2-ethoxynaphthalene = 2-naphthol ethyl ether = Nerolin II

reference - ethylation of acetaminophen to phenacetin The-Synthesis-of-Phenacetin-from-Acetaminophen.pdf

https://people.chem.umass.edu/mcdaniel/CHEM-268/Experiments/...

Attachment: The-Synthesis-of-Phenacetin-from-Acetaminophen.pdf (185kB)

This file has been downloaded 659 times

calculations:

M(2-naphthol) = 144,17 g/mol

M(K2CO3) = 138,21 g/mol

M(C2H5I) = 155,97 g/mol

36,0 g 2-naphthol (0,25 mol)

34,6 g K2CO3 (0,25 mol) but excess 50,0 g used which does not hurt - predried by heating in crucible at 300 C for half an hour

39,0 g C2H5I (0,25 mol)

300 ml 2-butanone density 0,805 g/ml = 241,5 g

pre-experiment preparation:

K2CO3 was dried in a nickel crucible with a lid at 300 C for 30 minutes in 2 batches, weight loss of the K2CO3 in first batch was from 42,6 g to 35,0

g (the K2CO3 used was a K2CO3.xH2O hydrate).

experiment itself:

Into 1 L 2-neck RBF equipped with reflux Liebig condenser and 100 ml dropping funnel there was added :

36,0 g 2-naphthol,

50,0 g K2CO3 (big excess circa 50%, cheap, does not hurt, dries possible traces of water in the solvent),

300 ml methylethylketone,

magnetic stirbar.

The content was refluxed on oil bath and magnetically stirred to dissolve as much of 2-naphthol as possible (C10H7OH + K2CO3 -> C10H7OK + KHCO3),

not all K2CO3 dissolved, that's OK. Then cooled down to circa 50 C.

39,0 g C2H5I was charged into dropping funnel and dropped into reaction during 15 minutes while stirring. A pipette had to be used to transfer it due

to its extremely low viscosity and very high volatility (little of was inevitably spilled by pouring it off the reagent flask on a glass rod, it

escaped on the outer surface of the reagent flask even the flask had specially designed neck to prevent escaping on pouring).

Then refluxed and magnetically stirred for 1 hour.

Reflux condenser rearranged into downward distillation condenser and 250 ml of MEK from original 300 ml distilled out on oil bath and magnetic

stirring, especially slowly and with careful heating near the end.

200 ml of warm water added into the flask and magnetically stirred - all inorganic salts dissolved. The product separated in upper layer.

Transferred into in 500 ml separatory funnel, upper organic layer kept and bottom aqueous discarded.

Washed with warm 200 ml of 2% NaOH, then washed 5 times with 200 ml of warm water until the scent of MEK gone, now the product in bottom layer.

Hydrodistilled (lazy simple distillation) on flame burner and boiling stones using the same flask as for reaction. Circa 1,5 L distillate collected,

after which no product in the condenser anymore. Distillate gravity filtered and water reused into hydrodistillation after discarding first 100 ml of

water (MEK scent).

yield 27,8 g

it has more orange scent than 2-methoxynaphthalene

??? Maybe acetone could work too, but it has lower b.p. (acetone 56 C, MEK 79,6 C) so the reaction would run slower (23,6 C difference = 5x slower

reaction).

reagents and predrying K2CO3 (it lost a lot of water)

2-naphthol + K2CO3 + MEK, refluxing it

C2H5I charged into dropping funnel, dropped into reaction, refluxing reaction

distilling off most of MEK was not captured on photos

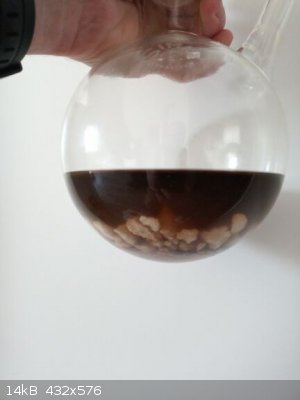

after removing most of MEK and added H2O into reaction to dissolve inorganic salts, organic layer in upper phase

washing with warm water in separatory funnel (thermally insulated with newspapers), the product in bottom layer (organic product lost MEK and water

phases decreased density because of purer water without inorganic salts), note the droplets of organic phase never connected and stayed dispersed in

water

hydrodistillation of the product, reusing water after gravity filtration (through dropping funnel back into distillation flask)

carefully watching condenser not to clog it, warm water melted the product which slid into receiving beaker

the product

|