mrjeffy321

Hazard to Others

Posts: 149

Registered: 11-6-2005

Member Is Offline

|

|

Gas Flow Rate Meter

I am trying to come up with a better way to measure the rate of gas production in one of my Chemical reactions.

The "get by" method I have been using is basically to collect the gas over water and time how long it takes to get a specific volume (example, 500 mL

/ 4 minutes). However, this requires a lot of manual labor on my part to keep track of everything while the production gets faster and faster (it is

gets pretty hectic at 9 L/min). Also, the data I collect using this method is naturally flawed in that I am not getting an instantaneous rate, rather

I am getting an average over the period of time it took to collect.

What I can do is when production is slow, collect very small samples (100 to 200 mL) and when it speeds up collect larger samples (1 L), but still,

when I graph the rate, it is obvious that it isn’t too actuate.

What I would like is some system that would involve much less work on my part and could give me a higher degree of accuracy and a more instantaneous

rate. (It would be wonderful if I could connect it to a computer and collect data that way.) [And it would be even more wonderful if this system

didn’t cost me hundreds of dollars as well.]

Any thoughts?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Look into the cost of rotameters. This will give you an instantaneous rated but not an integrated total volume. You should be able to find some that

aren't too expensive.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

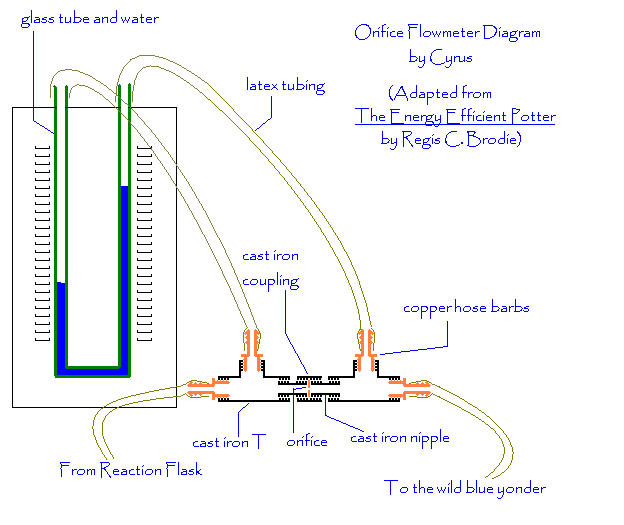

For another "instantaneous" gas measuring device, I had the following idea. (Taken from a book on pottery kilns, it is used to measure the flow of

natural gas- granted, that's a much larger flow, but the idea can be adapted.)

Have a tube that narrows to a very small and precisely drilled hole. (easy to do with plumbing fittings, put a sheet metal piece w/ hole btw. two

fittings and screw tight, or something similar.)

Now drill 2 holes in the side of this tube- one before the sheet metal piece, and one after. (or use plumbing "T" fittings and hose barbs) Then

connect a rubber tube or similar to each of these barbs/holes, and connect each end of the rubber tube to a "U" shaped tube (drying tube, etc.) Mount

the U shaped tube upright to something nice, draw measurements on it, and fill it partially with water. You can tell the pressure difference before

and after the sheet metal constriction in the tube, and with a bit of math, you can calculate the flow.

As long as the hole is drilled accurately, this should be a very accurate way to measure pressure and thus flow. (Assuming your flow is reasonably

constant, of course.)

Of course you can drill the right sized hole for any amount of gas- 1/4" for nat. gas for a kiln or so  , or a pinhole sized hole for your purposes, perhaps. If your interested I can post pictures of the concept and see if

I can dig out the equations. , or a pinhole sized hole for your purposes, perhaps. If your interested I can post pictures of the concept and see if

I can dig out the equations.

I thought it was a very interesting concept, and if I build another kiln, I would like to run it off of natural gas and measure the flow this way...

(OT, I know...)

Cy

|

|

|

mrjeffy321

Hazard to Others

Posts: 149

Registered: 11-6-2005

Member Is Offline

|

|

I was able to find several rotometers/flowrate meters that might work for me on eBay. The price isnt too bad, the only problem, most of them either

are calibrated to either measure very small flow rates or large rate, my expected rate will be somewhere in between most of the time.

Cyrus, I had originally considered trying something like what you suggested (using Bernoulli's principle), but couldnt figure out quite how to set it

up. Now I know.

I have never been taught any of that fluid dynamics stuff in school, so I was looking through my physics book for the equations and whatnot and what

do I find? One of the example problems has a diagram of exactly what you were describing.

The only dissadvantage to this approach is that , one I would actually have to build it rather than relying on some factory calibrated device.

I am still trying to decide what I will do. I think it might be hard for me to find the propper materials to build the Venturi meter in such a way to

get accurate results.

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

The orifice flowmeter, which is what Cyrus is describing, can also be used with a differential pressure transducer - which would make it computer

connectable. The whole thing is probably available OTC at a reasonable price (if you hunt long enough). The equations governing these devices are

well known, you should be able to find them in a fluid mechanics text book ( mine's at home somewhere). Be aware the charactistics will vary somewhat

depending on the composition of the gas you are measuring, and also on the gas density (= pressure and temperature).

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

Here's a diagram I made.

Obviously you're going to need to choose compatible materials and the right sized orifice, but if the gas isn't too corrosive, plain old materials

from the hardware store ought to suffice. What gas are you going to be using?

edit- this should be very accurate. Can you drill a 1/16" hole in a piece of plastic?  (The author of the book I mentioned recommended using steel and a long hole through a thicker/multiple pieces of the material. I don't

see why plastic wouldn't work.) (The author of the book I mentioned recommended using steel and a long hole through a thicker/multiple pieces of the material. I don't

see why plastic wouldn't work.)

Cy

[Edited on 3-3-2006 by Cyrus]

|

|

|

mrjeffy321

Hazard to Others

Posts: 149

Registered: 11-6-2005

Member Is Offline

|

|

This flowmeter will be used for primarily Hydrogen gas.

I have a question concerning your diagram.

The two latex tubes leading to the measurement apparatous both connect to the same size diameter "Cast Iron T", meaning that the gas will be traveling

the same speed through both sections, meaning that the pressures will be equal. The flow through the very tiny "orifice" is where thr gas will be

traveling fastest and where one of the tubes should connect to, I think.

I did a few calculations on just how much of a elevation difference there would be in the water.

If we assume a constant flow of 9 Liters per minute (1.5 E-4 m^3/s), through a 1/4" diameter pipe, the gas will be traveling at about 4.7 m/s. if the

pipe then contracts to half the diameter (to 1/8"), the gas will increase its speed to 18.7 m/s. This change in flow speed is caused by a pressure

difference of about 163.8 Pascals of pressure.

This pressure difference will cause a difference of about 16.4 cm in the height of the water (assuming my calculations are correct).

[Edited on 3-3-2006 by mrjeffy321]

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

| Quote: | Originally posted by mrjeffy321

The flow through the very tiny "orifice" is where thr gas will be traveling fastest and where one of the tubes should connect to, I think.

|

Don't get confused with a venturi flowmeter, which measures the pressure drop in the fast flow section of a convergent/divergent nozzle.

This page describes it all - with formulae!

[Edited on 3-3-2006 by Twospoons]

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

mrjeffy321

Hazard to Others

Posts: 149

Registered: 11-6-2005

Member Is Offline

|

|

I went ahead and build a venturi flowmeter (not an orifice flowmeter) out of 17 different brass pipe couplings and adapters.

I use 1/4 inch diameter tubing for almost everything, so my flowmeter takes the 1/4" tube, enlarges it to a 1/2 inch pipe (to which I connect one end

of the pressure tube), then shrink it down to a 1/8 inch diameter pipe (to which I connect the other end of the pressure tube) and then re-enlarge it

to 1/4" as the glas flows out.

I have not put the meter into actual use yet, I still need to test it.

When I simply blow through the end of the pipe with water in the pressure tube, I can see the water level rise a good 2 cm (meaning it must be

dropping 2 cm on the other side). it works pretty well I think.

However, I am having trouble trying to design the srt up for the actual pressure tube with water in it when it goes into actual use. I wanted to

build something like the one in the picture above, but it is proving more difficult than it might seem.

I am thinking, maybe just skip it all and use the differential pressure transducer that Twospoons had suggested so I can hook it up to a compuer.

Anyone know where I can find a good differential pressure transducer? I fond one on ebay, but it is $75 and I am not sure if that is exactly what I

am looking for.

As soon as I can find my digital camera, I will upload a picure of what my flow meter looks like.

|

|

|

mrjeffy321

Hazard to Others

Posts: 149

Registered: 11-6-2005

Member Is Offline

|

|

Beautiful isnt it [picture attached].

Now all I need to do is try to find a manometer in my price range to measure the difference in pressure, if I sacrifice the R232 port, I can knock off

about $40-$50.

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

How are your electronic skills? Because you can get the pressure sensor element from Freescale for a lot less than $75. You might even score a free sample. But then you have to build the interface. For which one of the Cypress

PSoC devices might be good.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Making a manometer is simple and cheap as long as you don't expect more than about 30 " H2O pressure difference. Just take a flat board and nail a

yardstick to it. Along side that attach a U-tube made of small diameter Tygon tubing. Fill U-tube halfway full of colored water. Done.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

mrjeffy321

Hazard to Others

Posts: 149

Registered: 11-6-2005

Member Is Offline

|

|

| Quote: | Originally posted by Twospoons

How are your electronic skills? |

Terrible. If it goes beyond simple circuits, I am lost. I once tried to build an amp hour meter out of electrical components thinking I could make

and program it myself....nope.

I could probably handle programming the serial interface between the manometer and the computer, but I'd just as soon not risk it.

I am in no hurry to get a fancy, digital, manometer; my homemade substitute is working fine for now. I hot glued a rubber tub to a board, drew 1/2 cm

markings and connected up the flow meter, it works pretty nicely. But for practical use in the long run, the digital manometer will be much more

convenient.

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

There is a simple device that can be homebuilt with ease. Do a google search on 'soap film flowmeter'.

It's tube with a bubble. Not really a bubble, but a flat soap film. As gas flows , the bubble moves. Measure the time the buble takes to pass through

two calibration marks, look up at a table you made previosly and that's it.

The tube has to be wet, the soap mixture must have some glicerin to prevent drying and you must figure some way to make the soap film as needed. Try

to copy the desings on the net. Google gives 60.000 hits. There is a description of one here:

http://jchemed.chem.wisc.edu/HS/Journal/Issues/2005/Feb/clic...

I would use a disposable syringe barrel as the tube. It already has volume marks.

Another idea for small flows:

Use a bubbler. Count how many bubbles per minute and look at a conversion table you made previously. Maybe a more viscous liquid would allow larger

bubles and, therefore, measurement of larger flows, but I'm not sure. An optic electronic bubble counter would be nice.

|

|

|