Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

SA Heater & Stirrer (Blog)

I need heating and stirring for my planned distillation rig.

I have decided to do-it-myself,

and use SM to host my construction blog and relevant Q&A.

I intend to build the stirrer and heating sections separate but stackable

with some provision for raising/lowering the assembly.

The heater must accomodate 500 ml R.B.F.s,

with the option of smaller, and possibly larger flasks.

I would like to be able to get up to 500 Watts into a 500 ml R.B.F. (?)

Plan A for the heater is based around one or two 'Fan Oven Heating Element' 220 V 2200 W

(ordered 2 for £7.82 total, eBay UK)

Outside diameter of heating coils c190mm, other dimensions to be measured on arrival.

I could use one (more than enough power) in the design and keep one as a spare,

Or use both in electrical series for 1.1 kW max with a larger area ... t.b.d.

This type of heating should allow the flask to be as near as practical to the stirrer for good magnetic coupling.

So, before I start ... any comments

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Harristotle

Hazard to Others

Posts: 138

Registered: 30-10-2011

Location: Tinkerville

Member Is Offline

Mood: I tink therefore I am

|

|

Hi.

If you have two elements in series, you will half your power, not double it. (Parallel will double watage)

mathematically:

power = volts * current

current = volts/ resistance (from Ohms law)

So the resistance of your heater can be found by rearranging

power = volts * volts / resistance.

R = 220V^2/500W

=96.8 ohms.

If you put two resistances in series, you add their resistance together (double it).

so P = (220V^2/(193.6) = 250W.

Other thoughts: I am not sure I like the low surface area contact of your heating element. It means your flask will have parts in contact strongly

heated, and most of it not strongly heated. This may encourage it to crack, if it is damaged/flawed.

There are some good threads here on making your own from refractory (fireplace) cement and nichrome wire - eg http://www.sciencemadness.org/talk/viewthread.php?tid=4190

That would be a good place to start.

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

Thanks, but I guess you missed it, 2200 W elements, two in series for 1.1 kW

and the heating coils, being c190mm diameter, will be well clear of a 100mm dia. 500ml rbf.

probably enough space for a sand/oil/water bath to fit of required

My initial concerns are with radiative heating (/hot air bath) ... will it work for most things that I may want to distill ?

Will I need a fan in the heater space ?

but I guess that in a couple of days I can find out

[Edited on 7-1-2017 by Sulaiman]

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Dr.Bob

International Hazard

Posts: 2817

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: Mildly disgruntled scientist

|

|

That is way more watts than most standard heating mantles, so you will need to be careful to use a low setting on whatever power controller you use or

the heat will heat very fast and be dangerous with flammable solvents. You might want to either use an aluminum hemisphere or block to spread the

heat better. But the idea seams fine, just need to make sure you don't over heat the target rbf. Few fans will survive that heat, might need to

fine some inert conductive material to help, however.

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

IF a fan is required I imagine motor and fanblades separated by some sort of heat shield / the wall.

My next mini-quest is to find common, cheap, thin, strong, heatproof, non-magnetic, heat-reflecting sheets for top and bottom.

equivalent to asbestos sheet.

the prototype will use gypsum/drywall, or metal, or whatever is nearby ... just for testing radiative heating.

I agree about the power, I bought the heating coils on impulse

... looked possible, easy, rugged, easily replaced, and most importantly, on offer ...

I will initially use a zero-crossing-switching 40A SSR with pulse width modulation 0 to X% at about 1 Hz

... where X will normally be much less than 33 ... but one has to test, right

may even try some toast ...

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

PWM will work to bring it down to something sane !

If you need any zcd opto-triac triggering chips plus triacs that can handle the power, pretty sure i got a bag full of each.

U2U if you need any FOC.

Edit:

I quite like the idea of the open ring heating elements - makes the stirrer mechanism fit much easier.

If there was a metal sheet on the top with a hole big enough to reach the half-way mark of an RBF, just add a fan at the bottom to make (possibly) the

world's first Fan Assisted heating mantle !

Same fan motor could run the stirrer, airflow would cool the fan motor & electronics ...

Actually, this is sounding like an excellent idea : forced air high temp air bath.

Don't bolt the plate on, so you can swap it for different RBF sizes.

[Edited on 7-1-2017 by aga]

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

I like the idea of fan blades below the rbf,

(prossibly centrifugal?, suck down and blow sideways, for low profile)

but I want to keep that area free for oil bath, toasting box, maybe even a crucible

and I think that fan speed and stirring speed should be independant

and I really would like the stirbar strongly coupled to the rotating magnets,

I've seen too many videos of erratic stirring.

(thinking about it, the fan blades and shaft could be removeable ..........)

I was inspired to choose these heating elements by Vogel's love of the hot air bath,

and his still designs inspired me on this distillation path in the first instance.

I will probably have a layer of sand at the bottom for insulation,

and as a 'buffer' for suicidal flasks and beakers.

(if no fan

everything is a variable at the moment, other than the heating elements in the post.

I am just looking for ideas and warnings at the moment.

P.S. thanks for the offer but I'm OK for electronics.

Initially I'll just use a rex c-100.

IF this seems feasible, I will try to build from scratch with eBay stuff in case others want to copy,

assuming I'm not electrocuted or incinerated, and it works

[Edited on 7-1-2017 by Sulaiman]

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

These heating maantle elements are on ebay .

http://www.ebay.com.au/itm/132029334401

I used a coffee can to build a surround for it.

http://www.sciencemadness.org/talk/viewthread.php?tid=67866&...

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

I saw and absorbed your project, and your approach was the most favourable, until I saw these heater elements.

My hidden agenda is to use it as an oven or modest kiln ...

usually 'universal versatility' in my projects leads to abandonment/failure,

so I am concentrating just on using it as an rbf heater ... initially.

And I do want to try a hot air bath, no special reason, I just want to try.

Otherwise, I really like your diy mantle.

P.S. I forgot who, sorry, but I also liked the airbath design using a hot air gun and tin can ... very simple and effective.

P.P.S. A 220 Vac heater run on 110 Vac consumes 1/4 of the power,

so a 220 V 2200 W heater would be just nice at 110 V = 550 Watts, just nice for a mantle etc.

and it should be extremely long life, running at 1/4 power rating.

[Edited on 8-1-2017 by Sulaiman]

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

mux

Harmless

Posts: 31

Registered: 11-12-2016

Member Is Offline

Mood: No Mood

|

|

Note that it's not just the power rating, but the actual temperature of the element (and then mostly: of its hotspots) that determines the lifespan. A

forced air heating element can easily be overdriven quite significantly if it's used in a (non-boiling) liquid, yet a direct touch heating element can

pop in no-time even at 1/4 power if it can't lose its heat quickly enough.

Long story short: you do need something fairly thermally conductive between the element and rbf.

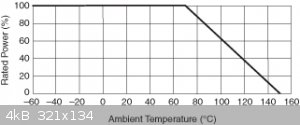

I'm sure you know this already, but this is called derating. Typical derating curves for heaters look like this:

[Edited on 10-1-2017 by mux]

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

Cancelled

I just got an eBay message telling me that the elements on offer are out of stock ... 20 days re-stocking delay ... cash refunded.

Enthusiasm for this project diminshed but not dead, just re-routed.

mux, I had not thought about hot spots without forced air ... pondering

I did a few quick calculations for radiative heating of a (500ml rbf) 100mm diameter black body,

. at 100 C the flask would radiate c34.4 Watts into darkness

. 550 Wats heating would need the flask to be surrounded by 646 C

650 C for nichrome is not a problem,

but considering that the flask would only be a hemisphere (half full) and the heating elements would not completely surround the flask, and now

hot-spot considerations,

radiated heat alone is not quie enough

On the brighter side, I can now look at cheap ovens on their backs

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

Enough messing about ... I bought one of the 500ml 250W mantle liners,

now that you have had yours for a while,

anything that you would change ?

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Sulaiman  |

Enough messing about ... I bought one of the 500ml 250W mantle liners,

now that you have had yours for a while,

anything that you would change ? |

No Sulaiman i am happy with the 250ml mantle, i also use a cheap ebay triac voltage control to vary the heating level .

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

I have ordered one of the eBay triac dimmer-type controllers, thanks for the reminder

I was going to make something similar, or use my small 1A variac,

but a ready made 4000 W (?) 'dimmer' for £1.24 ...

(4000 W / 220 V = 18 Amps ... I doubt it, especially with that tiny heatsink in a hot enclosed unventillated space

... but should be OK for my 1.1 A, 250 W diy mantle )

The only fibrous insulation material easily to hand is fibreglass loft insulation,

which I do not want to use because of potentially toxic fumes from the binder,

so I shall initially use vermiculite.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

That liner was a great deal.

But if you ever decide to try rigging up a hot air bath you might want to look into using a 'soldering station'.

They work like a heat gun, but the electronics are in a separate box isolated from the heating element and they often include a PID which controls the

hot air output temperature to a claimed accuracy as close as 1 degree centigrade. They also have adjustable air flow rates.

Some include an integral soldering iron, but others are just the hot air source and controls. (30-40 US$ cost range.)

Actually, I forgot who I was talking to here. I might want to consider using one of these, but YOU could obviously just make something up yourself

which functioned as well or better for a fraction of the cost.

I still think the PID controlled temperature and variable air flow would be desirable features though.

I have deferred my own plans along these lines because a great deal on some factory refurbished Briskheat mantles came along, but am still intrigued

by the whole hot air bath idea.

Perhaps the fiberglass used for 'chopped and blown' GRP would be useful for your insulation needs.

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

Hopefully my heating mantle will have a supporting role in my next YouTube detritus......

I am still interested in making a hot air bath, mainly because Vogel liked them (?)

(Vogel's 'Practical Organic Chemistry' from the SM library was the first book on organic chemistry that I read, two years ago, not counting school

40++ years ago)

I have since realised that any 'serious' Chemistry book must have >1000 pages

... scrolling chemistry.pdf files on my 'phone is such fun

Although I could design and build such things as pid controlled hot air blowers,

I would almost certainly buy one and modify it,

usually much cheaper, quicker and easier than starting from scratch.

I doubt that I will actually make a hot air bath in the forseeable future,

unless my heating mantle, hotplate, solder baths etc.

are not good enough for some experriment that REALLY interrests me.

I haven't even completed my super-duper fractionating still ... yet

Specifically for fractional distillation;

For heating power control I am of the opinion that simple (settable) constant power is second best only to

power control based on pressure difference between top and bottom of the fractionating column,

which I hope to try later this year.

I guess that like many here, I have more plans than time.cash.energy

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

Testing Heating Mantle for 500ml RBFs

For my heating mantle enclosure I used a thin steel cake tin,

and for heating power control I lashed up one of the eBay 'dimmer' type controllers.

The four screws on top hold an aluminium plate which has a hole just nice for the mantle,

which is clamped by the screws between the aluminium plate and the tin top (was the cake tin bottom)

The aim of these tests was to determine the effective heating power of the mantle by measuring the rate of change of the temperature of water.

Each test used 250 ml of tap water in a 500 ml RBF.

1) 'dimmer' power control set to max, no thermal insulation inside the tin ... 87 W

2) As above but directly connected to 240 Vac ... 112 W

3) Tin can filled with fibre glass wool, direct connect to 240 Vac ... 175 W

4) The dc resistance of the heating element is 150 R, so Input Power = 384 W

As each test started with all parts at 20 oC I guess that a lot of the input power goes to heating up the heater

No stirring yet, there is space in the bottom of the tin for spinning magnets but I've side-tracked myself for a while to investigate overhead

stirring.

P.S. The two nuts are part of the fastening of a ceramic 3-way connecter as the wires from the mantle element are not very long.

The third terminal will be for 'protective earth', not fitted in this lash-up ... I can feel the slight 'buzz' of ac current leakage

[Edited on 10-7-2017 by Sulaiman]

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Organikum

resurrected

Posts: 2342

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

I love the can, I had something similar back in the days and it worked like a charm, simple, cheap and functional.

I also lately tinkered with heating and magnetic stirring, infrared heating in special and I came up with this contraption made from a infrared

heating element with a 4000 W dimmer. a motor from a lawn trimmer and Sm/Co magnets epoxied to it, old PS and PWM controller. When appropriate the

heating is also connected to a REX C-100 PID controller with thermocouple and 40 A SSR.

It works perfectly well btw. 800 W are more then enough, the stirrer is incredible powerful, say the magnetic contacz is excellent and as there is

next to zero thermal mass there is no more heating after you turn it off. Only the lass from the flask has some heat stored. otherwise off means

instant off and I find this great.

[Edited on 14-12-2024 by Organikum]

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

I can certainly agree with the value of 'instant-off' for heating,

occasionally I'd wished for an 'emergency' rbf cooler.

My emotions are not as stable as I'd wish when things start to get exciting....

I've had run away reactions, and reactions that I've run away from

........................

Quote: "...heating is also connected to a REX C-100 PID controller with thermocouple and 40 A SSR."

I bought two similar sets some years ago - EXCELLENT product.

.......................

The IR heater must be nice in winter, but in summer?

Maybe a heat and light reflective or insulating ring a few cm high around the perimeter of the heater, but not touching it, e.g. Al foil

........................

My DIY 500ml heating mantle is disassembled at the moment,

part way through a second attempt to add magnetic stirring.

(meanwhile I've learned to like overhead stirring)

waiting to finally move to a permanent address and get some hobby 'work' done.

PS for others considering DIY heating:

temperature controllers like the C100 are great for maintaining a fixed temperature (eg significantly below a boiling point)

But for distillation I like constant heating power for constant vapour speed

So a dimmer/scr/triac/phase-controller......or variac etc, is preferred

[Edited on 14-12-2024 by Sulaiman]

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Organikum

resurrected

Posts: 2342

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

This is just the experimental version, the next iteration will have:

- a relector below the lamp alone to shield the stirrer, magnets and motor

- a much much smaller motor (3,5 V and 0,8 A was the absolute maximum needed up to now, professional stirrplates have 3 W to 5 W (effective) power

output. A 5 V/1 A geared motor is cheap and will do I say.

At 800W as this lamp has one needs a dimmer in any case to achieve equal heating, the PID controller alone does no good job here. Sadly the REX has no

"duty cycle" setting which would be needed to do this without dimmer. I believe one wants an SCR kind of dimmer to avoid problems with the SSR, but

somebody with more knowledge in electronics will know better.

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

I'm always concerned about flasks breaking during an experiment

(luckily not yet, but I do believe in bad luck, clumsiness and my own occasional stupidity)

So some sort of bowl as a last line of defense is a good idea.

I've bought a PYREX kitchenware bowl to put between the stirrer magnets and the heating element insulation

It should not mess with the magnetics, and should have reasonable thermal shock survivability...tbd

On reflection, maybe in your case a thick PYREX bowl would absorb too much IR.

A heat shield for the magnets and motor is definitely required,

A small DC motor with gearbox will wear out quite quickly,

and be noisy, and a source of sparks - but they are cheap

[Edited on 16-12-2024 by Sulaiman]

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|