VeritasC&E

Hazard to Others

Posts: 176

Registered: 29-1-2018

Member Is Offline

Mood: No Mood

|

|

Are all Schott Duran reagent bottles made out of borosilicate glass?

I know the newer Schott Duran reagent bottles are made of borosilicate glass but I wonder if it was already the case with older Schott Duran bottles

such as those produced in Germany until the early 90s?

[Edited on 25-7-2022 by VeritasC&E]

|

|

|

Organikum

resurrected

Posts: 2337

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

The older ones are often made from Jena Glass and not Duran. But funny, they write it both on the label, but I have some with only Jena Glas on it. I

believe...

[Edited on 25-7-2022 by Organikum]

|

|

|

VeritasC&E

Hazard to Others

Posts: 176

Registered: 29-1-2018

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Organikum  | The older ones are often made from Jena Glass and not Duran. But funny, they write it both on the label, but I have some with only Jena Glas on it. I

believe...

[Edited on 25-7-2022 by Organikum] |

What is the difference between the two?

|

|

|

MadHatter

International Hazard

Posts: 1339

Registered: 9-7-2004

Location: Maine

Member Is Offline

Mood: Enjoying retirement

|

|

Jena Glass Wikipedia

Jena glass (German: Jenaer Glas) is a shock- and heat-resistant glass used in

scientific and technological applications, especially in chemistry.

The glass was invented by Otto Schott in 1884 in Jena, Germany, where he had

established Schott AG with Ernst Abbe and Carl Zeiss.[1] Jena glass is a borosilicate

which, in early manufacture, contained added aluminum, magnesium, sodium, and

zinc. It was a predecessor to other borosilicate glasses which came into wide use in

the twentieth century, such as Pyrex.

Sounds fairly tough even for that time.

From opening of NCIS New Orleans - It goes a BOOM ! BOOM ! BOOM ! MUHAHAHAHAHAHAHA !

|

|

|

Organikum

resurrected

Posts: 2337

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

Jena Glass

The Jena Glass was the standard glass in the GDR and thats why in Germany we are blessed with huge amounts of cheap glassware, Anschütz-Thiele Vacuum

Adapters go used for less then 15 €, Splash Heads 6 € and stuff most cannot identify anymore like steam distilation adapters for 3 €. Not on the

meanwhile chronically overpriced Bay of course but at classifieds ("Ebay Kleinanzeigen") - also owned by Ebay but the mostly just hold it to prevent

anybody else taking the niche.

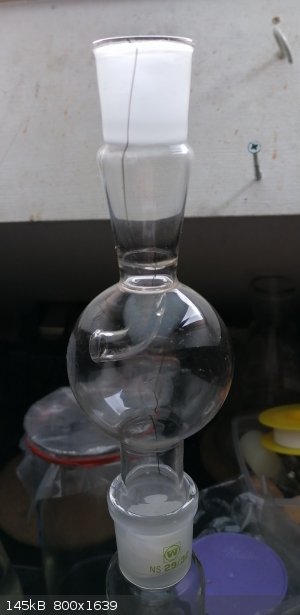

The Jena glass has usually a characteristic dark, mostly black, sometimes dark blue "thread" in the glass which is not as many believe nowadays an

imperfection but was put there on purpose as a sign of quality. Jena Glass is thinner then Pyrex or Duran, in special the grounded joints are much

more prone to break. But the thinness has the advantage of superior heat-transfer, I like it very much. Caveat is that the thermal expansion

coefficient is slightly different from Duran and it can become quite a challenge to get a vaccum tight grounded joint connection between the two. PTFE

tape, the thin kind of 0,05 mm to 0,1 mm thickness is mostly the solution.

Attached pictures of a splash-head and of a steam distillation adapter made from Jena glass with the typical "stripes".

|

|

|

VeritasC&E

Hazard to Others

Posts: 176

Registered: 29-1-2018

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by MadHatter  | Jena glass (German: Jenaer Glas) is a shock- and heat-resistant glass used in

scientific and technological applications, especially in chemistry.

The glass was invented by Otto Schott in 1884 in Jena, Germany, where he had

established Schott AG with Ernst Abbe and Carl Zeiss.[1] Jena glass is a borosilicate

which, in early manufacture, contained added aluminum, magnesium, sodium, and

zinc. It was a predecessor to other borosilicate glasses which came into wide use in

the twentieth century, such as Pyrex.

Sounds fairly tough even for that time. |

Thanks to both of you: I learned something entirely new! I had no idea there was a greater variety within the borosilicate category.

Can I correctly assume that all Schott Duran reagent bottles (not to be confused with reaction flasks), including those produced in Germany until the

early 90s, are made out of borosilicate glass of one type or another?

|

|

|

VeritasC&E

Hazard to Others

Posts: 176

Registered: 29-1-2018

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Organikum  | The Jena Glass was the standard glass in the GDR and thats why in Germany we are blessed with huge amounts of cheap glassware, Anschütz-Thiele Vacuum

Adapters go used for less then 15 €, Splash Heads 6 € and stuff most cannot identify anymore like steam distilation adapters for 3 €. Not on the

meanwhile chronically overpriced Bay of course but at classifieds ("Ebay Kleinanzeigen") - also owned by Ebay but the mostly just hold it to prevent

anybody else taking the niche.

The Jena glass has usually a characteristic dark, mostly black, sometimes dark blue "thread" in the glass which is not as many believe nowadays an

imperfection but was put there on purpose as a sign of quality. Jena Glass is thinner then Pyrex or Duran, in special the grounded joints are much

more prone to break. But the thinness has the advantage of superior heat-transfer, I like it very much. Caveat is that the thermal expansion

coefficient is slightly different from Duran and it can become quite a challenge to get a vaccum tight grounded joint connection between the two. PTFE

tape, the thin kind of 0,05 mm to 0,1 mm thickness is mostly the solution.

Attached pictures of a splash-head and of a steam distillation adapter made from Jena glass with the typical "stripes".

|

Thank you! This is all interesting and and very useful information.

I must say I has never heard of / seen an Anschütz-Thiele Vacuum Adapter before. What is the advantage compared to a simple vacuum adapter?

Do you know if Jena contains more aluminum than 3.3 Borosilicate?

I'm not sure I understand the thread part correctly, but it seems a bit odd to me at first glance. Certainly it cannot positively contribute to the

quality of the glass? Is it more of a sort of display / branding / distinction for their quality glass craftmanship?

|

|

|

Organikum

resurrected

Posts: 2337

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

Anschütz Thiele

The colored thread was a trademark and for fraud prevention as it seems to be very difficult to incorporate such a thing into the raw-material, what

is mostly tubes which were delivered to the manufacturers and glassblowers of the time. And this way the glassblower as his customers could be sure to

have gotten the real McCoy and not some cheap knockoff and there were plenty but none matched the quality of Schott for a long time, to be precise

until Corning came up with Pyrex.

The Anschütz Thiele Vorstoß might possibly be called a Perkins Triangle in bloody Albion and its colonies after the great renaming due to WWI.

Here we got the culprit:

[Edited on 28-7-2022 by Organikum]

[Edited on 28-7-2022 by Organikum]

|

|

|

VeritasC&E

Hazard to Others

Posts: 176

Registered: 29-1-2018

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Organikum  |

The Anschütz Thiele Vorstoß might possibly be called a Perkins Triangle in bloody Albion and its colonies after the great renaming due to WWI.

|

It seems like a very useful piece for many distillation (and quite indispensible for some).

There weren't any available there at a reasonable price right now but I put it on my acquisition queue list (there's many critical things I need to

get before that anyways, but I'll give it a look from time to time until destiny aligns).

The only option I have to carry an air/water sensitive distillation for the moment is to do it all at once in a completely closed system (it means for

instance that I can't collect fractions during distillation in a practical way, and if I have to dispose of a pre-fraction I have to do it in a

preliminary run). It isn't too much of problem because I simply plan ahead, but this fairly modest addition would make those distillations much more

simple and flexible.

Thank you very much for making me discover this!

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by VeritasC&E  |

Can I correctly assume that all Schott Duran reagent bottles (not to be confused with reaction flasks), including those produced in Germany until the

early 90s, are made out of borosilicate glass of one type or another? |

Great topic, I learned a lot.

I am surprised by Organicum's picture as I always understood tbat Duran is a glass made by Schott. I'm confused by Duran and Jena being both present

on the flask. Maybe it's just the place of manufacture in that case ?

Anyway, all the Schott media bottles I have are Duran glass. Unless you have extra money you should go for the simple and cheaper Boro 3.3 your

supplier certainly has. Save that money for quality caps from... Schott !

The spirit of adventure was upon me. Having nitric acid and copper, I had only to learn what the words 'act upon' meant. - Ira Remsen

|

|

|

VeritasC&E

Hazard to Others

Posts: 176

Registered: 29-1-2018

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Herr Haber  |

Great topic, I learned a lot.

I am surprised by Organicum's picture as I always understood tbat Duran is a glass made by Schott. I'm confused by Duran and Jena being both present

on the flask. Maybe it's just the place of manufacture in that case ?

|

As far as I know/understand: Schott is the manufacturer, Duran is the material, Mainz is the place of manufacture.

Could the composition of Jena or Duran glass (whichever preceded the other) have evolved over time?

For Instance: Schott Glass 2.0 may have been referred to as "Jena Glas," and Schott Glas 3.0 as "Jena Duran Glas"?

PS: I just learned that Duran is basically the brand name for Boro 3.3.

I wonder how Duran/Boro 3.3 then compared in terms of specifications (heat shock, elasticity, etc.) to what seems to have been its ancestor: Jena

Glas.

[Edited on 8-8-2022 by VeritasC&E]

|

|

|

Chemetix

Hazard to Others

Posts: 375

Registered: 23-9-2016

Location: Oztrayleeyah

Member Is Offline

Mood: Wavering between lucidity and madness

|

|

The history and evolution of the borosilicate glass industry is complex and still evolving. The one bend in the Main river near Wertheim where Schott

is situated in holds one of the worlds most concentrated areas of glass technology. Along Otto-Schott strasse is where Schott glass now called DWK

operates from. Across the road is Lenz, just down the road is Brand. Just along from Otto-Schott strasse is Ernst-Abbe Strasse where you can find

Schuller and Glaswerk Wertheim and opposite them is Witeg Labortechnik. Then nearby is Geissler Glas instrumente, Wertlab and Fraunhofer ISC in

Wurzburg. There's more I've missed but you get the picture. Within the scientific glassblowing industry there are times when you notice moulding and

manufacturing details that seem to indicate that the branding decal doesn't match what you could have sworn you saw before. It would be no surprise if

there was some crossover between the sites and some overflow production that makes it's way to other manufacturers. But the glass itself is

formulated as and sold as cullet mainly by The now called DWK. Cullet is glass tech speak for big chunks of pure glass for melting down and turning

into items. When borosilicate glass was in more demand than it is now there were other larger manufactures like TGI and Jena who produced tubing,

flasks and finished items. They more than likely started with Schott cullet.

The only other manufacturer to note in Europe is Kavalier just across the border from the Thuringia region in the Czech republic. They produce Simax

borosilicate glass. It's often noticeably different in its' glass formulation as it can give off a light blue glow at the end of the tube or the rim

of a beaker or bottle. From a glass blowers perspective the glass gets a lot less viscous when hot, probably to aid the molding of objects such as

beakers, flasks and bottles.

No doubt we'll continue to see companies be absorbed and manufacturing be passed to different sites as demand changes along with company directions.

But borosilicate glass and it's current formulation is likely to remain very consistent as it's a precisely tuned one that balances workability with

long term chemical and physical durability.

|

|

|

VeritasC&E

Hazard to Others

Posts: 176

Registered: 29-1-2018

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Chemetix  | The history and evolution of the borosilicate glass industry is complex and still evolving. The one bend in the Main river near Wertheim where Schott

is situated in holds one of the worlds most concentrated areas of glass technology. Along Otto-Schott strasse is where Schott glass now called DWK

operates from. Across the road is Lenz, just down the road is Brand. Just along from Otto-Schott strasse is Ernst-Abbe Strasse where you can find

Schuller and Glaswerk Wertheim and opposite them is Witeg Labortechnik. Then nearby is Geissler Glas instrumente, Wertlab and Fraunhofer ISC in

Wurzburg. There's more I've missed but you get the picture. Within the scientific glassblowing industry there are times when you notice moulding and

manufacturing details that seem to indicate that the branding decal doesn't match what you could have sworn you saw before. It would be no surprise if

there was some crossover between the sites and some overflow production that makes it's way to other manufacturers. But the glass itself is

formulated as and sold as cullet mainly by The now called DWK. Cullet is glass tech speak for big chunks of pure glass for melting down and turning

into items. When borosilicate glass was in more demand than it is now there were other larger manufactures like TGI and Jena who produced tubing,

flasks and finished items. They more than likely started with Schott cullet.

The only other manufacturer to note in Europe is Kavalier just across the border from the Thuringia region in the Czech republic. They produce Simax

borosilicate glass. It's often noticeably different in its' glass formulation as it can give off a light blue glow at the end of the tube or the rim

of a beaker or bottle. From a glass blowers perspective the glass gets a lot less viscous when hot, probably to aid the molding of objects such as

beakers, flasks and bottles.

No doubt we'll continue to see companies be absorbed and manufacturing be passed to different sites as demand changes along with company directions.

But borosilicate glass and it's current formulation is likely to remain very consistent as it's a precisely tuned one that balances workability with

long term chemical and physical durability. |

I'm impressed by your extensive knowledge on the topic (and by that of others here on SM).

Would you happen to know how Jena Glass (the original formulation with Magnesium inside, and maybe Zinc, and very little Aluminum), compares in terms

of the temperature differential it can handle vs the 165-180C temperature difference in the case of Boro 3.3?

|

|

|

pneumatician

Hazard to Others

Posts: 411

Registered: 27-5-2013

Location: Magonia

Member Is Offline

Mood: ■■■■■■■■■■ INRI ■■■■■■■■■■ ** Igne Natura Renovatur Integra **

|

|

in production now...

https://www.duran-bottle-system.com/

|

|

|

VeritasC&E

Hazard to Others

Posts: 176

Registered: 29-1-2018

Member Is Offline

Mood: No Mood

|

|

Wow! Super nice assortment. Were we to live in a sound society I'd definitely buy from them, but I expect they've been bought up by the rest of the

corrupt industry and sell at 10-100x profit to manufacturing cost ratio.

Good times will come again, and all these possibilities will be available to independent scientists.

|

|

|