| Pages:

1

2 |

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Synthesis of Ethyl ß-Naphtholate (Nerolin)

A. Introduction

This procedure is for the preparation of nerolin, a perfume, and scent fixative. It is an alkyl aryl ether and is prepared here using the Williamson

ether synthesis.

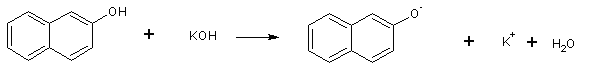

ß-naphthol, a weak acid, reacts with potassium hydroxide to form potassium ß-naphtholate:

The ß-naphtholate anion then reacts with ethyl iodide by an SN2 mechanism to give ethyl ß-naphtholate:

B. Reagents

8g of potassium hydroxide (corrosive!)

6mL of ethyl iodide

10g of ß-naphthol

100mL of methanol (anhydrous)

CAUTION: methanol is highly flammable, and poisonous

reagents

C. Equipment

250mL RBF

condenser (cold water cooled)

heating mantle

magnetic stirrer (optional)

600mL beaker

7cm Buchner funnel

suction flask

vacuum source

25mL Erlenmeyer flask

D. Procedure

Set up the 250mL RBF and condenser for reflux as shown in the photo below. The use of magnetic stirring is optional. However, it assists in mixing

the reactants prior to boiling, and mitigates the mild bumping that occurs in the latter part of the reflux period.

2 hour reflux

Place the methanol, ß-naphthol, KOH, and ethyl iodide in the 250mL RBF. Heat to boiling and reflux for 1.5 to 2 hours.

E. Workup

Fill the 600mL beaker to the 300mL mark with cracked ice. Then pour the hot reaction product onto the ice and stir well. The nerolin will

precipitate as shown in the photo below:

precipitated nerolin on ice

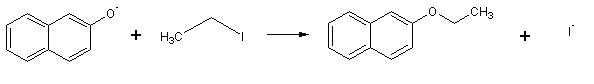

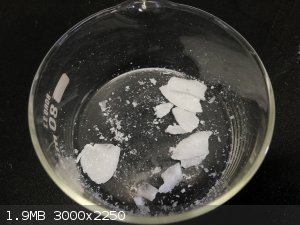

When the ice has melted collect the nerolin by vacuum filtration using the Buchner funnel. Crude nerolin (~5g) is shown in the photo below:

crude nerolin

Recrystallize the nerolin from methanol. You should get some glistening pure white plates as shown in the photo below:

recrystallized nerolin

F. Results

The recrystallized nerolin shown above had a melting point of 36°C. The literature value is 37-38 °C. My yield was only 0.32g.

G. Discussion

Nerolin is used in perfumery and as a fixative in soaps. Fixatives reduce the evaporation rate of other added volatile scents.

One source of the discoloration in the crude nerolin was likely the homemade ß-naphthol, as it is also off-color. During the recrystallization there

was a large amount of contamination that precipitated out first. I carefully removed the upper crystals which looked to be quite pure as shown in the

photo above. I then attempted to harvest more pure crystals from the heavy residue but was not successful.

I’m not sure why the yield of nerolin is so low. Perhaps steric hindrance plays a part as the ß-naphtholate anion is quite bulky. I should also

mention that I accidentally used 150mL of the solvent methanol instead of 100mL, which would reduce the concentration of the reactants.

This is a simple procedure and you are rewarded with a most delightful smelling compound. It smells so good you will not want to wash it off your

hands. I detect notes of vanilla and citrus.

H. Reference

This procedure is a 2X scale paraphrase of a college hand-out obtained in 2003.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Hexavalent

International Hazard

Posts: 1564

Registered: 29-12-2011

Location: Wales, UK

Member Is Offline

Mood: Pericyclic

|

|

Excellent work and write-up Magpie, as usual.

Do you have any future plans for your nerolin? Perhaps cleavage with a hydrohalic acid to give an alkyl halide and an alcohol? Or even chlorination to

give the alpha-chloroether? Good luck with your future work, I look forward to reading about more of your experiments.

"Success is going from failure to failure without loss of enthusiasm." Winston Churchill

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thanks, Hexavalent. No, I have no further plans for the nerolin.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

I wish there was a like function like facebook has just to show interest in threads where my post really wouldn't be of any real value. Either way

always a pleasure Magpie.

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thank you Sedit - very kind of you.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

reckless explosive

Harmless

Posts: 28

Registered: 1-12-2011

Member Is Offline

Mood: experimental

|

|

Could ethyl bromide be used in place of the ethyl iodide as long as its in the same stoichiometric amounts? As i cannot obtain the chemicals to make

ethyl iodide or buy but i could make ethyl bromide with a raid of thr local pool store.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

See the 2 posts of Nicodem in this thread:

http://www.sciencemadness.org/talk/viewthread.php?tid=11663&...

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

sbbspartan

Hazard to Self

Posts: 61

Registered: 6-3-2012

Location: Minnesota, USA

Member Is Offline

Mood: DEAD (diethyl azodicarboxylate)

|

|

For people interested in how to synthesize ß-naphthol, there is some information that might prove useful in this thread:

http://www.sciencemadness.org/talk/viewthread.php?tid=11663

Is that how you made your ß-naphthol Magpie?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Yes, I describe my preparation down farther in that same thread.

Maybe some don't know that 2-naphthol = beta-naphthol. That's IUPAC nomenclature vs the common name, I believe.

[Edited on 14-2-2013 by Magpie]

[Edited on 14-2-2013 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

sbbspartan

Hazard to Self

Posts: 61

Registered: 6-3-2012

Location: Minnesota, USA

Member Is Offline

Mood: DEAD (diethyl azodicarboxylate)

|

|

Funny, I didn't even realize the thread you listed was the same one I was looking at.

You use the same source of methanol as I do too. I like HEET, it's easy to get and cheap...

Good prep!

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

I too, recently finished the preparation of 2-ethoxynaphthalene via a slightly alternate procedure (that I more or less made up entirely as

modifications of this prep). Instead of KOH, I elected to use sodium methoxide produced freshly as base. My starting 2-naphthol was somewhat less pure

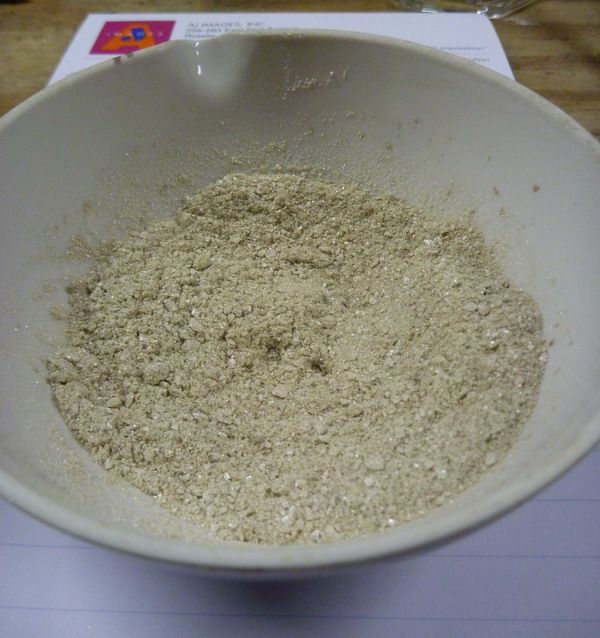

than Magpie's, melting from 118-120C (uncorr, lit. value 123C). This is pictured below.

A 250ml RBF was charged with a stirbar and 75ml of methanol (HEET, distilled to remove the fraction of a percent of oily high-boiling material). 1.33g

(0.058mol) of fresh sodium, cut into thin sticks to speed reaction was added and stirring started. The methanol became quite warm as the sodium

rapidly dissolved to an ever-so-slightly hazy solution of NaOMe in methanol.

7.21g (0.050mol) of the aforementioned (and pictured) mostly-pure 2-naphthol was added to this methoxide solution, rapidly dissolving to a dark brown

solution. A liebig condenser was placed atop the RBF as a reflux condenser. After stirring for ~5 minutes, 10.92g (0.10mol) of Ethyl

Bromide (I don't reccomend this. Just get some iodide. The reflux period is way too long with bromide unless you're making mol

quantities.) was poured down the condenser into the reaction mixture, and the condenser was topped with a CaCl2 drying tube.

Very gentle reflux was maintained for 26 hours (arbitrary, based on the advice of Nicodem in the 2-naphthol thread, I did not have TLC plates to

monitor with) The reaction mixture remained at ~50C during the entire period and at no time was the condenser permitted to rise above 20C through

addition of ice to the recirculating water bath. The color of the reaction mixture lightened over the reflux period, but remained brown.

The reaction mixture was then brought to a vigorous boil for 5 minutes with the condenser removed in order to expel excess EtBr and any ethereal

byproducts. The hot reaction mixture was poured into 300ml of ice water containing 2g of NaOH to help dissolve any unreacted naphthol. Initially, the

mixture was a milky off-white suspension, but with stirring the 2-naphthol slowly "curdled" and sank to the bottom of the beaker leaving a cloudy, but

decidedly translucent supernatant.

This solid was vacuum filtered and washed with 100ml of distilled water. It is highly hydrophobic. Air is drawn through the solid for some time and it

dries fairly easily, providing 7.41g of crude 2-ethoxynaphthalene as a tan powder (86% yield).

An attempt was made to purify this material by recrystallization from dry methanol, which failed. 90% methanol, 10% water was then tried, which

also gave a dark brown oil. I ended up reprecipitating with icewater, but the emulsion did not "curdle" like the first time and it remained white and

milky with some chunks of tan material at the bottom. An attempt at vacuum filtration did not separate the emulsion and the medium frit plate plugged

completely after a portion of "milk" was drawn through. DCM was added to the emulsion and stirred vigorously, but the "milk" remained. It was found

that adding a few grams of NaCl caused the emulsion to break and the aqueous phase to clear. The DCM phase was boiled down, transferred to a 50ml RBF

with stirbar and completely stripped of DCM under vacuum.

Disregard the above italics if repeating this preparation and simply transfer the crude 2-ethoxynaphthalene to a 50ml RBF with a small stirbar. The

crude material is vacuum distilled with a short path stillhead. An air condenser is suitable for this scale, but ~40C water should be used for any

larger amount.

The bulk of the material passes over at 170C (~30torr) with some forerun in the 160C range and is collected as a very slightly yellow oil that freezes

in the reciever to a crystalline solid. Yield is 6.31g (73% yield from 2-naphthol, 85% recovery) of 2-ethoxynaphthalene as a white crystalline solid

melting at 33-34C (uncorr. lit, 36-37C).

It has a powerful scent reminiscent of a more floral, sweeter version of methyl benzoate that is otherwise hard to put a finger on. At extremely high

concentrations (nose right up to the bottle) it seems to have a disagreeable fecal smell. This could be impurity, but it would not surprise me seeing

as how indole, which is floral at low concentrations is fecal at any decent concentration. Nerolin may activate the same receptors, but with different

affinities.

It might be possible to properly recrystallize the material at this point and improve the m.p, but I'm sick of working with it after the first

recrystallization failures.

[Edited on 10-26-13 by UnintentionalChaos]

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

Random

International Hazard

Posts: 1120

Registered: 7-5-2010

Location: In ur closet

Member Is Offline

Mood: Energetic

|

|

Nice work as always Magpie I love reading your experimental procedures.

|

|

|

vulture

Forum Gatekeeper

Posts: 3330

Registered: 25-5-2002

Location: France

Member Is Offline

Mood: No Mood

|

|

Nice work, both of you!

Question: Why the specific warning for methanol? I'd be more weary of exposure to alkylbromides and iodides.

One shouldn't accept or resort to the mutilation of science to appease the mentally impaired.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by vulture  |

Question: Why the specific warning for methanol? I'd be more weary of exposure to alkylbromides and iodides. |

No reason other than I am aware of the hazards of methanol. Not so much those for the halides. Thanks for the warning.

I think this is an interesting comparison of the results for two slightly different procedures by two different experimenters. Oil-outs are a bitch

and I think one is wise to go to distillation when they are encountered.

I placed my nerolin on a watch glass in my glassware cabinet. I am pleased by its pleasant smell every time I open the cabinet .

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Diachrynic

Hazard to Others

Posts: 226

Registered: 23-9-2017

Location: western spiral arm of the galaxy

Member Is Offline

Mood: zenosyne

|

|

2-Ethoxynaphthalene using ethanol and sulfuric acid

I want to present another alternative synthesis and workup for 2-ethoxynaphthalene, which avoids alkyl halides.

The preparation comes from an article by Gattermann from the late 19th century.[1]

Chemicals:

2.5 g 2-naphthol

2.5 mL absolute ethanol

1 g 98 % sulfuric acid

MTBE

Sodium hydroxide

Sodium sulfate for drying

For the pad:

Cyclohexane

Silica gel 60 A, 40-63 µm

Procedure:

The 2.5 g of 2-naphthol were dissolved in the ethanol (2.5 mL) in a 25 mL flask, then the 1 g of 98 % sulfuric acid was added carefully. This addition

is quite exothermic. A reflux condenser is added and the mix is refluxed for 4 hours by using an oil bath at 145 °C.

Then, the flask is allowed to cool a bit and the contents are dumped into 50 g of icewater, which is then extracted with 30 mL of MTBE in two

portions. (I'm sure diethyl ether would work just as well if not better.) The organic layers are combined.

15 g of sodium hydroxide was dissolved using 50 mL of water, left to cool and then used to wash the MTBE extract in two portions. Three phases are

observed: An aqueous bottom layer, above that a brown oil and above that a slightly brown MTBE layer. Only the top MTBE layer is retained. On standing

the brown oil solidifies into a glittering plate-like solid, it is 2-naphthol.

The MTBE is dried over anhydrous sodium sulfate, then removed in a simple distillation using a water bath. The residual liquid froze in the fridge.

Yield 2.19 g (73 %) of slightly brownish 2-ethoxynaphthalene.

Analysis:

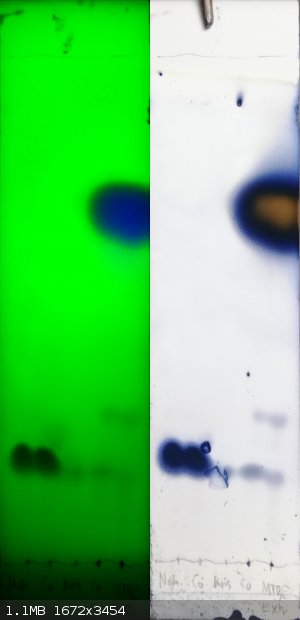

A TLC (silica 60 F254, glass backed) was done using 9/1, v/v, n-hexane/ethyl acetate as the eluent. Visualized with 250 nm UV

(2-ethoxynaphthalene shows a blue fluorescence) and by staining with Hanessians stain (developed at 250 °C with a heatgun). Approximate Rf

values are 0.21 for 2-napthol and 0.70 for 2-ethoxynaphthalene. The product contains traces of 2-naphthol and another unknown impurity at an

Rf of about 0.29.

Left lane: 2-Naphthol.

Middle lane: The brown oil.

Right lane: Final MTBE extract before evaporation.

Between the lanes co-spots of the adjacent lanes.

Left image under 250 nm UV, right one after staining with Hanessians stain.

Further workup:

The product was padded with cyclohexane. A glass frit with a diameter of about 2 cm and a height of about 10 cm (called a "filter tube, according to

Allihn", example from Roth) was filled with a slurry of silica gel (60 A, 40-63 µm) in cyclohexane. This was put onto a filtration flask with a vacuum

pump attached. Then the product was dissolved in about 20 mL of cyclohexane, added onto the column, the solvent was run into the silica and it was

eluted using about 80 mL of cyclohexane. In the end the column was pulled mostly dry with the vacuum. All the brown and yellow impurities stay within

1 cm of the top, the filtrate is colorless. The cyclohexane is recovered by distillation, a vacuum is applied at the end to remove the last amount of

cyclohexane, the residual liquid freezes into a white solid in the fridge.

After drying in air, the white solid weighs 1.97 g (66 % based on 2-naphthol).

Discussion:

Washing the MTBE with sodium hydroxide is supposed to remove most unreacted 2-naphthol. If the 2-naphthol that precipitated out was included, the

yield based on unrecovered 2-naphthol would likely be considerably higher.

The padding eluent was chosed by suggestion of CorrosiveChemistry, who I'd like to thank here. I'm quite happy with how it turned out.

The original paper also mentioned the same method works for the methyl ether. In this case they heated to 125 °C, but they do mention that it is

beneficial to work "under the pressure of a small mercury column". So some slight pressure seems to help in the case of the methyl ether. Maybe it

could work without?

Literature:

[1] - L. Gattermann, Justus Liebigs Ann. Chem. 1888, 244, 29-76. https://doi.org/10.1002/jlac.18882440104

[Edited on 29-11-2023 by Diachrynic]

we apologize for the inconvenience

|

|

|

DraconicAcid

International Hazard

Posts: 4412

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

Nice. I've made the methyl version by refluxing with methanol and sodium hydrogen sulphate, and I've added the ethyl bromide-based synthesis to my

organic lab. It works well. The purification is simplified by the fact that naphthol has very low solubility in dichloromethane.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

AvBaeyer

National Hazard

Posts: 655

Registered: 25-2-2014

Location: CA

Member Is Offline

Mood: No Mood

|

|

Diachrynic - It is quite possible that one of the lower Rf impurities is 1-ethyl-2-hydroxynaphthalene. Alkylation of 2-naphthol at the 1-position

under basic conditions is a known reaction.

DraconicAcid - Can you please post a procedure for your prep of 2-methoxynaphthalene using sodium bisulfate?

|

|

|

DraconicAcid

International Hazard

Posts: 4412

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

Hmm. I know I've done it, but I just went through seven lab notebooks and can't find it. I need to be more organized.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

DraconicAcid

International Hazard

Posts: 4412

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

Aha! Found the citation!

https://patents.google.com/patent/CN102285871A/en

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Metacelsus

International Hazard

Posts: 2543

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

This is a bit off topic, but it's my pet peeve when people write ß (the German double S) instead of β (the Greek letter).

Alzheimer's researchers who abbreviate amyloid-beta as Aß are making asses of themselves, see for example: https://pubmed.ncbi.nlm.nih.gov/11145990/

|

|

|

Texium

Administrator

Posts: 4665

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: Preparing to defend myself (academically)

|

|

Literally

|

|

|

DraconicAcid

International Hazard

Posts: 4412

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

I finally found my notes from that reaction.

1.424 g 2-naphthol, 0.60 g sodium hydrogen sulphate monohydrate, and 1.5 mL of methanol were refluxed for 90 minutes. The mixture turned dark brown

(probably due to oxidation of the naphthol). The solution was cooled to room temperature, and 5 mL water and 2 mL 0.5 M potassium hydroxide solution

were added. This was extracted with 3 x 3 mL of dichloromethane.

The combined extracts were washed twice with 0.25 M potassium hydroxide solution (which did not diminish the dark colour of the solution), The

extract was then dried over sodium carbonate, and filtered through a plug of alumina (which removed much of the colour). The solvent was removed by

evaporation.

I know I checked it by mp and TLC, but didn't record those numbers in the right spot.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Fery

International Hazard

Posts: 1052

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

DraconicAcid great! Washing with KOH certainly got rid of unreacted naphthol. So you did a methylation without methylating agent like dimethylsufate

or methyl iodide... When I used dimethylsulfate the first methyl group reacted quickly and I wanted to push more product by forcing the reaction with

the second methyl group. The second methyl group required steam distillation to remove the product to push the equilibrium towards the product:

https://www.sciencemadness.org/whisper/viewthread.php?tid=15...

I further tried ethoxy https://www.sciencemadness.org/whisper/viewthread.php?tid=15... and allyloxy https://www.sciencemadness.org/whisper/viewthread.php?tid=15...

All the 3 above experiments had something different like solvent / base used.

|

|

|

DraconicAcid

International Hazard

Posts: 4412

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

I'm not sure it's the KOH wash that's getting rid of the naphthol, but the use of dichloromethane (in which naphthol isn't very soluble) really helps.

I want to move away from chlorinated solvents, but it just works so damn well....

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

AvBaeyer

National Hazard

Posts: 655

Registered: 25-2-2014

Location: CA

Member Is Offline

Mood: No Mood

|

|

Questions about synthesis of 2-Ethoxynaphthalene using ethanol and sulfuric acid

Recently Diachrynic reported results (see above) on the acid catalyzed reaction of ethanol with 2-naphthol to afford 2-ethoxynaphthalene. A yield of

73% of initial product and 66% of purified product is reported. No melting point of the product is reported.

I have executed the same reaction under several conditions including that reported by Diachrynic and have never achieved a yield in excess of 35% of

crystalline 2-ethoxynaphthalene melting at 34-36 C. My reactions were all run using 5.0 g of 2-naphthol (mp 120-121 C), undenatured absolute ethanol

and 96% sulfuric acid (by titration). I use hexane to extract the product from the work up mixture. The crystalline product is isolated directly from

the hexane extract after a brine wash, drying, and evaporation of the hexane. I can recover about 85% of the unreacted 2-naphthol which is extremely

difficult to filter.

The basic procedure that I have followed is that reported by Stork for the synthesis of 2-methoxynaphthalene. Following that procedure at the 5.0 g

scale and using a slightly modified work up, I routinely achieve yields of at least 85% of 2-methoxynaphthalene. When using ethanol, the molar amounts

of ethanol and sulfuric acid are adjusted to match those when using methanol per the stoichiometry in the reference.

Modified work up: The hot reaction mixture is poured into 1 M NaOH using about 15 times the volume of alcohol used in the reaction. The final pH

should be about 12 (paper). A few chips of ice are added to cool the mixture which results in crystallization of the product. This is not filtered but

extracted 3 times with hexane each of which is about 1/3 the volume of the aqueous portion. The hexane extracts are washed with water, brine then

dried over sodium sulfate. The hexane is then removed by distillation. Residual solvent is removed at aspirator pressure during which time the product

crystallizes. Acidification of the aqueous layer precipitates unreacted 2-naphthol.

1. What is the melting point of Diachrynic’s product?

2. What type of ethanol was used? What is the denaturant, if any? I ask this to determine if methanol was used to denature the ethanol used. The

methoxy and ethoxy compounds are not readily distinguishable by TLC.

Reference: G. Stork, J. Am. Chem. Soc., 69, 576 (1947)

Any discussion?

AvB

[Edited on 11-12-2023 by AvBaeyer]

|

|

|

| Pages:

1

2 |