Antigua

Hazard to Others

Posts: 155

Registered: 27-9-2020

Member Is Offline

|

|

Formaldehyde bisulfite adduct preparation

Hey,

I'd like to prepare some pure formaldehyde bisulfite adduct as a powder. I've found a couple of sources about it, but none of them describe the

workup or how to crystallize the adduct.

My plan was to prepare a solution of sodium metabisulfite (CAS:

7681-57-4) and add it to 0.5 mol eq. of aqueous formaldehyde 36% solution.

The problem arises with separating the product. It seems really polar and the bulkier the carbonyl compound the less water soluble the adduct is.

The problem here is that formaldehyde is obviously the least bulky carbonyl compounds one could imagine.

Any ideas or experiences you could share, please?

I've searched sciencemadness and other forums without much luck.

Here are the sources I went through:

https://patents.google.com/patent/US3293214A/en (describes preparation of the adduct, but doesn't mention it's crystallization at all)

https://core.ac.uk/download/pdf/9640129.pdf (talks a little about adducts)

Thanks in advance

|

|

|

Antigua

Hazard to Others

Posts: 155

Registered: 27-9-2020

Member Is Offline

|

|

Additional source: https://www.chemicalforums.com/index.php?topic=70428.msg2539...

Information on solubility of the adduct is very sparse: https://pubchem.ncbi.nlm.nih.gov/compound/Sodium-hydroxymeth...

This page quotes it as "water soluble", but doesn't say to what extent. It also says this, though: "Needles from water /Monohydrate/

Budavari, S. (ed.). The Merck Index - An Encyclopedia of Chemicals, Drugs, and Biologicals. Whitehouse Station, NJ: Merck and Co., Inc., 1996., p.

718"

Which implies that the compound is recrystallizable. Do you guys think one could dehydrate it to anhydrous without destroying the adduct by light

heating in warm oven?

I was unable to find the Merck reference in two books I found on libgen.

|

|

|

njl

National Hazard

Posts: 609

Registered: 26-11-2019

Location: under the sycamore tree

Member Is Offline

Mood: ambivalent

|

|

Maybe an isopropanol/water solvent system would be better for recrystallization. Whenever I can't find good info on simple compounds like this I just

do a few test tube experiments ie. dissolve adduct in water and note the solubility changes when various alcohols are added.

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Is this the stuff that is known in the dying industry as Rongalite or hydroxymethylsulphinate?

|

|

|

Antigua

Hazard to Others

Posts: 155

Registered: 27-9-2020

Member Is Offline

|

|

No, these are different compounds. Rongalite is the adduct formed from dithionite, not bisulfite.

|

|

|

Antigua

Hazard to Others

Posts: 155

Registered: 27-9-2020

Member Is Offline

|

|

I'm going to conduct some experiments - luckily the formation of adduct leads to no side products. Therefore I could just evaporate the solution and

crystallize in the freezer without fear of side products precipitating too.

|

|

|

dawt

Hazard to Self

Posts: 74

Registered: 9-5-2016

Location: EU

Member Is Offline

Mood: fluorescent

|

|

Oh cool, I was planning on doing the same thing next week (due to me using formaldehyde so rarely it's polymerized whenever I need it) and came up

with zilch info on the workup as well. My plan was using an excess of formaldehyde to ensure all the metabisulfite is used up, evaporating and then

recrystalizing from water. I'll keep you posted and am looking forward to reading about your experience.

Edit: According to the publication below (if I'm reading it correctly, old German nomenclature is all messed up and there was quite an uncertainty

about the identity of the substance until 1926) the bisulfite adduct can be crystalized by addition of ethanol (but not methanol) to the aqeous

solution, and recrystallized by dissolving in warm water and adding ethanol.

https://chemistry-europe.onlinelibrary.wiley.com/doi/10.1002...

[Edited on 2020-12-20 by dawt]

[Edited on 2020-12-20 by dawt]

|

|

|

Antigua

Hazard to Others

Posts: 155

Registered: 27-9-2020

Member Is Offline

|

|

47.15g (1.1 mol eq.) of 35-38% (I assumed it was 35%) formaldehyde aq. solution (formalin) was poured into a high-walled 250ml beaker. 47.5g (0.5 mol

eq. of metabisulfite, works out to be 1 mol eq. of bisulfite due to the reaction (Na2S2O5 + H2O → 2 Na+ + 2 HSO3−) was added in small portions

with vigorous stirring. Each addition led to a slightly exothermic reaction as evidenced by water condensing on the sides of the beaker and the awful

vapor of formaldehyde reaching the experimenter’s nose... Distilled water from a squirtbottle was used in order to wash off any solid powder stuck

to the walls. The first few additions didn’t prove problematic, as everything dissolved nicely, but after ~half of the metabisulfite was added

further dissolution was difficult, and so additional 3.5g of the formalin solution was added alongside further additions of water. Then additional

2.1g of formalin was added, any cloudiness has been then removed by filtration. At this point the clear solution was similar to thinned out corn syrup

- clear and a bit heavy/viscous.

An aliquot was taken to a test tube and a couple drops were of ethanol were added. Surprisingly, 2 layers formed - probably due to the big differences

in density. Some cloudiness appeared in the aqueous adduct layer, but no precipitate fell out.

The bulk of clear, filtered solution was put into freezer - I’ll update if anything falls out. A seed crystal would be useful, so if nothing happens

in 2 days I’ll evaporate a bit of the solution and seed the mother liquor.

|

|

|

ChemichaelRXN

Hazard to Others

Posts: 103

Registered: 7-10-2010

Member Is Offline

Mood: Universal Eye

|

|

Yea maybe rotovap half of the solution not crystallizing or add NaCl to make a brine to reduce the solubility might work.

You are the same perception looking out, from the same elements around the universe.

You are everything to be anything to begin with.

Https://you-are.space

Https://syntharise.com

|

|

|

Antigua

Hazard to Others

Posts: 155

Registered: 27-9-2020

Member Is Offline

|

|

I feel like crystallization won't work here easily. After sitting in the freezer nice, white, thick needle like crystals do indeed start to form, but

they redissolve very easily into the original solution and aren't therefore easily separated. Maybe ethanol would indeed work well? I'm going to split

the syrup into two parts. One will be evaporated on low heat and the other will have 50ml of ethanol added to encourage precipitation. We'll see!

|

|

|

dawt

Hazard to Self

Posts: 74

Registered: 9-5-2016

Location: EU

Member Is Offline

Mood: fluorescent

|

|

No luck here either. I added the formaldehyde to a concentrated solution of sodium metabisulfite. Adding ethanol to that created a second layer, but

no crystals formed after a night in the fridge. Mixing the layers also didn't worked so i removed the ethanol (as well as the methanol used to

stabilise the formaldehyde) at the rotavap and tried isopropanol instead ... still nothing after a few hours in the fridge.

At least the hydroxymethanesulfonate appears to be stable at rotavap temperatures (no gas was evolved and no smell of formaldehyde or SO2 observed),

so I guess concentrating in vacuo would be the next logical step.

|

|

|

dawt

Hazard to Self

Posts: 74

Registered: 9-5-2016

Location: EU

Member Is Offline

Mood: fluorescent

|

|

Alrighty, so I removed the isopropanol and approx. 40 mL water at the rotavap until the solution turned opaque and quite viscous. Added back 20 mL of

water to redissolve everything after it had cooled to room temperature, added 99 % denat. EtOH and let it stand in the fridge for a day. The ethanol

has a slight yellow tinge to it and some needles have formed in the aqeous phase. I'll be gone for a few days and will process them when I'm back.

[Edited on 2020-12-26 by dawt]

|

|

|

Antigua

Hazard to Others

Posts: 155

Registered: 27-9-2020

Member Is Offline

|

|

Surprise!

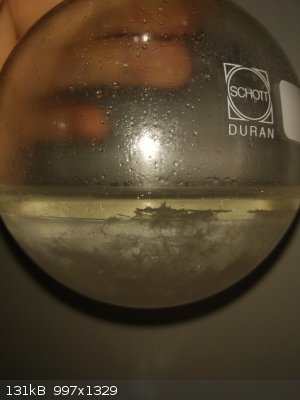

The flask sat in my freezer for a week now and wasted precious cold space. So I removed it and let it sit outside. Today I was greeted with snow-like,

wet crystals. Filtered them, washed with ~50ml of DCM and put into a makeshift NaOH/MgSO4 dessicator.

|

|

|

Antigua

Hazard to Others

Posts: 155

Registered: 27-9-2020

Member Is Offline

|

|

After a couple weeks of dessicating the solid over sodium hydroxide (replaced it once) beautiful, sparkling crunchy white crystals were weighed

(17.322g, 0.129mol, 26% yield, yikes). These have a very faint smell of formaldehyde to them, the melting point (or rather the decomposition point, as

the adduct is supposed to break down at 200C) is going to be measured soon.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Too much ethanol causes bisulfite to crash out. I had this happen when I attempted to extract phenylacetaldehyde too eagerly and presumed it was the

adduct. Another test with adduct forming compound that was not water soluble produced two layers, but administering few squirts of ethanol with

pipette caused a quick adduct cake formation, which was easy to filter and wash and produced over 80% yield when regenerated.

Formaldehyde might be a little tricky because it's in a solution already, and it likely causes large losses due to many factors, not only due to

dilution. Apparently paraformaldehyde'd be better in this purpose, but this was a test of it's own. Don't know if metabisulfite could be dumped

directly into formaldehyde solution.

|

|

|

Benignium

Hazard to Others

Posts: 115

Registered: 12-6-2020

Member Is Offline

Mood: Quasi-catatonic

|

|

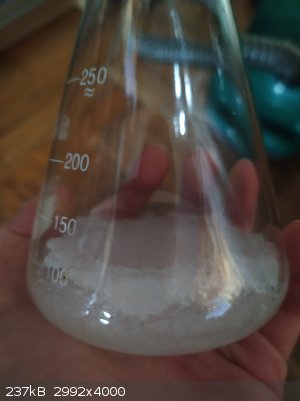

I, too, needed some adduct so I made it in the following way:

100 grams of paraformaldehyde was first dissolved in 170 mL of water at 60 deg. C with a few small flakes of KOH. The resulting solution was added

dropwise from an addition funnel into a well stirred slurry consisting of 368.4 grams of potassium bisulfite and 108 mL of water over an hour or so.

Once addition was complete, >150 mL of water was distilled off and the clear viscous solution cooled to near 0 deg. C. To the cooled mixture ~70 mL

of ethanol was added. The reaction flask was shaken vigorously for a few seconds causing it to crystallize. Crystals were filtered off and the flask

was rinsed with the filtrate to get everything out. The crystals were carefully dried in an oven first at 50 deg. C for a few hours to avoid having it

melt into a puddle and finally at 100 degrees overnight. The product seems stable at these temperatures.

Potassium metabisulfite was used because it's what I have on hand. The product has a mildly unpleasant odor like dog food. Not quite like

formaldehyde, in my opinion.

Damp crystals

|

|

|

Antigua

Hazard to Others

Posts: 155

Registered: 27-9-2020

Member Is Offline

|

|

Important!

The melting point of what I obtained was measured. The product started fizzing and effervescing in 200-201°C (lit. 200°C). A sample of sodium

metabisulfite was also put to test. Nothing happened to the solid in the capillary tube even at 220°C. I think this concludes that what we were able

to obtain is in fact the formaldehyde sodium bisulfite adduct. I'd love Benignium to test their product too, as I think your method is far more

efficient.

|

|

|

Benignium

Hazard to Others

Posts: 115

Registered: 12-6-2020

Member Is Offline

Mood: Quasi-catatonic

|

|

Apologies for taking so long, I did test this just now and indeed the product does melt and start producing gas at 200 degrees. This action seemed to

begin, to a small extent, at a little over 160 deg. C. However this is probably due to the crude testing setup, a test tube heated on a hotplate.

|

|

|

Antigua

Hazard to Others

Posts: 155

Registered: 27-9-2020

Member Is Offline

|

|

A nice addition to this topic:

75g of sodium sulfite (Na2SO3) was slushed up in 50ml of water. Then 150ml of 36% m/v formaldehyde solution was dripped into the

warmed up slush of sulfite in water. After prolonged heating and stirring the mixture finally cleared up. It was then covered in foil and heated up on

high temp to drive off the water. After the mixture became a white slush (at least 100-150ml of water stripped) I let it cool down and it solidified

into a white rock. 50ml of ethanol was added and it was heated up once again to try to soften up the rock. It was then broken up using a spatula and

dried in an oven for a couple of hours on 110C. To aid the drying I took it out and crushed the larger crumbs in a mortar.

In the end 111g (86%) of off-white powder was obtained. What's interesting is that it's flammable! I suppose heating it up releases formaldehyde which

can then catch fire. Interesting. Anyways, thanks to the weight and the flammability I know this is the product. It may be slightly contaminated, but

this method removes any problems with crystallization.

|

|

|

Benignium

Hazard to Others

Posts: 115

Registered: 12-6-2020

Member Is Offline

Mood: Quasi-catatonic

|

|

Something's going on with the potassium hydroxymethanesulfonate that I prepared back in January which warrants a small update. After several months I

started noticing a strange unpleasant smell lingering in the enclosed storage space where the adduct was kept in an LDPE ziploc bag inside a

supposedly airtight secondary container made of PMMA and a silicone gasket. Over a further couple of months the odor gradually became pungent enough

to prompt me to finally investigate and find that the adduct had developed a dog food-like funk of nauseating intensity but no irritating properties.

The smell had permeated the acrylic container and no amount of ventilation or washing could eliminate it. Physical contact with the container or its

contents left a strong residual smell on most materials, but fortunately this would eventually dissipate.

The secondary container was swapped out for a mason jar and some silica gel packets were placed in with the bag of otherwise seemingly unchanged

adduct. This has so far completely prevented further issues with the smell. In retrospect, degradation or not, it was a poor decision to make so much

of the stuff. Hopefully despite the stench it still remains as unchanged as it looks. Using it in a reductive amination will hopefully give some

indication, eventually.

Has anyone else observed this phenomenon with their material?

|

|

|