| Pages:

1

2 |

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

First o-toluidine synthesis - running into some issues with the reaction mixture

I'm in the middle of my first o-toluidine synthesis at the moment, using the protocol on the Altered Chemistry o-toluidine synthesis video.

I'm working on the same scale detailed in that video:

134mL of ±30% HCl (instead of 110mL of 36% conc)

26mL of o-Nitrotoluene

49g of granulated tin

90g of NaOH (in 150mL of DI water)

But I'm running into a problem while adding the concentrated NaOH solution (90g in 150mL of water). I've hardly added any of it, and it's pretty god

damn thick. My stirbar just gets gunked up very quickly, and I have to pick it up and swirl it around manually, which doesn't do anywhere near as good

of a job.

Since the next step is a steam distillation, I've added some extra water, but that doesn't help too much. Also, This is my largest flask (500mL) and

in the YT video referenced above (at the 4:04 mark) you can see that the contents of their reaction flask isn't all that thick, and it's nowhere as full as mine is already (and I still

have like ±120 mL of the NaOH solution to go).

The only 2 things I did differently is:

- I had a more diluted HCl, which I should have titrated, but I didn't (just assumed it was 30%, which is what I found online for the HCl I use). I had to add a little extra since the tin wasn't fully used up, but I just figured it was weaker than I thought (only had to add

about 10mL extra). But I would think that this would mean more water has been added overall, and the solution would be less thick, not more.

- I had to pause the addition of the HCl to the tin/NT mixture and resume it the next morning. Most of it was added though, and it seemed to pick

back up nicely the next morning when I finished adding the rest.

Here are some pictures: https://imgur.com/a/PvVpn63

Before I started adding the NaOH, I tested the reaction mixture by dropping a few drops of it into some DI, and no clouds or oily substance detected.

I can also not smell any more of the polish like NT aroma, and only horse shit. So I'm sure that step was completed.

I can kinda get it stirring again by adding a bit of water, but then right when I add just 1 or 2 mL of the NaOH solution, it immediately fucks with

the stirring.

Is this normal? I don't think it is. If anyone has any idea as to what I did wrong or what I can do to fix it, that would be awesome. Thank you.

P.S. It was suggested to let the reaction flask cool down after all the HCl was added and refluxed for 30 minutes, which I did. It's

now at around 40 °C, should I have it heated up? Would that help? (Trying it now, but not sure if that's was done in the protocol outlined in the

video).

[Edited on 14-3-2021 by SuperOxide]

|

|

|

Benignium

Hazard to Others

Posts: 115

Registered: 12-6-2020

Member Is Offline

Mood: Quasi-catatonic

|

|

Seems reasonable on paper. Add all of the NaOH solution, swirl it around manually, heat to boiling and see if you need to add more water.

If you cannot stir, see if you can't carry on with the steam distillation anyway.

|

|

|

RustyShackleford

Hazard to Others

Posts: 200

Registered: 10-12-2020

Location: Northern Europe

Member Is Offline

|

|

You need to add an excess of hydroxide to redissolve the tin hydroxide. It initially turns very thick and goopy but after you stir more in it becomes

quite fluid. I recently did this with zinc, which also redissolves in excess base, after adding all of the hydroxide it was thin enough of a fluid to

solvent extract from.

|

|

|

zed

International Hazard

Posts: 2284

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

Flask volumes are not entirely predictable. Your instruction video is in a 3-neck flask, which may indeed have an actual capacity of more than 500

ML.

Your flask on the other-hand, has a flat-bottom, a configuration I personally like. So much easier to work with. Sits flat on a hot plate, and you

can just set in down anywhere. Not quite as strong to vacuum as a round bottom, and more expensive.

What we used to call a Florence Flask. Quite possibly, it has an actual capacity of less than 500 ML. Other things being equal, that flat bottom may

have reduced the flask's holding capacity somewhat.

In the instruction video, that flask is getting pretty full. Then there is a cut-away. Showing the product in a large beaker, with solidified stuff

on top.

Finally, the product is transferred to a much larger flask, for steam distillation. So, if 500 ML is your biggest flask, You either need to acquire a

bigger flask somehow, or make two distillation runs.

Otherwise, everything looks OK to me. Your stuff has gotten pretty thick. Not entirely predictable. Maintaining higher temperature during reaction,

might or might not have helped. A coarser PPT, might actually be easier to stir.

I assume you don't have the capacity for over-head stirring. So you are dealing, with a thick colloidal glop, in a highly caustic solution, admixed

with a fairly poisonous product. And, your flask is too small.

Ahhh...Sweet memories!

You are going to succeed. Transfer some of your stuff to a smaller flask to finish the neutralization. Try to keep that concentrated NaOH out of

those ground glass joints, it can screw them up. Put a 1000 ML flask on your shopping list.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by Benignium  | Seems reasonable on paper. Add all of the NaOH solution, swirl it around manually, heat to boiling and see if you need to add more water.

If you cannot stir, see if you can't carry on with the steam distillation anyway. |

I chugged on ahead after

reading these posts, it's definitely easy to stir now, so I did just have to keep adding the NaOH though.

Quote: Originally posted by RustyShackleford  | | You need to add an excess of hydroxide to redissolve the tin hydroxide. It initially turns very thick and goopy but after you stir more in it becomes

quite fluid. I recently did this with zinc, which also redissolves in excess base, after adding all of the hydroxide it was thin enough of a fluid to

solvent extract from. |

Thanks! After reading that I went ahead and added more of the NaOH to get the tin hydroxide back into solution. I did however make a mistake in not

keeping track of the NaOH. I had 90g in the 150mL solution, but when I added extra water to the flask, I was running out of room so I added extra NaOH

to the solution to dissolve the Sn(OH)₂, and in my flustered state of mind I didn't weigh out the extra NaOH.

Is there any harm in adding too much NaOH? It doesn't seem to me like there would be, but I figured I'd ask.

Quote: Originally posted by zed  | Flask volumes are not entirely predictable. Your instruction video is in a 3-neck flask, which may indeed have an actual capacity of more than 500

ML.

Your flask on the other-hand, has a flat-bottom, a configuration I personally like. So much easier to work with. Sits flat on a hot plate, and you

can just set in down anywhere. Not quite as strong to vacuum as a round bottom, and more expensive.

What we used to call a Florence Flask. Quite possibly, it has an actual capacity of less than 500 ML. Other things being equal, that flat bottom may

have reduced the flask's holding capacity somewhat.

In the instruction video, that flask is getting pretty full. Then there is a cut-away. Showing the product in a large beaker, with solidified stuff

on top. |

This had occurred to me as well. I have a real 500mL RBB, then the one with the flat bottom you see

in those photos. I noticed one time when I was pouring solution from one into the other that there was a bit of a difference in the real volume. The

flat bottom Laboy flask is definitely not really 500mL (less, certainly).

Quote: Originally posted by zed  | Finally, the product is transferred to a much larger flask, for steam distillation. So, if 500 ML is your biggest flask, You either need to acquire a

bigger flask somehow, or make two distillation runs.

Otherwise, everything looks OK to me. Your stuff has gotten pretty thick. Not entirely predictable. Maintaining higher temperature during reaction,

might or might not have helped. A coarser PPT, might actually be easier to stir. |

Two distillation runs is

what I had planned after seeing how full this flask got. The Laboy flask is literally filled to the neck (I've never filled one that full before... Go

easy on me). So I was going to split the contents up into two runs (maybe even 3 so I can have extra room for extra water in the steam distillation).

Quote: Originally posted by zed  | I assume you don't have the capacity for over-head stirring. So you are dealing, with a thick colloidal glop, in a highly caustic solution, admixed

with a fairly poisonous product. And, your flask is too small.

Ahhh...Sweet memories!

You are going to succeed. Transfer some of your stuff to a smaller flask to finish the neutralization. Try to keep that concentrated NaOH out of

those ground glass joints, it can screw them up. Put a 1000 ML flask on your shopping list. |

Yeah, this reaction mix is definitely one of the more hazardous I've handled, that certainly isn't lost on me.

I have screwed up two ground glass joints using NaOH (both at the same time, ironically), so I use some teflon grease if I deal with concentrated NaOH

mixes now.

I've had a 1000mL flask on my to-buy list, but I'm not certain that my hotplate would be ideal for heating it (shitty Chinesium one), but I plan on

buying a better hotplate as well.

Update: Here are a few photos of the reaction mix as it is right now. Obviously the flask is way... wayyy too full, that's a bit embarrassing (I promise

this is the first I've ever filled one this full, lol). I'm going to split it up and continue on. The color is a bit different than what I expected,

much darker. Is that an indication that I haven't added enough NaOH? As detailed above I foolishly lost track of the amount of NaOH added, am I just

looking for a caustic pH?

Thanks for all the replies! Much appreciated. I guess the reaction was actually working out ok, I should have continued adding the NaOH and not have

added so much water. That really mixed things up.

Update 2: I turned off stirring and glad wrapped the top for now. You can see in these photos that it settled into two layers. I clearly added way too much water, lol.

It certainly is darker than I expected though. Not sure what to think about that (again, maybe not enough NaOH added? Maybe too much?)

[Edited on 14-3-2021 by SuperOxide]

|

|

|

zed

International Hazard

Posts: 2284

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

Um. You are going to steam distill it. Most of the brown gunk will be non volatile. So, that should clean things up nicely. Eventually, when your

product has been sufficiently purified, put it in the smallest possible brown glass bottle. If you have inert gas, flush things out before screwing

the cap down. Keep your Aniline/Toluidine in a cool dark place.

Clean fresh Anilines can go brown pretty quickly in storage, if you don't take precautions.

|

|

|

clearly_not_atara

International Hazard

Posts: 2799

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Idle speculation, but I think the secret to this synthesis is to use a different alkali. In particular, milk of magnesia (Mg(OH)2)

seems interesting. It should precipitate SnO2, but it won't form stannates -- or at least they'll be crystalline rather than polymeric. Mg(OH)2 in

equilibrium with water should also be basic enough to deprotonate an aniline.

Redissolving Sn(OH)6 with excess alkali works too, of course, but it would be nice to avoid gunk altogether.

[Edited on 14-3-2021 by clearly_not_atara]

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by zed  | | Um. You are going to steam distill it. Most of the brown gunk will be non volatile. So, that should clean things up nicely.

|

How about the amount of NaOH? Is there a downside to adding too much? I lost track of how much I added, so

I'm not sure if I should add more or not. Is there a pH I should try to reach? (close to 14?)

Quote: Originally posted by zed  | Eventually, when your product has been sufficiently purified, put it in the smallest possible brown glass bottle. If you have inert gas, flush things

out before screwing the cap down. Keep your Aniline/Toluidine in a cool dark place.

Clean fresh Anilines can go brown pretty quickly in storage, if you don't take precautions. |

For sure. I have some of those silly nitrogen cans that are used to keep opened bottles of wine fresh, so I can add some nitrogen. And I definitely

plan on keeping it in an amber bottle as well.

I can't get to the steam distillation today, I may end up doing that next weekend. I sealed the flask and put it in a container to keep the light out

until I can steam distill it.

Quote: Originally posted by clearly_not_atara  | Idle speculation, but I think the secret to this synthesis is to use a different alkali. In particular, milk of magnesia (Mg(OH)2)

seems interesting. It should precipitate SnO2, but it won't form stannates -- or at least they'll be crystalline rather than polymeric. Mg(OH)2 in

equilibrium with water should also be basic enough to deprotonate an aniline.

Redissolving Sn(OH)6 with excess alkali works too, of course, but it would be nice to avoid gunk altogether. |

Thats interesting. You plan on testing this out?

I didn't realize that tin was kinda expensive until I got the tin for this reaction (I know that I could have used iron too, but that seemed like a

mess). I may try to get the tin back out of this reaction once I have the toluidine.

[Edited on 14-3-2021 by SuperOxide]

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

This advice is too late, but why did you use Sn instead of Fe? Better yield / purer product / easier workup? IIRC when using Fe the amount of HCl

could be decreased as it is there only as a catalyst.

Oh I found the answer, in small lab scale the Sn method is better. For Fe you need very fine Fe dust:

https://www.prepchem.com/synthesis-of-aniline/

| Quote: | The reduction of nitrobenzene, as well as other aromatic nitro derivatives, is carried out on the large-scale by the use of iron borings. This cannot

be satisfactorily imitated in the laboratory; consequently it is usual to reduce nitrobenzene on the small-scale by means of tin and hydrochloric

acid. If, however, very finely divided iron or “iron powder ” is used, the reduction proceeds very smoothly, and a good yield is easily obtained.

120 g of iron, powder together with 160 ml water are placed in a large flask of 2-3 liters capacity with stirring. The flask is warmed slightly, and a

few drops of nitrobenzene added. Then 10 g of hydrochloric acid is poured into the flask, and the 100 g of the nitrobenzene in small portions at a

time. During addition the flask is well stirred and cooled with cold water. The addition of nitrobenzene and amount of cooling are so arranged that

the temperature keeps at about 80-90° C. When the reaction is finished (shown by no further rise in temperature), the contents of the flask are

distilled with steam (it is not necessary to make the mixture alkaline) till the distillate is no longer milky. The volume of the distillate is about

400-500 ml. The distillate is transferred to a separating funnel, allowed to settle (if necessary), and the aniline, which forms the lower layer,

drawn off. The water (which contains about 3 % of aniline in solution) is saturated with sodium chloride and allowed to stand for some time. The

aniline, which rises to the top, is separated with a separating funnel, added to the first portion of crude aniline. The aniline is purified by

distillation, were a little water passes over at first and is separately collected; the aniline then passes over at 182° C yielding 50-70 g of

aniline. Aniline is colorless oil with a peculiar smell, boils at 184° C. |

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by Fery  | This advice is too late, but why did you use Sn instead of Fe? Better yield / purer product / easier workup? IIRC when using Fe the amount of HCl

could be decreased as it is there only as a catalyst.

Oh I found the answer, in small lab scale the Sn method is better. For Fe you need very fine Fe dust:

https://www.prepchem.com/synthesis-of-aniline/

| Quote: | The reduction of nitrobenzene, as well as other aromatic nitro derivatives, is carried out on the large-scale by the use of iron borings. This cannot

be satisfactorily imitated in the laboratory; consequently it is usual to reduce nitrobenzene on the small-scale by means of tin and hydrochloric

acid. If, however, very finely divided iron or “iron powder ” is used, the reduction proceeds very smoothly, and a good yield is easily obtained.

120 g of iron, powder together with 160 ml water are placed in a large flask of 2-3 liters capacity with stirring. The flask is warmed slightly, and a

few drops of nitrobenzene added. Then 10 g of hydrochloric acid is poured into the flask, and the 100 g of the nitrobenzene in small portions at a

time. During addition the flask is well stirred and cooled with cold water. The addition of nitrobenzene and amount of cooling are so arranged that

the temperature keeps at about 80-90° C. When the reaction is finished (shown by no further rise in temperature), the contents of the flask

are distilled with steam (it is not necessary to make the mixture alkaline) till the distillate is no longer milky. The volume of the

distillate is about 400-500 ml. The distillate is transferred to a separating funnel, allowed to settle (if necessary), and the aniline, which forms

the lower layer, drawn off. The water (which contains about 3 % of aniline in solution) is saturated with sodium chloride and allowed to stand for

some time. The aniline, which rises to the top, is separated with a separating funnel, added to the first portion of crude aniline. The aniline is

purified by distillation, were a little water passes over at first and is separately collected; the aniline then passes over at 182° C yielding

50-70 g of aniline. Aniline is colorless oil with a peculiar smell, boils at 184° C. |

|

However the part you quoted does reference something I'm trying to figure out (which I put in bold in the quoted section above). I mentioned above

that I lost track of how much NaOH I've added to the reaction mixture, so trying to see if I should just continue adding NaOH until it hits neutral

(which it may have already, but I didn't check yet, ran out of time and will pick it back up maybe on Friday or Sat), or if I should make it alkaline

or not. Or does it not even matter?

I was hoping to get all the tin back if possible, so maybe I should make it all alkaline first? Need to do some research on that.

[Edited on 15-3-2021 by SuperOxide]

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

it needs to be at least slightly alkaline

you cannot distill toluidine hydrochloride, you need free base, then you can steam distill it

the Fe reduction I posted has a disadvantage that it is hard to use magnetic stirrer when there is a lot of Fe dust in flask, maybe shaking/swirling

using hand (of course overhead stirrer would be the best but only very few SM forumers owe it)...

the method using Fe uses only very little of HCl (10 g HCl for 120 g Fe) which reacts with Fe to FeCl2 so there is no excess of HCl to bind the

aniline and you can directly distill it out... IIRC the Fe2+ is oxidized to Fe3+ by nitrogroup while reducing nitro to amine and then Fe3+ hydrolyzes

to Fe(OH3) and releases HCl so HCl is recycling as a catalyst and 10 g HCl is enough

The reaction is C6H5NO2 + 2 Fe + 4 H2O -> C6H5NH2 + 2 Fe(OH)3

Your reaction is 2 C6H5NO2 + 3 Sn + 12 HCl -> 2 C6H5NH2 + 3 SnCl4 + 4 H2O

in case using Sn you need a lot of HCl and when neutralizing by NaOH, the hydroxide is probably first consumed for SnCl4 decomposition and only then

the amine is freed from hydrochloride salt and could be steam distilled out

you can find experiments with alternative routes of reduction of aromatic NO2 to NH2 here, although it concerns luminol synthesis from

nitrophtalhydrazide:

http://www.sciencemadness.org/talk/viewthread.php?tid=155164

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

BTW not all nitroaromatics are the same.

PS the pH and amount of NaOH to add does not need to be measured.

Stirring is not a requirement for the Sn or Fe reductions at any point. If done in a certain way. Details are naturally in my scans if anyone is

interested in takeoff and landing instead of crashing into buildings.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Not at all? Is there an endpoint I can

look for? I was expecting it to turn a bit lighter.

Quote: Originally posted by S.C. Wack  | | Details are naturally in my scans if anyone is interested in takeoff and landing instead of crashing into buildings. |

Jeez, not sure I'd call this a "crash into a building", more of a "premature hesitation in anticipation of crashing into a building"

perhaps.

And by scans I assume you mean the files on your Mediafire? Just saw it now, lots of great content! Thanks for that.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

It's been mentioned a couple times!

Yes well you're probably not Saudi either. That was aimed generally at not just members but also the unseen lurkers.

|

|

|

Benignium

Hazard to Others

Posts: 115

Registered: 12-6-2020

Member Is Offline

Mood: Quasi-catatonic

|

|

Somewhat unrelated, but I was left with a few grams of toluidine after the methaqualone preparation, and didn't have the heart to toss it. So, I

neutralized it with hydrochloric acid and it's been sitting around ever since waiting to get cleaned up. Today I decided to finally process it.

The nearly black acidic aqueous solution was first washed with two portions of toluene and filtered. The solution was made strongly basic and steam

distilled directly into dilute hydrochloric acid. The resulting clear solution was stripped of water using azeotropic distillation with toluene. The

resulting slurry was filtered and the solids dried.

I was left with 3.30 grams of off-white, almost cream colored crystalline powder. Some of the toluidine degraded toward the end of the steam

distillation because I initially had too little acid in the receiving flask. Discoloration happens very quickly in the presence of oxygen.

Discolored hydrochloride solution under toluene

Hydrochloride salt air drying. Doesn't seem at all hygroscopic.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by Benignium  | Somewhat unrelated, but I was left with a few grams of toluidine after the methaqualone preparation, and didn't have the heart to toss it. So, I

neutralized it with hydrochloric acid and it's been sitting around ever since waiting to get cleaned up. Today I decided to finally process it.

The nearly black acidic aqueous solution was first washed with two portions of toluene and filtered. The solution was made strongly basic and steam

distilled directly into dilute hydrochloric acid. The resulting clear solution was stripped of water using azeotropic distillation with toluene. The

resulting slurry was filtered and the solids dried.

I was left with 3.30 grams of off-white, almost cream colored crystalline powder. Some of the toluidine degraded toward the end of the steam

distillation because I initially had too little acid in the receiving flask. Discoloration happens very quickly in the presence of oxygen.

Discolored hydrochloride solution under toluene

Hydrochloride salt air drying. Doesn't seem at all hygroscopic.

|

Badass! Not completely unrelated, I planned on converting some (or all, not sure) of it to the HCl salt. I know that if I store it in an amber bottle

with N2 over it that it should last for a while, but I'm not sure when I will use it or what I will use it for, so I may store some of it this way.

|

|

|

Texium

|

Thread Split

16-3-2021 at 09:25 |

zed

International Hazard

Posts: 2284

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

Seems to me, someone reported successful Iron reductions, via magnetic stirring. By utilizing little spheres of steel wool, as the Iron source. I

haven't tried it, but it sounds good.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

FYI - finally got this synth/workup finished (mostly).

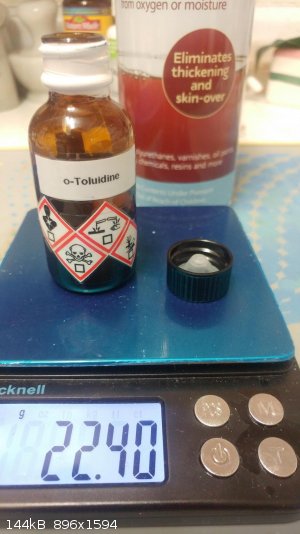

Here's the result:

Stored in a small glass amber bottle under nitrogen:

The yield was 22.40g, which seems a little too good to be true since it's a higher yield than Chemplayer got, and I think the theoretical yield is

23.44g. The only thing I can think it may be is DCM left in there. I separated out the DCM until the distillation rate stopped and the water bath got

to ~95 °C, so I can't see how any DCM could have stuck around.

Regardless, I'll probably run a vacuum distillation just to be sure (which I planned to do anyways).

Things I could have improved on:

Done a little more research, I should have known that it would have gotten that thick, and I should have just pressed onwards.

Kept track of the NaOH that was being added (since I added water to be able to stir it, then since I was running out of room in the flask I

added an overly concentrated NaOH solution, silly).

Keep track of how much DCM I used so I could weigh the DCM I get back out via distillation to be sure there's none left in there.

Thanks everyone for the replies. Definitely helped out! Much appreciated, as always.

P.S. I did keep everything that was left in the reaction flask after the reduction. I stopped running the steam distillation because the distillate

had been clear for some time, and it was kinda foaming a bit. When I let it cool down I looks like two different layers of solid settled out with a

yellow solution. I'll process this to get the tin out sometime.

[Edited on 25-3-2021 by SuperOxide]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Quote: Originally posted by zed  | | Seems to me, someone reported successful Iron reductions, via magnetic stirring. By utilizing little spheres of steel wool, as the Iron source. I

haven't tried it, but it sounds good. |

It would have to be a big stirrer because all the Fe is going to stick to the ends and sand a nice frosty o in the middle of the bottom of the glass.

Zinc powder stirs OK but I think there are reasons why it isn't used much in acid; not in the workup.

BTW I've seen preparations where the tin hydroxide or whatever is not dissolved, precipitated from NH4OH or not, but I think the way it's usually

written is simply the best plan.

|

|

|

Benignium

Hazard to Others

Posts: 115

Registered: 12-6-2020

Member Is Offline

Mood: Quasi-catatonic

|

|

Awesome! There is indeed going to be some DCM as there was no chaser solvent in the vessel. Another good way of getting rid of most of it would be to

heat above 40 deg. C and then displacing the gaseous DCM with nitrogen.

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by Benignium  | | Awesome! There is indeed going to be some DCM as there was no chaser solvent in the vessel. Another good way of getting rid of most of it would be to

heat above 40 deg. C and then displacing the gaseous DCM with nitrogen. |

I figured. I did get the flask up to at least 95 °C (maybe even higher). The water bath was almost starting to boil. This gave me the false

impression that there's no way any DCM could still be in the flask, but clearly I was wrong.

DCM boils at 39.6 °C, and when I was doing the distillation, the temperature in the head kinda maintained that temperature, but the distillation rate

had tapered off to pretty much nil. Usually I wait for the temp in the head to drop a bit before I conclude that it's all gone, but since the

distillation rate had stopped, I called it quits. Perhaps there was that last little bit that couldn't get over.

No biggie though, I planned on processing it a little further. I'm doing one more run right now, then I think I will combine the two yields and

attempt a vacuum distillation.

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

I found helpful video here:

https://www.youtube.com/watch?v=FIUgBfWkx7I

|

|

|

SuperOxide

Hazard to Others

Posts: 487

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Yep, I actually have seen that one, but should have reviewed it again before I ran this synth. It also doesn't mention how heavily it gunks up (though

it does say bring it to alkaline pH, which I definitely overshot).

I re-ran this synthesis and everything went just fine! It gunked up like before, but I just kept swirling the flask around manually and adding the

NaOH solution, it eventually was able to stir again, as expected.

Thanks for the reply!

P.S. I also should have remembered that NileRed mentioned this in his Aniline video, which the synthesis is pretty much the same for toluidine. That would have helped (but I should have just researched it further

than YT videos, which I have done since).

[Edited on 1-4-2021 by SuperOxide]

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

see this, in the reduction of aromatic -NO2 to -NH2 using Fe+HCl the HCl seems to be there only as a catalyst which activates Fe

https://sci-hub.st/10.1021/ja01238a049

https://sci-hub.st/10.1002/adsc.200404236

Attachment: hazlet1944.pdf (257kB)

This file has been downloaded 289 times

Attachment: liu2005.pdf (64kB)

This file has been downloaded 326 times

|

|

|

Amos

International Hazard

Posts: 1406

Registered: 25-3-2014

Location: Yes

Member Is Offline

Mood: No

|

|

Just now saw your most recent posts, SuperOxide, congrats on a job well-done. There is almost certainly excess DCM in your o-toluidine but I feel as

though in many reactions it will simply spectate.

In the past I have steam-distilled it out of the flask and directly onto a pile of sodium chloride, which gives usually results in an apricot-colored

upper layer and totally clear brine layer underneath. My DCM is precious to me, and this method also has the advantage of not requiring a second

distillation where unwanted mechanical losses and coloring of the product can occur. But as I said before, nice job on a good-looking product and

respectable yield.

|

|

|

| Pages:

1

2 |