minutes:

And again at about 1 hour:

After about an hour and a half, the solution in the cell had turned a very dark, opaque burgundy color and didn't appear to be making any further

progress. I checked the current and saw that it was only pulling about 1.5 amps, and was generating almost no heat at all. So at that point I

decided to switch from 5 volts to 12 to see if that made a difference. Immediately upon switching on the 12 volt power, a brown color was generated

at the anode, along with more vigorous oxygen production. The hydrogen evolution at the cathode was enough that it started splashing the catholyte

out of the compartment. I also noticed the the cell started to heat up a good bit (as expected) and the current draw shot up to over 6 amps.

Note the brown color starting to form around the anode

At that point, I decided to place a 50 watt DC lightbulb in series with the cell to help control the current. As of now, the cell is pulling about 3

amps, and gas evolution is not nearly as bad as it was before. There doesn't seem to be nearly as much heat produced as before either.

The cell has been running for a couple of hours now, and as soon as there has been significant change (or lack thereof) I will update the post with

further results. At this point, I am optimistic that Tyvek does indeed make for a suitable membrane for divided electrolytic cells.

UPDATE:

At about the 3 hour mark I went to check on the cell and found what appears to be a successful experiment. Even with no stirring, the contents of the

anode compartment were a deep brown, almost black color. The heat in the cell was a lot lower than I expected, less than 40C for sure. Now I just

need to figure out exactly how long to this thing go to get 100% conversion to the persulfate.

Here are some links to high res copies of the last 3 images. The small ones are a little hard to see.

http://www.sciencemadness.org/scipics//Hilski/persulfate_cel...

http://www.sciencemadness.org/scipics//Hilski/persulfate_cel...

http://www.sciencemadness.org/scipics//Hilski/persulfate_cel...

Questions, comments or suggestions about any of this are welcome. Ideas for scaling up would be great as well.

-Hilski

[Edited on 1-2-2007 by Hilski]

\"They that can give up essential liberty

to obtain a little temporary safety

deserve neither liberty nor safety. \"

- Benjamin Franklin

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

That flouropolymer braid fly line would probably be good for lacing the tyvek snugly around the top of a wide mouth bottle ....but there is another

idea that may be better .

Get one of those clear polyethylene food storage cylinders that has the snap on poly lid and test it to

see if you put a sheet of tyvek across the top and

depress some slack in the middle of it , if the lid

will still snap down into place , sandwiching the

tyvek in the seal groove in the lid and securing it

in place . The tyvek will probably wrinkle a bit ,

but if the sealing groove in the lid will seat over the

tyvek , and secure it in place .....then you can use

the lid as a retaining ring to secure the tyvek liner

bag to the rim of the container . You can take a

razor knife or boxcutter and cut a big hole in the

lid , but leave the outside perimeter intact for use

as a retaining ring . Some dots of hotmelt glue might work for securing the tyvek to the inside of the storage cylinder . Leave slack in the tyvek

where it loops

over the sealing edge , so that when you seat the ring it doesn't pull the liner taught and pop it loose . If you

make the lead cathode cylindrical , maybe 1/4 to 1/3

the diameter of the inside of the catholyte compartment would be about right , bubbles will have room to escape

without the foam climbing the inside of the tyvek . A plastic trivet like they use in the bottom of those lettuce keepers would make a good bottom

spacer , or just use

another smaller diameter plastic lid on which to rest the bottom of the cathode , bore holes in it too if you like .

Heavy solid copper wire could probably be used to make

a tripod suspension bridle for the cathode and catholyte

compartment , hanging it from a suspension harness as if it were an ornamental hanging basket planter . I would

form a ring of the solid wire all the way around the plastic

rim of the container underneath that stiffening ridge and

make attachment loops to that wire ring , rather than

just going through small holes made in the plastic .....

because that plastic softens and weakens when it gets hot , and the attachment points might stretch and tear loose .

You could do a similar thing with some polyethylene

braided cord if you can find some small enough diameter

to work with .

Another strategy is heat welding .....tyvek could stick very

well to the rim of a polyethylene container which was gently

melted at the edge , just to the point of inflammation then quickly blown out like a candle , the tyvek pressed quickly

and firmly against the melt as it solidifies . Or just the hot

tip of a soldering iron might be used to " spot weld " the

tyvek at points like a dotted line , to " stitch " it to the

rim of the container . Poking holes through with a hot

nail and actually stitching it with a sailmakers needle

and the fluropolymer line is another option for lashing it down

to the rim of the cathode compartment . Slippery stuff to

handle , but there's a few ways of managing it .

[Edited on 1-2-2007 by Rosco Bodine]

|

|

|

Hilski

Hazard to Others

Posts: 197

Registered: 13-9-2006

Member Is Offline

Mood: No Mood

|

|

Those are all good ideas, and the type of thing I would need to address if scaling up. But one thing I would like to try is eliminating the plastic

cathode container altogether. I want to make sort of a sleeve to put the cathode in that is tall enough to cover most the cathode and that has enough

volume to hold enough catholyte to keep the cathode mostly covered all the time. Then, after filling the pouch with the 55% H2SO4 solution, I would

use a zip tie to secure the top of the pouch around the top of the cathode to attach the tyvek in place directly to the cathode.

If I do end up using a plastic container, another thing I had though about was to use one of those tall, flat HDPE bottles that hand lotions and

shower gel etc come in. The bottles are tall enough to be able line with tyvek and fit a large cathode in. But they are flat enough not to take up

too much space when stood upright inside a larger glass or plastic container, in an arrangement similar to what I used in my small scale experiment.

\"They that can give up essential liberty

to obtain a little temporary safety

deserve neither liberty nor safety. \"

- Benjamin Franklin

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I definitely believe you should have some sort of rigid

compartment to keep everything positioned coaxially ,

so that hydrogen gas evolution from the cathode can

be managed smoothly , without " gurgling " and splashing .

Those red plastic press on cover " coffee cans " that

13 ounces of coffee is sold , are HDPE , 4" diameter

and about 5" tall might make a good compartment .

Something smaller in diameter and taller form cylinder

would be like a shampoo bottle . But the more narrow

and tall the container , the more of a geyser of liquid

will be carried up by the hydrogen bubbles , so your choice is going to set a limit on the current you can

manage .

|

|

|

Hilski

Hazard to Others

Posts: 197

Registered: 13-9-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Those red plastic press on cover " coffee cans " that

13 ounces of coffee is sold , are HDPE , 4" diameter

and about 5" tall might make a good compartment . |

My thoughts exactly. I just salvaged one of those from the pantry. You are right about the bubbling and foaming being worse with a narrower

container, but I want to be able to accomplish effective stirring within the anode compartment, which the cathode compartment will be sitting in. So

unless I use a pretty large container for the anode compartment (like an 8 or 12 liter plastic bucket) then I need to keep the cathode compartment as

small as I can. Using a plastic bucket for this would be great, except for the fact that I have no way of heating the contents of said bucket to 50C

for the actual toluene oxidation. I could transfer the persulfate solution to the 2 liter glass jar like I use for the alum, and heat it the same

way, but it would be nice not to have to transfer the solution around if I don't need to.

Thanks for the suggestions.

Hilski

\"They that can give up essential liberty

to obtain a little temporary safety

deserve neither liberty nor safety. \"

- Benjamin Franklin

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

It would probably be better to put the tyvek around the *outside* of the perforated plastic form , as opposed to

having it inside like a liner bag . I just think that using

the rigid compartment as an inner form around which the

tyvek is stretched .....would simplify things greatly all around .....instead of " all inside "

This would definitely be a better arrangement with the smaller diameter cathode compartments .

Since this is the cathode also , a carbon rod or a piece of

copper or stainless rod or pipe might work fine , as no worries about oxidation and the hydrogen blanket on the surface should provide a lot of "

anti-erosion " by " cathodic protection " .

[Edited on 1-2-2007 by Rosco Bodine]

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Maybe one of these would work:

http://www.maycocolors.com/shapes/shapeDetails.cfm?shape=101...

Low fired porous ceramic bisque.

|

|

|

moxsnixs

Harmless

Posts: 6

Registered: 9-2-2007

Member Is Offline

Mood: No Mood

|

|

In cycloknights original post he reacted MnO2 with HCL then with H2SO4 to get MnSO4. Anyone have a more detailed procedure?

|

|

|

jimmyboy

Hazard to Others

Posts: 235

Registered: 1-3-2004

Location: Texas

Member Is Offline

Mood: No Mood

|

|

So overall - what is the best method - opinions? toluene/persulfate or reflux/oxidation of cinnamaldehyde - this is abit more involved but not too

hard - some manganese - electrodes - power supply - it looks like you really need that stirbar - actually the supplies are easier to get - you have to

look a little for cinnamon oil - i am just looking at it from a yield standpoint

|

|

|

Hilski

Hazard to Others

Posts: 197

Registered: 13-9-2006

Member Is Offline

Mood: No Mood

|

|

Unless huge quantities are needed, oxidation of toluene by manganese compounds would be the simplest, cheapest and most OTC in my opinion. I have

never tried the cinnamon oil route, due to the fact that the stuff is actually more expensive than just buying benzaldehyde. A one gallon container

will easily hold enough oxidizer/H2SO4 to produce 200g or more of benzaldehyde or benzoic acid, formaldehyde, formic acid, acetaldehyde (maybe) etc.

| Quote: | | In cycloknights original post he reacted MnO2 with HCL then with H2SO4 to get MnSO4. Anyone have a more detailed procedure? |

Although making the MnSO4 from MnO2 isn't hard, it is much better to just order some fertilizer grade MnSO4 from the net. (NH4)SO4 can be found

cheaply and in large quantities in any decent garden center or nursery supply type store.

Here is a thread that goes into detail on some different methods for making MnSO4

https://sciencemadness.org/talk/viewthread.php?tid=6777#pid7...

[Edited on 10-2-2007 by Hilski]

\"They that can give up essential liberty

to obtain a little temporary safety

deserve neither liberty nor safety. \"

- Benjamin Franklin

|

|

|

moxsnixs

Harmless

Posts: 6

Registered: 9-2-2007

Member Is Offline

Mood: No Mood

|

|

OK thanks I added the Na2CO3 and got the MnCO3 but the final step with H2SO4 wasnt really hit on. Do you add it to the MnCO3 or filter the MnCO3 and

add it to that?

I would buy it but not in the USA and to buy it here requires a 3hr drive one way, get a hotel room then try to find where its sold.So making it

would save alot of BS .Thanks

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by moxsnixs

OK thanks I added the Na2CO3 and got the MnCO3 but the final step with H2SO4 wasnt really hit on. Do you add it to the MnCO3 or filter the MnCO3 and

add it to that?

I would buy it but not in the USA and to buy it here requires a 3hr drive one way, get a hotel room then try to find where its sold.So making it

would save alot of BS .Thanks |

Wash the MnCO3by to get rid of all the sodium salts, cover with water, and slowly add H2SO4 with stirring. Might be best to pre-dilution the sulfuric

acid if its concentrated. You want enough water to dissolve the MnSO4 formed.

If you don't protect the wet MnCO3 from air it will be oxidised and turn dark. Not a big deal if you're make the Mn(3+)-alum from it.

If your MnO2 wasn't pure, or if your HCl has iron in it, it might be best to set aside about a tenth of the MnCO3. Add just enough acid to the

remaining 90% to get it into solution, you'll not want an excess. Bring it to a gentle boil to drive off CO2, cool to it's just warm, add the

remaining MnCO3 with stirring, continue to stir and bring to a boil for a minute or two. Then let it cool, filter off the precipitate which is MnCO3,

iron carbonates/hydroxides, and hydrated oxides of manganese in 3+ and 4+ oxidation state.

|

|

|

moxsnixs

Harmless

Posts: 6

Registered: 9-2-2007

Member Is Offline

Mood: No Mood

|

|

And then evap the MnSO4 solution to obtain the powder correct? because I did and got a faitly pink\white powder

|

|

|

Hilski

Hazard to Others

Posts: 197

Registered: 13-9-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | | And then evap the MnSO4 solution to obtain the powder correct? because I did and got a faitly pink\white powder |

Correct.

Just FYI MnSO4 can be found on ebay. I think I remember seeing it sold for use on palm trees or something similar.

\"They that can give up essential liberty

to obtain a little temporary safety

deserve neither liberty nor safety. \"

- Benjamin Franklin

|

|

|

| Pages:

1

2

3

4 |