| Pages:

1

2 |

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Detonator casings

Here's a neat find, if you open up 9 volt alkaline batterys the cells are 8 mm diameter and long enough to load the equivalent of a no8

detonator.

The caseing is very thin nickel maybe stainless steel but its the closest ive seen to a off the shelf caseing .

Nux

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

Try these! That is if you are willing to risk importing them. I know that I'm not. But if you live in Europe or a country fairly lax then there

should be no problems.

http://pyrofire.eu/detail.php?product=114#.VPqPj2SUde8

|

|

|

greenlight

National Hazard

Posts: 754

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

@nux, is one end of those cells inside the battery sealed or are they open ended once you remove the contents? I can't see on the pictures

Be good, otherwise be good at it

|

|

|

Loptr

International Hazard

Posts: 1348

Registered: 20-5-2014

Location: USA

Member Is Offline

Mood: Grateful

|

|

I wouldn't be afraid to import those. They are used for making sensors and used as the housing. You could also contract out their manufacture as there

are several companies in a Google search that will produce closed end tubes.

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

NP's aluminium tubes look like the right stuff, but Pyrofire's shipping seems a bit rip-off!

Has anyone here had any dealings with them, I wonder?

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Looking at their prices for Chinese shells, fuses, quick match, pyrotechnic chemicals & etc., they are a bit high. Oddly, the electric match

prices were sort of OK (.5€) Didn't check shipping costs, as not ordering!

The picture does not show if the output end of the empty capsule is properly concave.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

An experimenter could probably easily make a little punch and anvil set for making/shaping a suitable dimple/concaved end in the tubes if needed.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

I get mine from there. Very happy with these tubes. I'll post pictures of tests I made with them some day. I've got some copper ones that I'll try

with something else than LA of course.

I get my fuse from them too. Their Visco is excellent and their Bickford fuse just need a roll of tape to make them a perfect fit for the tubes before

crimping. Nice people, we exchanged a couple e-mails at a time.

The specifications are wrong though:

Outer: a tad more than 5mm

Inner: a tad less than 5mm

Lenght: 56mm

(Sorry, my "whatever you call this in English" isnt digital

They also have shorter tubes with a bigger diameter that I havent found a use for. I got some to see if they gave me ideas.

Outer: a tad less than 7mm

Inner: 6mm

Lenght: 36mm

Also, note that the way these tubes are made the walls are thicker at the bottom than at the mouth.

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Hennig Brand  | | An experimenter could probably easily make a little punch and anvil set for making/shaping a suitable dimple/concaved end in the tubes if needed.

|

An experimenter could. The bottoms are flat and as mentioned above, slightly thicker than the walls of the tubes.

The bottoms are marked (not deeply) with an "A" for Aluminium I guess.

Also, it seems to me that they are not perfect tubes. The open end is ever so slightly larger than the closed end.

I couldnt give data, but I noticed differences in behaviours when working with these tubes and different loads. One of my tools would get stuck with

lesser loads.

Ah, maybe that's something I should explain if or rather when I create a topic about my experimentations.

@Bert: I belive they use these tubes, fill them with black powder and crimp whatever they need on top. I've gotten some other supplies from them (no,

not chemicals they're way to expensive) but their finished products are sometimes very nice for the price.

I have a couple of pyrotechnic igniters from them where the bottom is deeply marked with an X to ensure it breaks there. They are the same that they

use for some smoke bombs.

I guess they are selling the tubes alone because... well maybe they thought someone might want to use these tubes to house a sensor for example. Or

other

[Edited on 16-3-2016 by Herr Haber]

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by greenlight  | | @nux, is one end of those cells inside the battery sealed or are they open ended once you remove the contents? I can't see on the pictures

|

Yep Greenlight you cut the crimped end off and its a deep cup .

Added a cople of other photos with some more dimensions including sidewall and bottom thickness

[Edited on 17-3-2016 by nux vomica]

|

|

|

greenlight

National Hazard

Posts: 754

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Thanks Nux, nice find there. I have been using aluminum tubing from a hobby shop but the bottom's has to be sealed before filling them

Be good, otherwise be good at it

|

|

|

DrManhattan

Harmless

Posts: 32

Registered: 24-1-2015

Member Is Offline

Mood: No Mood

|

|

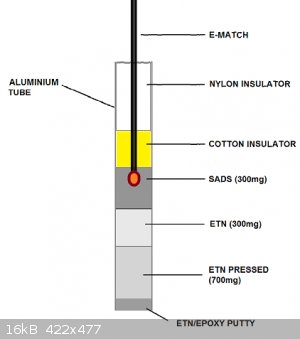

I have thought of the idea of using an ETN/epoxy mixture for making a putty to seal the end of open tubes for use as a blasting cap. Once dried it

should be reasonably strong, water tight, and unlike an inert plug it shouldnt decrease its initiation ability so long as it detonates from the

pressed ETN charge above it. What do you guys think?

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1407

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Your plug in output segment is too much thick. Without description of thickness. Here is more safety construction:

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Daffodile

Hazard to Others

Posts: 167

Registered: 7-3-2016

Location: Highways of Valhalla

Member Is Offline

Mood: Riding eternal

|

|

How would you crimp them?

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Traditionally, a fuse cutting and crimping tool.

Occasionally, I have used a small tubing cutter with a deliberately dulled cutting wheel, this gives a very uniform crimp. But requires having my

hands WAY too close to the cap.

|

|

|

MineMan

International Hazard

Posts: 1012

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Bert,

You have WAY too much cool stuff and antiques, those would fetch a lot of $.

Ok Time for safety talk. LOL, steel casings of that thickness should NOT be used for detonators, the shrapnel form that would be inconceivable. Steel

wire gloves under steel wire gloves or Kevlar was shown to greatly reduce injury by Robert Matyas... but I have tried this, dexterity is sacrificed.

The most ideal detonator casing is thin (.05mm or less Al), lets talk about why. I have seen FLAKES of copper from a copper detonator casing pierce

a 5 gallon bucket, these flakes would NOT register on a milligram scale. Copper is the worst material, because it is elastic, therefore the casing

will bend before ultimate failure, producing the HIGHEST Gurney velocity... In addition, at high velocities penetration is modeled by two main

variables, the density of the projectile, and the density of the target. The hardness does not matter at velocities over 1km/s. Therefore, copper is

the worst material for shrapnel, tantalum, probably being the most violent material imaginable... and hence is used for advanced shape charges.

Steel is brittle, but at a 2mm thickness, the fragments must be ungodly. DDT of CHP is still possible under .5mm aluminum, and should be used. your

hand might miss some fingers but you wont have holes out your backside, and yes, I have seen copper FLAKES pierce 1mm steel after going through tough

plastic. According to Matyas, even one pair of steel wire gloves helps a lot,same with kevlar or spectra. it will at the very least protect your

flesh and hold bones and fingers together.

A cap like the above shown could really easily kill, not just mame. If the material cannot achieve ddt in .5mm Al, then a steel sleeve should be

used, as it is in industry caps, but thick enough where it only deforms, not fragments. it only needs to cover 100mg of the material until it ddts...

No picture online shows a modern cap. But there is a thick sleeve that covers the LA, it helps if a truck runs over it, and it can help with our

members too.

|

|

|

Fulmen

International Hazard

Posts: 1725

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Bert: I have the same unit. Still works :-)

We're not banging rocks together here. We know how to put a man back together.

|

|

|

C6(NO2)5CH2CH(CH3)N(NO2)2

Harmless

Posts: 43

Registered: 4-4-2018

Member Is Offline

Mood: No Mood

|

|

I've opened up a 9v battery. Those are nicely shaped and sized casings. But the battery I opened had a very very hard graphite/Manganese

oxide layer up against the casing wall. It could be removed in chips, but not removed completely without destroying the steel casing. Are there any

special tips for getting rid of that layer, or should I just be more perseverent with the flat-tip screwdriver?

Put that in your pipe and smoke it!

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

https://www.aliexpress.com/item/5-pieces-OD-6mm-OD-7mm-OD-8m...

If you know spechs, there are many possibilities

|

|

|

OneEyedPyro

Hazard to Others

Posts: 280

Registered: 7-10-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by C6(NO2)5CH2CH(CH3)N(NO2)2  | | I've opened up a 9v battery. Those are nicely shaped and sized casings. But the battery I opened had a very very hard graphite/Manganese

oxide layer up against the casing wall. It could be removed in chips, but not removed completely without destroying the steel casing. Are there any

special tips for getting rid of that layer, or should I just be more perseverent with the flat-tip screwdriver? |

Submersion in dilute hydrogen peroxide should clean them up nicely if it's MnO2 inside.

Peroxide would likely begin to corrode the casings pretty quickly though.

|

|

|

ManyInterests

National Hazard

Posts: 937

Registered: 19-5-2019

Member Is Offline

|

|

While I still haven't made my primary or secondary yet. I have been thinking very hard about the detonator design, because without that, there is no

point in bothering to try making energetics.

While I've seen people speak very highly of aluminum tubes, I've also seen that cardboard or rolled printer paper can be used as a detonator housing.

But I've also been looking at using the body of a ballpoint pen as a house. I've attached a blurry pic of what I plan on using.

The pen's inner diameter is apparently 6.5mm or so, because I fit a 6.35 mm wooden dowel in easily. When I removed the cap and the actual pen

head/handle the result was a very nice plastic tube. I wanted it to be a little longer. So I cut off the head of the cap and sealed the end with hot

glue, then I used more hot glue to completely seal the cap to the body (I put some near the edge of one side and pressed the head against it, bringing

hot glue underneath it. The connection is very tight).

I made a paper funnel that will let me attach a glass lab funnel to that end, allowing me to pour the energetics into it easily (albeit I will need to

tape them together to make a firm connection). I filled it with 2 grams worth of sugar just to see if it'll fit that much, and it left plenty of space

for me to insert an electric match and seal the other end with epoxy.

Would this work as a detonator?

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

I like christmas tree lights.

And now is the season to get them.

They come with wire preinstalled.

fill and drain thin nitrocellulose syrup to coat.

Then primary and ETN.

Seal with thick nitrocellulose syrup.

Side note, the metal cans in 9v are usually zinc.

Same as other batteries.

Using a smaller christmas light initiator with a can filled with ETN would make an excellent larger initiator.

|

|

|

ManyInterests

National Hazard

Posts: 937

Registered: 19-5-2019

Member Is Offline

|

|

Quote: Originally posted by macckone  | I like christmas tree lights.

And now is the season to get them.

They come with wire preinstalled.

fill and drain thin nitrocellulose syrup to coat.

Then primary and ETN.

Seal with thick nitrocellulose syrup.

Side note, the metal cans in 9v are usually zinc.

Same as other batteries.

Using a smaller christmas light initiator with a can filled with ETN would make an excellent larger initiator. |

I got halloween lights (which come in orange and purple) and clear christmas lights. They are good, but with many small and long caps (like mine) you

will need to remove the bulb entirely in order to make it fit. This isn't a problem. I'm very good at cutting the tops off and filling them with

pyrogen (I used crushed match heads).

The only thing you need to know is that christmas light bulbs are polarized, meaning one wire is positive while the other is the ground. If you are

working with colored christmas lights, make sure you use the correctly corrected wires so you can connect them to the power supply correctly,

otherwise they might not ignite correctly.

If they are clear and you see the filament on the inside, the longer part is the positive while the shorter one is negative, makes it easier to get

the wires properly connected.

But if you completely remove the bulb from the container and attach the wires directly to the leg wires you do need take care that they don't touch

and create a short, this might cause your bulb not to light up when it needs to.

Personally I perfer my own matches. They are quite current and voltage sensitive (much more so than christmas lights) but I do have experience

building them and I did make sure what ever I have in mind will fit in my intended cap.

But that being said. If it works, it works.

My question still remains on making the setup to do the filling and pressing (the pressing is what worries me the most. Which is why I want to use

only the most insensitive explosives out there for that purpose. ETN as the secondary and NHN as the primary (with fast black powder as the

initiator).

but I am thinking about something. Is picric acid less sensitive than ETN? What about it's compatibility with NHN? I know picric acid hates all metals

except aluminum, but would it eat through my plastic pen body and the hot glue stopper I have at the end?

I am thinking a simple homemade hydraulic press like this might suffice:

https://www.youtube.com/watch?v=aWVqmgX-VrY

I know it looks all childish, but aslong as it lets me operate the pressing from afar (and keep the cap in a container that will contain the blast and

muffle the sound) I am OK with it.

[Edited on 20-10-2021 by ManyInterests]

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

That is an interesting hydraulic press.

I have been using a pretty sturdy metal press and a lever (pvc pipe) that allows me some distance.

But that could literally work from 100 ft away.

You need cheaper christmas lights, mine just use miniature light bulbs that run on 3v.

Hook 18v (two nine volts) to one and it vaporizes the filament pretty good.

The way the filament is oriented one side is longer than the other but it isn't 'polarized' in the sense that an LED is.

|

|

|

ManyInterests

National Hazard

Posts: 937

Registered: 19-5-2019

Member Is Offline

|

|

| Quote: |

You need cheaper christmas lights, mine just use miniature light bulbs that run on 3v.

Hook 18v (two nine volts) to one and it vaporizes the filament pretty good.

The way the filament is oriented one side is longer than the other but it isn't 'polarized' in the sense that an LED is. |

I think we're using the same incandescent mini-bulbs. I got them from a thrift store. They have an 'outdoor' mini-bulb that is rated for 3.5 volts

each and an 'indoor' one for 2.5 or 3 volts. LED lights are useless for pyrotechnics.

I did make one into an electric match and it did light up with a small CR2032 button cell, but a 9v is necessary to really get to light up. Albeit you

must not forget that the filament will still burnout once you break the bulb. They tend to not like the open air that much.

For my purposes even 2 9v batteries connected in series will not be enough. 9v are good if you're working close to the thing. But if the wires are

very long (and I cut some LONG wires) you'll not only need a strong voltage, but also a stronger current. connecting 6 or 8 D cell batteries in series

will give you 9 or 12 volts respectively, but the current provided by the D cell will crush anything a 9v can do.

|

|

|

| Pages:

1

2 |