RogueRose

International Hazard

Posts: 1594

Registered: 16-6-2014

Member Is Offline

|

|

Rotary joints for rotovap - what do they look like?

I've been looking at some of the pictures of rotovap's and through some of the sites that sell parts for them and it is a little confusing as to what

the joint looks like that spins. I'm guessing it is glass on glass or do they also make PTFE joints?

I have seen the ball and socket joints which would seem like they would work well for rotation.

But on this page the flasks and items with this joint are labeled "reveiver" flasks which are the collection flasks, which seems odd IMO.

https://www.laboratory-equipment.com/lyophilizers-evaporatio...

Are there any special joints that are used specifically for rotovaps or a specific taper?

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

they don't use glass on glass for the rotating part i think, i've never seen a dismantled rotovap but searching on the web i found they they use a

mechanical rotating seal

maybe you could use the joint used for mechanical stirrers to do a similar job

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

coppercone

Hazard to Others

Posts: 133

Registered: 5-5-2018

Member Is Offline

|

|

the type of bearing will or should be different in a rotovap vs a overhead stirrer, since the force is completely downwards on a stirrer and at a

shallow angle for a evaporator, this means your failure rate on the joint and wear on the bearing will be different and not well suited.

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by RogueRose  | I've been looking at some of the pictures of rotovap's and through some of the sites that sell parts for them and it is a little confusing as to what

the joint looks like that spins. I'm guessing it is glass on glass or do they also make PTFE joints?

I have seen the ball and socket joints which would seem like they would work well for rotation.

|

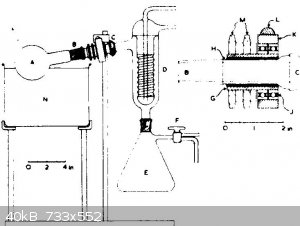

They do use special joints frequently but they also use those glass ball and socket joints for all glass sytems.

See the pic below. C is the ball and socket rotating joint.

Sorry I can not find the document I clipped the above crappy pic from. If you search for "all glass rotavap" you will probably find it or something

similar.

Borosilicate glass:

Good temperature resistance and good thermal shock resistance but finite.

For normal, standard service typically 200-230°C, for short-term (minutes) service max 400°C

Maximum thermal shock resistance is 160°C

|

|

|