| Pages:

1

2 |

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

A slightly dangerous but surprisingly effective way to make HCl

This setup uses a membrane chloroalkali cell which produces Cl2 and H2 and then is hooked up to a bubbler and sent to a quartz tube next to a UVC lamp

which produces HCl via these reactions.

HOCl + O3 = HCl + O2

H2 + Cl2 = HCl

The bubbler and the cell produces HOCl along with Cl2 also called wet chlorine.

Cl2 + H2O = HCl + HOCl

overall this process doesnt seem to happen explosively due to the existence of HOCl in the system but the gases produces can still ignite violently

and detonate so avoid any sources of ignition.

A future cell using mmo will have a PVC enclosure for the UVC lamp with input for gas and output for HCl liquid and vapor.

Video link below

https://youtu.be/SHX7EDW2hLw

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

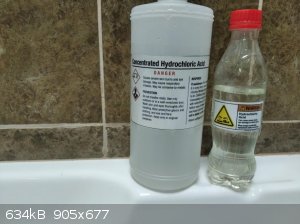

Fuming HCl produced after 11 hours of runtime.

https://youtu.be/kMKDrHb4W7Q

|

|

|

metalresearcher

National Hazard

Posts: 790

Registered: 7-9-2010

Member Is Offline

Mood: Reactive

|

|

What kind of membrane do you use ? Because a membrane is mandatory to prevent the OH- reacting with the Cl2 gas.

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

PVA + BORAX on synthetic cloth scaffhold

vid guide below

https://www.youtube.com/watch?v=dR7fW5J7njA

|

|

|

Syn the Sizer

National Hazard

Posts: 600

Registered: 12-11-2019

Location: Canada

Member Is Offline

|

|

I much prefer the safer OTC method of reacting sodium bisulfAte with NaCl products are sodium sulfate and HCl vapour. Of course this will also work

with H2SO4 with much better results. Though I just get muriatic acid from Canadian Tire for $15/4L

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

Heres my homemade HCl 24 hours runtime its already fuming like in the vid shown.

|

|

|

Syn the Sizer

National Hazard

Posts: 600

Registered: 12-11-2019

Location: Canada

Member Is Offline

|

|

Nice, well done.

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

after tweaking the cell a bit and messing with membranes and additives and current density to prolong the operating time I got 2 nice bottles of

fuming 12 molar HCl.

I got these by running the setup till HCl vapor was comming out of the 2nd hose in large amounts enough to turn the cumene test strip and pH paper a

nice red.

[Edited on 18-9-2020 by mysteriusbhoice]

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

Cost of production 82 Cents per liter of 37% HCl!!

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2171

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

What temperature did the pva membrane start failing at?

Was it the base material that failed or the pva started dissolving?

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

Quote: Originally posted by macckone  | What temperature did the pva membrane start failing at?

Was it the base material that failed or the pva started dissolving? |

the failure conditions are still unknown because upon testing the membrane fails at temp 95 Celsius when slowly heated on a pot of water on the stove.

The membrane however fails in the cell if I let it run for too long but if I drain it after current reaches a certain value of 5 amps then it wont

fail and ive done 3 cycles so far and it didnt fail doing that.

The question is whether its current density that caused failiure or concentration gradient and hence now im running at lower voltage which means lower

current and if it still fails or fails before the previous value of current then it will be current density.

The PVA itself failed the base material remained if you used synthetic fabric.

The mode of failure seems to be that the PVA is getting disloged and ends up precipitating or floating around in the cathod chamber only!.

My guess is the current flow being too high caused the ions to migrate even the polymer but I cant say for sure.

addition of copper chloride prevents buildup of hypochlorites in anode chamber.

[Edited on 20-9-2020 by mysteriusbhoice]

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Nice to see this process working!

On the other hand, don't bee fooled by the apparent safety of the reaction! H2 and Cl2 does explode on illumination by a strong light source. (Visible

light suffice.) Been there, done that. Keep this in mind before making adjustments to your reactor! :-)

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

Quote: Originally posted by Pumukli  | Nice to see this process working!

On the other hand, don't bee fooled by the apparent safety of the reaction! H2 and Cl2 does explode on illumination by a strong light source. (Visible

light suffice.) Been there, done that. Keep this in mind before making adjustments to your reactor! :-) |

I know that this can happen suddenly and hence theres now a shield ontop and a pool of water below.

I will even add a safety blow plug and hose in the final design for extra safety and it will be tested by detonation of gas inside.

The risk of this is with higher flow rate of input gas and yes the exit gases are still combustible but not explosive like the input gas when tested

in soapy water.

[Edited on 20-9-2020 by mysteriusbhoice]

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

The problem of failure of the PVA seems to be current density because after running it for really long continiously keeping the current below that

value at which it failed it got to a higher concentration and didnt fail completely.

The PVA in the cathode chamber seems to fail tho anyway but the anode chamber looks solid even at higher concentration gradient and since the anode

chamber membrane is still intact then I now calculated the current density of the membrane of the anode chamber at which it seems to fail and it looks

like its around above 58.4ma/cm^2.

my current operating current density is 51.66ma/cm^2

this is the borate membrane have to test the citrate and terephthalate membrane failure current density but the citrate seems to fail at higher

current density but its not easily repairable unlike borate so I will switch to that once care is taken to know the exact value at which it fails

probably once I get my variable current regulated power supply.

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2171

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

It sounds like there are three potential failure modes.

1) temperature gets too high (95C+)

2) sodium hydroxide concentration gets too high (commercial membranes fail at around 10%)

3) the current density is too high (58ma/cm^2)

A possible mechanism for the third failure mode is the mobilization of borate ions.

This would lead to depletion on the cathode side.

Since borate is responsible for the stability of the PVA film, its depletion would result in the film failing.

At some current density various nafion membranes fail as well.

So this is expected.

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

I have a new membrane that doesnt fail easily its Citrate crosslinked PVA and Terephthalate crosslinked PVA but if they fail these membranes are

harder to repair and unlike borate in which addition of borates into electrolyte mitigates 1 of those failures and borate membranes can be repaired in

30 seconds and used right away.

The NaOH definitely plays a role in fking up my membranes.

unless I can somehow think of a way to pump the NaOH out of solution and replace it or just increase the size of the cathode chamber so it can be run

on batch mode which is what I was thinking of in the final design.

The final design will be a 4 Liter cell like my chlorate one and the center will be anode and the 2 side compartments will be NaOH and membranes would

be PVA Citrate and using a current regulator buck converter set to a stable output at higher voltage I can essentially keep current constant and

calculate the run time based on when the cathode compartment gets to around 9.5% NaOH by wt.

[Edited on 20-9-2020 by mysteriusbhoice]

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Nice.

Could you, hypothetically, control the NaOH concentration by dripping in fresh solution from above and draining the used solution below?

|

|

|

papaya

National Hazard

Posts: 615

Registered: 4-4-2013

Member Is Offline

Mood: reactive

|

|

Quote: Originally posted by mysteriusbhoice  | I have a new membrane that doesnt fail easily its Citrate crosslinked PVA and Terephthalate crosslinked PVA but if they fail these membranes are

harder to repair and unlike borate in which addition of borates into electrolyte mitigates 1 of those failures and borate membranes can be repaired in

30 seconds and used right away.

The NaOH definitely plays a role in fking up my membranes.

unless I can somehow think of a way to pump the NaOH out of solution and replace it or just increase the size of the cathode chamber so it can be run

on batch mode which is what I was thinking of in the final design.

The final design will be a 4 Liter cell like my chlorate one and the center will be anode and the 2 side compartments will be NaOH and membranes would

be PVA Citrate and using a current regulator buck converter set to a stable output at higher voltage I can essentially keep current constant and

calculate the run time based on when the cathode compartment gets to around 9.5% NaOH by wt.

[Edited on 20-9-2020 by mysteriusbhoice] |

I want to ask you, have you ever tried the Na-CMC based membrane composition (which I proposed in other thread weeks ago), if yes - what are results ?

interesting to compare, since evidently you got very well versed in such things, good to know your opinion.

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

I havent found that ice pack containing CMC but I think it is sold on amazon so il try that when I can buy some but these times be rough for

international online shopping.

I will be trying Terephthalic acid-PVA membranes next which is easy for me to make now!

Just like the citrate it is probably also strong against acids but im hoping it also lasts longer.

|

|

|

papaya

National Hazard

Posts: 615

Registered: 4-4-2013

Member Is Offline

Mood: reactive

|

|

Where I live it's sold as a wallpaper adhesive (dry form almost like sawdust), used in renovation etc. Very cheap stuff, can always be found in stores

where things like paint plaster etc is sold. But anyway, thanks for reply!

[Edited on 20-9-2020 by papaya]

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2171

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

Na-CMC is going to be problematic outside of a solution that is closer to neutral.

Sodium Hydroxide is pretty aggressive towards cellulose.

Acids can degrade it as well.

Since it is modified cellulose it may hold up ok but I would not bet on it.

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

about removing NaOH from the reactor I can probably hook up a reservoir of water and a pump and also some aquarium tubes with a tap at the bottom

which can be opened after every few hours to replenish the electrolyte.

or I could also just do that manually but overall id rather not open the cell XD because obvious reasons usually the chlorine released while opening

is........ bad

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2171

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

You may want to use something a bit sturdier than aquarium tubing.

I tend to use HDPE ice maker tubing.

It is less flexible than the the clear pvc but it handles vacuum.

You could put a suction tube and an addition tube in through the lid.

Suction off the hydroxide and add water in measured amounts.

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

would aquarium pumps be fine handling the highly caustic NaOH solution though??

my other idea is to simply use the static head of the water by raising the cell and installing a bottom tap with a valve or plug.

btw borate membranes are pretty robust with boric acid additive in anode chamber which the acid form can crosslink PVA and hence stays in the anode

chamber dissolved.

I had one membrane run for 2 days with only a minor tear when it failed at the bottom due to mechanical stress when I manually drain the fluid in the

cathode side alone every cycle of dumping the contents of NaOH.

[Edited on 21-9-2020 by mysteriusbhoice]

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2171

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

You would probably be better served with a siphon type arrangement.

You can modify an aquarium pump to act as a vacuum.

The intermediate vessel can then be emptied without impacting the cell.

|

|

|

| Pages:

1

2 |