| Pages:

1

2 |

Vicarious3rdEye

Harmless

Posts: 16

Registered: 19-11-2016

Member Is Offline

Mood: No Mood

|

|

Transition (and other) metal salts of Carboxylic Acids and their properties

Hello all

I was curious about the properties and structure of salts of carboxylic acids such as Tartaric, Citric, Ascorbic , and Oxalic Acid. Especially Cations

like Co2+,Mn2+, Mn3+, Cu2+, Ni2+, as well as salts of metals such as Gallium and Bismuth.

I have made some Ga(NO3)3, Bi(NO3)3 although I think my Bismuth Nitrate hydrolyzed into it's Oxynitrate I was thinking of making Carbonates and

Hydroxides of them to form their salts of these aforementioned acids to see their properties. I will report back with pictures and observations but

wanted to see if anyone else is curious on this subject.

|

|

|

j_sum1

Administrator

Posts: 6333

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

I cannot speak for all of these cations but I know that a huge range of copper compounds have been successfully made. A good place to look is the

copper carnival competition that was run a couple of years back. In the submissions you will find details of synthesis and some descriptions as well

as occasional photos.

Copper acetate is a simple one and i rather like the teal-green colour of the crystals formed. From memory they are a hydrate -- which I think is to

be expected for most of these. Copper aspirinate, copper tartrate, copper ascorbate are others that I know were done.

As for properties, I think your question is extremely general and you are probably best to look up specific properties of compounds you are interested

in. I would hesitate to posit any general trends except to say that you are going to have some interesting colours with a mix like that.

Although you did not have Fe2+ on your list, I will say a couple of things about iron(II) oxalate.

This is ridiculously easy to make. Simply add a solution of oxalic acid to a solution of iron(II) sulfate. The salt will drop out as a vivid yellow

precipitate with quantitative yield. Filtering and drying is straightforward. This stuff has a nice party trick. Like many oxalates it will

decompose on moderate heating to give carbon monoxide. (Be careful here.) What remains in your test tube contains a significant amount of very

finely divided iron that is pyrophoric on exposure to air. Pour and ignite is always a lovely demo.

As an aside, this synthesis of iron oxalate is an excellent one for matching stoichiometric skills with experimental skills. It is a great student

exercise. It is great to have stoichiometry as more than just a paper skill and to demonstrate it in a practical situation.

|

|

|

Vicarious3rdEye

Harmless

Posts: 16

Registered: 19-11-2016

Member Is Offline

Mood: No Mood

|

|

Oh thank you for your comment I should of been less vague I apologize about that. I have been familiar with Nickel (II) Oxalate as well as the Iron

(II) salt you mentioned and am aware of the possibility of CO formation. I know of the use of these to make pyrophoric compounds which are very

interesting. I have made many Copper (II) compounds and especially the Ammonia complexes of the Sulfate, Nitrate (not the anhydrous form though only

the hydrated), Perchlorate (also hydrated to my knowledge), and even experimented with the Picrate salt by making Copper Picrate by dissolving Basic

Copper Carbonate in a hot solution of 2,4,6-Trinitrophenol and then adding NH4OH until the precipitated Cu(OH)2 redissolved. The solution became an

olive green color with a grassy colored green precipitate forming after cooling the solution. Maybe I will perform that experiment again and post

results on the Energetic Materials forum.

Anyways sorry to get off topic, my plan is to maybe focus on one carboxylic acid at a time and make various salts of it and post my findings here and

do a side-by-side of each one. Then move on to the next carboxylic acid. Possibly explore the ammonia complexes of each as well if you or anyone else

is interested, I certainly am .

I'll report back with my findings with reagent amounts and pictures.

I'll do everything on a small molar scale.

|

|

|

DraconicAcid

International Hazard

Posts: 4355

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

Yes, copper(II) acetate monohydrate is a lovely colour and makes nice crystals. It's actually a dimer, with a delta bond between the copper atoms;

chromium(II) acetate monohydrate has the same structure, but is much more challenging to make (it's a brick-red powder which, if not perfectly dry,

turns to black tarry crap upon exposure to air).

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

LearnedAmateur

National Hazard

Posts: 513

Registered: 30-3-2017

Location: Somewhere in the UK

Member Is Offline

Mood: Free Radical

|

|

In my experience, copper II formate is really strange. It forms the expected deep blue crystals of simple Cu2+ salts when in solution, but when

exposed to air, they become very pale blue, opaque crystals as if they've almost completely dried out. This is in contrast to sodium formate that I've

made, which is hygroscopic enough to form solutions exposed to the air. I'll snap a picture tomorrow and attach it to this post, disappointing yet

interesting stuff.

In chemistry, sometimes the solution is the problem.

It’s been a while, but I’m not dead! Updated 7/1/2020. Shout out to Aga, we got along well.

|

|

|

Texium

|

Thread Moved

12-11-2017 at 07:48 |

LearnedAmateur

National Hazard

Posts: 513

Registered: 30-3-2017

Location: Somewhere in the UK

Member Is Offline

Mood: Free Radical

|

|

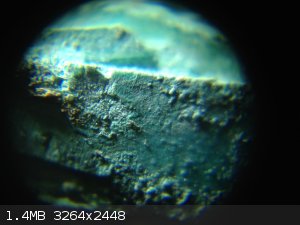

Copper Formate

Here are the pictures as promised, the second one is a closeup on the surface detail using my trusty laser pointer macro lens.

In chemistry, sometimes the solution is the problem.

It’s been a while, but I’m not dead! Updated 7/1/2020. Shout out to Aga, we got along well.

|

|

|

Rhodanide

Hazard to Others

Posts: 348

Registered: 23-7-2015

Location: The 80s

Member Is Offline

Mood: That retro aesthetic

|

|

Quote: Originally posted by j_sum1  | I cannot speak for all of these cations but I know that a huge range of copper compounds have been successfully made. A good place to look is the

copper carnival competition that was run a couple of years back. In the submissions you will find details of synthesis and some descriptions as well

as occasional photos.

Copper acetate is a simple one and i rather like the teal-green colour of the crystals formed. From memory they are a hydrate -- which I think is to

be expected for most of these. Copper aspirinate, copper tartrate, copper ascorbate are others that I know were done.

As for properties, I think your question is extremely general and you are probably best to look up specific properties of compounds you are interested

in. I would hesitate to posit any general trends except to say that you are going to have some interesting colours with a mix like that.

Although you did not have Fe2+ on your list, I will say a couple of things about iron(II) oxalate.

This is ridiculously easy to make. Simply add a solution of oxalic acid to a solution of iron(II) sulfate. The salt will drop out as a vivid yellow

precipitate with quantitative yield. Filtering and drying is straightforward. This stuff has a nice party trick. Like many oxalates it will

decompose on moderate heating to give carbon monoxide. (Be careful here.) What remains in your test tube contains a significant amount of very

finely divided iron that is pyrophoric on exposure to air. Pour and ignite is always a lovely demo.

As an aside, this synthesis of iron oxalate is an excellent one for matching stoichiometric skills with experimental skills. It is a great student

exercise. It is great to have stoichiometry as more than just a paper skill and to demonstrate it in a practical situation. |

I second all of this! I enjoy Copper salts because they're so easy to obtain from such basic materials, and can be made into so many different colors!

As for the Oxalates, I couldn't agree more. I've made the Iron, Nickel, and Cobalt derivatives, and I can say that they're all great fun to experiment

with. The color changes are nice, too. Nickel Oxalate turns from a toothpaste blue to a black, pyrophoric powder. Cobalt Oxalate turns from a rose-y

pink color to, again, a black pyrophoric powder. You know what Iron Oxalate does. I'm just wondering about Manganese Oxalate. Would the Manganese

powder formed from the Oxalate's decomp produce just MnO2 when it is formed? Or would it do the same as the other Oxalates?

|

|

|

Vicarious3rdEye

Harmless

Posts: 16

Registered: 19-11-2016

Member Is Offline

Mood: No Mood

|

|

Wow that is really pretty and interesting LearnedAmateur!

I was gonna focus on Carboxylic acid salts of Mn, Ni, Cu, and Co at first so I'll make some Manganese Oxalate first and upload pictures so we can see

how it behaves

I also was gonna make salts from many Carboxylic acids but there's just so many!

here is what I am proposing right now before I start doing it

As for acids: Benzoic Acid and it's derivatives (2-Aminobenzoic acid aka Anthranilic acid, 4-Aminobenzoic acid aka PABA the nutritional supplement,

2-Hydroxybenzoic acid which is Salicylic acid, Nicotinic Acid, Tartaric acid, Citric acid, and Ascorbic acid as well as Oxalic acid. There are so many

to choose and I am very curious as to what the reducing potential of Ascorbic acid will do to Manganese. As long as it isn't in excess it should be

fine correct?

That's how you make copper powder from CuSO4*H2O and and excess of said acid I believe.

I can't decide whether to start by the acid salts of one transition metal at a time i.e. making Co salts of all the aforementioned acids. Or to make

all the four proposed metal salts of one acid at a time i.e. making Co, Ni, Mn, Cu salts of Tartaric acid, then of Oxalic acid etc.

What do you guys think would be the best way to approach this?

|

|

|

Vicarious3rdEye

Harmless

Posts: 16

Registered: 19-11-2016

Member Is Offline

Mood: No Mood

|

|

I was gonna prepare this by making NiSO4*6H2O, CoCl2*H2O, MnSO4*H2O, and CuSO4*5H2O into their respective Carbonate (or Basic Carbonate) salts to then

make the Carboxylic acid compounds. So I will prepare these using Na2CO3 and drying the salts and do each compound on a 0.02 Molar scale, maybe

smaller for some as I only have 30g of CoCl2 but the rest I have much more of.

|

|

|

DraconicAcid

International Hazard

Posts: 4355

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

The anthranilates tend to be very insoluble, so you get fine powders (copper is a light green, nickel is a grey-green, cobalt(II) is a light brown,

IIRC). If you're trying to grow crystals, you can skip anthranilate.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Vicarious3rdEye

Harmless

Posts: 16

Registered: 19-11-2016

Member Is Offline

Mood: No Mood

|

|

I am very curious about these compounds that have little to no literature easily found on the internet or elsewhere so I thought the next step after

preparing these would be to measure different properties like Solubility in H2O and maybe other solvents, the Crystal structure , Color ,

Hygroscopicity. And what else would I be missing here?

I apologize for talking about it and not actually getting to posting the results they will be up within the next 24 hours if possible, 48 hours at

that most. I just wanted to hear your feedback first to see what you all thought on the best way to approach this.

|

|

|

Vicarious3rdEye

Harmless

Posts: 16

Registered: 19-11-2016

Member Is Offline

Mood: No Mood

|

|

Oh okay Draconic Acid, duly noted and thank you. I was more curious of these salts in general not specifically for crystal growing but just to see

what each are like.

|

|

|

Vicarious3rdEye

Harmless

Posts: 16

Registered: 19-11-2016

Member Is Offline

Mood: No Mood

|

|

I do have only about maybe 5 grams of Anthranilic Acid since I've only made it twice in very small quantities so it is good to know what you know

about Anthranilates. I appreciate the input.

|

|

|

Rhodanide

Hazard to Others

Posts: 348

Registered: 23-7-2015

Location: The 80s

Member Is Offline

Mood: That retro aesthetic

|

|

Quote: Originally posted by Vicarious3rdEye  | | I was gonna prepare this by making NiSO4*6H2O, CoCl2*H2O, MnSO4*H2O, and CuSO4*5H2O into their respective Carbonate (or Basic Carbonate) salts to then

make the Carboxylic acid compounds. So I will prepare these using Na2CO3 and drying the salts and do each compound on a 0.02 Molar scale, maybe

smaller for some as I only have 30g of CoCl2 but the rest I have much more of. |

If you're gonna make the Oxalates, then don't bother making the Carbonates. A MUCH better way is to just combine a metal salt solution with Oxalic

acid solution, and heat for an hour or two at medium heat. They should precipitate in quite the obvious manner. So let's say CoCl2 +

C2H2O4 -> CoC2O4 + 2HCl. Any left over impurities can easily be washed away with water,

leaving a pure product!

Using Carbonates will most likely lead to impurities in the final product.

Best of luck!

-T

|

|

|

woelen

Super Administrator

Posts: 8027

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

With salts of cobalt(II) and manganese(II) this is not very easy. Cobalt(II) and manganese(II) are very easily oxidized at high pH. A precipitate of

e.g. wet MnCO3 is very quickly turning brown, due to oxidation by oxygen from air. Only in the perfectly dry state these carbonates can be kept good

in contact with air. A similar problem exists for cobalt(II).

I do not have experience with oxalates. These are less alkaline than carbonates, but I can imagine that with these there also is oxidation. Just try

it.

|

|

|

Rhodanide

Hazard to Others

Posts: 348

Registered: 23-7-2015

Location: The 80s

Member Is Offline

Mood: That retro aesthetic

|

|

Quote: Originally posted by woelen  | | I do not have experience with oxalates. These are less alkaline than carbonates, but I can imagine that with these there also is oxidation. Just try

it. |

After three months in a Zip-Loc Bag, there seems to be no oxidation to my Cobalt Oxalate. If kept in the open air, there probably would be.

|

|

|

DraconicAcid

International Hazard

Posts: 4355

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

Quote: Originally posted by Tetra  |

If you're gonna make the Oxalates, then don't bother making the Carbonates. A MUCH better way is to just combine a metal salt solution with Oxalic

acid solution, and heat for an hour or two at medium heat. They should precipitate in quite the obvious manner. |

Agreed- most oxalates are insoluble, and will precipitate nicely as long as the solution is not too acidic (sodium hydrogen oxalate may work better

than oxalic acid). Just make sure you don't add an excess of oxalate, or you will get coordination compounds (my last attempt at making CuC2O4 gave

me a mixture of powder blue CuC2O4 and dark blue Na2[Cu(C2O4)2]).

Nickel carboxylates tend to be soluble. With soluble copper carboxylates, it can be difficult to isolate some of them due to the reaction CuX2 + 2

H2O -> Cu(OH)2(s) + 2 HX.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Vicarious3rdEye

Harmless

Posts: 16

Registered: 19-11-2016

Member Is Offline

Mood: No Mood

|

|

Thank you guys for your knowledge and experience with some of these compounds and Woelen I just want to thank you for the wonderful website you have

made, it is amazing and has been one of many godsends of chemistry experiments and demonstrations that have been extremely helpful to me.

I have already made MnCO3 about a month back with the intention of following Chemplayer's procedure for making Mn (II) Acetate and oxidizing it to Mn

(III) Acetate using KMnO4 but never got around to it. The MnCO3 was dried and stored in a HDPE bottle and didn't show any obvious signs of oxidation

but that doesn't mean it didn't oxidize to Manganese Dioxide (or maybe another oxide?).

So decided to use it and see what happens. I know it isn't very professional at all but I just used it to attempt to make Mn salts of Salicylic,

Nicotinic, Tartaric, and Ascorbic Acids. I know I probably should have started with the more well known or simple Carboxylic acids such as Oxalic,

Acetic, Formic, etc but curiosity got the best of me.

I should have pictures and a more detailed account up by later tonight.

And I'll go from there, I am curious to see the Ascorbate salt as I remember using Ascorbic acid to clean my glass frits that were stained with KMnO4

and it worked like a charm giving a completely colorless filtrate and white frit. I am guessing the acid gets converted to the Dehydroascorbic Acid

correct? (Sorry I don't mean to get off topic.)

|

|

|

Vicarious3rdEye

Harmless

Posts: 16

Registered: 19-11-2016

Member Is Offline

Mood: No Mood

|

|

Thank you Tetra I will try just using the Cl and SO4 salts directly with Oxalic acid and heat if necessary when making oxalates when I move on to the

next transition metals.

|

|

|

Vicarious3rdEye

Harmless

Posts: 16

Registered: 19-11-2016

Member Is Offline

Mood: No Mood

|

|

So this is what I have so far.

I have attempted to make Manganese salts of Tartaric Acid, Ascorbic Acid, Salicylic Acid, and Nicotinic Acid using MnCO3 added to a solution of each

acid. Most required heat to initiate it where there started to be effervescence/liberation of carbon dioxide. Each compound was made with 1.00 gram of

MnCO3 which is on a 0.0087 molar scale. Each acid was measured out at 0.0087 mole or 0.0174 mole depending on the charge of their respective acid

anion.

All acids were in just enough water to completely dissolve them (which varied between 24mL-48mL) unless the acid was highly insoluble like Salicylic

acid in which case was suspended in 48mL of H20. All H2O is distilled water bought at a CVS.

The Salicylic Acid was very interesting as a mixing suspension of MnCO3 and Salicylic Acid was just a milky off-white/ tan pinkish color and with the

temperature and magnetic stirring on the solution became a more darker color with a more pink color which is to be expected I would think of Mn 2+. As

the solution was allowed to cool to room temperature crystals started to precipitate. These were vacuum filtered and washed with a little H2O.

This is the mixture of Salicylic Acid and MnCO3

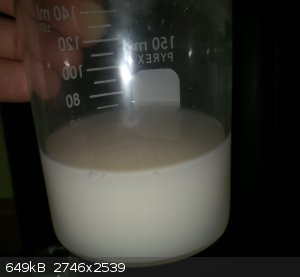

The product after heating for 10 minutes and allowed to cool to room temperature

After vacuum filtering and washing with a little water this is what precipitated

From left to right Manganese Tartrate, Manganese Ascorbate, Manganese Salicylate, and Manganese Nicotinate (but really I just think it is a mixure

of MnCO3 and Nicotinic Acid

With the Manganese tartrate the result of mixing MnCO3 and a solution of 1.306g Tartaric acid in 24mL of H2O was a pink precipitate that was

noticeably more colorful than MnCO3 indicating a reaction. I am not sure what is favored when making a tartrate salt or a Bitartrate salt but I am

assuming this would be the tartrate as I think I would need the acid in excess. Please correct me if I have that the other way around.

With the ascorbate salt, Ascorbic acid was dissolved in H2O and heated before addition of MnCO3 but once it was added it took a considerable amount

of time and heat to obtain a milky white compound to form .

The suspected Manganese Ascorbate

There was no noticeable reaction between the MnCO3 and Nicotinic acid so I will try to heat the solution for a considerable amount of time and see

what happens.

I will be testing the properties and try to analyze the compounds formed to try to confirm what they are.

Please let me know how this write up is, I did not include any equations but will try to in my follow-up post I just wanted to get this here tonight

to see what you guys thought on these results.

|

|

|

Vicarious3rdEye

Harmless

Posts: 16

Registered: 19-11-2016

Member Is Offline

Mood: No Mood

|

|

I am really sorry I am still getting used to posting here and I did not format that correctly. From the top left to right:

The MnCO3 mixed with Salicylic Acid, crystals precipitated after Salicylic acid solution before clear, the vacuum filtered crystals of said compound.

last picture of a single beaker is the product of Ascorbic Acid after heating for quite some time.

I apologize about this I will try to figure out how to fix this.

|

|

|

ninhydric1

Hazard to Others

Posts: 345

Registered: 21-4-2017

Location: Western US

Member Is Offline

Mood: Bleached

|

|

The manganese salts have the characteristic pale pink color of manganese in the 2+ oxidation state so no surprise there. I'm curious to see the

possible decomposition products for the more exotic carboxylic acids.

I would recommend typing out your procedure first then describing the pictures. The forum usually puts it at the bottom of the post so don't worry

about it.

The philosophy of one century is the common sense of the next.

|

|

|

Vicarious3rdEye

Harmless

Posts: 16

Registered: 19-11-2016

Member Is Offline

Mood: No Mood

|

|

Hello ninhydric1 thank you for your recommendation I will do that from now on. I was hoping to get some constructive criticism as I need it to get

better at posting experiments as well as for my own notes.

I originally was gonna make transition metal salts of simple carboxylic acids and still plan on doing so but have to admit I am more curious and

motivated by working with more exotic ones. I like that idea of trying to identify the products from decomposition I think I will do that. How would

you think the best way of going about that would be? Burning the material in a crucible, heating at a high temp. in a beaker on a hotplate, etc?

|

|

|

LearnedAmateur

National Hazard

Posts: 513

Registered: 30-3-2017

Location: Somewhere in the UK

Member Is Offline

Mood: Free Radical

|

|

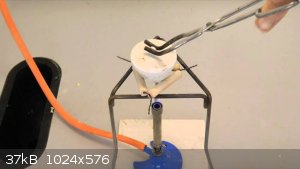

Usually when you do a solid state thermal decomposition, you use a ceramic crucible and heat from underneath with a Bunsen burner (or other flame, a

hot plate may not be powerful enough). I wouldn't use a metal crucible unless you know for sure that the reactants/products won't react with it, and

graphite crucibles may also work - these will be able to withstand higher temperatures as well, I've managed to crack ceramic crucibles when testing

rocket candy (KNO3 + sucrose) mixtures, but these were older and had seen their fair share of high temperatures.

If your reactant(s) decompose at lower temperatures (<500C) you can get away with using a test/boiling tube and GENTLE heating (don't let the flame

touch the glass for a minute or two) and this has the benefit of you being able to control where the gases go, but may also mean that you have to

sacrifice the tube if the sample fuses and can't be removed using a solvent or chemical reaction.

This is what the setup looks like, but you can substitute if you don't have the right bits. Image source for good measure:

https://m.youtube.com/watch?v=EWsTye5-J3k

[Edited on 16-11-2017 by LearnedAmateur]

In chemistry, sometimes the solution is the problem.

It’s been a while, but I’m not dead! Updated 7/1/2020. Shout out to Aga, we got along well.

|

|

|

Rhodanide

Hazard to Others

Posts: 348

Registered: 23-7-2015

Location: The 80s

Member Is Offline

Mood: That retro aesthetic

|

|

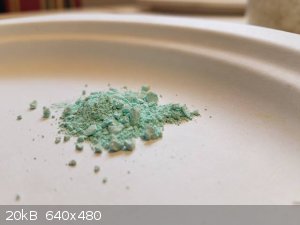

Here are very small samples of my Oxalates. Cobalt II, Nickel II & Ferrous (Iron II). I have about 200g of FeC2O4, 125g of CoC2O4, and 75-100g of NiC2O4.

|

|

|

| Pages:

1

2 |