| Pages:

1

2

3 |

BromicAcid

International Hazard

Posts: 3247

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Photochlorination apparatus, setup of multiple UV LED lights, help please...

Recently I bought a bundle of 100 UV LED lights from eBay. They work well but I know nothing about setting them up to function as more then one at a

time. Acutally, when I do get one to light it's overkill and the light starts out as that UV blue color then turns orange suddenly then goes out

forever. So I don't want to make a setup of 50 or so lights and run power through it and suddenly burn them all out at once.

So, here is the specifications for the LED lights that I got:

| Quote: | Specifications

# Size (mm) : 5mm

# Emitted Color : ULTRA VIOLET

# Forward Voltage (V) : 3.2 ~ 3.8

# Reverse Current (uA) : <=30

# Life Rating : 100,000 Hours

# Viewing Angle : 20 ~ 25 Degree

# Absolute Maximum Ratings (Ta=25 Degree)

# Max Power Dissipation : 80mw

# Max Continuous Forward Current : 30mA

# Max Peak Forward Current : 75mA

# Reverse Voltage : 5 ~ 6V

# Lead Soldering Temperature : 240 Degree ( < 5Sec)

# Operating Temperature Range : -25 Degree ~ +85 Degree

# Preservative Temperature Range : -30 Degree ~ +100 Degree |

So, what I want to do is insert 50 of these

lights into a setup and have them all function at once. And here are my questions:

Can I connect them in series? And if I do so what should be the specifications of my power supply, volts, amps, how can I figure it out so I

don't blow all of these bulbs or get no illumination.

I did some work in my physics class with light bulbs and series and parrallel setups and such but the resistances were much larger and we only used

two bulbs at once, not fifty so any other pointers would be great.

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

They are turning color as they scream in pain and then die forever. I would give you a value but you did not specify what voltage you are going to

use. You should wire them all in parallel, not series! The drop will vary too much in each one and they will not all turn on the same. Some will be

too dim, some will probably burn out. Each LED needs it's own resistor, typically 470 ohms 1/4 watt if you are using say 12 to 14 volts to power

them. So you will have 50 LED's and 50 resistors, all 50 +'s (long LED lead) together, and all 50 minuses together, with a resistor on one

side or the other of each one. Since R=E/I, if E is say 12, and I is say .03 or 30 Ma, then R= 400. Best to use the standard value of 470 ohms, this

will lower the current to about 25 milliamps in each led, giving very long life. Total draw would be .0255 X 50 = 1.275 amperes. So a nice little 2

amp 12 volt supply would be good for this setup. Do not go any other way here or you will lose LED's and have poor light output.

Remember after you decide upon voltage to just figure ohms = volts/amps to get the resistor value, and then pick the closest standard value.

Personally, I would have used a mercury bulb which was designed to go in the little eprom erasers (little bulb about like a flash bulb in size with

threaded base the standard nite lite size), much higher output and more in the high UV end of the spectrum. Also real easy to hook up as they went

straight to the 117 Vac line through a 10 uF 250 volt nonpolar cap, along with a switch. Very simple! You will find the LED's are real low in the

UV range in frequency. I know, I have a box, likely from the same seller you got yours from. In any case pick up a bundle of 1/4 watt 470 ohm

resistors before you start building your setup. I know it's a lot of work wiring but make a little circuit board and it will be much nicer. At

least you don't have to do 98 like I did when I built my night vision illuminator from hell using IR LED's.

|

|

|

BromicAcid

International Hazard

Posts: 3247

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Why 12 V if it necessitates the need for a resistor for each LED? I will purchase whichever power supply I need so wouldn't it just be easier

for me to get a power supply with a lower voltage to eliminate that need? So parrallel is the way to go, no problem, any other suggestions?

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

You could eliminate the resistor if you used a constant current supply, but then there would still be variances between LED's. It may work well

enough for your project, just multiply the total draw of each by the number of LED's and set the constant current supply to that value. You would

need a steady 1.25 amps to run all 50 at 25 mA. The best way to go is the way I described, each LED is ballasted on it's own, and you have a lot

of leeway as to supply voltage. What I was trying to give you was a very reliable way to go with all LED's of similar brightness and good

protection from harm. If you use less than 12 volts do the math for a smaller resistor value. You could also wire them all in parallel with no

resistors and step your way up until there was a 1.25 amp draw for the 50 LED's. There are many ways you can go here. Burning them up or having

poor output is hopefully not one of them.

I forgot to mention but think of a supply more in terms of current, rather than voltage (keeping in mind the voltage across each LED should not exceed

the specifications). Also, you could do a series-parallel string, but try to stay at a max of 3 in each series string, all of them in parallel. Much

more in series than about 3 and you will have a lot of variance in brightness among invididual LED's.

[Edited on 6-7-2005 by IrC]

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

You do want them in series groups of three, with a 68 ohm resistor for each group. Then you put these groups in parallel with each other and run the

whole thing from 12V. Doing one resistor per LED is a big waste of power.

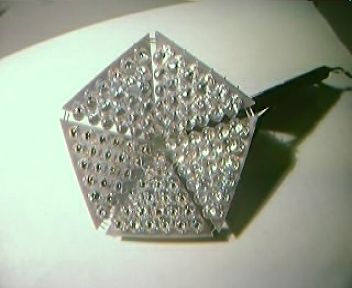

This is how I built my UV glue curing lamp, as in the picture below. Thats 105 LEDs on that sucker, all mounted on small PCBs (made by me) and aimed

at a point about 60mm from the middle.

The resistors are absolutly necessary, as the LEDs have bugger all resistance themselves, so the current will rapidly get out of hand if the voltage

is out by more than 0.1V. The resistor provides current control (of a sort).

[Edited on 6-7-2005 by Twospoons]

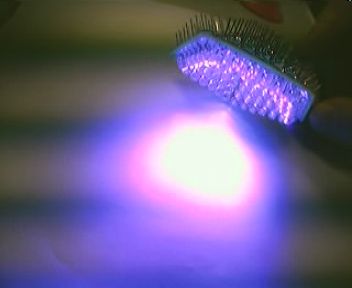

Damn. Forgot to add that you can expect those LEDs to get fairly warm, so when you mount them leave about 2cm of wire hanging out the back of each one

to act as a heatsink. I left about 1cm on mine, and I'd say the LEDs get to about 40C in one minute. Add a fan if you're concerned about

overheating during long runs.

[Edited on 6-7-2005 by Twospoons]

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Thought I'd add a pic of it running. You can see the heatsinking wires sticking out the back.

What did you pay for your LEDs? We got 500 for US$ 60, direct from the manufacturer.

[Edited on 6-7-2005 by Twospoons]

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

If he used 52 ohm resistors he would have almost 29 milliamps in the LED's. At 68 there would only be 22 mA, and these LEDS fall off rapidly

below 25 mA. Since they have little short wave UV output, with most of the energy density at the very bottom of the low UV range, I would want to try

to keep at least 25 to 27 mA in them. As to one resistor for each yes it's wasted power, but in the watttage range here it's not much,

compared to having very nearly equal brightness in each LED, as compared to dividing the ballasting by three. But as we have both pointed out three

per ballast will be adequate for decent performance. Like I said I would up the current above the 22 mA though, just to get more energy in the higher

frequency UV range, as well as greater power output. If say the total output is 4000 MCD and only 10 percent of that is at the high end of the range,

then 400 MCD of higher energy UV would be present. Say the output was reduced to 2,500 MCD, then only 250 MCD of shorter UV would be present.

I have not seen specs which rate the energy density per UV frequency VS LED current, probably it is not a large variance, so the main thing would be

just getting the total output as high as safely possible to gain the greatest amount short wave UV possible. He has not stated a voltage so the values

for resistors here are only ideas, if a number can be chosen then the exact value to get the right current would be easy to calculate. Just keep in

mind that it is important to very carefully stay within the range of 25 to 29 mA in each LED, no more, no less.

PS: that LED assembly is very nicely made. If I ever decide to build another one of my super IR illuminators I wouldn't mind buying the boards

from you. I especially like the work on creating a good focus.

[Edited on 6-7-2005 by IrC]

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Glad you like it!

Yeah, we spent a bit of time figuring out how to NOT fork out $5000 for a proper curing lamp.  The focus isn't that tight, I get a spot size roughly the same as one of those little triangle boards. The focus isn't that tight, I get a spot size roughly the same as one of those little triangle boards.

The resistors: I actually used 62ohms, since we have lots of them here, but its an oddball value, so I suggested 68. And 12V is a convenient supply

to run off. Also remember that the forward voltage will drop as the LEDs heat up, so it pays to have some margin on the current.

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

62 is good. I thought 12 volts was a good number also as it is a common supply voltage. What he needs is a little more than a wall wart can do, but

those 13.8 volt 3 or 4 amp radio shack supplies are common, in just about every garage sale and flea market on the planet. For mine (though IR and not

as much heat in the UV LEDS) I drilled holes in an aluminum reflector, where the LEDS just protrude through it. The metal carries the heat away quite

well, but drilling holes in Al is drillbit hell for sure. As to runaway, that was why I mentioned a constant current supply. Years ago I built many

laser diode boards for Meredith Instruments, and it was very important, especially in the early laser diodes which gave out extremely easy. In any

case sure a lot of work to do 50 LEDS no matter how he goes.

I wish you guys had some of those small mercury bulbs for eprom erasers, at the top end of the UV spectrum with very high output. One bulb would do

the whole job with much more UV of shorter wavelength than with a box full of the UV LED's.

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Eraser bulbs are no good for me. Only a few watts, and its a large diffuse light source, so I can't get the flux density needed. Might work for

Bromic though ...

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

It was just a thought. One of the germicidal tubes would also be cool, I keep thinking for Photochlorination he would need greater shortwave output

and I was not real impressed with the UV LED's I bought as far as short wave UV goes. But if it would work there is no doubt it would be a cool

project, though time consuming to wire all the LED's. I hope thought is given to making a PCB. My first array was handwired and after that I took

the time to make boards, no more of that handwiring a large number of small objects again for me.

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Bromic,

You need to use those resistors, sorry. The led needs a constant current to work. Typically 10mA for common leds. Check the datasheet

for your led, but I believe 10mA keeps you on the safe side.

The led internal resistance is close to zero, so you are probably burning them.

So you should put them all in parallel, each with it's own resistor.

Resistor=Voltage/current (R=V/I)

Any voltage should work if you do the math right, but for a 5 volt supply:

R=5/0,01 or 500 ohms

The commercial value you will find is 470 ohms, it should work.

Never mind the resistance of the led. However, if you put a few of them in series, you may need a higher voltage supply, since each led puts a voltage

drop in the circuit. It's not due to electric resistance, but to the semiconductor junction (N-P or Arsenide, or gallium or god-knows-what).

Good idea, by the way. I use a large germicide lamp as UV source, but a bunch of leds around a test tube sounds much cleaner and microscale.

|

|

|

NeutralIon

Harmless

Posts: 28

Registered: 19-6-2005

Member Is Offline

Mood: No Mood

|

|

Most LEDs work at best efficiency at higher currents -- usually above the max continuous current. This is done by pulsing the current thru the LED.

You might consider a design using a 70 mA peak current [< 75 mA max] and a 25% duty cycle which would give an average current of 17.5 mA. Even at

the max. 3.8 V drop the dissipation is <70 mW.

The pulsing could be done using a divide by 4 counter and a 2:4 mux to select one of 4 strings of LEDs that are turned on at any one time.

Twospoons suggestion of 3 LEDs in series with a current limiting resistor is also a good idea. There should be enough drop across the resistor so

that the current stays within safe limits regardless of the actual voltage drop of the LEDs.

Knowledge is Good

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

"... higher efficiency..." Well, thats not really true. There is always a maximum pulse current, regardless of the pulse duration, because

of the limits imposed by the thermal transient. LED efficiency actually drops as you get into higher currents, though if you're simply after the

brightest pulse then its worth doing. There's no real benefit in terms of average optical power.

Besides, running continous at 25mA with a resistor is waaaaaay simpler.

[Edited on 7-7-2005 by Twospoons]

|

|

|

NeutralIon

Harmless

Posts: 28

Registered: 19-6-2005

Member Is Offline

Mood: No Mood

|

|

Most LEDs do have a higher efficiency at higher currents. That is [in general] you could expect to get more light out of a 25% duty cycle, 70 mA peak

current than with an equivalent continuous current of 17.5 mA. To really know the best operating point one would need to see a curve of lumens vs.

current.

Agreed that a pulsed drive is more complicated but might be worth it if you can get more UV photons.

BTW, what is the peak wavelength for these diodes?

Knowledge is Good

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

The problem with pulsing is fracturing of the substrate. You need to carefully tailor the waveshape and peak amplitudes. Plus it is a lot of circuitry

to mess with when you are lighting up 50 at once!

Twospoons, do you have an image of a photoetch pattern for your LED PCB's? I'll gladly pay tuesday for a hamburger today.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Pffbt.. just a transistor and 555. Heck, I could do a full-blown adjustable PWM, F and I<SUB>pk</SUB> circuit on a single solderless

breadboard. It's pitiful what ICs today, well from the 70s and 80s, can do!

Im

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

IrC : Here's a pdf of my files - schematic, overlay, and pcb copper pattern. I set the pattern up for 0603 resistors, and the borders form the

power distribution. You can (of course) use any size resistor you wish, just solder where convenient. Enjoy!

Attachment: UvLampFiles.pdf (47kB)

This file has been downloaded 874 times

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

Thanks for putting it up. Acrobat wouldn't open the file, saying it was either not a pdf or was broken or something.

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

It works fine here. May be save it first, then open.

Bromic, what do you intend to use the UV light for... I can sense some chemical purpose in this!

Do you know the wavelength range it emits at?

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

The pdf was built with Acrobat 6.0, so you'll probably need Reader 6.0

Incidently, Nichia have some truely stunning UV Leds (Nichia) such as the one that puts out 100mW at 360nm. Probably cost an arm and a leg though.

[Edited on 12-7-2005 by Twospoons]

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

I saved it 2 or 3 times and each time it would not open. I have noticed for weeks now that any att I d/l here has a delay before the file comes in. So

I did what I hate to do, fired up IE and used the plug in, which it opened fine, and then I saved the file there. Now clicking on the file opens it in

my reader (6) like it should. Going back and using hex edit on the bad file, there are some missing bytes in the file. At least the save from the plug

in works fine.

The wavelength for his diodes should be 400 to 410 nanometers.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by IrC

I have noticed for weeks now that any att I d/l here has a delay before the file comes in. |

This happens to me 99% of the time too with attachments, it comes in like everything minus 4 kilobytes then just STOPS dead. Loading images I can hit

stop and it displays what it's downloaded, which is basically everything but the last row of pixels, but complete files like .PDFs don't

like to come in very well. It usually takes 5-10 minutes to finally finish loading?!

Hmm this post should probably be moved to forum matters...

Tim

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

It' s a shame that LEDs don't do less than 360 nm.

Say, at 200-260 nm things should become more interesting, as the most simple bonds (such as carbonyl) start to absorb, making this invaluable for a

variety of organic reactions!

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Lambda

National Hazard

Posts: 566

Registered: 15-4-2005

Location: Netherlands

Member Is Offline

Mood: Euforic Online

|

|

The narrow bandwidth of LED's

A very nice Spectrophotometer can be built with UV-Leds including other LED's due to there mono spectrosisity. They all show quit a narrow

bandwidth , which could be guided through a quarz cuvet containing the sample. A stable constant current source would be required here. No expensive

filters or special filterd gas discharge light sources will then be needed. For long term stability the LED's may be artificially made older. To

do this, just warm them up to maybe ~80 degrees celcius or more and cool them down in you freezer. Do this a couple of times, and you will have

antique LED's. Check this out by looking at the max. and min. storage temperature of your LED's, for the above mentioned temp. may be

drastically higher. 150 degrees celcius may be used for transistors, chips and resistors etc., but the bottlenek for LED's wil be the lenz

material.

Due to the narrow mono spectric emmision of UV-LED's, you may find yourself slightly pissing next to the pot in it's use in chemical

synthesis. The mercury filled UV gasdischarge source of a browning lamp may be better to use, for the intensity is very high (100-150 watt lamps) and

the spectum broader. If you use lenses with UV , make shoure you get quarz for this purpose. Normal glass absorbes a lot of UV radiation.

|

|

|

| Pages:

1

2

3 |