ScienceBum

Harmless

Posts: 22

Registered: 15-9-2014

Location: Florida/California/Arizona

Member Is Offline

Mood: decoherenced

|

|

Basic Copper Carbonate - a Copper Series

Hi all,

I've been fairly interested in doing a series on copper compounds and complexes for a while now(my first attempt at precipitating copper metal failed

initially). So I thought I'd revisit this and try to post my experiments with proper documentation, and for the first lab I decided on basic copper

carbonate.

There are a wide variety of copper compounds that can be made through a number of different ways. Many of them can be synthesized from extremely easy

to obtain chemicals, and basic copper carbonate is one of the easiest to make from off the shelf products. This makes it a good starting point.

Making Basic Copper Carbonate

Step 1: The Ingredients

We really only need 3 chemicals to make this compound. Water (also known as H2O), Copper (II) Sulfate (also known as root killer), and Sodium

Bicarbonate (also known as that thing my mom puts in the fridge a lot for some reason).

All of these were purchased at local stores(the root killer was bought at my hardware store, and the water and bicarb at my supermarket).

Step 2: The Stoichiometry

There are two very simple routes we can take to synthesizing our compound. We can either react an aqueous solution of Copper (II) Sulfate with Sodium

Carbonate, or Sodium Bicarbonate. In my case I chose to go the bicarbonate route since it's just not necessary adding an extra step for this reaction

in making Sodium Carbonate. The balanced reaction is:

2 CuSO4 + 4 NaHCO3 → Cu2(OH)2CO3 + 2 Na2SO4 + 3 CO2 + H2O

And if you feel like doing your experiments in 10-gallon buckets because you've got a giant lab, you absolutely can do that. For me however, I chose a

much smaller .1 scale for my tiny glassware, which corresponds to the following:

49.9 g CuSO4(aq) + 33.56 g NaHCO3 → 12.35 g Cu2(OH)2CO3 + 13.2 g CO2 + 1.8 g H2O

Step 3: The Procedure

First we measure out about 50 grams of our Copper (II) Sulfate, and get it in about 200mL of water. In my case, my copper sulfate crystals are so

gigantic because I did a recrystallization from my root killer. Doing so is absolutely not necessary for this lab, and you can simply use the ground

up pellets from the root killer directly.

It'll take a while for everything to dissolve into solution. Simply keep it on the hot plate and stirring, eventually it will become clear. Note: it's

not necessary to use a hot plate, you can also simply just microwave the solution for a few seconds at a time to get the water near boiling and the

copper sulfate will dissolve. It's just a little bit stubborn. Make sure to turn off the heat afterwards.

Next, measure out 33.56 grams of Sodium Bicarbonate, and EXTREMELY SLOWLY and with fast stirring, and I cannot emphasize this enough EXTREMELY SLOWLY

NO REALLY YOU'RE GOING TOO FAST, begin adding the bicarbonate to the sulfate solution. Use no more than a teaspoon per addition until the bubbling

dies down.

We are producing CO2 gas very quickly, and it is so easy to become overconfident and add too much of the bicarbonate too fast. This will cause it to

bubble out of the container. In my case, all I had to work with was a small 250mL flask. For a .1 scale of this reaction, I would recommend a 1-liter

flask or beaker just to make it easier to add the bicarbonate. It took me about 30 minutes to add 33.56 grams slowly.

In the event of an overflow and spill, it is important not to panic. Simply wipe up the liquid with some paper towels, wipe off the exterior of the

reaction vessel, and put the paper towels in a waste container for disposal.

The most important step in any lab procedure is safety. Although the copper compounds we are working with are not very harmful, other chemicals and

copper compounds can be very toxic and must be handled with care. Again, slow addition of the bicarbonate and patience would have prevented this.

Once the addition is finished, let the mixture continue stirring and reacting for a good half hour or so, and the CO2 bubble production should wind

down near the end. You should wind up with a blue-ish green precipitate that looks something like this:

Let the precipitate settle to the bottom of the flask, then wait until the bubbling dies down completely. The liquid at the top layer of the flask

should be very nearly clear and colorless once it's completely reacted.

Finally, decant off the top layer of liquid, and filter out the blue-green precipitate. Use a small amount of water to wash out the flask and filter

everything through. You should wind up with a greenish-blue wet paste. This can be left to dry in open air for a day or two until it becomes brittle

enough to powderize (I was not able to take a picture of these final steps since my phone decided then would be a good time to form a labor union and

go on strike against me ;_; ).

Step 4: So What Happened?

We are essentially performing an acid-base reaction, where the Copper (II) Sulfate solution (which is acidic) reacts with the Sodium Bicarbonate,

which is a mild base. In common acid-base reactions, typical byproducts will be CO2 gas and water. If you have these byproducts in a reaction, that

can be a fairly good indicator of an acid-base reaction. By adding the base we lower the acidity of the solution, precipitating our desired product.

Instead of creating a neutral compound however, our precipitate is actually a base, characterized by the addition of an OH- (hydroxide) molecule

attached to the compound, as well as the CO3- (carbonate) molecule. In this form, our final copper salt can be reacted fairly easily with a wide

variety of different chemicals to produce many different compounds in different oxidation states.

Note: There are different types and definitions of the terms 'acid' and 'base'. In the case of the classic acid-base reactions where CO2 and water are

produced, it's usually assumed that the acid in question is an H+ ion donator, and the base is an OH- recipient for the H+ ion. These are known as

Arrhenius acids and bases.

Step 5: In Conclusion

This is a fun little experiment which teaches some basic chemistry concepts and can be done with kids under adult supervision and with proper safety

gear. Clean up is fairly easy and all solid waste is tossed, all liquid waste can generally be safely poured down the drain with copious amounts of

water depending on your local sewage waste disposal laws and guidelines.

If you feel like I missed something important about this procedure or got something wrong, please let me know and I'll make an update. Thanks for

reading

|

|

|

Syn the Sizer

National Hazard

Posts: 600

Registered: 12-11-2019

Location: Canada

Member Is Offline

|

|

Nice, I have been doing some copper chemistry lately. I bought a pail of CuSO4, it was a powder and wanted to recrystallize to purify it.

There was some insoluble compound left in the filter so I mixed it with HCl, filtered out what didn't dissolve in HCl then added

Na2CO3, this helped to remove any water soluble impurities. I then re-acidified with HCl and made copper chloride. I look

forward to your future copper posts.

|

|

|

Sulaiman

International Hazard

Posts: 3695

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

Have a look at the SM Copper Carnival

http://www.sciencemadness.org/talk/viewthread.php?tid=62608

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Syn the Sizer

National Hazard

Posts: 600

Registered: 12-11-2019

Location: Canada

Member Is Offline

|

|

Nice, that would have been a fun contest, I wish I was on the forum then.

|

|

|

ScienceBum

Harmless

Posts: 22

Registered: 15-9-2014

Location: Florida/California/Arizona

Member Is Offline

Mood: decoherenced

|

|

After about a day of open-air drying this is what it'll look like (the shade of blue/green will be a little different since my lighting and camera are

awful):

You might find white specs and discoloration on the powder. This is likely either hydroxide decomposition or left over bicarbonate. There are some

ways to avoid this, but in general it should be fine for most copper complex demonstrations.

|

|

|

Big D

Harmless

Posts: 1

Registered: 2-5-2020

Member Is Offline

|

|

Hi - I believe your experiment produces the basic copper carbonate known in the mineral world as malachite. There is an even prettier mineral called

azurite, which is also a basic copper carbonate, but which has a higher percent of the CuCO3 along with the Cu(OH)2. This mineral is often found with

malachite and has a tendency to change to malachite over time (which is a shame, since it is a very pretty blue).

Do you or any other chemists know how to make the azurite basic copper carbonate (blue, not blue-green)? The two compounds are nearly identical, but

differ in color.

|

|

|

QuicksilverHg

Harmless

Posts: 6

Registered: 16-4-2020

Member Is Offline

|

|

Well done, Sciencebum! BigD is correct; the pigment ultramarine blue was renowned by Renaissance artists for its beauty, though many such works have

turned a rather dull black copper (II) oxide. I produced some basic copper carbonate not long ago, rather a sticky product, much like copper

hydroxide! Included are photos azurite and of the beautiful verdigris-colored pigment, I dried the material in a 'double boiler' essentially a steam

bath produced by a pyrex bowl over a vessel of boiling water. Then I sifted the product to a medium fine consistency.

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

I popped in to give exactly the same suggestion as Sulaiman. It was a great competition. I have downloaded all the entries as a resource to use and

dip into them on an occasional basis.

It has been far too long since the last competition/challenge. I have been sitting on one for a while. As soon as I am healthy enough to stand and

work in the lab, I will put it up. Something that everyone can join in with irrespective of their level of expertise.

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Sorry, all I have is a method for pure malachite. The direct precipitation route is tricky for a number of reasons. First of all it tends to produce a

random mixture of azurite and malachite, and the fine precipitate is hard to work with if you're trying to produce any noticeable quantity.

It might be possible to optimize the process for azurite, but the reaction seems to be fairly unpredictable.

A better product can be made by making a soluble carbonate/amine complex and then boil off the ammonia. This precipitates the carbonate more slowly,

allowing it to produce larger particles of pure malachite.

A solution of ammonia and sodium carbonate can even be used to dissolve copper metal, using atmospheric oxygen as the oxidizer.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Azurite can be made by slowly adding a copper sulfate solution to a solution of carbonate. The order of addition seems to be key here, my guess is

that azurite needs basic conditions to form.

Or you could do it via electrolysis of a saturated bicarbonate solution with a copper anode. Electrolyse until black copper oxide starts forming on

the anode and filter the solution. Leave the solution until crystals start to form.

[Edited on 5-5-2020 by Tsjerk]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Tsjerk  | 1. Azurite can be made by slowly adding a copper sulfate solution to a solution of carbonate. The order of addition seems to be key here, my guess is

that azurite needs basic conditions to form.

2. Or you could do it via electrolysis of a saturated bicarbonate solution with a copper anode. Electrolyse until black copper oxide starts forming on

the anode and filter the solution. Leave the solution until crystals start to form.

[Edited on 5-5-2020 by Tsjerk] |

Azurite, as a pigment, is also known as Blue Verditer.

1. Yes, Azurite needs alkaline conditions but whether the order of addition under high agitation really matters I don't know.

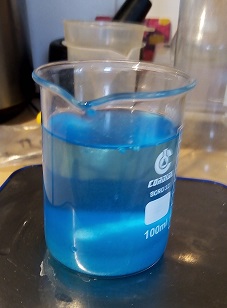

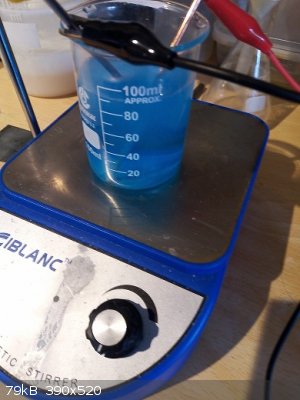

I mixed some 6 g Na2CO3 (anh.) in 100 g DIW, then with high stirring I added drop by drop sat. CuSO4, until no more

precipitate formed and the supernatant was light blue:

This looks suitably blue for Azurite.

I filtered off the precipitate and washed it:

Finally washed with MeOH and dried, I weighed 0.33 g of product, which is very low compared to the stoichio amount of 9.75 g.

I checked the supernatant and it was strongly alkaline and bubbled strongly on addition of HCl.

I'll determine the CO32- of the product tomorrow.

2. You're referring to the method described here:

https://youtu.be/UsaANlJo_OU

I've tried that 3 times no, w/o success, despite following 'AScannerClearly' guidelines.

Someone in the comment section of that UToob suggested the product might be Chalconatronite

(Na2Cu(CO3)2.3H2O). Chalconatronite is slightly soluble, so formation of crystals from a mother liquor is

quite probable.

Another method using Cu(NO3)2 and CaCO3 is described here:

https://youtu.be/Y9uZpZBy76w

[Edited on 4-2-2023 by blogfast25]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Here's my ad hoc 'gazometer', 25 mL capacity:

Samples were weighed to 1 mg precision (typically 0.1 g). Gas readings were adjusted for hydrostatic pressure and temperature.

Reaction is banal:

Carbonate(s) + HCl(aq) ---> CO2(g) + Chloride(aq)

Using two samples of basic copper carbonate described above I obtained values of CO2 w% of 14.2 and 14.7.

This doesn't really match the CO2 contents of either Azurite or Malachite, of resp. 25 w% and 19.9 w%.

But during development of the gazometer I repeatedly measured the values for NaHCO3 and Na2CO3 and found systematic

under estimation of 4 - 5 w%.

Adding that error to the values for the basic copper carbonate would then put its value in the 20 w% range, consistent with

Malachite, not Azurite.

And after drying the basic carbonate looked more like the blue green (green blue?) of Malachite than the azure blue of Azurite.

&&&&&&&&&&&&&&&&&&&&&

Next attempt will be to add either CO2 or CO32- to a solution of cuprate

(Cu(OH)42-.

[Edited on 10-2-2023 by blogfast25]

|

|

|

maldi-tof

Harmless

Posts: 39

Registered: 3-4-2019

Member Is Offline

|

|

Hi all,

My experience says that what you need to control in order to get azurite or malachite is the temperature of the reaction.

What I do not recall is what needs to be at higher temperature and which one at lower temperature.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by maldi-tof  |

My experience says that what you need to control in order to get azurite or malachite is the temperature of the reaction.

What I do not recall is what needs to be at higher temperature and which one at lower temperature. |

The video I linked to by "TheAlchemicalArts" claims that for Azurite the temperature should be less than 12 C. This was for the chalk + copper nitrate

process (the 'English process').

What process did you use?

My latest attempt with CuCl2 at about 18 C failed. I got Malachite (again!)

[Edited on 11-2-2023 by blogfast25]

|

|

|

Amos

International Hazard

Posts: 1406

Registered: 25-3-2014

Location: Yes

Member Is Offline

Mood: No

|

|

Or you got copper oxychloride(basic copper chloride) with some carbonate inclusion! IIRC the first thing that should form when basifying the chloride

will always be copper oxychloride, but at high PH additional base will begin to leach chloride out. You might want to start from a different

water-soluble salt.

[Edited on 2-11-2023 by Amos]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

The recommended salt is copper nitrate but really I don't see what difference the anion makes. And I don't have any copper nitrate right now.

The stoichiometry for Azurite from chalk is:

2 CaCO3 + 3 Cu2+ + 2 OH- --> Cu3(CO3)2(OH)2 + 2 Ca2+

Tonight another attempt with CuCl2 but at lower temperature.

All these basic double salts (carbonate, chloride, sulfate...) revert back to Cu(OH)2 when treated with strong alkali.

[Edited on 11-2-2023 by blogfast25]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

So I tried 'TheAlchemicalArts' method as shown in his long winded video (above), minus some of the obvious BS designed to make TAA look smart and...

erm... alchemical!

I used 6 g of copper nitrate trihydrate (which arrived a few days aqo) and 2.5 g of calcium carbonate, making a molar ratio of 1:1, in 80 ml of DIW.

I kept the temperature strenuously below 12 C, stirring every hour or so, for about 2 days.

All I got was more Malachite, while the supernatant was colourless.

The Azurite Gods do not favour me...

[Edited on 19-2-2023 by blogfast25]

|

|

|