| Pages:

1

2

3

4

..

18 |

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by MineMan  | Yes Xeon. Right up against the gloves. 75mg blows through 2 layers...

For the ematch why not dip it in nitrocellulose and primary mix? Say 15NC 70NiAgKCLO4, 15 Ammonium perchlorate.

|

that's exactly what is don, first dip is that, second and third are re-enforcing coatings to immobilize the bridge wire and prevent damage for hard

packed dets

Only mine is Lead styphnate befor that was Mercury fulminate

https://www.google.com/url?sa=t&rct=j&q=&esrc=s&...

[Edited on 23-3-2019 by XeonTheMGPony]

|

|

|

FeedMe94

Hazard to Self

Posts: 87

Registered: 1-4-2017

Member Is Offline

Mood: No Mood

|

|

I want to use my det caps as boosters too. Will this do the job ? 0.7 cast ETN, 0.3 hand pressed ETN and 100mg SADS

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

I've never bothered to cast, just press the ETN and go. but that should work.

[Edited on 27-3-2019 by XeonTheMGPony]

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by FeedMe94  | | I want to use my det caps as boosters too. Will this do the job ? 0.7 cast ETN, 0.3 hand pressed ETN and 100mg SADS |

That'll do the job just fine.

I suppose some people would say that 100mg SADS is overkill but... why be cheap ?

I thought hand pressed on top of melt cast ETN was a good idea until I saw some tests where loose ETN failed to initiate while melt cast did initiate

with the same amount of primary. These tests stand against every other publication on the subject, stand against common sense and intuition too so

dont take my word for it.

|

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

Hand pressed ETN goes easily to 0.85 g/cm3 and hence about 70 kbar. 1 g of 70 kbar material will initiate anything that will detonate just from a

blasting cap, provided that the BC material is not more than 3 mm thick in case of plastic or 1 mm in case of aluminium.

Extra high densities (pressing, melting) are just a game- Sure, it is nice - it saves material and it might - from time to time - mean a success

where u'd fail with hand pressed ETN.... but that is rare

Press it inside a blast mittigation device - like my bucket and wear protection.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

3mm steel plate.

1g hand pressed ETN

0.5g Mercury fulminate/ Potassium Chlorate 80/20

a dash of lead styphnate as a flame catcher (I've used Nitro Cotton in the past for this function)

Tube is sealed with glue impregnated tissue paper, then above that is crimped when the glue has set.

7mm OD 6.5mm ID, by 50mm length, 4.8 grams total assembly weight. End is sealed with a drip of Nitro Lacquer

[Edited on 28-3-2019 by XeonTheMGPony]

|

|

|

FeedMe94

Hazard to Self

Posts: 87

Registered: 1-4-2017

Member Is Offline

Mood: No Mood

|

|

Good looking detonator and works perfect. Is it arduino sensor casing ?

|

|

|

FeedMe94

Hazard to Self

Posts: 87

Registered: 1-4-2017

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Rocinante  | Hand pressed ETN goes easily to 0.85 g/cm3 and hence about 70 kbar. 1 g of 70 kbar material will initiate anything that will detonate just from a

blasting cap, provided that the BC material is not more than 3 mm thick in case of plastic or 1 mm in case of aluminium.

Extra high densities (pressing, melting) are just a game- Sure, it is nice - it saves material and it might - from time to time - mean a success

where u'd fail with hand pressed ETN.... but that is rare

Press it inside a blast mittigation device - like my bucket and wear protection. |

Thank you for the info. Will it be better to add some PETN at the bottom and then some hand pressed ETN ?

Also whats a blast mittigation device?

|

|

|

FeedMe94

Hazard to Self

Posts: 87

Registered: 1-4-2017

Member Is Offline

Mood: No Mood

|

|

Wiki says that density of ETN is 1.72g / cm3 and

PETN 1.77g/cm3. That means i can fill 1.5g per cm3 easily ?

|

|

|

underground

National Hazard

Posts: 702

Registered: 10-10-2013

Location: Europe

Member Is Offline

|

|

Quote: Originally posted by FeedMe94  | Wiki says that density of ETN is 1.72g / cm3 and

PETN 1.77g/cm3. That means i can fill 1.5g per cm3 easily ? |

Yea

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by FeedMe94  | Wiki says that density of ETN is 1.72g / cm3 and

PETN 1.77g/cm3. That means i can fill 1.5g per cm3 easily ? |

Not easily and please DO NOT start forcing it! The density values stated in Wiki are pretty much the maximum that can be achieved and to reach them an

enormous pressing force has to be applied.

Shooting for 1,0-1,3g/cm3 is excellent for starters, as far as any practical purposes are concerned.

Keep safe!

Exact science is a figment of imagination.......

|

|

|

FeedMe94

Hazard to Self

Posts: 87

Registered: 1-4-2017

Member Is Offline

Mood: No Mood

|

|

Thank you for that info. My casings are 6*50mm. For primary i have SADS and secondary i have ETN and PETN. Any advices or tips for how to do it ?

My fuse is visco

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

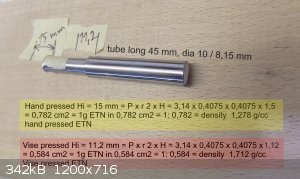

CHP - ETN

According this test is possible go to on density 1,7 g/cc in the vise. Enormous pressing force was 150 - 200 Kg in described cavity.

For hand pressing was use about 30 - 40 Kg on density 1,3 g/cc.

Others values in the pictures..... ...LL ...LL

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

7mm chromed brass hobby tube, it is hard to find where I moved to, so am running out, but on AliExpress I found thermal wells that are near identical

but better. they're sealed at the end and stainless steel

Can make nice commercial quality hermetically sealed dets.

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

How many manipulations with your hands close to the det when you:

- Melt cast ETN

- Pour and press repeatedly

So no, it's not just a game. Obviously there is less danger if you boil a glass of water and suspend your det in in that ramming powder in increments.

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Hey. What kind of glue to you all use to seal your caps?? I bought like 4 different kinds. My goal was to find a thick clear gel glue that would dry

rubbery like a glue gun. I would use a glue gun but it dries before it goes below the fuse.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

https://www.ebay.ca/itm/5-pcs-OD-6mm-OD-7mm-OD-8mm-SS304-The...

I use a good quality wood glue, no need to go all fancy. Weld bond is a good one.

I all so used 2 part epoxy for the ones I intended for under water stuff, using sand as a filler, after it is set I crimped to comperes seal it on top

of the epoxy bond.

For the lower seal (Providing you care fully test for comparability) is Tissue paper and super glue for a fast seal, then a wood glue on top of it.

Other wise epoxy is a solid go to.

[Edited on 29-3-2019 by XeonTheMGPony]

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Ok I fabricated a simple primary pellet press to demonstrate.

When the pellet is placed over the base charge is when the cap is truly armed

Bore is 5mm deep by 4.5mm od, with the ejection pin it is 4.5mm deep.

The ID of the paper cartridge is 4mm, and will hold 200mg of Mercury fulminate/chlorate mix, and is made with standard printer paper.

A small bit of parchment paper can make a end cap on the under side (Ejection pin surface)

[Edited on 31-3-2019 by XeonTheMGPony]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

When I see fulminate and its pressing, my hair gets up in horror. Well, what. We all need our dose of adrenaline..... ...LL ...LL

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

Very nice Xeon !

The pellet looks very sturdy. Any idea on the pressure applied ? Did you use a binder ?

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

It is bound in the paper tube, I hand pres lightly then do a final tamp with a hammer and machined pressing mandrel, few taps safely compresses it

down solidly (Holding the mandrel remotely so fingers are not over it), no binders. You must use at minimum 2 layers of paper on the side to

facilitate safe ejection

It is carefully cleaned between each operation to remove any lose primary from every part of it!

it is quite safe, even if it goes off the mandrel will be shot away with moderate force and you get confetti (Risk goes up as less paper is used) mind

you I have yet to ever have it go off on me (Know what your primaries do, test test and test some more befor doing any thing with them)

An Arbour press is better but yet to get one, it is all so much safer with a proper press as one operation has much lower risk of one going off then

multiple pressing operations.

So first press all your base charges, then press your primary pellets, then when ready those are pressed over the base charge and continue down the

line

tools needed to make such a thing?, 2 drill bits, A drill press, 2 quality nails, a file, a drill, patience, and a fairly accurate means to measure.

Drill the guide hole as to accommodate the nails shaft that allows smooth movement, in the drill file down the head to a tight fit inside your chosen

tube id, and find a matching drill bit. make a means to limit the depth of the drill bore for this larger diameter, and make a second drill hole.

Smooth out all edges high grit count sand paper does this nicely. File a matching nail to the ID of the paper carrier shell and don (Again ensure this

is nicely smoothed as well sharp edges are risks.

Brass is the best body material due to non sparking nature and is self lubricating to a degree but steel can be used, just implement more

precautionary measures.

[Edited on 1-4-2019 by XeonTheMGPony]

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by XeonTheMGPony  | It is bound in the paper tube, I hand pres lightly then do a final tamp with a hammer and machined pressing mandrel, few taps safely compresses it

down solidly (Holding the mandrel remotely so fingers are not over it), no binders. You must use at minimum 2 layers of paper on the side to

facilitate safe ejection

It is carefully cleaned between each operation to remove any lose primary from every part of it!

it is quite safe, even if it goes off the mandrel will be shot away with moderate force and you get confetti (Risk goes up as less paper is used) mind

you I have yet to ever have it go off on me (Know what your primaries do, test test and test some more befor doing any thing with them)

An Arbour press is better but yet to get one, it is all so much safer with a proper press as one operation has much lower risk of one going off then

multiple pressing operations.

So first press all your base charges, then press your primary pellets, then when ready those are pressed over the base charge and continue down the

line

tools needed to make such a thing?, 2 drill bits, A drill press, 2 quality nails, a file, a drill, patience, and a fairly accurate means to measure.

Drill the guide hole as to accommodate the nails shaft that allows smooth movement, in the drill file down the head to a tight fit inside your chosen

tube id, and find a matching drill bit. make a means to limit the depth of the drill bore for this larger diameter, and make a second drill hole.

Smooth out all edges high grit count sand paper does this nicely. File a matching nail to the ID of the paper carrier shell and don (Again ensure this

is nicely smoothed as well sharp edges are risks.

Brass is the best body material due to non sparking nature and is self lubricating to a degree but steel can be used, just implement more

precautionary measures.

[Edited on 1-4-2019 by XeonTheMGPony] |

Christ on a cross!! Hammering on primaries is really the last "best practices" approach that should be advertised publicly. Shock loads are the worst

kind of danger factor, even when supposedly dosed in a gentle manner. I'm sure you know your limits and the substances, but someone less experienced

may not and such practice should not be advocated as a viable approach regarding the topic at hand.

One can easily build a simple lever pressing device....out of wood for example. It takes no more than a saw, some drill bits, couple of bolts and

screws. And it can be adequately shielded by simple means. Something that is very unlikely to be achieved with the "tapping" method.

Exact science is a figment of imagination.......

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

My opinion is, using instead all metal parts hard wood. For example from the Beech. And using 2% oil + 2 % PIB as binder.... ...LL ...LL

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

twelti

Hazard to Others

Posts: 217

Registered: 20-2-2019

Member Is Offline

|

|

How does this pellet system work, I am not familiar. maybe a sketch?

[Edited on 2-4-2019 by twelti]

[Edited on 2-4-2019 by twelti]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Because pellet is preesed, create solid one part. This is advantage for next manipulation, inserting to cavity with low danger exces.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

| Pages:

1

2

3

4

..

18 |