| Pages:

1

..

3

4

5 |

Fulmen

International Hazard

Posts: 1725

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

@Boffis: You're right, seems I jumped the gun a bit. I ended up boiling down the solution almost to dryness, then redissolved it in a large amount of

water to wash out any salt. Most of the product dissolved, so it can't be the acid. Most likely I only isolated the ammonium salt. Too bad, because

the direct ppt is a real pain in the ass.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

MrDoctor

Harmless

Posts: 23

Registered: 5-7-2022

Member Is Offline

|

|

Quote: Originally posted by Boffis  |

The decarboxylation of terephthalic acid to benzene or benzoic acid has been discussed on this site in several threads but I have found no published

article specific to terephthalic acid for this process yet.

|

I happened upon this a few weeks ago, thought id share it.

http://www.fsrj.org/act/7_nenkai/09/Proceeding-9/1_8.pdf

It describes an industrial process of processing PET bottles in which, a "benzene yield of 74%" is achieved, with 97% or so selectivity/purity. theres

a chart that indirectly states how much PET and CaO is used, PET:CaO being in a 1:5 molar ratio.

|

|

|

Texium

Administrator

Posts: 4618

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

Very poorly written paper. After reading through it though, I pieced together that for the method that gave them the highest yield and purity, they

don’t use a 1:5 molar ratio of PET to CaO, but a weight ratio of 0.5 grams to 50 grams. They describe it as a “packed column reactor” that they

heated very slowly from 300 to 550°C using superheated steam. It’s hardly an “industrial process” since they only did it on a 0.5 gram scale.

Sounds extremely impractical for the home lab, and there’s no indication that it scales well.

|

|

|

MrDoctor

Harmless

Posts: 23

Registered: 5-7-2022

Member Is Offline

|

|

Quote: Originally posted by Texium  | | Very poorly written paper. After reading through it though, I pieced together that for the method that gave them the highest yield and purity, they

don’t use a 1:5 molar ratio of PET to CaO, but a weight ratio of 0.5 grams to 50 grams. They describe it as a “packed column reactor” that they

heated very slowly from 300 to 550°C using superheated steam. It’s hardly an “industrial process” since they only did it on a 0.5 gram scale.

Sounds extremely impractical for the home lab, and there’s no indication that it scales well. |

I found another one with a very similar name and process, but better written i think. similarly though they used something like 1g pet to 25 or 50g

CaO.

Its a bit annoying they described this process as being suited for continuous use, but then dont actually prove it.

Hydrolysis with heated steam seems a bit difficult but ive seen videos of making TPA with lye and acids and it seems more messy than difficult. It

does make me want to try preparing 100g or so of TPA and then feeding it into a steel pipe loaded with coarse CaO and see what happens

Attachment: Hydrolytic degradation of poly(ethylene terephthalate) in a pyrolytic two step process to obtain benzene rich oil.pdf (529kB)

This file has been downloaded 248 times

[Edited on 24-8-2022 by MrDoctor]

[Edited on 24-8-2022 by MrDoctor]

|

|

|

MrDoctor

Harmless

Posts: 23

Registered: 5-7-2022

Member Is Offline

|

|

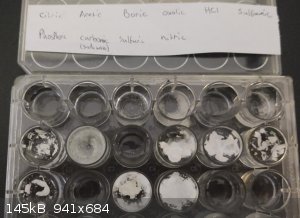

since its not stated explicitly, i decided to run a test to see exactly what acids can precipitate TPA from NaTP, i also just really wanted to use

this little tray i found in my box of 2nd hand lab goodies.

the following are viable:

Citric, Acetic, oxalic, hydrochloric, sulfamic, phosphoric, sulfuric and nitric

the following are not:

Boric, carbonic

And just a note to mention, some of these acids, particularly nitric, may react with the formed TPA, all i wanted to confirm here was what acids other

than sulfuric might be used. They may not necessarily all be safe to have in contact with TPA.

Also, in the photo, the top row was used to dissolve the solid acids before they were added to NaTP solution. The second and third correspond to what

is written.

Anyway hopefully someone finds this useful and doesnt think they need to only use sulfuric acid, especially since many producing this from PET plastic

will be using excess NaOH to speed things up.

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

MrDoctor - nice experiment!!! The power of acid depends on its pKa. Equilibrium is also shifted when terephthalic acid precipitates due to its low

solubility in water. Personally I would use HCl, it is the cheapest one. Diluted nitric acid at room temperature does not nitrate terephthalic acid,

it is very hard to nitrate it - Boffis in the beginning of this thread already wrote that fact and he is very skilled in nitrations.

|

|

|

MrDoctor

Harmless

Posts: 23

Registered: 5-7-2022

Member Is Offline

|

|

I feel a bit silly as i did not specifically know about kPa's, but now i do

|

|

|

| Pages:

1

..

3

4

5 |