| Pages:

1

2

3

..

5 |

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

Fume Hood Construction

Working on the design for my own fume hood.

My main reason for posting today is to ask Magpie how his window frame is attached to his fume hood.

I want to copy his approach of using a standard vinyl window for the fume hood face, but looking at the installation instructions for the Jeld-Wen

products at Home Depot, they apparently have a "nailing fin" attached to the outside of the frame, and expect you to nail it into a wood frame

surrounding the window frame. Undesirable for several reasons - minimizing wood used in construction (I want it to be nearly all metal), adds extra

width to the unit, etc.

Magpie has somehow mounted it flush to the (wood?) frame directly behind the window frame.

How he do that?

My own design concept is to make a free standing unit that can be taken apart for moving. I want to base it on this product, which is reasonably

priced square aluminum framing that bolts together in modular fashion (80/20 Inc. Ready Tube):

https://8020.net/catalog/category/view/s/shop/id/837/?cat=38...

Painted galvanized steel sheet (cheap, strong) will be screwed on to the sides to make the enclosure.

The 1.5" frame makes a convenient baffle set-up. Attach steel to the outside back, then baffle steel sheet to the inside, using the 1.5" gap as the

draft space. Install frame tubes with connector inserts at suitable locations, and you have nice attachment points for mounting stuff on the frame

inside the box.

I am puzzling out how a window frame can be best mounted on a Ready Tube frame.

My idea for a work surface (a removable table surface that can be inserted through the window and rests on the frame) is to use bar-top epoxy resin:

the stuff that make hard transparent surfaces. Attach aluminum edging to a plywood table, and pour the resin to make the work surface. Epoxy does not

dissolve in any solvent, and you can always re-pour a new layer to refresh the surface if desired. It also has the nice property of being

self-leveling - it always makes a perfectly flat, level surface.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by careysub  | Working on the design for my own fume hood.

My main reason for posting today is to ask Magpie how his window frame is attached to his fume hood.

I want to copy his approach of using a standard vinyl window for the fume hood face, but looking at the installation instructions for the Jeld-Wen

products at Home Depot, they apparently have a "nailing fin" attached to the outside of the frame, and expect you to nail it into a wood frame

surrounding the window frame. Undesirable for several reasons - minimizing wood used in construction (I want it to be nearly all metal), adds extra

width to the unit, etc.

Magpie has somehow mounted it flush to the (wood?) frame directly behind the window frame.

How he do that?

|

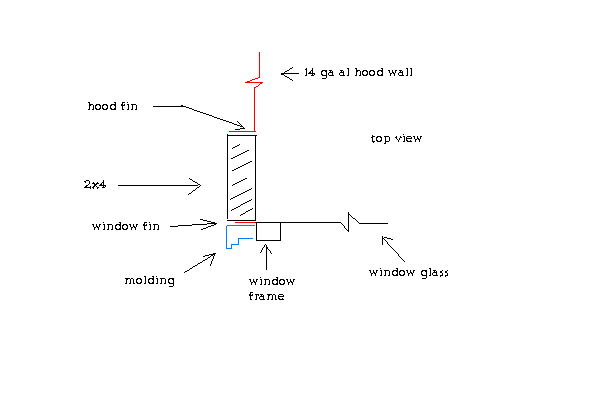

Glad to give some details:

The support frame for my Jeld-Wen window is composed of 2x4's on end, so to speak. This does add an extra 1.75" of width on each side.

The window fins are nailed to the 2x4's on the front side. On the back side my 14 ga aluminum hood fins are likewise nailed to these same 2x4's. On

the front side the window fins are covered by a molding of 1.75" width, as a cover, and for cosmetic reasons. The inner edge of the moulding strips

are sealed to the window using a bead of caulk.

I'm sure you know this but one shouldn't obsess about small leakage gaps and non-perfect seals as small inflows of air are inconsequential.

Will you use a single pane constant flow design?

[Edited on 5-7-2016 by Magpie]

[Edited on 5-7-2016 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

Thanks! I want to build on your success.

Quote: Originally posted by Magpie  |

I'm sure you know this but one shouldn't obsess about small leakage gaps and non-perfect seals as small inflows of air are inconsequential.

Will you use a single pane constant flow design? |

Taking the second comment (the question) first:

No, I intend for the sash height to modulate the inflow velocity.

And:

Yes, I do know that. In fact I was contemplating having a non-windowed intake gap at the bottom (between the table and the frame on the side) to

create a background inflow rate to reduce the degree of dependence on in-flow with sash height (it would lift an aluminum strip that would drop down

blocking the intake when the fan is off). Not sure if I will pursue this idea.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I know some or most of the professional hoods have a bypass located on top and/or possibly under the hood opening. These are redundant and an

over-complication if a constant flow design (like mine) is used.

I'm trying to muzzle myself but I can't over-emphasize the benefits of the constant flow design:

1. Air velocity is constant no matter the sash position. Therefore your fumes will be carried out and your bunsen burner will not be blown out. A

closed window allows no airflow and the fumes will just sit there.

2. A blower has an optimum air flow for best performance. The constant flow design provides this unvarying optimum flow no matter the sash position.

3. For maximum body/face protection pull the single window all or most of the way down. Airflow is unchanged as it is now all or mostly all going in

over the window above your head.

I don't think I've ever convinced anybody yet but since you are making some effort and expense to do it right I thought I'd try one more time.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

Well I could always change it to a constant flow design later simply by knocking out the top pane...

Speaking of protection - do you have a film on your glass (or else a special glass) to prevent fragmentation in an explosion?

[Edited on 6-7-2016 by careysub]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Right....

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

CharlieA

National Hazard

Posts: 646

Registered: 11-8-2015

Location: Missouri, USA

Member Is Offline

Mood: No Mood

|

|

from careysub:

I want to copy his approach of using a standard vinyl window

You might want to look into using polycarbonate sheet instead of vinyl. You could make the window from yourself or use the PC sheet to re-glaze an

existing window. PC is much safer than a glass window.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by careysub  |

Speaking of protection - do you have a film on your glass (or else a special glass) to prevent fragmentation in an explosion?

|

The sash is double-pane tempered glass per my order from Home Depot. There's no special covering on the glass.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

I am considering this fan, in lieu of a belt driven fan:

http://www.mcmaster.com/#19135k67/=135nfas

It has a "totally enclosed motor", aluminum blades, and a plastic body. An in-line fan is much more convenient for me space-wise, and this is

significantly cheaper to boot.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Whatever fan you select it must be able to deliver enough flow to provide 1.0-1.5 fps face velocity at your hood opening. It also must be corrosion

resistant and spark free in the exhausted air environment.

If you don't have a constant flow design your face velocity is going to vary all over the place, depending on sash position.

My squirrel cage fan blades are epoxy coated steel. I have never inspected my fan internals since installation (11 yrs ago). I just know that the

fan still works well.

3/8" SP looks a little weak to me but I don't know the diameter, shape, and length of your ducting. My fan delivers 400-500 cfm at 3/4" SP.

All of this guidance I have repeated several times in the hood threads to various posters. In the end I find that people just do whatever they had in

mind in the first place. Everybody has their own space and money constraints. As garage chemist said: "any ventilation is better than none."

[Edited on 6-7-2016 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

I need 285 CFM for 1 FPS with the sash wide open on a 36"x48" window.

The total distance from the 8" x 12" trunk duct plenum on top of the fume hood (I intend to use a slot along the top for extraction) using 8" ducting

is 4 feet to the garage side vent with one 90 degree bend. I calculate a pressure drop of 0.01" (rounding up). So 310 CFM at 0.375" looks good.

OTOH, I was also looking at this, and using a carbon filter (static pressure drop 0.5") to reduce odoriferous releases:

https://www.amazon.com/Can-Fan-Inline-6-Inch-Minute/dp/B004C...

which delivers 283 CFM with a filter.

At $100 it could be considered a replaceable item if it fails from corrosion.

Having a carbon filter upstream may provide some protection (I know they do not do much with acid gases), and I would endeavor not to put lots of

corrosive gases through it (the hood is after all primarily a safety system, not a chemical disposal system). Proper experiment set-up should try to

capture and neutralize such releases, and I do have the option of doing some simple operations outside if corrosive release seems unavoidable.

Getting an indutrial type blower rated as "explosion proof" (is "spark resistant" a suitable substitute?) is a problem, it looks like it multiplies

the cost by about 10, pushing it into the "unaffordable" column, and makes units delivering adequate static pressure in my size very hard to find at

any price, and many of the units offered in this category are extremely loud.

The only possibly suitable units from McMaster-Carr are $860-$1000 and are 65-70 dB (I would be standing just a few feet away).

Someone on this thread suggest boat bilge blowers. They are "ignition protected, spark proof", and are amazingly cheap - $25-40.

For example this one I can find a static pressure curve for (see attached):

http://www.westmarine.com/buy/shurflo--yellowtail-marine-blo...

Even at 0.5" static pressure the 220 CFM $38 unit delivers about 165 CFM. I would need two of these 4" units, but they are small and I could mount

them inside a foam/fiberglass plenum box (helps muffle them too). Requires a 13.6 V, 10.4 A power supply, but I need to drive LED lighting anyway.

Looks like maybe the way to go. With an encased motor and a nylon blade sounds like it is corrosion-proof also.

Attachment: 911-723-C.pdf (177kB)

This file has been downloaded 2708 times

[Edited on 6-7-2016 by careysub]

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

A potential solution may have been invented in 1815 https://en.wikipedia.org/wiki/Davy_lamp

with minor modifications ...

Some reliable simple flame arrester may help ? https://en.wikipedia.org/wiki/Flame_arrester

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

Interesting. I knew about the safety lamp, but had not considered this.

Actually the use of the carbon filter, upstream of the fan which is the preferred arrangement, might be an effective flame arrester. The air must pass

thought the 2" carbon bed to get to the fan and motor. This should have the same effect in preventing propagation of a flame front back to the hood,

especially since the flame front has to move against the air flow which would in the neighborhood of 10 ft/sec, but 25 ft/sec at the throat of the

filter.

(This posted before I could complete it.)

Attached in a paper on the flame front velocity of diethyl ether/air, which indicates a maximum velocity of 70 cm/sec. This suggests that it cannot

propagate against the duct flow regardless.

Of course a flame arrester (if it works) prevents propagation not ignition, and the flame would probably continue to burn downstream from the motor

once the gas mixture was ignited. If this happened just before the external vent this result may not be too bad, if there is nothing combustible right

outside the vent.

It would be interesting to set-up an outdoors duct/motor test set up to investigate ignition and propagation.

[Edited on 6-7-2016 by careysub]

Attachment: gillespie2012.pdf (713kB)

This file has been downloaded 1501 times

|

|

|

Sulaiman

International Hazard

Posts: 3779

Registered: 8-2-2015

Member Is Offline

|

|

Please take with caution ... an idea, not from experience

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

So, you have a 3'W x 4'H nominal window. Mine is a nominal 4'W x 5'H. A few times I have wished my working space was wider, and a few times higher.

So with your window full open you have an opening of of 3' x 1.6', approximately - correct? This will be a good working opening and I assume will

give you 1.0 fps face velocity at 285 cfm? When you bring the sash down to half that opening (0.8') your face velocity will double to 2 fps. I

predict that will blow out your bunsen burner.

Quote: Originally posted by careysub  |

The total distance from the 8" x 12" trunk duct plenum on top of the fume hood (I intend to use a slot along the top for extraction) using 8" ducting

is 4 feet to the garage side vent with one 90 degree bend. I calculate a pressure drop of 0.01" (rounding up). So 310 CFM at 0.375" looks good.

|

I'm really glad to see that you are staying with the 8" diameter duct. So many people go to 4-5" dryer duct, which in my thinking would be terrible

due to the corrugation and small diameter.

So you have a run of 4' and 2 ea 90° elbows (counting the one at the hood plenum). Is that correct? As, you say, that won't be much duct pressure

drop. I assume you included the contraction loss at the plenum and the louvre loss at the exit vent. I'll do a calculation of my own to provide a

check.

Quote: Originally posted by careysub  |

OTOH, I was also looking at this, and using a carbon filter (static pressure drop 0.5") to reduce odoriferous releases:

https://www.amazon.com/Can-Fan-Inline-6-Inch-Minute/dp/B004C...

which delivers 283 CFM with a filter.

At $100 it could be considered a replaceable item if it fails from corrosion.

Having a carbon filter upstream may provide some protection (I know they do not do much with acid gases), and I would endeavor not to put lots of

corrosive gases through it (the hood is after all primarily a safety system, not a chemical disposal system). Proper experiment set-up should try to

capture and neutralize such releases, and I do have the option of doing some simple operations outside if corrosive release seems unavoidable.

|

I'd forget about carbon filter, scrubbers, etc, if at all possible. They will eat all your lunch in pressure drop.

Quote: Originally posted by careysub  |

Getting an indutrial type blower rated as "explosion proof" (is "spark resistant" a suitable substitute?) is a problem, it looks like it multiplies

the cost by about 10, pushing it into the "unaffordable" column, and makes units delivering adequate static pressure in my size very hard to find at

any price, and many of the units offered in this category are extremely loud.

|

This is why I advocate the belt driven squirrel cage blower. The motor is not in the air flow. A squirrel cage is a centrifugal blower and can

inherently deliver more SP than any axial flow fan such as you are considering.

Noise is a consideration. Some knowledgeable posters here have stated that most of the noise is just due to air rushing through the duct.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

Quote: Originally posted by Magpie  |

So, you have a 3'W x 4'H nominal window. Mine is a nominal 4'W x 5'H. A few times I have wished my working space was wider, and a few times higher.

So with your window full open you have an opening of of 3' x 1.6', approximately - correct? |

I estimated 33" wide. But in that ballpark, I need go look at an actual window.

| Quote: |

This will be a good working opening and I assume will give you 1.0 fps face velocity at 285 cfm? When you bring the sash down to half that opening

(0.8') your face velocity will double to 2 fps. I predict that will blow out your bunsen burner. |

When would I need to reduce the sash height by that much?

In college I worked with a fume hood that did not have a variable sash height. I've never worked with one that did, so the necessity of doing that is

not obvious to me.

| Quote: |

So you have a run of 4' and 2 ea 90° elbows (counting the one at the hood plenum). Is that correct? As, you say, that won't be much duct pressure

drop. I assume you included the contraction loss at the plenum and the louvre loss at the exit vent. I'll do a calculation of my own to provide a

check.

|

The area of an 8" duct is about 50 square inches, the slot into the trunk duct would maybe be 100 square inches, also the exit vent is a louvered

13"x17" window that would be blocked by a steel sheet and use an 8" x 12" right angle register to exhaust. I assumed no significant pressure loss at

either end since there was no constriction, just the right angle turn.

| Quote: |

I'd forget about carbon filter, scrubbers, etc, if at all possible. They will eat all your lunch in pressure drop.

|

They introduce a specific, known static pressure drop, 0.5" according to the manufacturer of the one I was looking at. It is the only significant

pressure loss in the system. I can see no reason that this cannot simply be factored into the fan selection, as I am doing.

Quote: Originally posted by Magpie  |

Quote: Originally posted by careysub  |

Getting an industrial type blower rated as "explosion proof" (is "spark resistant" a suitable substitute?) is a problem, it looks like it multiplies

the cost by about 10, pushing it into the "unaffordable" column, and makes units delivering adequate static pressure in my size very hard to find at

any price, and many of the units offered in this category are extremely loud.

|

This is why I advocate the belt driven squirrel cage blower. The motor is not in the air flow. A squirrel cage is a centrifugal blower and can

inherently deliver more SP than any axial flow fan such as you are considering.

|

Is there any particular reason why the bilge blower approach would not work? They are rated to be non igniting (they have a UL rating for this), and

the pressure/flow rate chart seems to work out.

I did look around for some belt driven squirrel cage blowers, but found none that were small enough. No doubt they exist somewhere, but have proven

hard to locate. Yours in larger than what I can use, I haven't found one even as small as that. This general design seems to be reserved for systems

with CFMs and price tags both north of 1000.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: | | Quote: |

I pull my window down when I think there is a potential for an explosion or an implosion. There's always a potential for an implosion when doing a

vacuum distillation.

Quote: Originally posted by careysub  |

Is there any particular reason why the bilge blower approach would not work? They are rated to be non igniting (they have a UL rating for this), and

the pressure/flow rate chart seems to work out.

|

I have nothing against bilge blowers if they have adequate flowrate. I would not want to use them in parallel due to the likelyhood of push-pull

oscillation of airflow. Also there is the issue of running on 12vdc. I would not want to have to monkey with that.

In regard to noise my blower is rated at 46db at 5 ft.

In regard to corrosion I think this may be less of a concern than we think. Most of the airflow is just that, air. I have given my system extended

service with Cl2 and HCl and other likewise corrosive gases. The vent louvre shows no signs of corrosion. It is most likely made of aluminum or

steel and is painted with acrylic house paint. I have not inspected the fan blades or fan housing internal surfaces however. My fan has been in

service for 11 yrs and continues to work well. I haven't even had to tighten or otherwise adjust the belt. Zero maintenance.

addendum 1:

Here's a possibility for you at $251 for the blower only. You would have to add your own motor, direct drive or with a belt. My motor is 1/4 hp and

runs at 1725 rpm. The blower runs at 1000 rpm. My guess is that this would be a good match for this blower to give you the SP and airflow that you

need. blower

I'll continue to look for a blower.

[Edited on 6-7-2016 by Magpie]

[Edited on 7-7-2016 by Magpie] |

|

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I did the head loss calculation. Assuming a flow of 285 cfm, 6 ft of smooth 8"pipe, 2-90° ells, 1 protruding pipe exit, and 1 protruding pipe

entrance, I came up with 0.12" H2O pressure drop. So I have to concur with you that a blower capable of 3/8" H2O SP seems adequate.

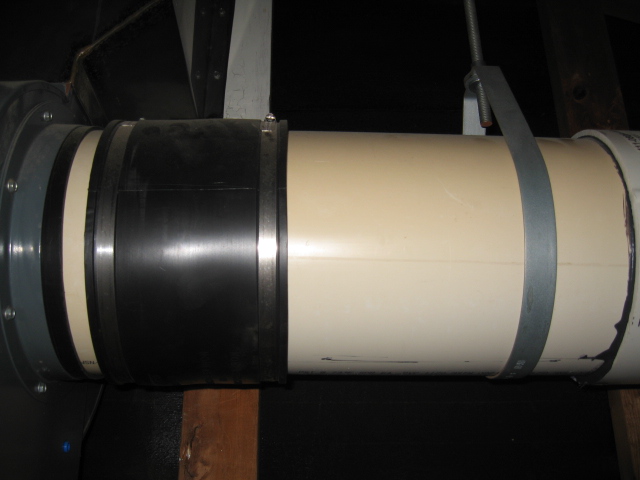

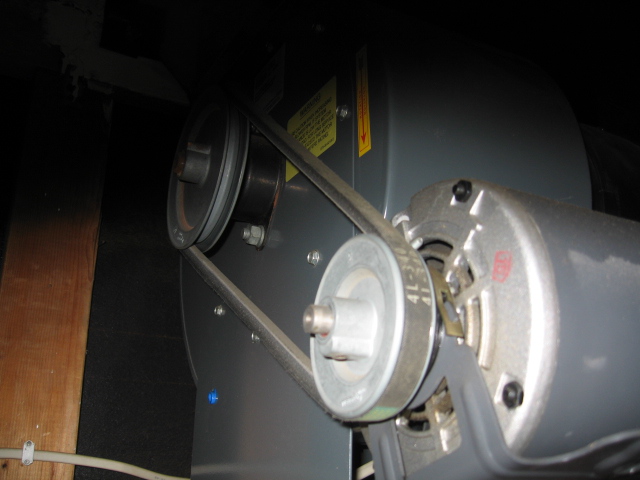

I crawled up in the rafters and inspected my blower today. Everything looks solid although the pipe hanger right before the blower was slightly

loose. There are signs of corrosion around some of the edges of the SS plenum and around the blower shaft bearing.

Here's some pictures:

blower inlet

blower drive end & bearing

blower motor & belt

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

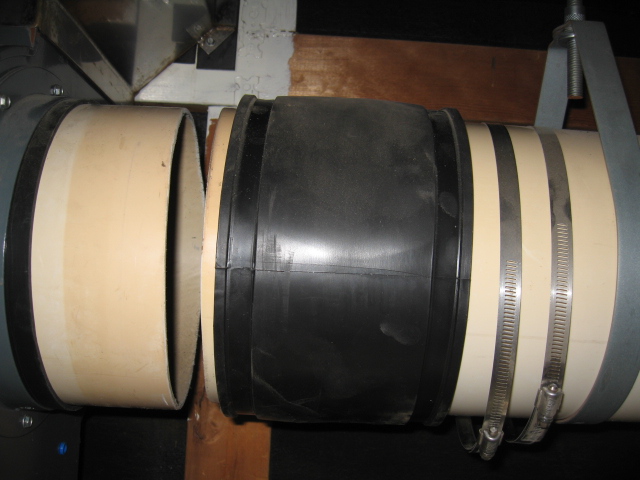

In the vein of Mark Twain, my earlier reports of "no findings" for my 11 yr old blower were greatly exaggerated. Further inspection has revealed

heavy deposition on the inside of the blades as shown below:

rubber boot pulled back

forward-curved blower blades

I will likely remove the blower wheel so I can clean it properly.

As can be seen the end of the steel shaft is heavily rusted but the epoxy coated housing, also steel, is not. The blades look to be somewhat rusted,

however. I'll be able to tell more after I clean them.

The inside of the 8" duct has only a light coating of dust.

This inspection was prompted by a performance drop I detected today as determined by a tissue streamer compared to what I recall when the blower was

first installed.

[Edited on 8-7-2016 by Magpie]

[Edited on 9-7-2016 by Magpie]

[Edited on 9-7-2016 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

Very interesting Magpie, thanks!

But first I have to clean out the area of the garage where the fume hood would go. That is a bit of a project in itself!

Plans of course will continue to be refined until it comes time to actually build, e.g., I am now considering the American Craftsman 37.75 in. x 56.75

in. 70 Series Double Hung window at Home Depot for a minor price increase (whole project cost considered), slightly larger, and gives me maximum

flexibility with flow and shielding.

Looking at the Dayton blower you linked to, that is actually a direct drive - not a belt drive model. It appears that all of the belt drive units are

larger than what I need. But

I am considering the direct drive version, perhaps with the totally enclosed motor, as I don't really want to mess with the belt anyway. This also has

the motor out of the air flow, and perhaps a metal screen - a la the Davy safety lamp - could be installed between the motor and the blower.

[Edited on 9-7-2016 by careysub]

|

|

|

Texium

|

Thread Topped

9-7-2016 at 06:13 |

Texium

Administrator

Posts: 4665

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: Preparing to defend myself (academically)

|

|

I went ahead and split this discussion of fume hoods into its own thread and stickied it.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by careysub  |

This also has the motor out of the air flow, and perhaps a metal screen - a la the Davy safety lamp - could be installed between the motor and the

blower.

|

I believe that a direct drive motor would be safe as it is out of the exhaust path. Also the area around the shaft is sealed by 2 ball bearings. And

due to its location at the center of a centrifuge is at a vacuum condition. A Davy flame arrestor certainly wouldn't hurt anything, however. I've

seen these on some carburetors.

My motor is a split-phase, sleeve bearing, 1/4HP (Grainger 5K907). All this time I thought it had sealed ball bearings! I will definitely oil the

bearings before putting it back in service.

Right now I'm in the middle of my millwrighting. The wheel is ready to pull off the shaft. But it's not going to come off without a fight. I'm

soaking the hub/shaft interface with penetrating oil.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

BTW - I've dropped the idea of the carbon filter. Nearly all of the time it would be a waste.

If I contemplate a procedure that is especially odoriferous, I would probably set up a special apparatus to deal with the fumes.

|

|

|

Texium

Administrator

Posts: 4665

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: Preparing to defend myself (academically)

|

|

I have a squirrel cage fan from my old AC unit, and it's a direct drive, so the motor is inside of the cage. Would this be inappropriate to use as an

exhaust fan, even if I were to give the whole thing a good coat of epoxy? I was thinking that if I have to, I could remove the motor and set it up as

a belt driven fan like Magpie's, but I'd of course prefer to keep it the way it is if possible.

I've read that the motors in these things have to be sparkless because of the possibility of igniting dust in AC ducts, so I'm not concerned about it

starting fires, I just want to know if the motor will hold up in that environment.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I think the motor wouldn't last long in the corrosive exhaust stream.

I wouldn't trust that sparkless claim, not with a duct full of ether fumes above the LEL.

I took a look at my old furnace blower and decided its performance characteristics were not matched to the needs of my hood. It provided high flow at

low SP where my hood needs medium flow at high SP.

[Edited on 10-7-2016 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

| Pages:

1

2

3

..

5 |