Fery

International Hazard

Posts: 1055

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

benzyl acetone = 4-phenylbutan-2-one by hydrogenation of benzylideneacetone with H2 on palladium catalyst

calculations:

benzylideneacetone 4,9 g = 33,5 mmol (M = 146.19 g/mol)

33,5 mmol H2 = 750 ml at 1 atm and 0 K, 1 L was prepared (excess)

Procedure:

1 L plastic bottle was filled with H2 gas produced by electrolysis. Bottle full of tap water was closed and turned upside down, submerged into water

bath and its mouth was opened below water level in the bath. Some NaCl was dissolved in the bath to create an electrolyte. Metallic cathode from an

insulated wire which end was uninsulated was inserted into the mouth of the flask under water level and graphite anode was put into the electrolyte

outside of the flask. Electrolysis was performed with current 1-1,5 A at voltage of 6 V using an archaic battery charger supporting decades old and

not anymore produced Trabant car which batteries used voltage of 6V. Some weak smell of Cl2 was noticed during the electrolysis but most of the Cl2 dissolved in the

bath.

To a 2-valve adapter was connected a transparent hose of length 1,0 m (too much shorter either longer are not convenient). The hose should be

transparent, medium hardness, not too soft either too hard. Adapter was greased and connected into empty 1 L RBF. RBF was evacuated using very weak

vacuum circa -0,2 atm which should be enough for 1 m of water height in the hose. RBF was then elevated into uppermost position so the hose was

suspended freely downwards. The opened bottom of the hose was inserted into water bath. The valve was slowly opened to allow water to slowly enter and

raise the whole height of the hose and also the tiny space of the stopcock and the valve was closed. The open end of the hose filled with water was

inserted through water bath into the bottle with hydrogen. RBF was lowered below the level of water bath in such a position that the most part of the

hose was leading continually downwards under small angle so the still partially evacuated RBF was at the undermost position. The valve was slowly

opened and when the H2 gas entered the full length of the hose and through the stopcock into the RBF, the stopcock was immediately closed. There is no

need to have very strong vacuum in the flask, only very weak vacuum is recommended as the water travels very slowly through the narrowest part in the

stopcock, but when the whole path is replaced with hydrogen the flow suddenly rapidly increases and sucks relatively large amounts of gas in a

fraction of second.

Into 50 ml RBF was put 4,9 g benzylideneacetone and 0,50 g 10% Pd on carbon, stir bar, and as the last was added 20 ml of methanol.

The 2-valve adapter was detached from the 1 L RBF, dried from water drops by a strip of filter paper, regreased and connected to the reaction 50 ml

RBF. Now the air in the apparatus had to be replaced with inert gas (N2, Ar, CO2) by evacuating the flask and filling it with inert gas and repeating

that few times, but inert gas was not available and this important step to prevent ignition of flammable solvent had to be skipped. Using

dichloromethane as non-flammable solvent was not tried.

Water aspirator vacuum pump was connected to the second valve of the adapted. Magnetic stirring was commenced at a moderate speed as used in vacuum

distillations. Water was run through the water aspirator pump and the second valve was opened. Methanol started to boil under reduced pressure for few

seconds and replaced the air, then the second valve was closed and first valve slowly opened so H2 entered the reaction. Repeating that second time

could remove remainders of air but was not done due to already almost exact the amount of necessary H2 in the bottle thus no extra volume to waste.

The position of hydrogen/water level on the plastic bottle was marked using a pen. The bottle with H2 was sunken in a bucket of water as the hydrogen

was consumed. Few drops of water were allowed to enter the hose at the beginning of the hydrogenation which then flew down to the lowest position in

the siphoning part of the hose and was good indicator of gas speed consumption by seeing bubbles of gas flowing through the short part of water in

transparent hose. The reaction was stirred at high RPM. When absorption ceased after 5 hours 35 minutes, the level of H2/water in the flask was marked

with a pen. Now the reaction RBF had to be filled with inert gas (N2, Ar, CO2) to prevent fire but any inert gas was not at hand so this important

step to prevent fire was skipped again. Alcohols are allegedly the most prone for igniting on Pd from all the flammable solvents commonly used. And

the methanol has the lowest b.p. of all alcohols...

The volume of H2 was measured by filling the flask to the last pen mark with water and then adding water into the flask from graduated cylinder until

the first pen mark was reached.

810 ml of H2 was consumed.

The RBF was set aside for the next day, Pd/C very slowly settled to the bottom.

The next day the stopcock was opened, it was heard a hissing as a sign that there was a vacuum in the flask so some H2 was still consumed overnight

(the second benefit of replacing the H2 with inert gas which was not done, but the dead volume of the apparatus was circa 40 ml so only 5% of the H2

consumed totally = 810 ml and as the pressure lowers less and less of H2 reacts). The 2-valve adapter was detached and now the operation was risky of

fire ignition but luckily nothing happened. The clear supernatant was gravity filtered through dense filter paper and then the catalyst was rinsed

from the flask into the filter using few portions of methanol with total volume 20 ml. A watch glass was at hand to cover the filtration funnel in

case of flammable solvent vapors ignition. Filtrates were merged and methanol distilled out, the still hot flask was then attached to a water

aspirator pump while swirling in hand to remove last traces of solvent.

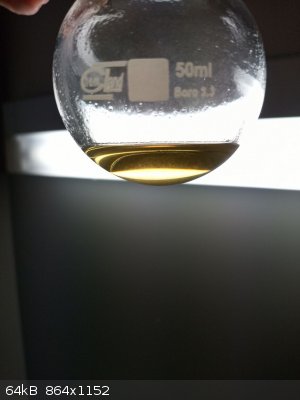

Yield 4,7 g, some small amount of the product stayed adhering on the walls of RBF.

No further purification was performed. A very little of side reaction should occur by converting ketone group to alcohol (according literature not

more than 4%) and in case some part of the reactant was not reduced there could be a little of reactant present. The double bond of the reactant could

be attacked by a water solution of KMnO4 which could also oxidize the alcohol group back to ketone. Adduct of the ketone with bisulfite could be made

and recrystallized. The product could be vacuum distilled in a semi-microscale distillation apparatus which was not available.

The product has very pleasant and strong scent of flowers.

I've bought 4-(p-hydroxyphenyl)-2-butanone (raspberry ketone) from es-drei.de which had very weak scent at room temperature so I decided to synthesize

something else - due to lower b.p. of 4-phenyl-2-butanone its scent is much stronger at room temperature than raspberry ketone.

calculations:

pV = nRT

1,01 * 10^5 * 0,81 * 10^-3 = n * 8,314 * (273+20)

n = 81,81 / 2436 = 0,0336 mol H2 consumed

Questions: Pd/C is wetted with water, the amount of catalyst should be recalculated into its dry form or is it OK to calculate its wetted weight? Or

does the concentration of 10% means there is 10% of Pd in the wetted form (so if initially it is 10% Pd + 40% C + 50% H2O then after drying there is

20% Pd + 80% C)?

5% Pd/C has better performance than 10% Pd/C because 10% Pd/C has larger Pd particles so less effective surface.

references and useful info:

https://www.sciencemadness.org/talk/viewthread.php?tid=12780

https://gousei.f.u-tokyo.ac.jp/document/img/hydrogenation.pd...

https://pubs.acs.org/doi/10.1021/acs.oprd.1c00190

https://patents.google.com/patent/US6441242B1/en

https://patentimages.storage.googleapis.com/75/61/96/e0cb2ed...

https://asset-pdf.scinapse.io/prod/1976016712/1976016712.pdf

https://www.youtube.com/watch?v=CLunEhl2uTs

https://en.wikipedia.org/wiki/Benzylideneacetone

Chemical formula C10H10O

Molar mass 146.19 g/mol

Appearance pale yellow solid

Density 1.008 g/cm3

Melting point 39 to 42 °C (102 to 108 °F; 312 to 315 K)

Boiling point 260 to 262 °C (500 to 504 °F; 533 to 535 K)

Solubility in water 1.3 g/L

Solubility in other solvents nonpolar solvents

https://en.wikipedia.org/wiki/Benzylacetone

Chemical formula C10H12O

Molar mass 148.205 g·mol−1

Density 0.989 g/mL

Melting point −13 °C (9 °F; 260 K)

Boiling point 235 °C (455 °F; 508 K)

http://www.thegoodscentscompany.com/data/rw1024231.html

benzyl acetone

4-phenylbutan-2-one

Specific Gravity: 0.98500 to 0.99100 @ 25.00 °C.

Refractive Index: 1.50900 to 1.51500 @ 20.00 °C.

Melting Point: -13.00 °C.

Boiling Point: 233.00 to 235.00 °C. @ 760.00 mm Hg

Boiling Point: 115.00 °C. @ 13.00 mm Hg

Vapor Pressure: 0.056000 mmHg @ 25.00 °C. (est)

Odor Type: floral

Odor Strength: medium

Substantivity: 172 hour(s) at 100.00 %

floral balsamic

Odor Description: at 100.00 %. floral balsam

photos will follow but I had to split the post into 2 posts due to limit of attachments in 1 post

Attachment: hydrogenation.pdf (524kB)

This file has been downloaded 288 times

Attachment: US6441242.pdf (256kB)

This file has been downloaded 245 times

Attachment: 1976016712.pdf (715kB)

This file has been downloaded 287 times

[Edited on 2-12-2022 by Fery]

|

|

|

Fery

International Hazard

Posts: 1055

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

filling 1 L bottle with H2 produced by electrolysis

reactants

filling the hose with water

filling the hose with H2 gas, on the first photo the flask empty with weak vacuum, on the second photo all the water from the hose flew into the flask

and the hose is filled with H2

the 2-valve adapter was detached from 1 L RBF, dried with strip of filter paper, regreased and connected to the reactor 50 ml RBF

stirring commenced at RPM as used in vacuum distillations and water aspirator pump vacuum applied, the methanol started to boil at room temperature

under reduced pressure and in few seconds it replaced the air in the apparatus, then the vacuum valve was closed and valve with H2 opened

H2/water level was marked with a pen on the bottle wall

reaction was stirred at highest possible RPM

bottle was submerged in a bigger bucket of water during which few drops of water entered the hose which gave better choice to measure the gas

consumption

here good counter of bubbles of H2 thanks to few drops of water entered the hose, this is very precise reaction speed counter, looking to the level of

H2/water in flask is not so much precise, in these 2 photos the bubble of H2 is passing through the short lowest part of the siphon of hose where is

the small amount of water, the difference between these 2 photos are 2 seconds

when the speed of reaction ceases do a second mark of the H2/water level with a pen on the plastic bottle

the catalyst was allowed to settle overnight

supernatant was filtered through dense filter paper and catalyst was washed from RBF into the filter paper with few portions of methanol, a watch

glass was at hand to cover the funnel in case of flammable solvent vapor ignition

solvent was distilled out

remainders of solvent were removed by applying water aspirator pump vacuum to still hot RBF while swirling it in hand

the product

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Very good, Fery! A low pressure hydrogenation on Pd/C! Without inert atmosphere. With the help of a repurposed plastic bottle. Semi professional

amateurism?

On the serious side: did you check the purity of the end product in any way? The difference in polarity might be not big enough after the

hydrogenation that it would make a big difference in Rf values of a TLC... If there were some alcohols produced too, it would surely show up though.

I have some Pd/C and it is a free flowing powder. I would calculate with the dry weight of the catalyst if I were you.

Once I used Pd/C in methanol and after filtering it off of the reaction mixture it almost caught fire. The filter paper started to smoke but I noticed

it and drenched it with water. The time between finishing the filtering and the detection of the first smoke trails was around one minute at room

temperature. So yes, Pd/C in methanol if left to dry surely will self-ignite - at least if it was previously activated by H2 exposure.

|

|

|

Fery

International Hazard

Posts: 1055

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Hi Pumukli, I was very afraid of fire too. I studied all solvents and there is a link in the initial post that alcohols are the most prone solvents

for igniting and methanol of course the worst due to its lowest b.p.

20 ml of burning methanol wouldn't be any disaster but the product could be lost. That's why I let the catalyst to settle overnight and filtered

quickly the supernatant and only then washed the catalyst with fresh methanol. I let the H2 to be consumed overnight, in the morning there was

significant vacuum in the flask, maybe that helped. Also the Pd/C was 10% which has less active surface than 2-fold weight of 5% Pd/C. The catalyst

was bough in sale-out, with unknown age, unknown activity, whether it was already used and then recycled or whether it is fresh is also unknow. The

only info on the package states that it is 10% Pd/C, nothing else. Whether that 10% means in dry form or wetted form - unknown.

I believe leaving it overnight in sealed reactor made the remainders of H2 to be consumed and maybe that helped to avoid fire???

Unluckily I do not have any inert gas yet. Just before the hydrogenation I replaced air with vapors of low boiling point solvent (methanol) and after

the hydrogenation I did not use inert gas either but I was prepared to choke the air availability for possible flames in filtration funnel using an

hour glass.

I did not check the purity of the product. My goal was to smell this fragrance compound. Even the reactant has nice scent but weak, the product scent

is very pleasant and much stronger. According the small amount I did not purify it further. If I would do something with it I would try water solution

of KMnO4 which could oxidize alcohol back to ketone and make diol from unreacted double bond, the diol could then be removed as a residuum after

vacuum distillation (I expect much more higher boiling point for the diol).

I did not perform chromatography. The volume of H2 consumed matched very nicely and there should not be too much side products (in one link there is

written that not more than 4% of alcohol is produced).

I like to reuse "useless" things like the 6V batteries charger and empty plastic bottle from milk.

Pumukli - if you dry the catalyst on air for some time, hasn't it negative impact on its activity? Maybe not, I'm just asking as I do not know. I read

some paper how the activity of Pd/C catalyst decreases during reusing cycles, but I did not save the link. There were also microscopic photos how the

particles changed every reusing cycle which explained its decreased activity (the particles merged into bigger particles which reduced the surface

area).

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

@Fery:

what was your target product?

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Fery, I bought my Pd/C on a sort of sale too. I don't know anything else about it besides the bottle says 10% Pd/C and the color seems right: fine,

blackish powder.  I never used it before so it even might be fake as well. I never used it before so it even might be fake as well.

On the other hand when I had that "fiery" encounter with another Pd/C batch it was a 5% one - but it was also a dry powder! And it was stored in a

brown glass wide mouth powder "jar", nothing fancy, just a general chemical storage thing. It was active, maybe even too active for what I wanted to

achieve. I wanted to use it to remove a benzyl-group from a secondary amine, but not only the benzyl-group was removed but the silicon-containing ring

of the amine (a disila-morpholine) broke too. That powder was stored in that bottle for at least a year by the time I used it. The only precaution we

had to adhere to was the "No metal spatulas here". (No one with a metal spatula was allowed to touch this Pd/C. Only plastic ones were allowed to

touch the powder.)

Your solvent vapour "deoxigenation" method surely helped. I'll try to remember that.

Yes, that overnight settling probaly didn't hurt either. My pyroforic Pd/C came straight from a small Parr hydrogenator where it spent the previous

hours under 20 (or was it 40?) atm H2 pressure. So it was saturated with H2 too.

Do you know if you had started from vanilline instead of benzaldehyde you could synthetise zingeron, one of the active aroma compounds of ginger?

Don't you want to give it a try?

[Edited on 2-12-2022 by Pumukli]

[Edited on 2-12-2022 by Pumukli]

|

|

|

kmno4

International Hazard

Posts: 1517

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

I made this ketone years ago, but in very similar way: 10%Pd/alumina with H2 generated by electrolysis (directly, without any separation).

Also slightly yellow product was obtained. It was then converted into NaHSO3 adduct and washed with toluene (or something similar). It gave much less

coloured ketone (after its recovery), and deeply orange toluene solution.

The ketone was then distilled under normal pressure.

It turns out, that I still have foto of the distillate

Слава Україні !

Героям слава !

|

|

|

Fery

International Hazard

Posts: 1055

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

@blogfast25 the target product was only the benzyl acetone so far

@Pumukli - this catalyst may perhaps have slightly different properties according the usage it was made for? E.g. for lab usage vs. for industry usage

(more elevated pressures of H2 expected in industry?), for reductions of nitro to amino vs. hydrogenation of alkenes etc? Also its age and count of

cycles it was already used may change its properties? I already performed aldol vanilin+acetone but the product was not satisfactory. In fact I

initially wanted to make zingerone but then I changed my mind and did benzaldehyde+acetone and then hydrogenation on Pd.

@kmno4 - that's very useful info, thx! Your product has much better color! Its b.p. is 233 - 235 °C @ 760 mm Hg. You produced quite nice amount of

it! I did only some very small scale of it, just to try it. If synthesizing more in the future I would certainly vacuum distill it. But I usually do

not repeat experiments because I have a big list of to-do experiments waiting in queue...

|

|

|

kmno4

International Hazard

Posts: 1517

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

My distilled product was completely collorless, as it should be.

I do not like making impure preparates, especially as end-products.

As far as I remember, I prepared oxime of this ketone and reduced it into amine in two independent ways.

Anyway - good luck in experimentation and let your products be always in high yields !

Amen.

[Edited on 3-12-2022 by kmno4]

Слава Україні !

Героям слава !

|

|

|

ChemichaelRXN

Hazard to Others

Posts: 103

Registered: 7-10-2010

Member Is Offline

Mood: Universal Eye

|

|

Did you ever make the following chemical with benzyl acetone to make; 1-phenyl-3-methylaminobutane ?

(NaBH4 and methylamine )

You are the same perception looking out, from the same elements around the universe.

You are everything to be anything to begin with.

Https://you-are.space

Https://syntharise.com

|

|

|

Fery

International Hazard

Posts: 1055

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Hi ChemichaelRXN, I didn't the reaction you mentioned. The product has some psychoactive properties, hasn't it?

There is a post about preparation of raspberry ketone in the forum. But I have commercial raspberry ketone. So I decided to produce something else.

Scents databases claim that benzyl acetone has pleasant scent of flowers which interested me. There are preparations of zingerone if you search

internet. But I did not find any preparation of benzyl acetone (maybe I did not search enough). I tried the simplest conditions using methanol as a

solvent and it worked well. Maybe other solvent could be better, safer, faster, etc.

|

|

|