| Pages:

1

2

3 |

greenlight

National Hazard

Posts: 754

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Electrical ignition system

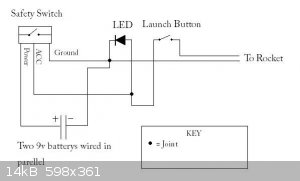

I came across this design for an electrical initiation system for model rocketry.

I would like to construct one but for setting off charges so I can eliminate dodgy fuse but I am not quite sure of the electronics.

The diagram runs of two 9 volt batterys linked in a battery pack but I am quite sure that this will have a very short range for reliable ignition.

Could the power source and wiring be upgraded to a level that it would reliably work 50 meters away every time?

How many 9 volt batteries would be needed to acheive this?

My plan for the actual igniters is to use s small piece of 32 awg nichrome wire dipped in BP slurry and then coated in NC for a protective waterproof

layer.

[Edited on 28-3-2017 by greenlight]

Be good, otherwise be good at it

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Skip the B.P.

Steel wool strands means much less current needed and faster response but a bit more effort in fabrication.

Get an old disposable camera with the flash circuit (Well 3 of them)

Take the caps off the two and solder them to the first.

Use a push button for the flash trigger, desolder one side of the flash and make it so it hookes up in series to your wire.

Gives good range and power dilivered (200+ volts) hence why you need the steel wire, it behaves ideal with this system

Once I made my element I'd dip it a couple times in nitro lacquer to glue it all together. I did all sorts of fancy things like making Nc plastic and

using mach head powder and such, eventually I dropped it all as a simple dip in the lacquer was all it really took.

But if the heart is set on it, dip it in the nitro lacquer then the BP

[Edited on 28-3-2017 by XeonTheMGPony]

|

|

|

greenlight

National Hazard

Posts: 754

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

So steel wool strand instead of nichrome wire on the igniter?

Is it possible to make the above diagram with a safety switch but with a series of 9 volt batteries instead of just two?

[Edited on 28-3-2017 by greenlight]

Be good, otherwise be good at it

|

|

|

Sulaiman

International Hazard

Posts: 3723

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

I know litle about igniters,

but in the schematic above, the LED needs a series resistor.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

As some one who did model rocketry it is! but in the above schematic it is just a "You got power/ Circuit armed" light

the LED is a continuity indicator ensuring the ignition is all hooked up, model rocket igniters are current based, very thick NiChrom.

Any blasting systems function is to ensure power can not be accidentally supplied to the cap while working on it.

For my pyrotechnic system I used an automotive key lock and a SPST covered switch, key was global power, covered switch was the firing system power,

and to fire two NO switches must be pressed.

When one of the NO push buttons was pressed a buzzer sounded to warn you are fully hot and ready to fire.

So to make a simple battery operated system use 1 toggle switch that is covered to prevent accident arming and a normally open push button, for the

circuit verification use a 4.5K resistor and a red LED across the NO push button, enough current will flow when armed to illuminate the led but to

never fire the cap/igniter

[Edited on 28-3-2017 by XeonTheMGPony]

|

|

|

DubaiAmateurRocketry

National Hazard

Posts: 841

Registered: 10-5-2013

Location: LA, CA, USA

Member Is Offline

Mood: In research

|

|

http://www.nakka-rocketry.net/igniter.html

This guy's website have a comprehensive guide in amateur rocketry.

edit: missing word

[Edited on 28-3-2017 by DubaiAmateurRocketry]

|

|

|

TheMrbunGee

Hazard to Others

Posts: 364

Registered: 13-7-2016

Location: EU

Member Is Offline

Mood: Phosphorising

|

|

for igniters: https://www.youtube.com/watch?v=zjAABCRhm8c

As for the launcher I used wireless car lock system and 12V lead battery, got two working channels from it. wireless is allways better!

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

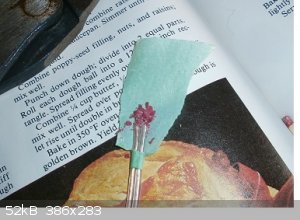

I just made this in less then 1 minute and used a dead AA to fire it. steel wool is the best, allot of those are rather poor design and use excess

material.

Normaly it is allot more packed with more punch, but this was a fast 1 minute demo of the set up.

[Edited on 28-3-2017 by XeonTheMGPony]

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Using a staged ignitor allows you to use less material more efficiently.

Easy ignitable susbance> Lesser > Lesser but hotter.

So Wire with steel wool strand doped in NC > NC/Nitroglycerin blend for ignitors.

For caps, first stage is as above, and atm I am using HMTD then ETN final stage. top is capped with paper cap and crimped, bottom is some tape and

fused ETN to make a solid plug.

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

Nichrome wire has higher resistance than steel.

The wire thickness is critical.

Too thick and it won't heat correctly.

Old style flash systems are great for the voltage pump.

|

|

|

greenlight

National Hazard

Posts: 754

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Thanks for all the replies...

I will use a similar igniter to Xeons in the actual cap.

I will have to do some tests and see how much power I need to heat the igniter from about 50m away.

Be good, otherwise be good at it

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

that's the point you want a bit of resistance but not much, it is the current that makes the heat, Steel has just enough resistance but poor thermal

dissipation to heat fast and effective with little energy!

@Green, it is volts that push the amps, higher the volts the longer you can go on a given wire I^2R gives you the resistance losses for a given

current

200 feet of wire at 14awg at 12 Volts will do the job easily, at 1 amp you'd have a 9.8V potential across the wire ends, plenty to get steel wool to

white heat fast, nichrom is much slower. You can go to as low as 16guage, just might take a tad longer to fire, so 2 series 9V will be plenty for the

job!

Steel wool: Fast to fire, low energy cheap and widely available, works with capacitor discharge systems effectively. Con: It is delicate to work with

and can be finicky

NiChrom: Strong, durable, easy to handle, Con: Expensive, hard to source, long time delay from power to ignition, will not work with cap discharge

systems with out very precise length controls.

I have used both and I still do depending on the target goal, but more and more I am using steel wool as it is much better for multicap timed systems

for firing patterns.

I blasted out my old cistern using steel wool elements with a pressed time delay using mach heads, it worked but I plan to use a Silicone CaSO4

thermite comp for the next batch of time delayed caps, So for it to work right I need all elements to fully ignite fast off a single energy burst.

Steel wool does this the most reliably in a parallel pattern then nichrom would due to the delay issue

|

|

|

Sulaiman

International Hazard

Posts: 3723

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

Why not have your high current battery near to the launch pad,

connected to the fuse by normally-open relay contacts, and power the relay coil remotely ?

(e.g. 5 V relay coil and 9V battery)

This way you need not invest in expensive, bulky, heavy lengths of high voltage or current cable.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Praxichys

International Hazard

Posts: 1063

Registered: 31-7-2013

Location: Detroit, Michigan, USA

Member Is Offline

Mood: Coprecipitated

|

|

I like to use old Christmas lights. If you're careful, you can clip off the top with a pair of wire cutters to expose the filament. Wrap electrical

tape once or twice around the intact portion of the bulb to cover the jagged edge, making a cap shape the diameter of the bulb and about half an inch

long. Make an acetone paste of smokeless powder (or use nitrocellulose lacquer, or basically any match paste that will harden) and carefully fill the

remains of the glass lamp and tape tube. When dry, check continuity with an ohmmeter. If it's not an open circuit (which means you broke the

filament), there is basically a 100% chance it will work. I use a firing circuit made from disposable camera flash caps and a charging circuit, and

fire through 1/4" coax cable.

Alternatively, a suitably sized straw can be pressed over the remains of the lamp and 200mg of lead azide poured in, then taped shut for direct

primary initiation.

I do this because now that LED Christmas lights are popular, everyone is throwing out their incandescent ones. You can get 150 ready-made filament

assemblies for free for each strand of lights you find, and each lamp assembly has about 6" of leadwire already attached.

[Edited on 29-3-2017 by Praxichys]

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Do you all so go by Codies lab? or another guy all together?

I tried to email him once on a more reliable delay system, because he did a sequential blast and had issues.

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

I once made a mix of graphite and ping pong balls dissolved in acetone. This way I could make pretty consistent electric fuses after dipping a short

piece of sound cable in it. This is an easier way than breaking open light bulbs which easily break. Also you don't have to use tape to hold things

together as the NC putty becomes a tuff plastic.

|

|

|

yobbo II

National Hazard

Posts: 764

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Tsjerk  | | I once made a mix of graphite and ping pong balls dissolved in acetone. This way I could make pretty consistent electric fuses after dipping a short

piece of sound cable in it. This is an easier way than breaking open light bulbs which easily break. Also you don't have to use tape to hold things

together as the NC putty becomes a tuff plastic. |

Is the mixture of graphite and ping pong balls conductive?

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

I also use christmass tree light bulbs...the extremity can be easily cuted off with a dremel and this leaves the main cylindric part of the light bulb

with the electric tungsten wire integer.

Then you can put anything you want into it BP, Flash, CuO/nano Al thermite, KClO3 BP, NiHN, NC to make ignition devices or SADS to make detonator.The

hole needs to be closed with NC glue.

A low voltage (1V) current is sufficient to allow for ignition/deflagration/detonation.

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

greenlight

National Hazard

Posts: 754

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

@xeon, I will attempt to use the diagram with 14 gauge wire and two 9 volts in a series for power and steel wool as the connector in the initiator.

@sulamain, I am nervous for my first attempts at having the power source connected so close to the charge in case of accident. I was thinking I could

place the charge, run the cable back and then connect it to the power supply and fire it.

I don't have any of the old christmas light reels here so I will try the steel wool and see how that goes otherwise I found this on ebay. 200 of the

old style bulbs with just the wires out the back to connect:

http://m.ebay.com/itm/302159705581

Be good, otherwise be good at it

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

remember to short the end of the wire where you'd hook up the firing modual.

The added safety never hurts!

[Edited on 31-3-2017 by XeonTheMGPony]

|

|

|

greenlight

National Hazard

Posts: 754

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Twist the wires together you mean until ready to fire?

[Edited on 31-3-2017 by greenlight]

Be good, otherwise be good at it

|

|

|

dillee1

Harmless

Posts: 9

Registered: 1-4-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by PHILOU Zrealone  | | I also use christmass tree light bulbs...the extremity can be easily cuted off with a dremel and this leaves the main cylindric part of the light bulb

with the electric tungsten wire integer. |

^This. Although I use 2.4-3.6V flashlight light bulbs+20mg perchlorate flash as pyro primer. With 20m 24AWG, 9V drive voltage it is 100% ignition

rate.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

yup or any other means really, to snuff out any induced voltage in the wire from power lines/radios so on.

|

|

|

greenlight

National Hazard

Posts: 754

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Okay thats extremely important because my site has large high voltage power lines a couple hundred meters away.

Be good, otherwise be good at it

|

|

|

yobbo II

National Hazard

Posts: 764

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

| Quote: |

Some conversation:

remember to short the end of the wire where you'd hook up the firing modual.

Twist the wires together you mean until ready to fire?

yup or any other means really, to snuff out any induced voltage in the wire from power lines/radios so on.

Okay thats extremely important because my site has large high voltage power lines a couple hundred meters away.

|

It is important to tie the wires together BESIDE the bomb. NOT at the end where the battery/power supply is located as this will have the exact

opposite effect.

Yob

|

|

|

| Pages:

1

2

3 |