smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

Toluene --> Sodium Tosylate --> p-cresol

I needed a simple phenol to run some alkylation experiments. Therefore, I decided to make p-cresol. To do this, I synthesized sodium tosylate from

toluene and sulfuric acid. The p-cresol was subsequently prepared by alkali fusion of the sodium tosylate.

The procedure for sodium tosylate was taken for vogel. The vogel procedure is complete bullshit, don't even read it, it is clear that whoever wrote

it had never actually performed the synthesis. The p-cresol procedure is from orgsyn, it is a good procedure.

Sodium Tosylate

A mixture of 70 mL conc. H2SO4 and 140 mL of toluene was refluxed for one day under vigorous stirring in a 500 mL flask. After reflux, the mixture

had become nearly homogeneous with only a very small amount of unreacted toluene (say 5 mL). The solution was allowed to cool, causing it to solidify

in the flask as wet crystals. The crystals were transfered to a 1L beaker by washing out the flask with 3x100mL water (some exotherm upon addition of

water, but manageable without ice-cooling). This aqueous solution of tosic acid was diluted to 500 mL with water and then partially neutralized by

the careful addition of 60g NaHCO3 under vigorous stirring. Next, 200g of NaCl was added and the solution was boiled until completely saturated with

salt. The mixture was quickly vac filtered through a buchner funnel (preheated by filtering boiling water moments before filtration of this product

*switch receiving flasks*). The filtrate was allowed to cool on an ice bath for a few hours (btw: the filter cake was predominantly undissolved

NaCl). The thick crystalline mass was broken and then separated from the supernatant solution via vac filtration, with the filtrate used to complete

the transfer. The filter cake was sucked fairly dry, washed with the minimum amount of conc. brine to just wet all the product (~50-100 mL) and then

sucked as dry as was reasonably possible. The crystals were added to ~425 mL of water and the mixture was bought to a boil under vigorous stirring.

NaCl was added portionwise until the solution had just saturated; at this point another 25 mL of water was added. The mixture was allowed to

crystallize at room temp for ~12 h and then at ~0c (outside on winter day) for another 12h. The crystals were collected via vac filtration and washed

as previously with conc. brine, sucked as dry as possible and then washed with 50mL of cold denat. ethanol (sodium tosylate is very sparingly soluble

in cold ethanol). After being sucked dry, the crystals were further dried in a warm place, and finally in the oven for a few hours at 200c (this is

almost unnecessary, they are quite dry after standing on a radiator). In total 124.9g (49% yield) of sodium tosylate was recovered as a colorless

crystalline powder.

The product melted at a very high temp ~300c. When a spatula-full of sodium tosylate was placed in a bunsen burner flame, strong direct heating was

required to get the Na Tosylate to burn, even then, when removed from the flame it would eventually self extinguish.

I ran this again on double the scale; I only recovered 200g, because of mechanical loses (over-filled buchner) and because my final product got rained

on while recrystallizing (I thought it was going to snow, there were apparently some holes from corrosion in the aluminum foil covering the flask).

That being said I made some changes. First, after reflux instead of shutting everything down, I set-up for simple distillation and removed the

toluene (without doing this the unreacted toluene evaporates during the neutralization, stinking up the lab). Also, I skipped the ethanol wash, it is

an unnecessary step and useless if you just leave it on the pump to dry. I would also recommend to anyone trying to repeat this to use more sulfuric

acid to try to get all the toluene to react (say 10% more, remember to use 10% more bicarbonate during neutralization).

Cooled after reflux, showing soldified toluenesulfonic acid.

Final product after recrystallization.

Product from second batch on double scale

p-cresol

Setup

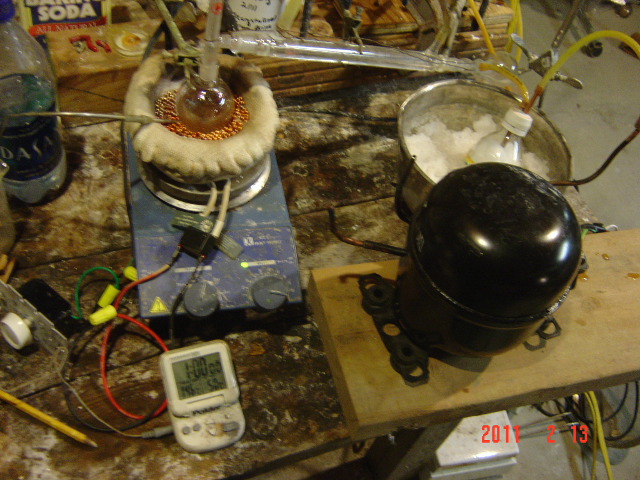

I did this in a silver plated copper basin ($3 thrift store  ). I set this over

a bunsen burner with clamps, and then used aluminum foil to provide a "skirt" along the perimeter of the basin to help keep the heat in and stop the

sides from cooling (causing caustic to cake up, unmelted). The thermometer was protected by inserting it into a piece of copper tubing crimped at the

end by a vice; the middle portion of the thermometer was further protected (from splattering base) with aluminum foil. The spoon seen in the pictures

below is totally unnecessary. I stopped using it early on; the thermometer is more than sufficient to stir the reaction mixture. ). I set this over

a bunsen burner with clamps, and then used aluminum foil to provide a "skirt" along the perimeter of the basin to help keep the heat in and stop the

sides from cooling (causing caustic to cake up, unmelted). The thermometer was protected by inserting it into a piece of copper tubing crimped at the

end by a vice; the middle portion of the thermometer was further protected (from splattering base) with aluminum foil. The spoon seen in the pictures

below is totally unnecessary. I stopped using it early on; the thermometer is more than sufficient to stir the reaction mixture.

Procedure

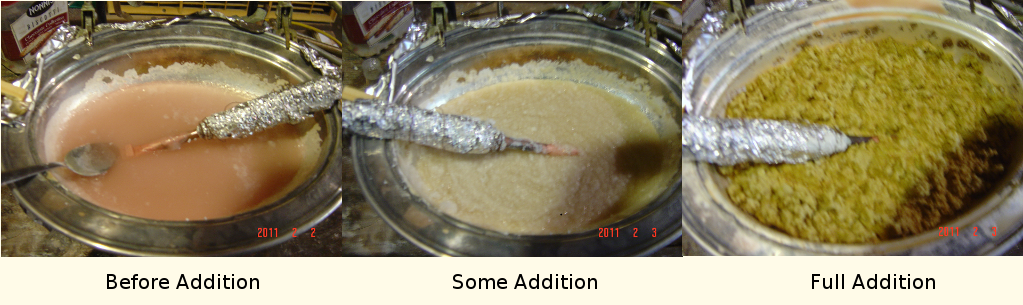

A mixture of 80g of KOH and 200g of NaOH was melted in the basin (heated by bunsen burner). The burner flame was adjusted to maintain a steady 230c

and 120g of sodium tosylate was added in portions while slowly increasing the temperature of the melt. The melt was pretty vigorously stirred with

the thermometer, no spattering was noted during the addition. As the addition continued the melt progressively got thicker and thicker with

undissolved crap, after addition (I didn't time it) the temp of the melt was raised to 330c. At this point the melt was not homogeneous, but I

freaked out because the melt had darkened somewhat, so I (prematurely) poured the melt onto a big cast iron lid.

After solidifying the melt was scraped off of the lid with a SS spoon (MASSIVE PITA), and dissolved into 1.5 L of water (watch the exotherm, do this

in portions). The solution was allowed to cool to room temperature (don't worry if every last bit of the melt hasn't dissolved) and 180 mL of conc.

sulfuric acid diluted to 600 mL with cold water was added portionwise (exotherm). Then small portions of conc. H2SO4 were added until a persistent

(not fleeting, must be persistent) smell of SO2 is noted. This mixture was transfered into a 3L flask and diluted to ~2300mL. The p-cresol was

separated by steam distillation, it came over as a yellow green oil. The distillation was tracked by treating portions of the distillate with bromine

water, really though this is too sensitive. The distillation is done when the distillate is no longer milky looking (no longer a suspension). The

distillate (ca 1.5L) was saturated with NaCl and the p-cresol was was separated from the brine. The brine was extracted with 1x25 mL of toluene (just

to pick up whatever cresol was emulsified). The extract was combined with the oily cresol and then vac distilled. Once all the toluene had been

removed, the apparatus was setup for short-path vac distillation, an intermediate fraction was collected (toluene to 112c, < 1g) and finally the

product was collected at 112-114c (don't know pressure). The product crystallized on cooling. In total 12.5g (v. low yield) of p-cresol was

recovered as a colorless, peculiar (mostly unpleasant) smelling solid. The product was found to be one spot (though some "ghosting" near baseline) by

TLC (neat DCM).

What I did wrong/what I would change

The sodium tosylate is only sparingly soluble in the reaction melt, the orgsyn procedure has been optimized to minimize the amount of KOH used.

Sodium tosylate is way less soluble in NaOH than KOH. As a consequence of this procedure it is hard to get all the sodium tosylate to dissolve. The

sodium tosylate must dissolve to react. I stopped the reaction way too early (because I wasn't keeping track of time). If in doubt this reaction

should be run too long. A little product lost to oxidation in the melt is acceptable when compared to having loads of unreacted starting material as

I did. When I was doing the reaction, I didn't have a great handle on the factors at play, so immediately when I saw some mild darkening I said OMG

I'm overcooking it and stopped the reaction. When I consider how tedious this workup is I REALLY regret this. When I do this again, I will do it in

a pure KOH melt (enough to make it the same volume as the melt in the orgsyn procedure), and I will absolutely under no circumstances stop the

reaction before with any undissolved solids present. That being said, if you follow the orgsyn procedure to the letter, I am sure it will work as

reported.

Also, this is a long procedure, I spaced everything out over the course of many many days. This was bad, I knew it, but free time was scarce. If you

can fit the whole procedure into a day (it would be 12h of work or more) go for it. If not, try to give yourself 8-9 hours to do everything through

the steam distillation and then you are at a good stopping point and can do the vacuum distillation at your leisure. Having cresol suspended in

strongly alkaline and fairly acidic solutions is going to decompose it over long periods.

One thing I underestimated is how rank the smell of p-cresol is. At first it is acceptable, but the problem is it is such a lingering smell.

Finally I ran into some difficulties with the vacuum distillation (my first in an amateur setting). At first I didn't grease the joints, this was

fine, for stripping toluene (at less <40c) but once product started coming over I noticed my joints started smoking! The cresol which had worked

its way into my joints through capillary action was decomposing in contact with air. Because of this I had to quickly shut everything down. I

greased the joints with "plumbers silicone grease" and this worked phenomenally. To compound this hiccup when I was disconnecting the vacuum hose at

the end of the distillation, shifted the apparatus causing a good amount of product to be sucked into my cold-trap.

Blurry setup (not showing aluminum foil skirt)

Progression of the reaction, don't make my mistake, no matter what only stop when melt is homogeneous!

Solidified semi-broken-up melt. What a pain in the ass

Toluene stripping

Collecting cresol via improvised short path distillation. It worked pretty well.

Product in receiving flask

Some product on a spatula

[Edited on 2-15-2011 by smuv]

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Great job with the pictures and the detailed synthesis report!

Your chosen method of sodium tosylate synthesis is an interesting alternative to the textbook preparation of p-TsOH from toluene and H2SO4 using a

Dean-Stark trap.

When no more water is collecting in the trap (all H2SO4 has reacted), one adds a small, carefully measured amount of water to the mix after cooling

which makes the p-TsOH crystallize from the excess toluene as the monohydrate. The byproduct o-TsOH does not form such a hydrate and stays in

solution.

The filtered crude p-TsOH*H2O is then purified by dissolving it in half its own weight of water and saturating the solution with HCl gas.

If your cresol has the correct melting point then you know that you've isolated the p-TsONa in sufficient purity.

I'm wondering, which step in this synthesis separated the isomers, and what is the principle behind it?

The next time you do the sulfonate + caustic melt, make a test run with small amounts and heat it properly hot and long. Do a rudimentary workup

(dissolve, acidify, add salt and separate phases) to see whether this has given a good-looking yield.

One little correction: you wrote that you saturated the steam distillate with sodium hydroxide. Surely you meant NaCl?

|

|

|

entropy51

Gone, but not forgotten

Posts: 1612

Registered: 30-5-2009

Member Is Offline

Mood: Fissile

|

|

Fantastic writeup, smuv.

I like your vacuum pump! Is that copper shot you're using for heat transfer in your heating mantle?

|

|

|

bahamuth

Hazard to Others

Posts: 384

Registered: 3-11-2009

Location: Norway

Member Is Offline

Mood: Under stimulated

|

|

Nice writeup.

Started the synthesis of p-cresol myself, but also wanted some anhydrous tosylic acid for other stuff so did it according to Vogel with a improvised

Dean Stark, worked well IIRC, do not know where I have my notes ATM though, so can not report any yields.

Got quite a lot of charring, which partially was removed by recrystallization from water saturating it with HCl gas, note that this is not something

to do on your kitchen bench as I did, figured that I would be able to contain the gas, which I did until I took the apparatus apart...

For the tosylic acid, it is still resting in the desiccator over KOH/CaCl2 as I found it extremely hygroscopic.

Like your way of solving the issue with a silver container for the fusion, and also now I have the incentive to finish the synthesis myself between

school and work..

Edit:

Apparently tosylic acid is not so hygroscopic as previously experienced, as I just transferred them to a suitable container.

Thinking it could very well have been residual HCl trapped in the semi large crystals making them melt in contact with air

[Edited on 15-2-2011 by bahamuth]

Any sufficiently advanced technology is indistinguishable from magic.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Nice going smuv and thanks for the write-up.

I also did an alkali fusion, using NaOH and disodium m-benzene disulfonate to get resorcinol. My fusion vessel was a 3.5" cast iron Lodge frying pan.

Since I needed a temperature of 310C and the mp of NaOH is 318C I just provided enough heat to keep the mix molten. I did measure it a few times

with a TC and it was right in the 300-330C range. I used a glass stirring rod to keep it mixed and was surprised that this was not severely attacked.

How did your thermometer make out in that molten KOH? I heated the melt for 1.5hrs. My original plan was for 2 hours but I got tired of standing so

quit early.

I will also provide a write-up when I have completed the synthesis and can report the yield and purity.

[Edited on 15-2-2011 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

Thanks everyone!

@GC The purification is a simple recrystallization, the ortho and meta sulfonates are much more soluble than the para species. On top of that, in

refluxing toluene/sulfuric acid the high temp strongly favors para formation. A better procedure than Vogel (which explains this part) can be found

in the book by Fieser in the forum library.

You are right about that error, I will edit it.

@Entropy, I don't know if they are copper (probably plated), but they are BB's for airguns. They work much better (and less mess) than sand. The

pump is from a wine cooler I found in the dump. I had to manually add a switch to energize the start-up coil of the pump to allow it to start (this

is probably why it was thrown away in the first place). For vac filtrations it is great, for distillations it is so-so. The pump is capable of lower

pressures than I was using it at, but at low pressures the vacuum pressure fluctuates a lot (the pump cannot maintain a consistent rpm, you can hear

it racing), so the tubing must be adjusted to allow a tiny leak to avoid this.

@bahamuth, I recommend that you go the route I did, without isolating the free acid. I did not notice charring (in fact I skipped the activated

charcoal step). The sodium tosylate synthesis is fun, pretty easy and provides nice looking crystals.

@Magpie, the thermometer came out fine, no change at all. The copper tubing was crimped well, no caustic was able to touch it. I look forward to

reading your writeup. Its great that you made both the benzene and SO3 starting materials for you synthesis.

[Edited on 2-15-2011 by smuv]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

This surprises me. I severely frosted one of my good high-temperature thermometers using it as a stirring rod for fused alkali. I'll have to go back

in my notebooks to find the conditions.

Not the benzene. I stopped making that years ago along with glacial acetic acid.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

Read the setup/look at the pictures, the thermometer is protected from the alkali by a copper tube crimped at one end.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by smuv  | | Read the setup/look at the pictures, the thermometer is protected from the alkali by a copper tube crimped at one end. |

Oops - sorry. I see that now.

I could not find anything in my notebooks but suspect it occured during my attempts to make electrochemical sodium about 5 years ago. The thermometer

case itself I marked "tip eroded by molten NaOH."

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

bfesser

Resident Wikipedian

Posts: 2114

Registered: 29-1-2008

Member Is Offline

Mood: No Mood

|

|

I'm planning on following either your synthesis, smuv, or an adaptation of Vogel's. I have a question, however. Why exactly does Vogel call for

thiophene-free toluene in the preparation of sodium p-toluenesulphonate? Would it hurt to use distilled hardware store grade toluene with the same

procedure?

|

|

|

benzylchloride1

Hazard to Others

Posts: 299

Registered: 16-3-2007

Member Is Offline

Mood: Pushing the envelope of synthetic chemistry in one's basement

|

|

Excellent work and write up. I ran this same synthesis about eight months ago. It takes a long time for the sodium p-toluene sulfonate to dissolve in

the NaOH/KOH melt. The lingering smell is horrible, my dad thought that the odor was reminiscent of burro dung. The procedure that I used was taken

word for word from Vogel's. I methylated the p-cresol that I obtained using methyl iodide and sodium methoxide as the base. I plan on doing a Birch

type reduction of the p-methyl anisole to make the diene which will then be isomerized to the conjugated diene which I plan on using the make a iron

tricarbonyl complex out of. I have seen a procedure for running a Birch type reduction of an aromatic system using sodium amalgam in Orgsynth. I

wonder if this would work for this substrate.

Amateur NMR spectroscopist

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I wonder why? Doesn't OrgSyn say it smells like a typical phenol. I don't find phenol unpleasant at all.

Good work, both of you. I will be back on the trail of fusions to make resorcinol when the weather cools off and I can get back in my lab.

Here's something I found interesting/relevant. Sorry I can't post it but only have it in PDF:

http://pubs.acs.org/doi/abs/10.1021/ie50517a056

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

@ Bfesser: Modern aromatics don't likely contain thiophene . This was brought up in another thread (thread), essentially processes has changed--aromatics are made from petroleum these days, not coal. Also, I used toluene right from the bottle

(hardware store).

@Magpie: p-cresol smells really bad. It does have a lingering smell too. I think I read somewhere (probably wiki) that it is in pig sweat and gives

its characteristic smell.

[Edited on 8-20-2011 by smuv]

"Titanium tetrachloride…You sly temptress." --Walter Bishop

|

|

|

MeSynth

Hazard to Others

Posts: 107

Registered: 29-7-2011

Member Is Offline

Mood: http://www.youtube.com/watch?v=5ZltqlVuDIo

|

|

Is it possible to synthesize any other isomers using sodium tosylate as the starting material? To the best of my memory there are two others. o and

another that I dont remember. let me check. the other is m.

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

No its not possible directly to form the other isomers from sodium p-tosylate.

Toluene should probably be purified as in Perrin's as even some lab grade toluenes give a dark colouration on mixing with concentrated sulfuric acid,

due to impurities. On a separate note, recrystallisation by gassing a concentrated aq. solution of TsOH with HCl is just plain nasty and should be

avoided. Vacuum filtration of the precipitate causes choking and rapid rusting in the vicinity, especially if using a ptfe diaphragm pump with no

traps. The method utilising a saturated aqueous solution of TsOH, and crashing out by adding three(?) volumes of conc. HCl is not particularly

pleasant for the same reasons. I also found that the collected precipitate rapidly liquified, even in a desiccator over CaCl2/NaOH. Over time, a oily

liquid appeared onthe inside of the desiccator, reminiscent of toluene, although no efforts were made to ascertain its identity.

|

|

|

MeSynth

Hazard to Others

Posts: 107

Registered: 29-7-2011

Member Is Offline

Mood: http://www.youtube.com/watch?v=5ZltqlVuDIo

|

|

This chemical p-cresol is the key component of stench in pig buisness.. and look how he made it with out a fume hood. hehe

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

| Quote: | | recrystallisation by gassing a concentrated aq. solution of TsOH with HCl is just plain nasty and should be avoided. |

If you let the reaction mixture cool (in the synth I posted), a lot of TsOH precpitates, to the point that the reaction mixture becomes a solid mass.

I am sure if I filtered this through fritted glass, I would get quite good yields of TsOH. After washing in the funnel (I would probably do conc.

HCl, then cold ether) I think this product would be pure enough for most purposes.

"Titanium tetrachloride…You sly temptress." --Walter Bishop

|

|

|

redox

Hazard to Others

Posts: 268

Registered: 22-2-2011

Location: The Land of Milk and Honey

Member Is Offline

Mood: Chalcogenetic

|

|

I performed this synthesis today, but I did it slightly different from Smuv.

I added 92 grams (1 mol) of toluene and 98 grams (1 mol) of sulfuric acid to a 250 mL round bottom flask.

By louf11 at 2011-08-21

Here you can see the reactants.

By louf11 at 2011-08-21

The RBF was connected to a dean-stark apparatus, condenser, claisen, and thermometer. The reactants were heated for approximately 3 hours and 45

minutes under vigorous magnetic stirring. The reflux was stopped when the calculated 18 mL of water had collected in the dean-stark trap. The trap had

to be drained after the first 12 mL due to the trap's being full.

By louf11 at 2011-08-21

Here is a nice picture of the toluene vapor pouring into the trap.

By the end of the reaction, the flask had turned greenish-black. I assume this is due to charring and dehydration of the toluene by the sulfuric acid,

however it may be due to impurities present in the toluene, as it was only hardware store grade.

By louf11 at 2011-08-21

The flask's contents were poured into a large beaker along with 600 mL of water. A large amount of calcium hydroxide (aquarium grade Kalkwasser mix)

was added to neutralize the acids and precipitate the calcium sulfate. Potassium carbonate solution was added to an endpoint, precipitating calcium

carbonate and leaving a solution of potassium tosylate. The beaker's contents were filtered through several filter papers, and the solution was left

to evaporate.

By louf11 at 2011-08-21

By louf11 at 2011-08-21

Here you can see the solution evaporating. Some crystals are visible on the bottom of the flask.

In a few days, when the solution evaporates down, I will weigh the crystals, perform a recrystallization, and determine percent yield.

The whole reaction was performed in a homemade fume-hood, under swift ventilation. Very little toluene vapor escaped, due to an effective friedrichs

condenser (that I bought from Dr. Bob, along with the Dean-Stark apparatus ). ).

[Edited on 22-8-2011 by redox]

[Edited on 22-8-2011 by redox]

[Edited on 22-8-2011 by redox]

[Edited on 22-8-2011 by redox]

[Edited on 22-8-2011 by redox]

My quite small but growing Youtube Channel: http://www.youtube.com/user/RealChemLabs

Newest video: Synthesis of Chloroform

The difference between chemists and chemical engineers: Chemists use test tubes, chemical engineers use buckets. |

|

|

starman

Hazard to Others

Posts: 318

Registered: 5-7-2008

Location: Western Australia

Member Is Offline

Mood: No Mood

|

|

@redox.No stirring? Not required obviously.Your post reaction mix looks a lot darker than smuv.

Chemistry- The journey from the end of physics to the beginning of life.(starman)

|

|

|

redox

Hazard to Others

Posts: 268

Registered: 22-2-2011

Location: The Land of Milk and Honey

Member Is Offline

Mood: Chalcogenetic

|

|

I stirred. Under the picture of the apparatus, I wrote "under vigorous magnetic stirring." You must have missed it. No worries!

As for the dark color, it gradually darkened throughout the reaction, but near the end I think I went a little too far and I charred the toluene. The

color didn't affect the post-reaction workup, though.

My quite small but growing Youtube Channel: http://www.youtube.com/user/RealChemLabs

Newest video: Synthesis of Chloroform

The difference between chemists and chemical engineers: Chemists use test tubes, chemical engineers use buckets. |

|

|

Bot0nist

International Hazard

Posts: 1559

Registered: 15-2-2011

Location: Right behind you.

Member Is Offline

Mood: Streching my cotyledons.

|

|

Awesome redox! I think I need to hit up Dr. Bob...

U.T.F.S.E. and learn the joys of autodidacticism!

Don't judge each day only by the harvest you reap, but also by the seeds you sow.

|

|

|

redox

Hazard to Others

Posts: 268

Registered: 22-2-2011

Location: The Land of Milk and Honey

Member Is Offline

Mood: Chalcogenetic

|

|

Thanks! I really recommend the Dr., his prices are incredible and he has a massive selection. I got the dean-stark and the condenser for about 35$,

plus a bunch of other stuff, adding up to 100$ total. Absolutely worth it!

My quite small but growing Youtube Channel: http://www.youtube.com/user/RealChemLabs

Newest video: Synthesis of Chloroform

The difference between chemists and chemical engineers: Chemists use test tubes, chemical engineers use buckets. |

|

|

starman

Hazard to Others

Posts: 318

Registered: 5-7-2008

Location: Western Australia

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by redox  |

I stirred. Under the picture of the apparatus, I wrote "under vigorous magnetic stirring." You must have missed it. No worries!

As for the dark color, it gradually darkened throughout the reaction, but near the end I think I went a little too far and I charred the toluene. The

color didn't affect the post-reaction workup, though. |

Yep,sure did.Most be going blind in my old age.Maybe wishful thinking.I was planning on running this one (to pTSA monohydrate only) and have a

dean-stark but I am a little doubtful of my stirrer decoupling from the bar in concentrated H2SO4.

Chemistry- The journey from the end of physics to the beginning of life.(starman)

|

|

|