Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

What does it take to make liquid oxygen from air using compression?

This has been bouncing about it my head for a while. What sort of pressures and equipment would be necessary to make small amounts of liquid oxygen,

using a compressor? I tried doing the calculations but I kinda lost myself several times and just got garbage. I'm more of a practically oriented

person anyways...

So I've got the basics down. Compress, cool down, decompress. Preferably decompress via work, e.g. force it to drive a load of some sort, I understand

this converts a significant amount of energy that would otherwise be used to evaporate more gas. I suppose keeping the air meticulously dry is

valuable too. Waste of cold to make a bunch of water ice.

Is it doable with "normal" compressors? I.e. <20 Bar, if combined with non exotic temperatures, say >-25°C? If not, what might be the minimum

pressure necessary to liquify a useful amount?

This is largely hypothetical and out of pure interest, so no need to feel compelled to call it stupid and unrealistic. If it's within the realm of

possible though, itd be pretty awesome to give it a try, successfully or not. This is mostly born out of my stubborn cheapskating to not what to buy

oxygen to fuel my torches haha.

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

It's called the Linde process, and I believe there is at least one SM member who has managed to do this. Should turn up in a search.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

Wow. This really seems within the realm of doable. The linde process, using only a nozzle for the "work"-part is dead simple. Since it is continuously

operated it also seems to me like pressure and power does not necessarily matter. Cold will accumulate regardless, and whether you reach actual

liquefaction will really only depend on how well insulated the condensation chamber is, and perhaps some efficiency. The wiki article has examples

like 5-50 bar, and 10°c cooling baths. That's not any sort of extreme at all.

So perhaps using a refrigerator compressor and just letting it feed itself in a loop is all that's needed. Hmmm.

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Except that more is better. Bigger delta P means bigger delta T.

More power means more ability to overcome thermal losses.

If I were doing this I'd definitely put both a dryer and a CO2 scrubber on the inlet, and recirculate uncondensed gas back to the inlet so the

dryer/scrubber dont have to work so hard.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Have a look at this page:

http://homemadeliquidnitrogen.com/

It do does get rather bulky, complex and technically demanding, while the conceptual idea behind the process is quite simple and straightforward. Also

if one starts from liquid air, then a fractional distillation/separation stage has to be included into the system to separate the nitrogen from the

liquid air. Luckily nitrogen boils at lower temperature (77K) compared to oxygen (90K). So leaving a batch of liquified air to boil away in a

controlled manner should yield an oxygen enriched liquid phase. There shall be considerable losses at this stage, I presume....

One does need quite a bit of equipment and machining ability to bring it all together.

Liquid oxygen is not to be underestimated, it is a dangerous beast that can form powerful explosive mixtures with anything that is able to react with

oxygen. So keeping the system free of organic impurities like oil or other combustible materials is of utmost importance. That also goes for the

compressor. It must be an oil free system.

One might also pursue the following path to liquify air or oxygen via a cryocooler system:

https://www.youtube.com/watch?v=7PWESWqhD8s

Does not really seem less complex than the first approach though...

The active part of the system is elegantly compact, but the periphery tends to become complex and bulky as always.

[Edited on 13-8-2020 by markx]

Exact science is a figment of imagination.......

|

|

|

Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

Quote: Originally posted by Twospoons  |

Except that more is better. Bigger delta P means bigger delta T.

More power means more ability to overcome thermal losses.

If I were doing this I'd definitely put both a dryer and a CO2 scrubber on the inlet, and recirculate uncondensed gas back to the inlet so the

dryer/scrubber dont have to work so hard. |

Yes, of course. I just meant that there is no "hard treshold" for achieving liquefaction, e.g. it doesn't have to be a minimum drop of 80 bar or

nothing happens. In my experience that usually means something is more practically possible, and if it doesn't work the first attempt you can refine

the design in iterations, while you're learning.

Dryer, definitely, but why is a CO2 scrubber important? You think it might clog the system if it turns solid?

Quote: Originally posted by markx  | Have a look at this page:

http://homemadeliquidnitrogen.com/

It do does get rather bulky, complex and technically demanding, while the conceptual idea behind the process is quite simple and straightforward. Also

if one starts from liquid air, then a fractional distillation/separation stage has to be included into the system to separate the nitrogen from the

liquid air. Luckily nitrogen boils at lower temperature (77K) compared to oxygen (90K). So leaving a batch of liquified air to boil away in a

controlled manner should yield an oxygen enriched liquid phase. There shall be considerable losses at this stage, I presume....

One does need quite a bit of equipment and machining ability to bring it all together.

Liquid oxygen is not to be underestimated, it is a dangerous beast that can form powerful explosive mixtures with anything that is able to react with

oxygen. So keeping the system free of organic impurities like oil or other combustible materials is of utmost importance. That also goes for the

compressor. It must be an oil free system.

One might also pursue the following path to liquify air or oxygen via a cryocooler system:

https://www.youtube.com/watch?v=7PWESWqhD8s

Does not really seem less complex than the first approach though...

The active part of the system is elegantly compact, but the periphery tends to become complex and bulky as always.

[Edited on 13-8-2020 by markx] |

Oh, cool, thanks. I'll definitely have a look at that.

Yes, I've gathered that liquid nitrogen actually can be quite a hazard due to it collecting and liquefying O2 from atmospheric air, which remains for

a bit after all the nitrogen has disappeared. This can of course spell disaster if someone was keeping it something extremely combustible and with a

high surface area, like maybe styrofoam.

Shit, yeah that's true. An oil free compressor complicates things a great deal. They're either expensive, or tiny. Though a meticulously designed oil

mist separator should be good enough. No liquid oxygen should ever be present at the compressor right? That, combined with treating all parts of it as

potential bombs.

Well, chemistry and physics may not be my strongest competence, but I'm a pretty damn good mechatronics engineer and a decent machinist with access to

a lots of machining equipment, so that part shouldn't be a big issue...

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Separating oil mist can be quite complicated to be honest. Like keeping volatile stuff and water vapour out of a vacuum pump....no matter how hard one

tries, it always finds a way to penetrate into the pump sooner or later. So the liquid O2 really does not need to reach the oil in the compressor. It

usually goes the other way round: the oil creeps out and reaches parts of the system that house the dangerous liquid.

I've found regular water filters (with thread wound elements) to be quite effective against catching oil mist at compressor tank outputs....not

perfect, but good enough for acceptable quality paint and clearcoat jobs.

Exact science is a figment of imagination.......

|

|

|

Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

Wouldn't oil absorbent, the granular stuff used for oil spills, work quite well? Just a canister stuffed with it. Probably use a HEPA filter as well

to avoid dragging particulate from it.

Edit: Actually, I see a very optimal solution here. Calcium Oxide should provide everything. It scrubs CO2, binds water and it should also adsorb oils

very efficiently as well. Right?

Otherwise I do have an automotive oil mist separator unit, but it might be a little too heavy duty and introduce a bit too much heat into the system.

It's 100-200 ish watts. Works via centrifugal force and an absorbent mat. Used for removing oil in pneumatic systems.

[Edited on 13-8-2020 by Junk_Enginerd]

[Edited on 14-8-2020 by Junk_Enginerd]

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by markx  | Also if one starts from liquid air, then a fractional distillation/separation stage has to be included into the system to separate the nitrogen from

the liquid air. Luckily nitrogen boils at lower temperature (77K) compared to oxygen (90K). So leaving a batch of liquified air to boil away in a

controlled manner should yield an oxygen enriched liquid phase. There shall be considerable losses at this stage, I presume....

One does need quite a bit of equipment and machining ability to bring it all together.

|

I've visited a huuuge German factory bunker around 300 m long, two stories high and a roof all of it inside a quarry based on that same principle

(liquify everything, evaporate nitrogen).

It's purpose was to produce liquid oxygen for the V2 rockets. By the size of each individual emplacement for compressors and tanks it would have been

an interesting place for sure. And noisy !

I found all kind of interesting data translated German data on the evaporation rate of O2, the inevitable losses and the other gasses that could be

separated in that factory.

The idea sounds fun and doable for a hobbyist.

The spirit of adventure was upon me. Having nitric acid and copper, I had only to learn what the words 'act upon' meant. - Ira Remsen

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Quote: Originally posted by Junk_Enginerd  | W

Edit: Actually, I see a very optimal solution here. Calcium Oxide should provide everything. It scrubs CO2, binds water and it should also adsorb oils

very efficiently as well.

[Edited on 14-8-2020 by Junk_Enginerd] |

Have you got a way of stopping it becoming a solid lump of concrete?

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

I guess one could either try to make prills or something similar, or perhaps letting something "carry" the calcium oxide so it cannot form a solid

mass. Silica gel, maybe.

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

"Is it doable with "normal" compressors? I.e. <20 Bar, if combined with non exotic temperatures, say >-25°C?"

No.

You need it a lot colder : −118.6 °C

https://en.wikipedia.org/wiki/Critical_point_(thermodynamics)

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

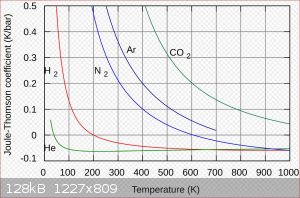

The Linde process uses regenerative cooling, so you dont need -118C . What is important is the Joule-Thompson coefficient, which determines whether the temperature will rise or fall as the gas expands. Fortunately, air will cool when

expanding at room temperature.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

wg48temp9

National Hazard

Posts: 784

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

The graph below shows the JT coefficient for some gases. From the graph nitrogen when expanding from 100bar at 300K decreases about 20K.

So to utilise that 20K temperature drop to get down to 77K (-196C boiling point of liquid nitrogen at 1bar) to you need heat exchange. That can done

but its not easy.

From Wiki

A JT cooler for a small IR detector. The heat exchange is a spiral of copper capillary tube that is fined or coiled.

Could a JT cooler be constructed in a similar manner from several meters refrigerator capillary tubing and would it be sufficiently efficient?

Edit to put decimal point in the correct place.

[Edited on 8/16/2020 by wg48temp9]

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Twospoons  | | The Linde process uses regenerative cooling, so you dont need -118C . What is important is the Joule-Thompson coefficient, which determines whether the temperature will rise or fall as the gas expands. Fortunately, air will cool when

expanding at room temperature. |

It's not important how you get there.

The critical temp of oxygen does not meet the OP's criterion of "non exotic temperatures", does it?

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by wg48temp9  | The graph below shows the JT coefficient for some gases. From the graph nitrogen when expanding from 100bar at 300K only decreases about 2K.

So to utilise that 2K temperature drop to get down to 77K (-196C boiling point of liquid nitrogen at 1bar) to you need a very efficent and low

friction heat exchange. That can done but its not easy.

From Wiki

A JT cooler for a small IR detector. The heat exchange is a spiral of copper capillary tube that is fined or coiled.

Could a JT cooler be constructed in a similar manner from several meters refrigerator capillary tubing and would it be sufficiently efficient?

|

I think you have misplaced the decimal point. The temperature drop associated with a 100 bar drop would be about 20K

Still bad, but not as bas as 2K.

|

|

|

wg48temp9

National Hazard

Posts: 784

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Quote: Originally posted by unionised  | Quote: Originally posted by wg48temp9  | The graph below shows the JT coefficient for some gases. From the graph nitrogen when expanding from 100bar at 300K only decreases about 2K.

|

I think you have misplaced the decimal point. The temperature drop associated with a 100 bar drop would be about 20K

Still bad, but not as bas as 2K. |

Oops, Yes your correct, I am pleased somebody is awake. 20k drop is probably much more achievable and if dry ice was used to precool the nitrogen

that would increase to 50K. I will edit my post.

Of cause a 100bar compressor is still needed they cost about £200 on ebay

Ps: below is a link to a home built 300 bar compressor. 300 bar gives about a JT temperature drop of 60K for nitrogen.

[Edited on 8/16/2020 by wg48temp9]

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

I worry that simple maths is going to get someone killed.

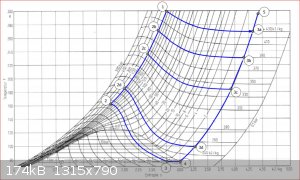

That graph is valid for atmospheric pressure. At high pressure and cryogenic temperatures the picture is different. If you look at the TS diagram here from the wikipedia page... The liquefaction curve used as an example in the text has two points crossing 130K; nitrogen at 130K expanding

from a pressure of 350bar produces the same yield as it does expanding from a pressure of 75bar.

The reason is that around 200bar, perhaps slightly less, there is an inversion point. The slope of the graph is the JT coefficient. The heat

produced when the nitrogen expands from 350bar to 200bar is balanced by the cooling produced by it expanding from 200bar to 75bar.

So the extra effort in compressing from 75bar to 350bar isn't just dangerous, it's wasted.

The curve is fairly shallow above 100bar, and the less well designed the liquefier is the lower the operating temperature will be, and the less room

it will have inside the inversion curve. So it may be 200bar is too high.

|

|

|

wg48temp9

National Hazard

Posts: 784

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Below is is a T-s graph for nitrogen from https://arxiv.org/ftp/arxiv/papers/1501/1501.07392.pdf

The left vertical blue curve is the constant 200bar curve and the right vertical curve is the one bar constant pressure curve. The horizontal curves

represents the expansion from 200bar to one bar starting at various temeperatures

Marvin@ is correct as the JT inversion condition is approached the JT coefficient having increased then falls to zero and past the the inversion point

becomes negative.

Examining the 2-3-4 curve has a TJ drop in temperature of about 85K for 200 bar and there is almost no increase at 300bar.

If I am reading the graph correctly the good news is that at only 50bar the TJ temperature drop is still about 60K.

I suspect the difficulty must be in constructing a sufficiently efficient heat exchange.

CAUTION: As Marvin suggests high pressures are potentially dangerous make certain any experiments are safe.

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

I seem to recall hearing somewhere that the heat exchanger in Linde's patent was on the order of 100m long.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Texium

|

Thread Moved

29-11-2023 at 13:35 |