BL1996

Harmless

Posts: 10

Registered: 22-8-2019

Location: Poland

Member Is Offline

|

|

Selenium dioxide recovery from selenium

Hi all!

I tried to prepare 1,2-cyclohexadione dioxime from cyclohexanone following this procedure

http://www.orgsyn.org/demo.aspx?prep=CV4P0229

I misinterpreted the cooling part and ended up with extremally low yield of the dione. I placed flask in an ice-bath while adding SeO2 solution but

that was a mistake. I've found some papers and it turned out that the temperature should be maintained at about 70 C.

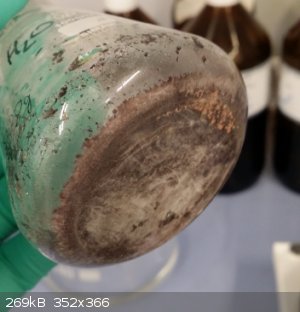

Anyway now I'm trying to recover selenium dioxide from selenium left after the reaction and I have some troubles with purifying it.

I placed the selenium in a flask and slowly in small portions added conc. nitric acid until no more of NO2 fumes were produced. Then distilled most of

nitric acid. I wanted to filter the product when the flask cools down but when it did I had a compact mass and literally no liqiud. I added some

water, heated it again to dissolve and transfered to erlenmayer flask. I thought that I'll try to evaporate the water and acid to get "pure" product

but it didn't work. I think I overheated the solution because instead of white solid I got some black crap in flask (selenium dioxide somehow

decomposed). I added another small portion of acid, heated it gently this time and everything dissolved and had a yellow colour as before. I

evaporated it almost to dryness and got yellow-white compact mass again.

If I want to use it again it cannot have any nitric acid, some water left is ok. So how can I remove the nitric acid? Neutralizing it with some base

won't work because SeO2 will also react. I thought about adding some water, evaporating to almost dry and repeating the process few times but I'm not

sure if it will work. Is there any "smarter" way to purify it?

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

The best method to purify the recovered selenous acid is to dry it and then sublime it, this both gets rid of the remaining N oxide and dehydrates it

to selenium dioxide. I usually treat the liquid waste with sodium metabisulphite until no more red-brown ppt forms and then boil briefly to make the

selenium more readily filterable. The solid is washed and dried before reoxidation with nitric acid. I have had several cases when recovery was

difficult and some of the selenium appears to end up in organic crud that is not easily oxidised with nitric acid back to selenium dioxide solution. I

have toyed with the idea of fusing it with a mixture of sodium hydroxide and a little sodium nitrate to burn off the organics and then recover the

selenium with metabisulphite on the acidified residue but I haven't tried this yet as the scale I was working on didn't seem to justify the effort.

|

|

|

BL1996

Harmless

Posts: 10

Registered: 22-8-2019

Location: Poland

Member Is Offline

|

|

Thanks for the answer. So you' re saying that I should gently heat it and try to evaporate as much acid/water as I can, then wait for it to solidify

and sublime it right? Now when it is solid it has like 20g. Initially I used about 13,6g of selenium so theoretically I should have about 19,2g of

SeO2 in that mass

|

|

|

BL1996

Harmless

Posts: 10

Registered: 22-8-2019

Location: Poland

Member Is Offline

|

|

Nevermind. Today I gently heated the flask and managed to evaporate it to dryness. I got nice white powdered crystals. I was in a hurry and forgot to

take a picutre but next time I will.

So the lesson for me is - when evaporating to dryness heat GENTLY and don't try to speed things up.

|

|

|