| Pages:

1

2

3

..

18 |

twelti

Hazard to Others

Posts: 217

Registered: 20-2-2019

Member Is Offline

|

|

Det Cap Strategies

Having done a lot of reading here and elsewhere, a question arises. It seems there are two strategies for making caps. One is to use a primary that

needs confinement to achieve DDT. So, safer to work with before it goes into the detonator, but probably needs metal tube to work. The metal tube

isolates the primary and secondary (good) but would create shrapnel if it detonates prematurely (bad). Other way is to use a primary that does not

need (much) confinement. I have seen peroxide primaries put in straws for example, or maybe SADS, or the like. It is perhaps not as safe to work

with (all other things being equal), and less protected in the less rigid tube (bad), but would be less dangerous if it exploded (good). Is this a

correct assessment? Which way is safer overall?

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

type detonators

Table:

Low senzitive primary : manipulation, storage ..................+

...........................................filling.......................................+

.......................solid cavity + but production -.....................0

hard shrapnel .................................................................... -

High senzitive primary : manipulation, storage ................... -

filling.................................................................................... -

........................soft cavity - ......(production +)......................0

soft shrapnel............................... ........................................ +

Development of primarily - secondary substances: CHP (2015) neutral CHP and Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024) Diper

60 (2025)

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

The assessment is correct.

I'd follow LL's results.

|

|

|

Deathunter88

National Hazard

Posts: 545

Registered: 20-2-2015

Location: Beijing, China

Member Is Offline

Mood: No Mood

|

|

Keep in mind metal fragments are much easier to locate in the body than plastic pieces. (Not saying which one is better, just something to note.)

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

Critical and most worst operation is always filling and pressing. In this operation arises 90% incidents. Therefore is much better use low senzitive

materials. For example Tetraamine copper-hexamine perchlorate. (TeCHP or CHP marked ) Which is primary and secondary substance in one. With low

senzitive on the friction, but with high detonation pressure (20 - 25GPa) in solid cavity at density 1,8 g/cc or higher. On air only burn, but in

metal cavity goes into detonation. In paper or plast cavity not. But at slow heating in aluminium foil confinement, 5 layers, can cross to detonation

also. CHP is possible mixed in any ratio with ETN. For example 80:20 or 50 :50 or 25: 75. Results in solid cavity is always same. Full detonation.

Even 20 % of CHP can force full detonation on ETN. But only in solid cavity. Most easy for filling detronators is ration 50:50. For all segments. For

hogh pressed output segment and also for starting segments.

Development of primarily - secondary substances: CHP (2015) neutral CHP and Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024) Diper

60 (2025)

|

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

thin 0.3 - 0.5 mm aluminium is the 3rd option

overall, sturdy plastic or thin aluminium is the best option

thick metal walled detonators have only one real advantage - they are safe from friction induced detonation (pulling on the e-match cable)

|

|

|

XeonTheMGPony

International Hazard

Posts: 1641

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Why re-invent the wheel, industry standard practices, over 60,000,000 million made a year with very few if any defective units or detonations

unintended.

Do research, pick a form factor, make some basic tools and be don with it.

I use two standard of tubing, 7mm od 6.5mm ID or 6mm Od, and 5.5 ID

I get high quality nails, then lath them down to the size of the tube then a hair more to allow clearance and that has a paper spacer to ensure the

metal never makes contact to the tube.

Base charge is pressed in, primary charge is pressed into a solid paper tube that firmly fits in the tube, so on.

Very safe, very reliable, very simple, and each stage can be don on mass.

What gets you in danger is changing things up all the time, not having a solid system in place, and good job specific tooling, it doesn't need to be

fancy or high tech, it just need be made for the task at hand

|

|

|

MineMan

International Hazard

Posts: 1030

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

I know of no perfect system. If you can do what pyro guy says if you have paper tubes that fit in. But I don’t see how that works. Because you need

to seal the end of the paper tube, then the primary is not against the main attraction... the main charge. TBH it’s tuff. But I have some OCD so

nothing seems safe.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

Anyway, most researchers will still use straw and organic peroxide + ETN. And the safe and quality detonators still stay only in discuss on the

science madness.

Development of primarily - secondary substances: CHP (2015) neutral CHP and Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024) Diper

60 (2025)

|

|

|

underground

National Hazard

Posts: 715

Registered: 10-10-2013

Location: Europe

Member Is Offline

|

|

You can also construct an EBW device for safe detonations. Use the search engine and you will find lots of information.I am planning to built one in

the near future, i will post it on SM then i will finish it.

[Edited on 20-3-2019 by underground]

|

|

|

XeonTheMGPony

International Hazard

Posts: 1641

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

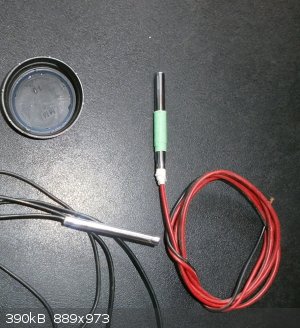

made entirely out of paper, was a test of concept

then my more standard units

|

|

|

XeonTheMGPony

International Hazard

Posts: 1641

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by MineMan  | | I know of no perfect system. If you can do what pyro guy says if you have paper tubes that fit in. But I don’t see how that works. Because you need

to seal the end of the paper tube, then the primary is not against the main attraction... the main charge. TBH it’s tuff. But I have some OCD so

nothing seems safe. |

the small paper tube for the primary is open at both ends it is only a confinement re enforcer and carrier for the primary, flame catcher mix, and

delay element if any

Parchment paper is used to prevent any sticking to the mold / press it does not interfere in any system thus far and if desired easily removed

Reason is the most dangerous part of the whole venture is compressing the azide/styphnate pellet, if it goes off you get paper confetti and some lead

vapor and odds are sore ears.

Once you have the primaries pressed, they can be placed in the tube, I usually put some loos main charge in, then press the assembly down, this forms

a perfect interface with a small amount of low density base charge to ensure full effective initiation.

the bridge wire is set in some wood dowel, the wires are glued in with wood glue after the resistance wire been attached (this rests in a cut groove

of the wood), once that assembly is dried, a low viscosity mixture of NC in Acetone with a priming mix added is dripped onto the bridge wire grove (I

have found with my formulation 3 drips is more then good enough to both glue every thing solid and ensure a powerful initiation flash

Back in the day this was Mercury Fulminate, in this decade it was HMTD, I am now going to be using Lead styphnate.

I'll stop befor this becomes a practical tutorial, but now you under stand how every stage is well divided, so any accident is unlikely and if one

does occur is well mitigated to a very small amount of working material

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

@MineMan: if I understand Xeon's idea correctly

1 Take your Al tube

2 Fill it with a secondary

3 Meanwhile find paper tubes that would fit snugly into you Al tube and cut them to the desired size so they hold the amount of primary you want

4 Fill those paper tubes with the primary and I suppose a binder

5 Drop 1 of these "primers" in your Al tube

6 Finish as usual & crimp

|

|

|

XeonTheMGPony

International Hazard

Posts: 1641

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Herr Haber  | @MineMan: if I understand Xeon's idea correctly

1 Take your Al tube

2 Fill it with a secondary

3 Meanwhile find paper tubes that would fit snugly into you Al tube and cut them to the desired size so they hold the amount of primary you want

4 Fill those paper tubes with the primary and I suppose a binder

5 Drop 1 of these "primers" in your Al tube

6 Finish as usual & crimp |

Correct, I wind my tubes to shape with normal printer paper that been soaked with watered down wood glue (Working on a better method as it gets

tedious)

The fit is very tight so they need to be pressed into the aluminium tube, so they stay put no glue needed, but a dash is recommended.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

@...XeonTheMGPony.... The last picture seems as good detonator for insert to any plast...Muhaha.... ...LL ...LL

Development of primarily - secondary substances: CHP (2015) neutral CHP and Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024) Diper

60 (2025)

|

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

This is the basic principle: keep your hands away from the explosive (applies to all types of blasting caps)

https://commons.wikimedia.org/wiki/File:TATP_blasting_cap_di...

https://commons.wikimedia.org/wiki/File:Blast_mittigation_de...

https://commons.wikimedia.org/wiki/File:Filling_blasting_cap...

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

I use better principle: Keep your the thinks away from HMTD and TATP.... -.....LL -.....LL

Development of primarily - secondary substances: CHP (2015) neutral CHP and Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024) Diper

60 (2025)

|

|

|

MineMan

International Hazard

Posts: 1030

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

I just don’t get how the primary does not fall out of the paper tube...

Anyways. With NiGKCLO4. I think one can just have 100mg of primary in a 2-3mm THIN Al tube. 100mg of 32GPa should do almost everything. You only need

to press one time. Just FYI. Test confirm these small caps destroy 2layers of steel Kevlar gloves. They dent a quarter too.

Just put it in a vice. And bingo. I thinks that’s the easiest safest way... if it goes you don’t have copper pieces that I have witnessed going

through a steel cooking pot!

|

|

|

Rocinante

Hazard to Others

Posts: 121

Registered: 13-11-2017

Member Is Offline

Mood: No Mood

|

|

"Test confirm these small caps destroy 2layers of steel Kevlar gloves."

In direct contact? If not, at what kind of distance?

As to my first post, you can use mineral wool if you like to mittigate the danger of delayed detonation due to burning wool (i.e. the e-match being

removed away from the primary filling by accident, igniting the wool but not the primary). Also, mark the the height of the tube on your e-match leads

so you can confirm that the e-match is making contact with the primary. .

Also, have a tried method for attaching a string to your blasting cap. That way you can topple your charge and pull out the blasting cap from safe

distance (30 m) in case of mis-fire.

"I use better principle: Keep your the thinks away from HMTD and TATP"

this principle applies to all primary explosives - lead azide, clathrates, acetylides...

You need a face shiled (use 3 layers of plastic - buy 3 face shields and join them). Kevlar/steel gloves or leather gloves (wear 2 pairs at the same

time), several layers of kevlar sleeves. ear plugs + ear muffs and serious body protection. Use serious bucket cover when working with metal tubes.

Also, use two trees to shield you from accidental blast when connecting the leads to your main loine or RF terminal - like this:

[Edited on 21-3-2019 by Rocinante]

Attachment: phpi1REt9 (21kB)

This file has been downloaded 1205 times

|

|

|

XeonTheMGPony

International Hazard

Posts: 1641

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by MineMan  | I just don’t get how the primary does not fall out of the paper tube...

Anyways. With NiGKCLO4. I think one can just have 100mg of primary in a 2-3mm THIN Al tube. 100mg of 32GPa should do almost everything. You only need

to press one time. Just FYI. Test confirm these small caps destroy 2layers of steel Kevlar gloves. They dent a quarter too.

Just put it in a vice. And bingo. I thinks that’s the easiest safest way... if it goes you don’t have copper pieces that I have witnessed going

through a steel cooking pot! |

Pressure lots and lots and lots of pressure, I have yet needed to use a binder but if one must there is a great deal to chose from.

Every thing starts at the ematch! So I'll start here

First pick is the lay out, the Nitro lacquer is at a runny viscosity so it will coat and excess will drip off leaving a nice film.

The Wire is 30 AWG NiChrome, the distance I have the lead wire set to will make a rather predictable 1.5Ohm +- .3ohm

this is dipped in the Nitro Lacquer, then dipped into the primary of choice, in this case it is lead styphnate

After which the first dip has fully dried continuity is checked by multimeter, if passed it then gets a second dip.

After it has fully dried it is again checked and dipped a 3rd time.

This does several things, it primes the wire with a pyrotechnical mix, it glues every thing together rock solid and protects the bridge wire during

handling.

After fully dried it is again checked for resistance and shape.

[Edited on 22-3-2019 by XeonTheMGPony]

This makes a very reliable and safe e-match that is quite durable and offers extremely reliable ignition as on firing you get flaming bits of nitro

cellulose shooting every where with a strong shock pulse from the Lead Styphnate.

Normally I mix the primary in with a thinner mix of Nitro Lacquer, but I need more wide mouth bottles to do it this way. When that is don it gets 3

primary dips, then 2 thicker Nitro Lacquer dips to seal and protect.

[Edited on 22-3-2019 by XeonTheMGPony]

|

|

|

twelti

Hazard to Others

Posts: 217

Registered: 20-2-2019

Member Is Offline

|

|

Quote: Originally posted by Laboratory of Liptakov  | CHP is possible mixed in any ratio with ETN. For example 80:20 or 50 :50 or 25: 75. Results in solid cavity is always same. Full detonation. Even 20

% of CHP can force full detonation on ETN. But only in solid cavity. Most easy for filling detronators is ration 50:50. For all segments. For hogh

pressed output segment and also for starting segments.

|

If the CHP is very good, what is the advantage of adding ETN?

|

|

|

twelti

Hazard to Others

Posts: 217

Registered: 20-2-2019

Member Is Offline

|

|

Quote: Originally posted by underground  | You can also construct an EBW device for safe detonations. Use the search engine and you will find lots of information.I am planning to built one in

the near future, i will post it on SM then i will finish it.

[Edited on 20-3-2019 by underground] |

I am very interested in that. i saw one one youtube (https://www.youtube.com/watch?v=o4KuD-c_gRY)

where he made a simple EBW and detonated ETN. It is ia bit dangerous in a different way, but maybe more predictable is you are well versed in

electrical engineering.

|

|

|

twelti

Hazard to Others

Posts: 217

Registered: 20-2-2019

Member Is Offline

|

|

Quote: Originally posted by underground  | You can also construct an EBW device for safe detonations. Use the search engine and you will find lots of information.I am planning to built one in

the near future, i will post it on SM then i will finish it.

[Edited on 20-3-2019 by underground] |

I am very interested in that. i saw one one youtube (https://www.youtube.com/watch?v=o4KuD-c_gRY)

where he made a simple EBW and detonated ETN. It is ia bit dangerous in a different way, but maybe more predictable is you are well versed in

electrical engineering.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

Quote: Originally posted by twelti  | Quote: Originally posted by Laboratory of Liptakov  | CHP is possible mixed in any ratio with ETN. For example 80:20 or 50 :50 or 25: 75. Results in solid cavity is always same. Full detonation. Even 20

% of CHP can force full detonation on ETN. But only in solid cavity. Most easy for filling detronators is ration 50:50. For all segments. For hogh

pressed output segment and also for starting segments.

|

If the CHP is very good, what is the advantage of adding ETN? |

Because ETN and PETN has better brizancion than CHP. For detonators is brizancion and initiation mightiness main parameter always.

Development of primarily - secondary substances: CHP (2015) neutral CHP and Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024) Diper

60 (2025)

|

|

|

MineMan

International Hazard

Posts: 1030

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Yes Xeon. Right up against the gloves. 75mg blows through 2 layers...

For the ematch why not dip it in nitrocellulose and primary mix? Say 15NC 70NiAgKCLO4, 15 Ammonium perchlorate.

|

|

|

| Pages:

1

2

3

..

18 |