| Pages:

1

..

10

11

12

13

14

..

37 |

Matsumoto_Hideki

Banned

Posts: 103

Registered: 27-12-2004

Member Is Offline

Mood: detonated

|

|

I am going to do lead block tests tonight! maybe

I figure what the hell, I will do some tests tonight as my neighbourhood is going to be full of fireworks tonight anyway.

I will keep you guys posted about anything that happens tonight.

|

|

|

Mickhael

Hazard to Self

Posts: 65

Registered: 17-11-2004

Location: B.C. Canada

Member Is Offline

Mood: Terrificlawful

|

|

Thankyou for the excelent response, being as I have now read about a dozen slightly different synths over the course of this 12 page forum, what

"current method" are you refering to?

Because if like you say there is minimal worries of creating to much AP I will go ahead with my own experimentation, I have everything I need for

small synths, so why not contribute to the overal tests

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The current method is forming the polymerized acetone addition product with HCl and then peroxidation of that

product using a catalytic amount of additional HCl and H2O2 . There are variations on the quantities , times , temperatures , orders of addition by

people trying to discover the method which gives the highest yield of purest product with the greatest ease . I am working on that aspect myself by

my experiment with low heating of a mixture of acetone and HCl for an extended time , so that I may observe the changes occuring in slow motion ,

seeking knowledge of how the precursor is formed . There are distinct stages through which the reaction develops and that series of reactions has

not been really explained . It is possible that this polymerization scheme for acetone has never been described in the literature .

There is much published about the aldol condensation under basic conditions and a whole lot of references , but not much in the way of description of

acid catalyzed condensation and addition products for acetone and HCl . If anyone should find any pertinent literature references for phorone

dihydrochloride by that name for the compound which I have designated for it , or any other reasonable name for the same structure , please share the

citation or the article itself . It is difficult to break new ground in chemistry , and we very well may be doing so if no such citation exists .

Often if a literature reference exists in support of a patent designated reaction , the citation will be noted in the patent . And since no such

literature citation is noted in the Mackowiak patent , then it reenforces my suspicion that phorone dihydrochloride may never have been named and

characterized . It could also be that because of the lack of details in the Mackowiak patent that the significance of

his invention was unappreciated by others who were unable to confirm his findings . Thereafter anything related to the patent including the precursor

and the end product , also the intermediate pentachlorophorone , may have received no professional recognition nor scrutiny .

Sad for Mackowiak , if this is the story , but this sort of thing happens too often where an invention is rediscovered thirty years or more later from

an inventor who never received that reward he had been deserving .

|

|

|

Matsumoto_Hideki

Banned

Posts: 103

Registered: 27-12-2004

Member Is Offline

Mood: detonated

|

|

Cold formation sounds much more efficient

Ok. I have done cold formation before although slow it is

often best for observation of the chemical processes.

One direction I may steer you in is adding HOT fuming HCL to cool acetone and this creates an instant chemical change and a green-yellow hue to

appear almost immediatly. Then take your phorone HCl and keep heat on it for 24hrs @ 60c.. after this test for remaing HCl and freeze to -20c or so..

the liquid should be like toffee and solid masses of PHCl crystals should be forming at the bottom of the flask.

I got my best yeild with this method. See my webshots acount.

BTW... Could find the crystal structure of DPPP and contrast it against AP? maybe sketch it or something.

I think you will be impressed with your results.

[Edited on 1-1-2005 by Matsumoto_Hideki]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The sealed bottle in which I have been slow heat digesting 225 ml acetone and 200 ml HCl 31.45% , has been at 66 C for 72 hours , and an upper layer

is separating slowly from the mixture below .

The upper layer is about 8 mm thick now and it appears to be single material of extremely deep yellow color in thin layers , and absolutely ink black

en masse . The lower layer appears that it may be a fairly stable emulsion of the same material as the upper layer , along with water or some other

clear oily material . It is the separation of these materials into separate phases I am seeking . It probably isn't necessary to separate the

mixture for the benefit of making DPPP , but at this point I am trying to identify what exactly are the components contained in the strange mixture to

satisfy my curiosity , and perhaps test the components reaction to peroxidation separately to see what results for each , if anything . The formation

of DPPP may require both components of the mixture , or it may require the mixed components used before the point of digestion to which I have

extended the reaction . I intend to cover all the obvious possibilities in studying this reaction . I suspect that the product from the slow

digestion I am performing is the same as what is gotten by use of shorter times and higher temperatures like others are doing , but the slow progress

of the reaction is allowing for me to observe what changes cannot be seen in a boiling mixture . Has a phase separation been observed in the mixtures

which have been refluxed and at higher temperature , or is this a peculiar development in the slower digestion of the mixture which I am watching

occur ?

Later I am going to monitor the temperature on a refluxed mixture in a stir mantle , ramping the temperature and

perhaps comparing the result both with and without water removal during the reflux . I also intend to examine the possibility of a monohydrochloride

of phorone , and some other possibilities because I am not entirely certain that the reactions which Mackowiak has designated are necessarily correct

, although it does seem likely they are correct . One thing I want to resolve entirely is whether the coloration of the DPPP is indeed due to the

DPPP or if it is a tint which results from a byproduct or impurity . Recrystallization , and some activated charcoal in the solvent could resolve that

question . I am curious also

about the color fade which I saw occur overnight where a drop of the precursor was left as a stain upon a white paper towel , whether the colored

material simply evaporated , or if the material changed composition on contact with air .

There is a very slight chance that the precursor could peroxidize itself in contact with air , which is an interesting possibility . There is simply

more we don't know about the process and the materials involved than we do know . But it is damn good that at last it appears experiments are

producing the desired product , which ends the long frustration of trial and error experiments which were

not producing much answers before except proving what did not work

Now we are getting somewhere in nailing down the details of the process and understanding more what Mackowiak was doing . Having his lab notebook

would save a lot of needless duplication of work ,

and "reverse engineering" the process , which has been something of a riddle to be solved . Have to wonder what other stuff this fellow may

have invented , and filed or never filed applications concerning .

|

|

|

Matsumoto_Hideki

Banned

Posts: 103

Registered: 27-12-2004

Member Is Offline

Mood: detonated

|

|

Ahhh only 31% I see..

I don't know if it is going to make any difference but I strongly suggest you get some concentrated muratic acid (35%) as the yeild is going to

be better. My guess is that when you are finished your reaction you will have a dark red layer (unreacted acetone) and a black red layer to contend

with as I do think you may run into partial digestion of the acetone therefore resulting in dimers, Trimer's and Tetramers of Acetone as

suggested by some on Rogue science forums. It does seem to make sense.

And don't forget that DPPP seems to like to form at temperatures below 0c.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I would be surprised if it makes any difference whether 36% or 31.45% HCl is used in this reaction , other than perhaps

changing the time of the reaction slightly .

Look at it this way , the difference between the two is that the weaker is 68.55% water , while the "stronger" is 64% water , a difference

in water content of 4.55% , not much in the scheme of things .

So far as I can tell there is no unreacted acetone after the first hour , perhaps two hours at the most in terms of polymerization , and thereafter

the reaction is probably 90% or more complete in 24 hours . I think the phorone dihydrochloride product

is likely all there as an unstable emulsion with water , and further heating and standing simply leads to separation of the

mixture into phases having lower water content from higher water content . Possibly all I am doing by extended heating is destabilizing the emulsion

and no further chemical changes are occuring .

What you say about "unreacted acetone" if you mean not free acetone , but polymerized acetone not yet converted to phorone dihydrochloride ,

because I used no excess of HCl to drive the reaction , well I agree that is a possibility . Actually I had wondered about that myself and thought

about adding 20 ml of HCl and seeing if this led to any reduction of the volume of the upper layer . If that does occur , then it would confirm an

excess of HCl is needed , in the molar ratio of 2 moles HCl to 3 moles acetone . This is one of the parameters I am evaluating so I will probably set

aside a small sample of the upper layer and then see if some added HCl will result in any change .

The upper layer is so densely colored that I really do think it is phorone dihydrochloride , and not unconverted triacetone dialcohol . I have been

reviewing the observations made earlier ,

and it would seem possible that the phorone dihydrochloride has been completely formed at 16 hours from the beginning of the mixing of the acetone and

HCl maintained at 66 C , and the appearance of traces of a floating oily slick as an upper layer is a marker for

what is the completion of the chemical reaction producing the phorone dihydrochloride . All subsequent observations may be attributable to the

physical destabilization of the emulsion

of phorone dihydrochloride in water on continued heating . It would be reasonable to test this theory on the next batch by proceeding with the

peroxidation after

the acetone and HCl has reacted at 66 C for 16 hours .

[Edited on 1-1-2005 by Rosco Bodine]

|

|

|

Tweenk

Harmless

Posts: 15

Registered: 7-12-2004

Location: Poland

Member Is Offline

Mood: safety-consciou

|

|

Not emulsion...

Have anybody read about two-phase systems? Those are systems of two partially miscible liquids. For every such system there are two temperatures,

lower critical temperature (minimum temperature below which the system is always homogenous no matter the ingredient content) and upper critical temp.

(above which system is also always homogenous). In most cases though both of them cannot be observed as before it happens a boiling or freezing point

of one of the ingredients is reached. We might have such a system here and when you start heating Rosco you might be just decreasing the solubility of

phorone derivative in water and therefore dark crystals precipitate out of the soln.

A friend of mine is doing this rxn on a small scale in a jar and after ca. 30 hours in a warm place (near the computer) the soln turned very dark red.

When the jar is tipped, some tarry residue is left on its wall. I think it is because phorone derivative content is now higher than that which can be

dissoluted in water (this is one of the clues to prove the 2-phase system hypothesis).

[Edited on 1-1-2005 by Tweenk]

And now we add powdered sugar to the previously liquefied chlorine dioxide...

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The "tarry residue" which you are seeing when the liquid is sheeting across the glass is something I have observed too , but it is not as

simple as it seems . Observe the droplets of the "tarry residue" closely in bright light , and use a magnifier if you need it to see that

the residue droplets separate into two phases

as they slide slowly across the surface of the glass , each droplet is a small globule of a darkly colored material which is surrounded by a clear

layer of water clear material , something like an egg yolk sitting in its surrounding egg white liquid which is more fluid than the "yolk" .

Then there is an even more fluid and mobile third liquid present which sheets into a film across the surface of the glass as a bright yellow material

which flows away quickly from the more "sticky" droplets of "tarry residue" . It appears to me that

a three phase system is present . From my past experience with doing liquid-liquid extractions , the appearance of the complex mixture squares with

what is called a "persistent" emulsion , or an "intermediate boundary layer"and heating is one of the things that drive a phase

separation . This complication occurs when organic materials have a great solubility but not a complete miscibility with water and is aggravated by

the presence of some solvent which may have a similar limited water solubility while being miscible completely with the organic phase . But often the

deliberate addition of a yet another material can

cause the phases to separate cleanly into two phases an organic phase and water .

Salting out with some salt highly soluble in water but insoluble in organic liquids can cause separation , or the addition of a low density solvent

like toluene can cause separation . Sometimes simply changing the pH by adding a few drops of acid can facilitate separation .

But here is the potential fly in the ointment with regards to use of the mixture in further reaction to produce DPPP , where it is likely best that

the emulsion be as homogeneous as possible

so that the very small globules can have great surface area for further reaction during the chlorination / peroxidation step to follow . I suspect

that the highest yields of DPPP will be obtained when the

mixture containing the phorone dihydrochloride has a highest content of that material in terms of conversion of the original acetone , *but* that the

material should be unprecipitated , maintained in a finely dispersed emulsion where it is available for further chlorination and peroxidation to DPPP

. This may be the

built in limiting factor which determines the maximum yield , and could also account for tinting of the end product , should it be found that pure

DPPP is actually white , although I am not declaring that it should be white , but only that it is conceivable . I will have more insight into this

after observing the peroxidation and doing recrystallizations using charcoal to attempt decolorization .

For me everything is speculative at this point but I share these ideas as they may have bearing and others may be thinking along the same lines . A

thing I have considered is that perhaps some sort of detergent or dispersion agent or emulsifier which is totally inert to reaction with the materials

present in the system ,

should increase the quality of the emulsion and the yield and purity of the DPPP produced from the improved emulsion of phorone dihydrochloride .

Candidate dispersion agents would need to be stable in acidic medium , perhaps one of the sulfonic acids for example or

a soluble acidic phosphate are things which come to mind . By use of such a dispersion agent , it should be able to drive the initial reaction

further to completion forming a higher concentration of phorone dihydrochloride in stable suspension , before any precipitation of that product as a

separated phase . This may or may not have any usefulness , I cannot say until experiments are done to see if this has any effect or not . Another

thought which I almost don't want to share is that it seems possible that the triacetone dialchol , phorone dihydrochloride , pentachlorophorone

, and DPPP , are *all* entirely colorless products themselves and that the color changes which have been observed may be due to perhaps the presence

of 10% of an unknown byproduct impurity which has no bearing on the reactions we are observing , other than to create total confusion by a

presentation of color changes which are meaningless except in our own mistaken belief they have significance

[Edited on 1-1-2005 by Rosco Bodine]

|

|

|

Atom

Harmless

Posts: 15

Registered: 1-1-2005

Member Is Offline

Mood: No Mood

|

|

Can phorone dihydrochloride be made with only a small percentage Hydrochloric acid, like 10 %.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Just a guess , but I would say probably so , it will just take longer for it to form with the more dilute acid .

|

|

|

Atom

Harmless

Posts: 15

Registered: 1-1-2005

Member Is Offline

Mood: No Mood

|

|

Okay, it's in the freezer for about 2 hours now and it still didn't change colour. Does anyone know how long this will take?

To change colour I mean.

[Edited on 1-1-2005 by Atom]

|

|

|

mr.pyro

Harmless

Posts: 21

Registered: 27-12-2004

Member Is Offline

Mood: No Mood

|

|

I just tried the written synthesis by Rsert. The oily substace appeared after heating for 2 hours at 50 C and then heating for 15 h at 30 C. I

cooled it to -10 C and Added 50Ml H2O2. IT was cooled back down to -10 C but no black crystals came out, because there was already a heavy yellow

precipate. I waited for about 1/2 hr to see if any balck crystals would precipitate out, none did, so I added 200 ml more H2O2 and the precipitate

was similar to Rserts pictures.

Edit

I just filtered what ever precipitated out and after neutralization, can not be more then 10g of DPPP. This seems like a shitty yeild from more then

400 Ml of Reagents.

[Edited on 1-1-2005 by mr.pyro]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by Matsumoto_Hideki

My guess is that when you are finished your reaction you will have a dark red layer (unreacted acetone) and a black red layer to contend with as I do

think you may run into partial digestion of the acetone therefore resulting in dimers, Trimer's and Tetramers of Acetone as suggested by some on

Rogue science forums. It does seem to make sense.

|

I think you are correct about the upper layer being a separation of unreacted or not fully reacted acetone polymer , if that is what you mean . A few

minures ago I attached a teflon capillary to a syringe and transferred a 1 ml sample of the top layer to a clean test tube . The oily material is a

slightly yellowish brown , mostly dull brown colored liquid which is imiscible with water , and imiscible with denatured alcohol . A spot test on

white paper towel leaves a light brown stain .

To the dull colored sample of unknown oily material was added an equal volume of 31.45% HCl and the test tube is swirled a few times to mix the

imiscible liquids . In a few minutes the color brightens , and an emulsion is forming having the same bright red yellow color as is seen in the

initial reaction mixture from which this sample has been withdrawn . After heating for a few minutes , the effect increases and a more and more

finely dispersed and highly colored emulsion forms , actually it appears it may be going completely into

solution , without any of that opaque dark "milky" or solid pigmented appearance of suspended matter or

liquid in liquid dispersion . From this observation I think it is reasonable to

conclude that at least some excess of HCl to acetone is indeed required to drive the reaction to completion for producing the phorone dihydrochloride

, and that this slight excess of theoretical requirement HCl is necessary for keeping the phorone dihydrochloride product in good solution in the

reacted mixture . If the HCl amount is deficient , then an emulsion is going to be the result from digestion of the acetone HCl mixture , and some

incompletely reacted acetone polymer , which will not only reduce the yield of phorone dihydrochloride , but produce a reacted mixture whose

properties are inferior for the further reaction to be performed in the peroxidation step to follow . This mixture is pH sensitve , and needs the

acidity of a little extra HCl to be fit for use . This observation is in agreement with the patent specification ,

so it would seem that the patent is correct on the molar ratio of HCl to acetone which is going to be useful .

I am going to add 25 ml of HCl to my

sealed bottle mixture and continue that experiment to see if everything goes into

solution again as hopefully the emulsion

and phase separation vanishes . That amount of added HCl should bring the

mixture up to the equal volumes of HCl and acetone referenced by the patent .

|

|

|

Matsumoto_Hideki

Banned

Posts: 103

Registered: 27-12-2004

Member Is Offline

Mood: detonated

|

|

Yes, I agree

This is what I have to end up doing just to make sure all the acetone is converted to Phorone HCl

and then to Pentachlorophorone. However don't add too much or you end up overheating the reaction.

I used a modified version of R_Serts peroxidation technique.

Another thing... slowly add your H2O2 over the course of serveral hrs while the mixture is -20c -30c

in a cold freezer. I find this works very very well.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

From what I have observed with my sealed bottle experiment , it definitely is

important to get the acetone to HCl ratio just right , with a bit in excess for HCl , to discourage separation of the product into water soluble and

insoluble phases , and to avoid incomplete conversion of the polymerized acetone to phorone dihydrochloride . It would seem desirable to settle for a

lower yield of the phorone dihydrochloride , but have it in a strong solution or stable dispersion which can be

diluted by the peroxide without that dilution causing a phase separation , as opposed to driving the reaction with high heat and long reaction times

to get a higher yield of phorone dihydrochloride , but have it separate as an undilutable and water imiscible oil , or as a coarse emulsion . The

reaction is best run with the right proportions of acetone and HCl from the start , and then it is my guess that when the reaction reaches that dark

red orange color where it looks like freshly brewed very strong tea , barely transparent to a strong light but not yet cloudy , that is probably the

point

where the heating should be ended and the product should be allowed to cool and peroxidized . Has anyone tested the mixture to see if this

"cloud point" where

it begins to lose transparency , is a good marker for the point where good yields of DPPP will be obtained by the peroxidation ?

Looking back on my notes , it was only about 6 hours into the reaction at 66 C

when the dark red orange tint was developed and then at 7 and 1/2 hours

the mixture began clouding . So it looks like somewhere in that time window the

reaction was possibly mature . You follow what I am thinking , the mixture may produce more phorone hydrochloride with passing time , but it appears

in a form which is less and less dispersed so it may give poorer response when diluted by the

water content of the peroxidation mixture . Does this sound reasonable ?

[Edited on 2-1-2005 by Rosco Bodine]

|

|

|

Matsumoto_Hideki

Banned

Posts: 103

Registered: 27-12-2004

Member Is Offline

Mood: detonated

|

|

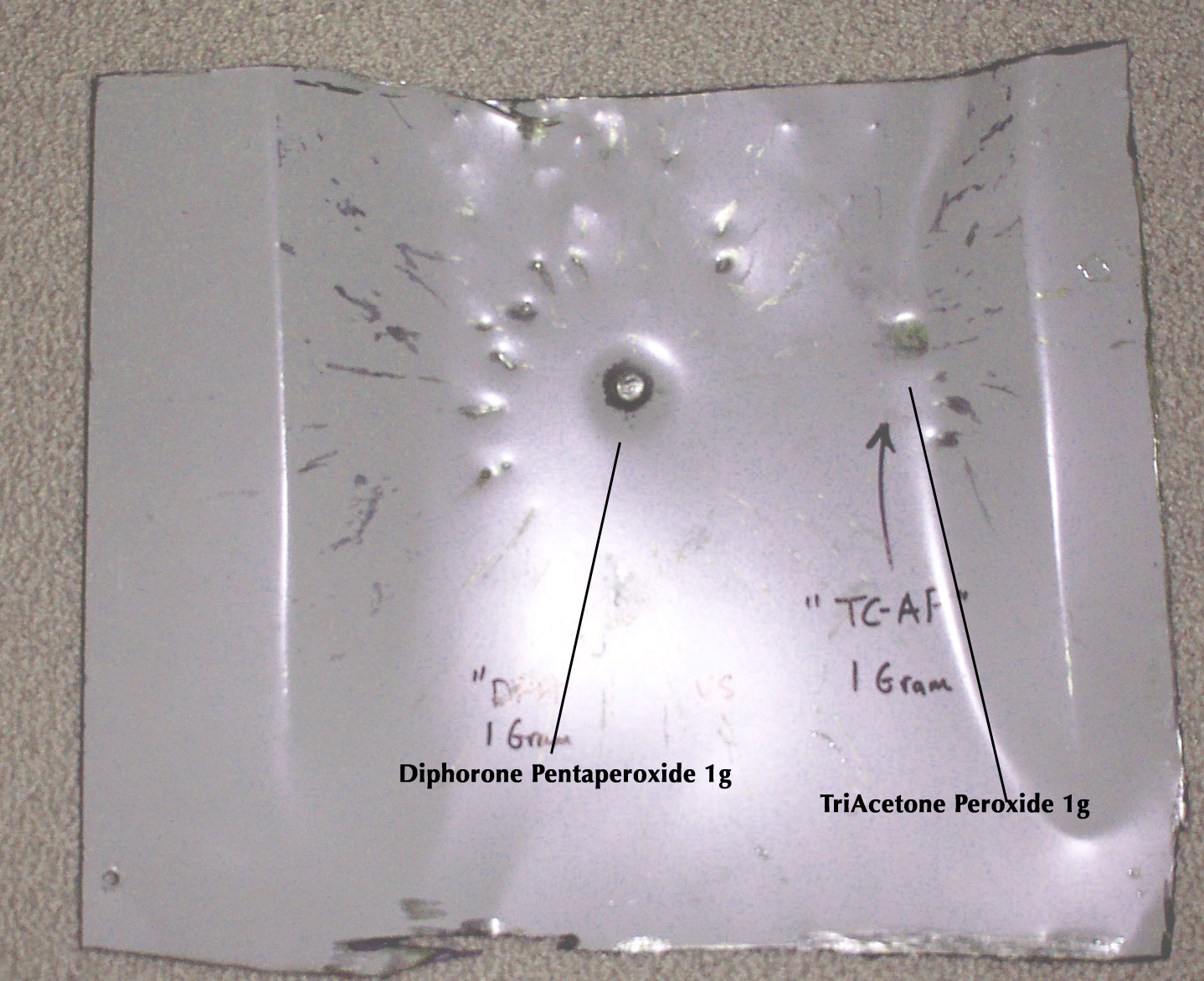

Holy shit... I just did a velocity test and look at this pic

Everyone ... drop your shit and look at this picture of my .223 shell velocity test against 4mm steel.

Both mini shaped charges were full of AP and or DPPP..

You can clearly see which subtance has more power.

1# AP charge with exactly the same # of grains as DPPP

detonation was strong enough only to nipple the primer and propell it and the base of the shell into the metal. primer was still in the bottom on

the caseing which was retrieved later.

2# DPPP charge was strong enough to punch a BIG crater in the steel and propell the primer almost completely through the target. BIG blast marks are

visible in the target surface indicating a MUCH higher velocity and energy signiture. I have pictures of the recovered metal fragments from the AP,

whereas there was nothing left of the DPPP casing. The primer in the DPPP charge was atomized as well, but only the very bottom case rim although

mageled was left!  YES !!! THIS PROVES THE PATENT'S CLAIM!!! YES !!! THIS PROVES THE PATENT'S CLAIM!!!

[Edited on 2-1-2005 by Matsumoto_Hideki]

[Edited on 2-1-2005 by Matsumoto_Hideki]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

That radial pattern spray of impact welded

fragments of brass is not something typical for the velocity of AP , more like usual for picric acid or better . That sort of surface gouging and or

perforation by small fragments is an evidence of a brisant explosive , paricularly in the case of a softer metal like brass doing that to a harder

metal like steel .

|

|

|

Axt

National Hazard

Posts: 795

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Matsumoto_Hideki

test against 4mm steel.

|

Did you actually measure that, It looks like something hacked from a filing cabinet. 4mm is quite heavy steel and small, high velocity, brass

fragments are unlikely to bend the plate at that angle, rather it will crater, pit and gauge the steel. The cut marks look like ~1mm plate, through

4mm it would be straighter and less scrappy. Unless its prefabricated like that, those bends are very unlikely as well.

Sorry to those that would rather be misled and lied to, but I'm yet again calling bullshit. Credibility is everything, if one cant be trusted to

report the true parameters of the experiment, how can on be believed that the results arn't fabricated to show what they <i>want</i>

it to show.

I'm prepared to be proven wrong with a picture of the plate, side on, with a ruler for scale.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

LOL

Yes that scrap of tin isn't any 3/16" plate ,

and as a former metalworker I did recognize that 18 gauge ( if that much ) for what it is , along with Quasimoto's habit for exaggeration other

wise known as bullshitting in most circles

But you know , that doesn't change a thing about the impact welds in that starburst pattern .....even if there was no

"shaped charge" involved either (which there wasn't )

Now the exaggerations aren't cool at all ,

no not impressive trying to read through and separate the shit from the shinola .

You aren't talking to novices here , not by a long shot . So take a hint from Axt ,

underscored by yours truly and knock it off

with the bullshit . Save us the work of

guessing how much of what you say is true and how much is your idea of humor or an estimation on your part of the IQ of your audience . Science is

about facts ,

not charisma and tale telling skill . Engineering is by the numbers , numbers that can't be faked . So get it or get on down the road .

You'll be happier there

where nobody knows the difference and you can seem to be the smartest of all to

all your gullible and naive true believers .

You'll find no cult following here , just a gang of dedicated proof testing skeptics .

Everything gets analyzed here , so spare youself the discomfort of a thorough proctological , by keeping on the level .

|

|

|

Mickhael

Hazard to Self

Posts: 65

Registered: 17-11-2004

Location: B.C. Canada

Member Is Offline

Mood: Terrificlawful

|

|

| Quote: | Originally posted by Rosco Bodine

Everything gets analyzed here , so spare youself the discomfort of a thorough proctological , by keeping on the level . |

I have to agree with that...if he could just make more solid statements it would certainly help...and hey...why not take the picture with the ruler

and prove what is what? I'd love to see that.

Also Rosco, what % of Acetone and HCl are you using that has the excess HCl needed? One of the numbers I heard was something like 300ml Acetone to

200ml HCl, was that even close to what your using, or am I way off? Also have you had any more tests with adding the extra HCl just before the H2O2 to

restart the reaction? Thanks

|

|

|

Matsumoto_Hideki

Banned

Posts: 103

Registered: 27-12-2004

Member Is Offline

Mood: detonated

|

|

Woops, backtrack a bit... This is serious!!

Go look for yourself , alright I may have miscalcutalted on the measuremant... turns out it is 2.5mm thick car flooring woops... Ok... So I though the

gaugue in question ment 4mm woopdy shit! This is high strength painted metal flooring guys, not flimsy filing cabinet crap metal.

Seriously you have to try it out.. i am not kidding here.

GO DO SOME TESTS INSTEAD OF SITTING BEHIND A DESK A WAITING FOR OTHERS TO DO THEM FOR YOU!

Rosco, Radial patterns for AP is quite typical for a rounded shell charge they just don't create deep gouges since the dvol is low.

DPPP on the other hand is quite a different story.

Lets start the banning crap all over again guys, that will really help, HAPPY FUCKING NEW YEAR!!

[Edited on 2-1-2005 by Matsumoto_Hideki]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The equal volumes of acetone and HCl 31.45% would seem close to correct for

providing the slight excess of theoretical

requirement of 2 moles HCl per 3 moles acetone . You can do the math . A mole of acetone is 73.53 ml . A mole of HCl is contained in 100.06 ml of

31.45% HCl .

3 X 73.53 = 220.59 ml acetone

2 X 100.06 = 200.12 ml HCl 31.45%

If the amount of HCl is increased to be equal the amount of acetone the amount of HCl in relation to theoretical requirement will be 220.59 / 200.12 =

1.10 or 110% of theory , 10% excess of HCl required by theory provided by equal volumes .

From my observations of an acetone lossless reaction in a sealed bottle , a slight excess of HCl helps the solubility of the reaction product . There

is an unstable "phase equilibria" affecting the polymer solution past a certain concentration where it reaches a "cloud point" and

the

polymer solution degrades to an emulsion

and then futher develops phase separation of a water imiscible product .

It seems logical to me that for reaction with a peroxide solution which is 70% water , you are better off to have a reactant which is still a stable

solution so that the components can be mixed intimately for reaction and not separate into imiscible phases which generally react only with difficulty

and slowly . So

I think it is likely that the precursor needs

to be prepared according to a controlled

scheme and then very soon subjected to the peroxidation step to get reliably good yields .

|

|

|

Matsumoto_Hideki

Banned

Posts: 103

Registered: 27-12-2004

Member Is Offline

Mood: detonated

|

|

Got anything you want to say rosco?

Hey, you wanted evidence , now you have it !!What the fuck to you means shaped charge? It fucking well was!

Give me your definition rosco?

[Edited on 2-1-2005 by Matsumoto_Hideki]

|

|

|

Joeychemist

Hazard to Others

Posts: 275

Registered: 16-9-2004

Location: Canada

Member Is Offline

Mood: Sedated

|

|

What evidence are you talking about Hidiki? I hope you're not referring to that shity picture you posted above because I can't even tell

what I'm looking at

What type of material did you use for the liner (the cone) of the shaped charge? How was the charge placed on the witness plate, was there any stand

off, if so how far away was the charge from the witness plate???

|

|

|

| Pages:

1

..

10

11

12

13

14

..

37 |