Fery

International Hazard

Posts: 1052

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

phenoxyacetic acid

one of its derivate discussed here:

https://www.sciencemadness.org/whisper/viewthread.php?tid=62...

I wanted to prepare it at 100g scale and using 2,5 L of ether for extraction discouraged me, so I tried different way than this one:

Also an interesting reaction not in water environment here (but ethyl chloroacetate instead of chloroacetic acid used as a reactant)

Attachment: brettle.pdf (333kB)

This file has been downloaded 347 times

97% yield claimed fusing wet phenolate and chloroacetate in microwave oven:

Attachment: villemin1996.pdf (178kB)

This file has been downloaded 332 times

So here my experimental work (experimental is only the workup part)... if someone interested to improve it I suggest to perform it at least twice, for

the first time after overcoming some problems you only get ideas what to improve in the second batch... unfortunately I don't plane to repeat it for

the second time as I obtained enough amount of the product.

Dissolve 71,0 g K2CO3 (0,51 mol, but it is never pure either completely dry) in 125 ml of water and add dropwise to 94,5 g monochloroacetic acid (1

mol) while stirring and slightly heating (approx 50 C) until it dissolves and CO2 evolution finishes. Check the pH with universal indicator paper, it

must be alkaline, if not (to much water in K2CO3) add a little of K2CO3 (second sign that the neutralization is not yet finished is bubbling of CO2

when a drop of K2CO3 solution falls into the reaction mixture, but don't confuse this with natural CO2 evolution from its saturated solution).

in the left picture the beginning, the hose connected to the apparatus was lead outside of building, the acid was investigated for

toxicity/genotoxicity/mutagenicity and it is much safer than bromo/other halogen derivates of this acid) that's why I decided to minimize risk of

vapour / CO2 stream blowing droplets out of the flask etc (perhaps the hose was not necessary, but never hurts)

in the middle picture the middle of addition / neutralization

in the right picture the end of addition (later I had to add a little of K2CO3 as the solution was not yet alkaline - seems my K2CO3 was wet or

perhaps some hydrate instead of anhydrous, it was bought from a shop focused on selling items to soap producers)... I do not know why one of the doc

mentioned earlier used carbonate instead of hydroxide, perhaps it is more polite to Cl and hydroxide could damage the Cl like elimination of HCl or

substitution to -OH?

Then add solution of phenol 94,1 g (1 mol) liquified with 10 ml of water (warm slightly together to dissolve). Then add 45 g 98% NaOH (1,1 mol)

dissolved in 50 ml of water (exothermic, cool it down in water bath during dissolving) from dropping funnel dropwise during 10 minutes while stirring.

in the left picture the K chloroacetate on the left, phenol liquified with H2O in the middle (red-pink, maybe traces of Fe3+ ?), solution of NaOH on

the right

in the middle picture the middle of NaOH addition

in the right picture the end of NaOH addition

Then start heating the flask while stirring that it does NOT reflux and the walls of the flask manage to condense vapour. After approx 20 minutes the

product starts to precipitate, continue stirring and heating and after 1 hour turn heating off and continue stirring for extra 1 hour. It is quite

thick mass and you need good stir bar (big diameter and longer) and powerful magnetic stirrer. Then turn stirring off. I let it to stay overnight, the

reaction is very likely done and no need to wait, it was just too late and I had to sleep.

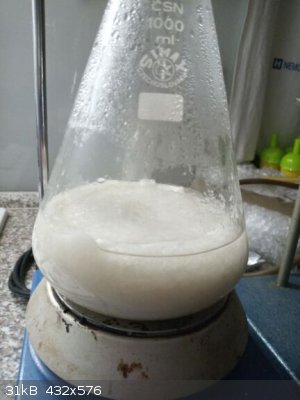

in the left picture the reaction 30 minutes after starting

in the middle picture 60 minutes after starting (it is barely visible but it is still stirring thanks to thick and long stir bar and powerful magnetic

stirrer)

in the right picture the reaction in the morning the next day

Vacuum filter and while still wet (no need to dry) add 120 ml distilled water, heat below boil to dissolve (total volume after dissolution 300 ml) and

let to slowly crystallize at room temperature and then put into fridge overnight to 4 C, vacuum filter. It must be vacuum filtered to get rid as much

of mother liquor as possible as the mass after crystallization is quite thick (thick glass rod was used to break it). The mother liquor was heated

upto boil and while stirring slowly added NaCl 20% of its weight (30 g NaCl for 150 ml of mother liquor) and then cooled down to 4 C.

Perhaps it could be better to recrystallize the product from 10-20% solution of NaCl instead from distilled water as then the mass not so thick,

bigger volume of liquid used for crystallization removes more of impurities as the amount of mother liquor adhering on crystals comparable but bigger

volume of mother liquor driving out more impurities...

I decided to recrystallize it again by adding 120 ml of distilled water, heated upto boil (surely less NaCl/KCl contamination = better solubility, 100

ml was not enough, or less water trapped in crystals than in previous crystallization). I just decided that repeating the previous step once more

again was necessary according to the big mass of crystals and so little of mother liquor and I also sucked the product on the sinter with powerful

vacuum pump for a long time (10 minutes).

The mother liquor after sucking off Na phenoxyacetate was processed again by salting out using NaCl (25 g of NaCl for 125 ml of liquor) and it yielded

extra crop of the product as in previous step (these were kept separately as they were contaminated with NaCl, but that won't mind when decomposing it

with HCl to free acid where NaCl will be byproduct).

I acidified the mother liquor (stayed after salting out and sucking off Na phenoxyacetate) with 2 ml 35% HCl, cooled to 4 C and it yielded 2,5 grams

of phenoxyacetic acid, then adding extra 0,5 ml 35% HCl and cooled down to 0 C yielded extra 0,1 g of the acid. This free acid was quite colorless so

I decided that this recrystallization was the final one and no need to repeat it again.

in the left picture the extra 2,5 g phenoxyacetic acid obtained by acidifing mother liquor with HCl

the middle picture, from the left, first 3 bigger vessels with sodium phenoxyacetate: dish with the product after salting out first mother liquor,

dish (with a short glass rod) with the product obtained by salting out the second mother liquor, beaker with the purest product (crystals from second

mother liquor, this was obtained earlier than the crystals in the dish with short glass rod), sinter with 2,5 g of phenoxyacetic acid crystals after

acidifying the second mother liquor with HCl

in the right picture the 2,5 g of phenoxyacetic acid (in the middle picture it was in the sinter on the right side)

yields:

15,3 g (first mother liquor + 30 g NaCl), this is in the picture with 4 products in the left dish, this is contaminated with a little of KCl from

K2CO3 and with some NaCl

26,6 g (second mother liquor + 25 g NaCl) this indicates more of product stayed dissolved in second mother liquor as the NaCl contamination was less

than in previous step, this crop is in the picture with 4 products in the second dish from the left (the dish with short glass rod)

98,6 g of pure sodium phenoxyacetate, in the pricture with 4 products in the 600 ml beaker

2,5 g of phenoxyacetic acid, in the picture with 4 products on the right side in the sinter and in the next picture dry in the Petri dish

The solubility of Na phenoxyacetate in water is at range 20%, that's why I decided to salt it out using NaCl, maybe better to crystallize it from

solution of 10-20% NaCl instead of distilled water, but I went the way without NaCl to obtain the last crop pure from NaCl and only then salted out

liquors to reduce loses due to high solubility.

https://echa.europa.eu/cs/registration-dossier/-/registered-...

Sodium phenoxyacetate hemihydrate

Molecular weight: 174.1

Sodium phenoxyacetate is a solid with a melting temperature of 266.6 °C.

Sodium phenoxyacetate decomposed during and immediately after melting.

The relative density is 1.4975 at 20 °C.

The water solubility is high: 223.6 g/L at 20.0 °C.

But certainly lower solubility in NaCl/KCl solution... I approximate 50 grams in 1 L of 20% NaCl.

I acidified (with 35% HCl) also mother liquor obtained by filtering the reaction mixture and mother liquor obtained from first recrystallization and

they yielded dirty phenoxyacetic acid as shown in the following pictures, this very impure crops of phenoxyacetic acid were discarded, but perhaps

they could be purified by extraction with ether and then extraction from ether using Na bicarbonate (the doc suggests Na2CO3 but I think phenoxyacetic

acid is strong enough to be extracted into water solution of NaHCO3 while phenol wouldn't react and stay in ether layer). I just discarded these

because I obtained enough of pure product. This could yield approximately 5 g of extra phenoxyacetic acid when purifying it further. These pictures

are here as a comparison with 2,5 g of almost colorless phenoxyacetic acid obtained from the last mother liquor (previous picture with Petri dish).

The 15,3 g + 26,6 g crops of Na phenoxyacetate (somewhat contaminated with NaCl) will be decomposed with HCl to free phenoxyacetic acid (NaCl will be

a sideproduct).

The 98,6 g of pure Na phenoxyacetate was stored in a bottle.

|

|

|

Boffis

International Hazard

Posts: 1897

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Good and thorough write-up Fery! Nice clean looking recrystallised product too.

What do you intend to do with the sodium phenoxyacetate? Isn't it a plant ground regulater?

|

|

|

Fery

International Hazard

Posts: 1052

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Hi Boffis, I would like to make allyl phenoxyacetate = pineapple fragrance

Na phenoxyacetate + HCl -> phenoxyacetic acid

phenoxyacetic acid + allyl alcohol + H2SO4 (cat.) + hexane + Dean Stark trap apparatus -> ester

alternative route Na phenoxyacetate + allyl bromide

That's why I let some Na salt and did not convert everything to free acid - I already converted only the less purer crops (15,3 g + 26,6 g) and packed

the most pure crop (98,6 g) into a bottle.

If you have any suggestions please let me know (different catalyst than H2SO4? like H3PO4, or toluenesulfonic acid? is it OK to perform the

alternative route in water environment - I expect bad solubility of allyl bromide in water?). I have all reagents at hand, I prefer the first route as

I expect allyl bromide to be the most nasty compound from the all above (I have never opened its original bottle yet) and the ester will be dedicated

to occasionally smell it, not to stay in closed bottle for good (pineapples and pears are my beloved scents). I could also use benzene instead of

hexane but hexane seems to be more health friendly compound than benzene, hexane is sometimes used in healthcare, e.g. mixture of isomers under name

medicinal petrolether for e.g. removing adhering plasters / cleaning skin after removal or under name spiritus cum benzino denat. applied to skin as a

disinfectant... of course I have never seen any such usage of benzene in medicine and will never see and nobody will...

|

|

|

Fery

International Hazard

Posts: 1052

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

obtaining free acid from its salt

To 600 ml beaker was put 200 ml H2O + 22 ml 35% HCl and 41,9 g sodium phenoxyacetate. It was heated until it dissolved, oily substance observed on the

bottom so the volume adjusted to 500 ml. HCl was in small excess so the final solution was acidic to methyl orange, pH below 3,0 (you can also use an

universal indicator paper). Then it was slowly cooled down to room temperature. During cooling an oily substance appeared on the bottom at first

(which later solidified) and then crystallization in the water solution started. Using a glass rod the bottom solidified oil was detached from the

bottom and crushed into few pieces. Then a thermometer was inserted and the content was heated while stirring the content using a glass rod. When

reaching 50 C most of the small crystals in the volume dissolved but the bottom solidified mass of oil didn't (it is necessary to detach it from the

bottom to allow heat to enter the volume of breaker instead again liquifying the solidified oil), few crystals floating at the surface were still

solid. Then it was decanted into another 600 ml beaker and it was let to cool down to room temperature standing on wooden table (metal is not good as

it quickly cools the bottom of the beaker). Then it was let to cool to 0 C outside of building. Crystals sucked on sinter. Mother liquor returned to

the first beaker and again heated to 50 C, decanted from a little of mess on the bottom into second beaker and slowly cooled down to room temperature

sitting at wooden table and then transferred outside to cool to 0 C (winter weather). Crystals sucked on sinter.

The mother liquor was slowly evaporated from 500 to 100 ml and was let to crystallize.

Nice crystals form only on very slow cooling and only from solutions saturated at 50 C. Cooling down saturated solutions from boiling point first

produce oily product on the bottom.

I suggest to play a little with this oiling out phenomenon as the oil seems to have an advantage in concentrating impurities. Add mother liquor and

heat slowly that the solidified oil does not melt but it does slowly dissolve so it gets darker and darker as getting smaller and smaller while the

water phase is clear and colorless (you end up with tiny blob of impurities at the bottom).

It is possible to produce big needle shape crystals > 1 cm when using new not scratched beaker and slowly cooling down at most 3% solution (after

crystallization it becomes 1 %, but you can reuse the mother liquor for subsequent crystallizations and add only depleted phenoxyacetic acid which is

2 %).

I also obtained some quite pure acid from the dirty crops of crystals obtained in the synthesis of Na phenoxyacetate. The purification was based on

concentrating the impurities in oiled out acid at the bottom.

Now notes concerning crystallization / solubility.

Solubility of phenoxyacetic acid in water at 4 C (fridge temperature) is cca 10 g / L (my approximation) and literature claims 12 g / L at unknown

temperature (very likely 20 C).

https://www.merckmillipore.com/INTL/en/product/Phenoxyacetic...

If you crystallize 5% solution (5 g of the acid in 100 ml of water) you get cotton like product (4 g of crystals and 1 g remaining in 100 ml of

water).

If you would like bigger needle shaped crystals (cca 1-2 cm long) you need to crystallize less concentrated solution (2 or at most 3 g of the acid in

100 ml of water).

You can reuse the mother liquor. So e.g.

Initially 3 g acid + 100 ml water -> heat to 50 C to dissolve -> slowly crystallize -> 2 g of crystals of acid + mother liquor (1 g of acid

in 100 ml of water). Then add 2 g of acid into the mother liquor, and repeat (heat until dissolve, it is usually enough to 50 C and then let to

crystallize in new unscratched glass as slowly as possible, undisturbed, first at room temperature for few hours and then transfer into a fridge for

few hours).

The slower the crystallization the bigger the crystals obtained. Also use new unscratched beaker (less crystallization centers, the less number of

crystals and thus bigger crystals).

Dissolving 5 g of acid in 100 ml of water is done at cca 50 C, no need to heat upto boil.

When crystallizing too much concentrated solutions (prepared by dissolving a lot of the acid in boiling water) then on cooling down the solution

becomes foggy (emulsion) and the acid separates at first as an oil at the bottom, crystallization starts when the T drops below cca 50-60 C.

When cooling down concentrated solutions prepared at boiling temperatures and the T reaches 50 C you can simply decant the water phase and let it to

crystallize. The oil phase at bottom seems to extract some impurities from the water phase. Later you can extract the solidified acid from oil bottom

layer with mother liquor but now at lower temperature (not at boil) - a small blob of dark impurities at bottom remain at the end (the slower you

dissolve and at lower temperature the better).

I somewhere read about using 1:1 water:ethanol for crystallization, this could probably prevent oiling out of the acid, but I did not try this.

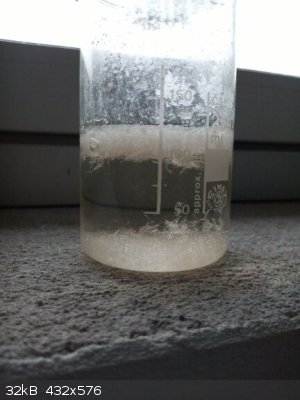

here the solution was too much concentrated so on cooling down the acid oiled out of the solution at first, the oil is hardly visible as steam

condensed on my cold camera lense (there is slightly yellowish-reddish semilunar shape on the bottom of the picture)

here the oiled out acid better visible, it seems to concentrate impurities so you can decant the clear upper water phase into new beaker to let it to

crystallize

cotton like product in the left bigger dish by crystallizing cca 5% solution and bigger crystals in the right Petri dish by crystallizing cca 3%

solution

the biggest crystals when crystallizing 2% solution (unscratched new beaker, cooling slowly standing undisturbed at wooden table)

|

|

|

Fery

International Hazard

Posts: 1052

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Here yield.

I started from 1,00 mol of phenol + 1,00 mol of monochloroacetic acid.

Na phenoxyacetate 98,6 g = 0,54 mol (somewhere I read it could be hemihydrate which has molar mass 174,13 g/mol + 18,02/2 g/mol = 183,14 g/mol, if it

is anhydrous then 0,57 mol)

https://pubchem.ncbi.nlm.nih.gov/compound/Sodium-phenoxyacet...

phenoxyacetic acid 31,8 g = 0,21 mol (Molar mass = 152.15 g/mol) from 41,9 g of Na phenoxyacetate

phenoxyacetic acid 6,8 g = 0,04 mol from dirty crops of Na phenoxyacetate + from 2,5 g of phenoxyacetic acid in Na salt synthesis

so the total yield 54%+21%+4% = 79% if assuming Na salt as hemihydrate, 82% if assuming anhydrous

|

|

|

Fery

International Hazard

Posts: 1052

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

melting points, the termometer is graduated in steps of 0,2 C

the 31,8 g sample (cotton like product) m.p. 98,4 - 100,0 C

the 6,8 g sample (long crystals from purifications of dirtiest crops) m.p. 99,6 - 101,6 C

http://www.thegoodscentscompany.com/data/rw1033781.html

Melting Point: 99.00 to 103.00 °C. @ 760.00 mm Hg

Boiling Point: 285.00 °C. @ 760.00 mm Hg

[Edited on 2-12-2020 by Fery]

|

|

|

|