low.safety.standards

Harmless

Posts: 28

Registered: 17-7-2018

Member Is Offline

|

|

Borosilicate under pressure?

Hello people,

Do anyone know of work with pressurized glassware? I'm looking for something that could withstand 20 atm at a couple hundred degrees with some 250ml

volume (working pressure would be around 10 atm). There's a guy in youtube exploding a wine bottle just under 250psi (~15 atm). Any idea on what I

could use or what thickness should I ask the glass maker to make it?

|

|

|

Sulaiman

International Hazard

Posts: 3738

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

Should be OK provided that you have the correct PPE

|

|

|

Deathunter88

National Hazard

Posts: 527

Registered: 20-2-2015

Location: Beijing, China

Member Is Offline

Mood: No Mood

|

|

Just. No. Use something else like stainless steel.

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

Borosilicate is not pressure safe.

Champagne bottles will handle a lot of pressure but aren't thermal shock safe.

Stainless steel would be the way to go.

If you need to do a reaction at high pressure and stainless steel would corrode too badly, you can use PTFE coatings or a borosilicate apparatus

inside of a stainless steel autoclave of some kind.

220+ psi is pretty high pressure for a home lab and using poorly designed apparatus may result in casualties.

For reference a champagne bottle is designed with a high safety factor and for an operating pressure of 90 psi. They are designed to be safe to 12

atms and possibly more depending on the bottle (some are rated higher). They will certainly handle more pressure than a wine bottle. A good

champagne bottle should handle 220+ psi but see the above safety apparatus.

A stainless steel CO2 fire extinguisher should be the right item to hold that kind of pressure.

|

|

|

Heptylene

Hazard to Others

Posts: 319

Registered: 22-10-2016

Member Is Offline

Mood: No Mood

|

|

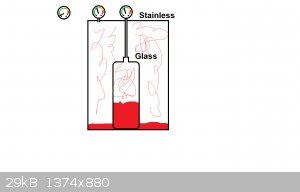

As proposed by macckone, you can place the glass reactor inside a stainless steel one. By using a liquid with the appropriate boiling point inside the

stainless steel reactor you could mitigate the pressure the glass reactor is subjected to. The glass reactor will only "feel" the pressure difference

between inside and outside.

For this to work you would need to make sure the intended reaction inside the glass reactor doesn't produce a lot of gasses, and you would have to

heat and cool the whole thing slowly, such that the pressure differential between the inside and the outside of the glass reactor is minimized.

I've seen pressure glass reactor on ebay that are stated to work up to 6 bars. I wouldn't trust those on their own, but if contained inside a

stainless steel shield they should be safe enough.

The gauge in the drawing show 3 pressure gauges: ambiant atmosphere, inside the SS reactor, and inside the glass reactor.

|

|

|

low.safety.standards

Harmless

Posts: 28

Registered: 17-7-2018

Member Is Offline

|

|

Ingeniously simple solution! Part of the problem is corrosion, most of it is that I wanted to see inside

...but that can be achieved with a 1" polyurethane window on a CO2 fire extinguisher holding my "not pressure rated" borosilicate reaction vessel,

thanks!

Anyway, also found https://www.schott.com/d/tubing/9a0f5126-6e35-43bd-bf2a-3499... which gives an approximate pressure rating equation for tubular glass given wall

thickness and outside diameter.

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

If polyurethane is suitable for a containment vessel, you may be able to use a polyurethane tube and then use end plates attached with high strength

steel. Not sure what thickness you would need for that pressure rating. Honestly I would go straight stainless with a camera inside.

If you are using a fire extinguisher you still need to get your reaction equipment inside, if you are using a test tube that should be easy. For a

500ml flask, not so much.

|

|

|

low.safety.standards

Harmless

Posts: 28

Registered: 17-7-2018

Member Is Offline

|

|

It's not, I meant it as a window for the pressurized autoclave containing the borosilicate glass.

|

|

|

nimgoldman

Hazard to Others

Posts: 304

Registered: 11-6-2018

Member Is Offline

|

|

Look up "hydrothermal autoclave reactor" on eBay. The lowest grade ones withstand up to 3 MPa which is almost 30 atm. There are 6 MPa and even 22 MPa

models, though much more expensive.

It basically a thick-walled stainless steel vessel with fine threads on one end and internal chamber made of PTFE or PP.

They come in variety of volumes from 10 mL to 500 mL.

Another (cheaper) option is a stainless steel pipe with threads on both ends. You can cover the threads with Teflon tape and tightly seal with caps.

[Edited on 21-9-2018 by nimgoldman]

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

Can I ask what we’re you planning to do under such pressure?

|

|

|

Metacelsus

International Hazard

Posts: 2542

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

I've used thick-walled borosilicate pressure vessels at 150 °C and 10 bar pressure. I'm talking about something like this: https://us.vwr.com/store/product/4831644/pressure-tubes-with...

(They can also withstand 300 °C and 5 bar, but I'd be wary of using 10 bar at that temperature.)

|

|

|

BromicAcid

International Hazard

Posts: 3254

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

I've used Ace pressure tubes like these:

https://www.sigmaaldrich.com/catalog/product/aldrich/z564591

I used an oil bath to heat them. Even though they were rated for the pressure I was using, I put them behind a blast shield and attached them to the

end of a rod on a pivot so I could dunk them and lift them out of the liquid without having to get behind the shield.

|

|

|

Metacelsus

International Hazard

Posts: 2542

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

Yes, a blast shield is highly advisable (and something which I forgot to mention in my post above!)

I've never had one explode, but I expect if the tube broke under pressure a powerful BLEVE would result.

|

|

|

Dr.Bob

International Hazard

Posts: 2766

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: Mildly disgruntled scientist

|

|

For 250 ml, a glass vessel is really pushing it, even for the Ace or Aldrich pressure tubes, and if you heat them, the rating goes down further.

Just use a glass lined steel pressure reactor, they can handle that with little hazard, just have to be careful when opening them to vent them slowly.

Even the best chemical microwave systems barely go up to those pressures and temps, typically only for 2-20 ml.

|

|

|