RogueRose

International Hazard

Posts: 1593

Registered: 16-6-2014

Member Is Offline

|

|

The catalytic converter (platinum & PM) paradox of converting NOx, SOx and NH3

Last week I was researching the thread about using platinized quartz wool (heated) to convert NH3 +O2 into NO/NO2 and eventually HNO3 based upon the

ostwald process. I also researched the contact process which stated that platinum used to be used as the catalyst to convert SO2 into SO3, also with

addition of O2 I believe - but now V2O5 is preferred due to cost.

Now when I researched the catalytic converters the main goal of these is to keep things like NOx and SOx and even NH3 out of the atmosphere by

converting them to N2 + H2O

Two-way cat

| Quote: |

A 2-way (or "oxidation", sometimes called an "oxi-cat") catalytic converter has two simultaneous tasks: Oxidation of carbon monoxide to carbon

dioxide:

-2 CO + O2 → 2 CO2

Oxidation of hydrocarbons (unburnt and partially burned fuel) to carbon dioxide and water:

-CxH2x+2 + [(3x+1)/2] O2 → x CO2 + (x+1) H2O (a combustion reaction)

|

This is the process of a three way cat:

| Quote: |

Reduction of nitrogen oxides to nitrogen (N2)

-2 CO + 2 NO → 2 CO2 + N2

-hydrocarbon + NO → CO2 + H2O + N2

-2 H2 + 2 NO → 2 H2O + N2

Oxidation of carbon monoxide to carbon dioxide

-2 CO + O2 → 2 CO2

Oxidation of unburnt hydrocarbons (HC) to carbon dioxide and water, in addition to the above NO reaction

-hydrocarbon + O2 → H2O + CO2

|

The only thing it did say was that there is a problem with fuels (LNG & diesel) which contain sulfur because during combustion it produces SO2 and

then further catalyzed to SO3 in the cat, which leads to "acid rain". Now I've heard that when SO3 + H2O mix (which should happen in exhaust) a very

large amount of heat is released, and this should take place behind the cat and I would suspect that there is acutally sulfuric acid exiting the

exhaust if not H2SO3 if the SO2 didn't oxidize in the process (maybe not enough O2 for this to happen?). Either way, the H2SO3 would probably turn

into H2SO4 in the moist air - is that a correct assumption or am I missing something.

Now this whole idea seems to be counter intuitive to what is going on in the ostwald process and I am wondering if the pressure in the reaction tube

(in the members experiement) is causing low yields).

What I would really like to do is figure out a way to use ammonium sulfate as a source for NH3 and SO2/SO3 and pass it through a reactor (platinum for

the NH3 and V2SO5 for the SOx) as the decomp point of amm sulf is about 280F (relesaes NH3) and then about 660F (nice high temp to start the reaction

in the reactor!) as the bisulfate where it releases NH3 and SOx (IDK if it is SO2 or SO3 it releases, if SO3 then no need for V2O5 I guess!). In

addition I would like to use an O2 concentrator where a pipe flows behind the reactor (to pre-heat the O2 and cool the NO2 as it exits catalyst) and

then is fed into the NH3 stream prior to the catalyst. If anyone sees problems with this, please let me know.

As a collection method for the gases I was thinking of a vertical stainless pipe (~2.5-3" diameter & 18-36" tall) filled with fiberglass

insulation - the puffy stuff - and then have a mister spraying down on top of the glass wool with re-circulating water/acid. This should give a lot

of surface area for the gases to contact as they rise through the column. I guess a cap could be inserted on this to feed any gasses to a bubbler but

IDK how much more NOx/SOx would be present - maybe use H2O2 in the bubbler?

In the end you would have a mixture of sulfuric and nitric acid which would have to be distilled but I don' think that is the hardest part in most

areas.

AS for the catalyst i'm working on a few ideas for support structure and have thought about using large grain Al2O3, the course stuff used in sand

blasting to coat it with platinum and also V2O5 though I'm researching the best method for this. The Al2O3 seems to have a crystal structure (very

rough) that may help support the catalyst where the pure SiO2 I've looked at seems very smooth and IDK how much can be supported without it flaking

off especially at higher temps. Both of these are available in a range if sizes from pottery stores for very little $$.

Here are some compounds with very high melting points that are available at most pottery shops (or they can order them), most are very inexpensive.

All temps are listed in F even if not noted.

MgO (5,200)

Fe3O4 (2,940F)

Fe2O3 (2832F)

Dolomite - (4700 - 8420F)

Calcium Silicate - (3,900F)

TiO2 - (3,350F)

SiO2 (pure quartz sand) - (3,115)

Al2O3 - (3,762F)

Silica gel (3,115)

Calcium magnesium Silicate (CaMgSiO4) - insulation temp rating of 2380F melts MUCH higher - great pourosity & comes in flexible insulation sheets

-

Forsterite (Mg2SiO4) 3850F MP

https://en.wikipedia.org/wiki/Catalytic_converter

https://en.wikipedia.org/wiki/Ostwald_process

https://en.wikipedia.org/wiki/Contact_process

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

I'm about to try something similar. I'm currently test firing some alumina mixed with about 10% bentonite clay. Both came from the local pottery

store. The clay body looks very white. The alumina dilutes out the iron content of the bentonite.

It's a bit tough to handle when dry, as it remains rather fragile, but I was able to shape it with a knife. A sharp blade shaves it like butter. I'm

firing it at 800°C for now, to see whether or not enough strength is gained at this temperature. I could go up as high as cone 10, but this is hard

on the heating elements.

I'm actually awaiting the arrival of a pound of Veegum T. My pottery store ordered it for me. At $15/lb it's a bit pricey, but is used only in small quantities. The aforementioned link shows

different articles made from alumina or zircon with only about 3% Veegum. So it's possible to make a ceramic with almost 100% alumina that is plastic

enough to be thrown on a wheel and shaped. Interesting.

Two key terms that may be of use to you are selective catalytic reduction (SCR) and selective catalytic oxidation (SCO).

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

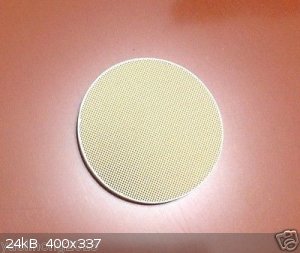

I dont know if ether of you have seen these ceramic honeycomb blocks it might make things easier .

https://www.ebay.com/itm/80mm-SOLDERING-BOARD-CERAMIC-HONEYCOMB-SOLDER-BOARD-HEATING-/271640811782?_ul=AU

|

|

|

Chemetix

Hazard to Others

Posts: 375

Registered: 23-9-2016

Location: Oztrayleeyah

Member Is Offline

Mood: Wavering between lucidity and madness

|

|

The ostwald process seems to work at oxidising nitrogen rather than reducing it because there's no carbon in the mix. I'm unsure as to how the Ostwald

scheme would work with SOx in the feed.

I postulated that SO2 in contact with NO2 should turn to SO3 and NO, where it would then re oxidise with excess air. The result should be a nitric

sulphuric acid mix. A one stop acid plant producing the two most valuable acids would have to be of benefit to many out there.

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

Looks like there are a lot of these floating around on eBay:

https://www.ebay.com/itm/25-TWENTY-FIVE-Ceramic-Honeycomb-Pi...

|

|

|