Diachrynic

Hazard to Others

Posts: 226

Registered: 23-9-2017

Location: western spiral arm of the galaxy

Member Is Offline

Mood: zenosyne

|

|

Electrolytic reduction of pyridine to piperidine

This is a preliminary result but it worked and was in my opinion interesting enough to be shared. Pyridine can be reduced to piperidine, for example

with sodium in ethanol or with hydrogen on platinum group metal catalysts. In this experiment I followed german patent DE104664A on the

electrochemical reduction using lead electrodes in dilute sulfuric acid.

It should be noted that the patent states that iron and copper ions are detrimental to the reaction and most other electrodes do not work.

Chemicals:

Pyridine (distilled from copper chromite and niacin per DougsLab)

Sulfuric acid (food grade, ~16%, easily made from higher concentrations by dilution)

Water

Sodium hydroxide

(Ethyl acetate)

Electrodes:

Lead cathode (sheet, 10x15 cm, rolled into an approximately 5 cm diameter and 10 cm tall cylindrical electrode)

Lead anode (rod, 8 mm diameter, 20 cm long, placed centrally inside the cathode)

The lead was bought for electrochemical purposes and claims to be 99.95% pure.

Cell design:

This first experiment was performed without separation of anode and cathode compartments as the patent stated this is not required, but using a split

cell with a diaphragm is something I plan on eventually trying. The electrodes were slotted into a polypropylene food container and fit both well into

a 150 mL beaker placed inside the box. The lid of the box contains a small hole to relieve pressure. To make this temporary, the electrodes were

sealed with hot glue, but I recommend epoxy as the heat softens the glue quite a bit.

Preparation:

22 g (216 mmol) of 96% sulfuric acid was carefully diluted in 113 g of water, making up for 135 g of a 15-16% solution. To this was added 10 g (126

mmol) of pyridine. The solution was mixed, left to cool to room temperature and placed inside the beaker. The electrodes were lowered into the

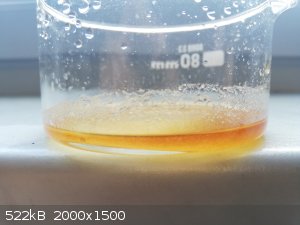

solution and 5.1 A of current were passed through it. The voltage ranged from 4 to 5 V during the reaction. Immediately changes occur to the

electrodes: The cathode goes blank and shiny while the anode turns black. Gas evolution begins as well. The solution was electrolysed for 8 hours

(theoretical 4 hours, it was planned for 6 hours, but some delay occured). The temperature rose and it was felt necessary to keep the temperature down

with an ice/water bath. The solution hovered between 20-50 °C for the electrolysis. The solution acquired a somewhat rancid smell and a brown color.

Workup:

The workup of this preparation still needs to be improved. After the solution was made basic with a solution of 25 g (625 mmol) of NaOH in 40 g of

water and 10 g of ice (this melted), one could solvent extract with ethyl acetate, then reextract with hydrochloric acid, boil the solution down and

free the piperidine with more NaOH. This would likely prevent some of the problems that were encountered during the steam distillation. The basic

solution was then distilled off. During this simple steam distillation water (> 100 mL in portions) and some more NaOH (~10 g) were added into the

flask. In total the steam distillation took 4 h and 220 mL of distillate was collected. After this time the distillate coming over was still strongly

basic to pH-paper while the residue in the flask had coagulated into a sticky brown mess. The distillate was acidified with 2.87 g (28 mmol) of 96%

sulfuric acid and boiled almost to dryness. After placing it in the freezer, a brownish syrup containing small crystals was obtained.

This was treated with 4 g (100 mmol) of NaOH dissolved in 6 g of water. This caused phase separation and the top piperidine layer was collected using

a separatory funnel.

The yield was 3.90 g (46 mmol) of brownish piperidine, which should be redistilled (due to the small amount I have postponed this for now). If pure

this would be around a 36% yield.

The residue in the distilling flask still smelled of piperidine, however extraction with ethyl acetate, reextraction into acid, evaporation to near

dryness and treatment with NaOH as before only gave 0.25 g of very discolored piperidine and thus it was discarded. The extended heating seemed to

cause a lot of impurities to form - if the piperidine is extracted without being excessively heated with base before I suspect a cleaner product will

be obtained in less time.

Chemical tests:

The presence of piperidine in the mother liquor, the steam distillate and the final product can be detected using Reinecke's salt

NH4[Cr(SCN)4(NH3)2], which can be prepared fairly easily and which is a rewarding inorganic preparation in

its own right.

The sample is brought into an excess of ammonia solution (the mother liquor was partially neutralized with NaOH first). To this, a solution of

reineckes salt in dilute ammonia is added. Piperidine produces a precipitate which depending on the color of the solution may range from light purple

to beige. Pyridine produces no precipitate under these conditions.

This test is positive for mother liquor (pic 1), steam distillate (pic 2) and final product, and negative for the starting material (pic 3).

Discussion:

For a first test with many flaws it worked quite well. The brown discoloration can be avoided by using a split cell, according to the patent. Sulfuric

acid may be replaced with hydrochloric acid. I have not tried this.

Extraction might be a better method for recovering product. The product should be redistilled. I think I electrolyzed for too long as well.

The patent states that traces of copper and iron ions are detrimental to the reaction and therefore care should be taken to exclude these metals or

their ions.

Overall I think this is a promising way, despite the low yield on this first run, to produce piperidine from pyridine without the use of pressurized

hydrogen, precious metals or large amounts of sodium.

Sources:

German patent DE104664A

Attachment: DE000000104664A_all_pages.pdf (269kB)

This file has been downloaded 290 times

L. Kum-Tatt, Quantitative Separation of Nitrogenous Organic Bases using Ammonium Reineckate. Nature 1958, 182, 655–656.

https://doi.org/10.1038/182655a0

Attachment: kum-tatt1958.pdf (188kB)

This file has been downloaded 273 times

https://www.youtube.com/watch?v=FNsqYwzm40M (Doug's Lab video on pyridine from niacin)

[Edited on 21-6-2022 by Diachrynic]

we apologize for the inconvenience

|

|

|

DocX

Hazard to Others

Posts: 179

Registered: 22-10-2015

Member Is Offline

Mood: No Mood

|

|

Great stuff! If you work out how to get better yield and possibly using larger volumes this looks like prepublication material.

[Edited on 20222222/6/21 by DocX]

|

|

|

Triflic Acid

Hazard to Others

Posts: 486

Registered: 27-9-2020

Member Is Offline

Mood: Slowly Oxidizing into Oblivion

|

|

Super interesting. I've always wanted to try electrochemical reductions for organics, rather than have to go for conventional metal reductants, but I

never had the resources. Have you tried using other pyridine derivatives like niacin directly? If the conditions are right, I would hope that you

might be able to decarboxylate in the acidic solution with enough heat and get a one-pot synthesis of piperidine. You should move this thread to the

pre-pub section, since its basically a full prep of a very useful reagent.

There wasn't a fire, we just had an uncontrolled rapid oxidation event at the power plant.

|

|

|

Diachrynic

Hazard to Others

Posts: 226

Registered: 23-9-2017

Location: western spiral arm of the galaxy

Member Is Offline

Mood: zenosyne

|

|

Thanks DocX and Triflic Acid!

Quote: Originally posted by Triflic Acid  | | Have you tried using other pyridine derivatives like niacin directly? If the conditions are right, I would hope that you might be able to

decarboxylate in the acidic solution with enough heat and get a one-pot synthesis of piperidine. |

This sounds interesting, but I am somewhat worried that a Kolbe-electrolysis might occur, producing a 3,3'-bipyridine or 3,3'-bipiperidyl... In a

split cell potentially, since this happens at the anode, while the reduction occurs on the cathode?

It could also just not decarboxylate at all, forming nipecotic acid. I'm not sure if that can decarboxylate easier. This paper describes its decarboxylation in the gas phase, but I guess that is not really relevant here.

From decarboxylating niacin I got the impression it does not readily decarboxylate, however. The yield of pyridine with copper chromite is good

(around 80% for me) so the extra step isn't that bad.

Regarding prepublication, I felt it wasn't quite polished enough for it yet. I might try using a split electrolysis cell, more careful reaction

control and better workup for a re-run. But I wanted to get it written up because I don't know when I will get to it and it might still be useful in

this form.

[EDIT]

Another improvement to be done is to actually test when the reaction goes to completion. I looked into photometric methods for pyridine, but most use

bromo- or chlorocyanogen. The precipitation of the light green copper-pyridine-thiocyanate complex (with the formula

[Cu(py)2](SCN)2 or [Cu(SCN)2(py)2] or Cu(py)2(NCS)2 depending on the source) seems

interesting however. Next time I will test if this is a viable method to check for the completion of the reaction.

I have attached some literature.

G. Spacu, H. Grossmann, R. Ripan et al., Fresenius, Zeitschrift f. anal. Chemie 1924, 64, 330–342, 10.1007/BF01358204

Attachment: pyridine_copper_thiocyanate_german_10.1007_BF01358204.pdf (820kB)

This file has been downloaded 240 times

M. Kabešová, J. Kohout, J. Gažo, Monatshefte für Chemie 1976, 107, 641–651, 10.1007/BF00906770

Attachment: pyridine_copper_thiocyanate_10.1007_BF00906770.pdf (618kB)

This file has been downloaded 247 times

J. Soldánová, M. Kabešová, J. Gažo, Inorganica Chimica Acta 1983, 76, L203–L204, 10.1016/s0020-1693(00)81507-8

Attachment: pyridine_copper_thiocyanate_10.1016_S0020-16930081507-8.pdf (158kB)

This file has been downloaded 214 times

F. D. Snell, C. T. Snell, Colorimetric Methods of Analysis, Third Edition, Volume IV, 1954, p. 243-246

Attachment: ColorimetricMethodsOfAnalysis_PyridinePiperidine.pdf (383kB)

This file has been downloaded 225 times

E. H. Pietsch et al, Gmelins Handbuch der anorganischen Chemie, Kupfer Teil B Lieferung 4, 8th Edition, 1966, p. 1510-1514

Attachment: CopperPyridineThiocyanate_Gmelin_german.pdf (803kB)

This file has been downloaded 237 times

[Edited on 22-6-2022 by Diachrynic]

we apologize for the inconvenience

|

|

|

Hexabromobenzene

Hazard to Others

Posts: 122

Registered: 27-4-2021

Member Is Offline

|

|

You got a low yield probably due to the lack of a diaphragm in the electrolyte. The cathode can be immersed in a perforated polypropylene tube with a

wound separator from a lithium-ion battery

Electrosynthesis requires an excess of electricity to flow to completion. I usually take

2x

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

Use of lead electrodes instead of something more exotic makes this quite accessible.

Please do write this up for prepub. It is lovely work.

|

|

|

PirateDocBrown

National Hazard

Posts: 570

Registered: 27-11-2016

Location: Minnesota

Member Is Offline

Mood: No Mood

|

|

I've had good results using a terra-cotta pot a a diaphragm for electrolysis. They can be had as small as 50mm in diameter. Just fill the bottom hole

with some silicone sealant, or epoxy.

Phlogiston manufacturer/supplier.

For all your phlogiston needs.

|

|

|

Diachrynic

Hazard to Others

Posts: 226

Registered: 23-9-2017

Location: western spiral arm of the galaxy

Member Is Offline

Mood: zenosyne

|

|

Thanks j_sum!

This is probably true. The patent states that the solution will be colorless in that case, but also states that "It does not matter for the production

of piperidine". Clearly the brown color and smell is indicating some decomposition however, so I imagine the yield is probably higher.

This might be an issue, since the clay probably leaches some of its iron content into the acidic solution, which according to the source is

detrimental to the reaction. But I haven't had experience with it, so maybe it would be fine.

A membrane made from cloth treated with dechlorinated PVC-cement seems like a good option to me.

we apologize for the inconvenience

|

|

|

Hexabromobenzene

Hazard to Others

Posts: 122

Registered: 27-4-2021

Member Is Offline

|

|

Pyridine can dissolve PVC. Use separator from li-ion spent battery from polypropylene. Its very OTC

|

|

|

kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

I like this experiment.

However, it is hard to say that "The yield was 3.90 g (46 mmol) of brownish piperidine". There is no proof of its purity or anything like this. ~4 g

of something ammonia-like means nothing, unfortunately. It would be easy to prepare hydrochloride of this "piperidine" and make at least some

determination of its melting point. Literature values found: 238-240 C and 245-248 C, from different sources.

It seems that in your experiment, too little of H2SO4 is used, it should be at least 3 moles of H2SO4 per 1 mole of pyridine.

Absence of any larger amounts of Cu, Fe, Ni... etc in solution will cause no reduction of pyridine. It is obvious, becuse these metals will destroy

high hydrogen overpotential on Pb cathode .

The experiment is worth trying, with separation of anolyte and catholyte, at least partial (membrane or salt bridge filled with conc. Na2SO4,

"immobilized" on PP wool, etc)

In attachment, English version of mentioned earlier patent.

Attachment: US680543A.pdf (135kB)

This file has been downloaded 249 times

[Edited on 24-6-2022 by kmno4]

Слава Україні !

Героям слава !

|

|

|

monolithic

Hazard to Others

Posts: 436

Registered: 5-3-2018

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by PirateDocBrown  | | I've had good results using a terra-cotta pot a a diaphragm for electrolysis. They can be had as small as 50mm in diameter. Just fill the bottom hole

with some silicone sealant, or epoxy. |

Does this work well with a concentrated acid electrolyte? I tried plugging the hole with plumber's putty (read it somewhere on here) which failed

within a few hours.

|

|

|

Diachrynic

Hazard to Others

Posts: 226

Registered: 23-9-2017

Location: western spiral arm of the galaxy

Member Is Offline

Mood: zenosyne

|

|

Can it still in dilute, highly acidic solution? It will be pyridinium sulfate after all.

Thanks kmno4 for the added information, quite useful. I agree that the characterization, apart from forming the reineckate, was lacking. I decided to

postpone the purification by distillation for when I retry.

I looked into TLC and it might be possible to separate pyridine and piperidine that way, as another purity check. Potentially even as their

reineckates.

Melting point of a salt is also a good idea.

I tried the analytical test for pyridine on my starting material and confirmed that it is a very nice method for detecting pyridine.

Here I used a 10 mM copper solution, 2 eq. of thiocyanate and 2 eq. of pyridine. It's a lovely, rich, dark green, flocculent precipitate. For fun I

also recrystallized from hot water after filtration and took some microscope pictures. Enjoy:

we apologize for the inconvenience

|

|

|

Corrosive Joeseph

National Hazard

Posts: 915

Registered: 17-5-2015

Location: The Other Place

Member Is Offline

Mood: Cyclic

|

|

Cool experiment...... Where did you acquire your lead electrodes.

Would you bee so kind as to link me to your lead source please.....?

Quote: Originally posted by Diachrynic  |

Electrodes:

Lead cathode (sheet, 10x15 cm, rolled into an approximately 5 cm diameter and 10 cm tall cylindrical electrode)

Lead anode (rod, 8 mm diameter, 20 cm long, placed centrally inside the cathode)

The lead was bought for electrochemical purposes and claims to be 99.95% pure.

|

/CJ

Being well adjusted to a sick society is no measure of one's mental health

|

|

|

Diachrynic

Hazard to Others

Posts: 226

Registered: 23-9-2017

Location: western spiral arm of the galaxy

Member Is Offline

Mood: zenosyne

|

|

Sure, I got them from polymet. They also sell on ebay.

[Edited on 28-6-2022 by Diachrynic]

we apologize for the inconvenience

|

|

|