Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Joining metal vessels to ground glass?

Only reasonable joint I could come up with is an adapter turned from PTFE having a tapered inner surface and that is mounted on a mating metal piece

with tri-clamp(pic attached). Directly mating glass and metal would cause a disaster by thermal and sealing issues. PTFE would withstand anything up

to 250C. Possibly the PTFE and metal surfaces wouldn't need additional gasket as the clamp would seal them. The mating flange turned from PTFE

wouldn't withstand much mechanical stress or pressure, but it would hold perfect against vacuum.

Are there any more simple methods known? Guys who work in chemical industry?

For higher temps, possibly graphite adapter would be a viable option?

Being able to mount any ground glass into a metal device would allow for unlimited applications up to joint/glass max operating temp, compared to

anything that's made with duct tape, glue, solder or even welding.

EDIT: Actually, parts can be bought ready, for example 1.5" pipe fitting and suitable clamp:

https://www.ebay.com/itm/1-BSP-Female-x-1-5-Tri-Clamp-304-St...

https://www.ebay.com/itm/1-5-to-4-Tri-Clamp-Clover-SS316-Sta...

The fitting could be welded to the device, and the PTFE adapter could be turned to mate the fitting and the clamp from round stock of suitable

diameter.

Even more simple adapter could be turned by just making outer thread and a collar ring to the tube, turning PTFE adapter to rim the tube and clamping

it with the collar. This sort of assembly could likely be made out from nominal pipe thread parts by cutting an opening to house the glass joint to

the threaded blind plug. The PTFE adapter would seal between the lip of the tube and the plug.

[Edited on 22-2-2021 by Fyndium]

|

|

|

mr_bovinejony

Hazard to Others

Posts: 130

Registered: 20-4-2018

Member Is Offline

Mood: ASS

|

|

If you're doing any kind of glass mounting to other material I highly recommend one of these

https://www.ebay.com/itm/24-Thermometer-adapter-with-thread-...

You can do pretty much anything with it all while having removable glassware. And since it's teflon it's easy to file or grind down to make it fit

your needs

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

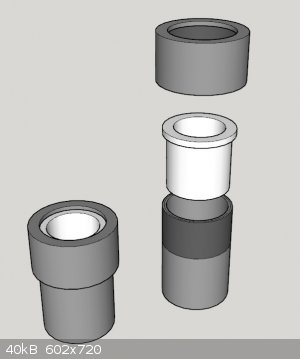

I was thinking something more like this.

Those stirrer adapters would only work the other way, by joining a vessel to a metal tube. It has added risk of cracking the joint on high heat, as

this happens already sub 100C by my experience. It jams so tightly even a wrench cannot turn it.

For 24* joint, a 1" NPT nipple is used, and a fitting piece is turned from 35mm PTFE stock of 30-40mm long if 29 or 40mm long taper is desired. A 1"

NTP cap has 28mm hole drilled through it, and it is used to clamp the adapter in place. The nipple can be welded to any suitable vessel.

Likely, as I said, turning it from graphite could allow for extra high temperatures. By using quartz joint, one could for example distill sodium.

|

|

|

Chemetix

Hazard to Others

Posts: 375

Registered: 23-9-2016

Location: Oztrayleeyah

Member Is Offline

Mood: Wavering between lucidity and madness

|

|

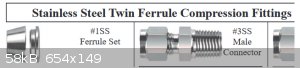

I've used the simpler option of a compression fitting

You can use O- rings instead of the metal ferrules for glass. The ferrules can be bought as PTFE if you need high temp inert seals. A bead of teflon

tape has worked for me in the past.

If you want to go hi temp with quartz then carbon fibre wound onto the quartz as a ferrule could work. Quartz is brittle so don't apply much force to

the seal.

|

|

|

digga

Harmless

Posts: 43

Registered: 11-6-2018

Member Is Offline

|

|

I punched a hole in paint can lid, inserted the male fitting of the glass in the hole and then puttied the joint with high temp putty. Used it to

make benzene.

|

|

|

wg48temp9

National Hazard

Posts: 784

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

To avoid differential expansion and contraction problem a flat flanged joint or a ball and socket joint could be used.

I have broken the female glassware part on tapered joints using male ptfe adapters. Probably a combination of vacuum and thermal expansion.

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

SWIM

National Hazard

Posts: 970

Registered: 3-9-2017

Member Is Offline

|

|

I've used small flat flange connectors (borosilicate) against metal surfaces with good success on a few occasions.

I think I've got a few spare in 19/38 joint sizes.

They were originally tops for really old Virtis flasks.

If this size is suitable I can send you one, but they were pretty cheap on Ebay and you can probably pick one up there with a bit of patience cheaper

than I could mail you one unless you're Canadian or Mexican. (postage from the US to most other countries is actually pretty high. Its cheap to mail

stuff to here, but expensive to mail from here to most other places. Back when I was dealing glass this really bugged me.

They seat okay as long as the metal isn't too thin and flexible.

If you can afford it, there are people who can make you an adaptor that's metal on one end and a glass joint on the other, which is a great sounding

solution to me.

I'm not sure how they fuse the glass to the metal, but those joints are supposed to be pretty good at handling heat.

I've got a few tubes (thin, and part of some unidentified apparatus)) with joins like that from glass to some reddish-grey metal.

The transition from glass to metal looks as smooth as the transition from vanilla to strawberry in a Neopolitan ice cream sandwich

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

There's the beautiful, but fiddly Housekeeper seal

Someone has posed some details here

http://www.imajeenyus.com/vacuum/20100923_houskeeper/index.s...

You can use molten silver chloride as a glue/ seal on the metal to glass joints ofvacuum systems- but you need to be sure the expansion coefficients

of the materials match.

And if you pick the right alloys- like kovar, you can seal them through glass (So, I presume you can seal glass through them.

Or you can ram crumpled up cooking foil into the gap as caulk.

It rather depends on the application.

|

|

|

wg48temp9

National Hazard

Posts: 784

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Nice find. That's the best How To info for a housekeeper seal I have seen. In particular the methods for precoating the copper with borax or

powdered glass.

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

zed

International Hazard

Posts: 2283

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

Umm. I have a couple of Stainless Steel Pressure Cookers, I would like to utilize for something. I just figured I would go all-stainless. Then, I

tried some simple drilling, and threading, and tapping; utilizing Stainless Steel components. Not so easy. Might need Tungsten Carbide tools to make

any headway. Ordinary machine tools, were totally impotent. In fact, my taps...Are no longer taps. Oh no, they didn't snap off. The cutting edges

were simply flattened, while the Stainless showed nary a scratch.

|

|

|