Fery

International Hazard

Posts: 1015

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

1,2,3,4-tetrahydrocarbazole

Initially I had these references:

https://sci-hub.wf/10.1021/ja01203a506

Attachment: ja01203a506.pdf (275kB)

This file has been downloaded 193 times

https://www.youtube.com/watch?v=TFMQBruo5k0

https://www.youtube.com/watch?v=TaNA-K0skEs&t=281s

When everything was done, I found ultimate reference at:

http://orgsyn.org/demo.aspx?prep=CV4P0884

http://orgsyn.org/Content/pdfs/procedures/CV4P0884.pdf

Attachment: CV4P0884.pdf (317kB)

This file has been downloaded 201 times

https://en.wikipedia.org/wiki/Carbazole

| Quote: | | A classic laboratory organic synthesis for carbazole is the Borsche-Drechsel cyclization. In the first step, phenylhydrazine is condensed with

cyclohexanone to the corresponding imine. The second step is a hydrochloric acid-catalyzed rearrangement reaction and ring-closing reaction to

tetrahydrocarbazole. In one modification, both steps are rolled into one by carrying out the reaction in acetic acid. |

In this experiment the 1,2,3,4-tetrahydrocarbazole was prepared at 50 mmol scale which caused some challenges in comparison with 1 mol scale in the

original method.

calculations:

cyclohexanone 4,9 g (50 mmol), M = 98,15 g/mol

phenylhydrazine 5,4 g (50 mmol), M = 108,14 g/mol

acetic acid 18 g

Into 50 ml round bottomed flask was added cyclohexanone 4,9 g (50 mmol), acetic acid 18,0 g and boiling stones. Liebig condenser was attached and the

mixture was heated. When it started to reflux, during 1 hour was dropwise added phenylhydrazine 5,4 g (50 mmol) through the top of condenser (using 2

neck flask and dropping funnel would be more advanced but the simple design used here worked well too). Some solid precipitate formed in the bottom of

condenser which melted after stopping cooling water circulation for a while. Then the reaction was refluxed for another 1 hour. Then it was allowed to

cool down to room temperature (it started to crystallize very soon while still very hot) and overnight in a fridge at +4 C (acetic acid does not yet

crystallize at +4 C as it contains some water from the reaction 50 mmol of H2O = 0,9 g H2O with 18,0 g acetic acid = 95% acetic acid).

The solid product was vacuum filtered using Buchner funnel and filter paper, the mass was quite thick and hard to get from the reaction flask, using

wide ground glass joint flask is recommended (29/32 joint size was used), scraping the mass using glass rod and rinsing the flask with a little of

water which was added to the funnel was necessary. The product was rinsed with a little of mixture of water + methanol 1:1 on the filter paper which

improved its color.

The product was air dried for 2 weeks, smell of acetic acid in the beginning was observed which soon faded away, but the weight continued to decrease

slowly for a long time. It really lasted so long, only after that long time the weight ceased to decrease and stayed stable for few days.

8,4 g of product obtained (yield 98%). 100% yield at 50 mmol scale = 8,56 g (M = 171.24 g/mol).

The crude product was recrystallized from 45 ml of methanol (it dissolved well in only 35 ml on boiling but after cooling down the crystalline mass

was too thick so finally 45 ml of methanol was used by adding extra 10 ml to original 35 ml). Solution was cooled down slowly to room temperature and

then to +4 C in fridge, crystals were vacuum filtered on sinter, washed with 5 ml cold methanol (+4 C) on sinter, air dried until stable weight during

3 days.

Yield 6,0 g = 70%.

m.p. 118-120 C (according literature the m.p. depends on the rapidness/slowness of heating)

Notes:

The stirring was not necessary as stated in the original method. Refluxing was enough. Adding boiling stones was necessary then.

Addition of phenylhydrazine through top of condenser avoided clogging of additional funnel stem, but some phenylhydrazine acetate crystallized in the

condenser which had to be melted by temporarily stopping cooling water circulation through condenser. The weaker the reflux, the better (less

phenylhydrazine acetate in the condenser and all the acid condenses in the bottom of condenser and not higher). It is recommended to use short and

wide condenser, mounted as straightly as possible, dropping the phenylhydrazine through the middle of the condenser tube, not on its walls. A

medicinal syringe was successfully used for that and it stayed in the top of the condenser for the whole addition and just pressing its piston to add

phenylhydrazine drop by drop.

Mother liquor remaining after the recrystallization from methanol was boiled with activated charcoal but its color did not change significantly. It

was only a test whether it was feasible to use activated charcoal during recrystallization. When using charcoal the filtration would require heated

funnel at 1 mol scale so at 20 times smaller scale the product would certainly crystallize heavily during filtration so the charcoal was not used

during recrystallization. Testing charcoal later even did not improve the color of mother liquor remaining after recrystallization so its usage seems

to be not much advantageous. If you want to use charcoal anyway, use much more methanol and reduce its volume after filtering off the activated

charcoal.

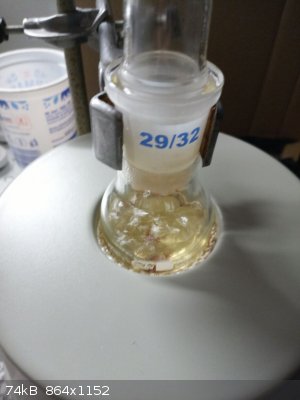

the beginning, cyclohexanone + acetic acid in RBF with wide ground glass joint, boiling stones (5 small brown glass balls) in the flask

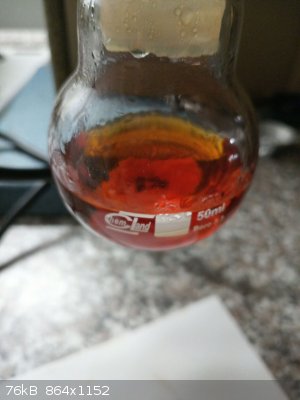

after addition of first few drops of phenylhydrazine

after addition of all phenylhydrazine during 1 hour

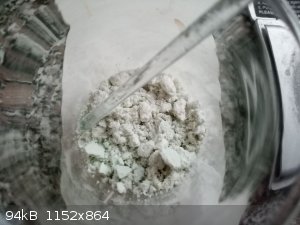

after 1 h of reflux and removing from heating mantle the product started to crystallize immediately, the amount of acetic acid is at the edge, even in

the first picture just after removing from heating mantle there was already a little of crystallized product, in the last picture the content in the

flask was completely solidified

vacuum filtration, rinsing the product with a little of mixture of water+methanol 1:1 on filter paper improved its color (second picture)

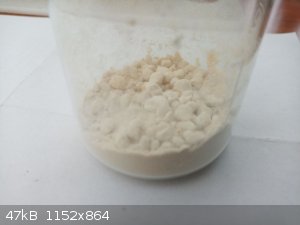

air drying the product for 2 weeks

recrystallization from methanol (45 ml used although it dissolved in minimal amount of 35 ml)

vacuum filtration on sinter (methanol has low b.p. and partly evaporates at reduced pressure so filtering very cold mass is recommended)

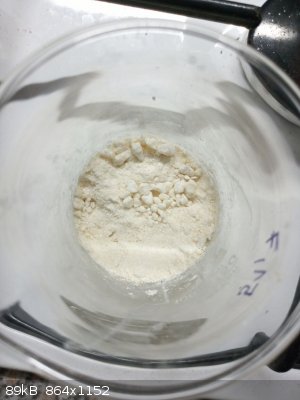

air dried final product

[Edited on 13-11-2022 by Fery]

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@ Fery; nice write-up once again. Any particular reason why you chose tetrahydrocarbazole as your target? Can it be dehydrogenated to carbazole?

|

|

|

Fery

International Hazard

Posts: 1015

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Hi Boffis, the experiment was for the beauty of chemistry, to synthesize some heterocycle. Of course I will try the dehydrogenation, just I would like

to avoid Pb3O4 and try something else.

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Fery  | | Hi Boffis, the experiment was for the beauty of chemistry, to synthesize some heterocycle. Of course I will try the dehydrogenation, just I would like

to avoid Pb3O4 and try something else. |

Yep, sometimes its just got to be done because you can!!

By the way how is the dehydrogenation going?

|

|

|

Fery

International Hazard

Posts: 1015

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Hi Boffis, so far I already got the required Pd on C catalyst. The hydrogenation reaction catalysed by Pd is reversible, so the same catalyst which is

usually used for hydrogenation could be used also for dehydrogenation. It just requires some high boiling solvent for reflux, p-cymene (b.p. 177 C) or

mesitylene (b.p. 165 C). I have only cumene at hand right now (b.p. 152 C) so the reaction would run at lower temperature reflux and its speed would

be somewhat slower. But better than xylene (b.p. 138-144 C).

https://sci-hub.wf/10.1021/ed054p383

Btw I have one question: The catalyst is usually wetted (I suppose water). Water should not be good as it would reduce b.p. of the solvent and thus

slow down the reaction. So should I remove the water? If yes then how? Air drying which would last few hours or 1 day - wouldn't air poison the

catalyst? Adding a little of methanol or acetone and then air drying in few minutes - risk of igniting vapors of flammable solvent? Moreover the man I

bought the catalyst from, does not have more info than it is 10% Pd on C and it is from a lab from a chem factory. So not sure whether it was not

already used or not...

[Edited on 22-11-2022 by Fery]

|

|

|

Texium

Administrator

Posts: 4580

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

Nice, carbazole synthesis is something I wanted to do a long time ago but never got around to, so I find myself once again living vicariously through

your syntheses!

Assuming you only need to use 5 mol% or less of your catalyst, the amount of water used to wet it should be negligible, and not affect the boiling

point of your mixture too much. I would just go for it and not worry about it.

|

|

|

|