twelti

Hazard to Others

Posts: 217

Registered: 20-2-2019

Member Is Offline

|

|

Detonator casing physics

I'd like to learn more about the physics of detonator casings. For example, would it be better to leave the end of the det tube open, so there is

direct contact of the primary to the secondary when inserted - ignoring for the moment the safety issue of not having the primary totally isolated?

Is it better to increase confinement, at the cost of having more material between the primary and secondary explosives? Does a paper tube transmit

energy from primary to secondary as efficiently as a rigid metal tube? Basically, for a primary that doesn't NEED confinement to detonate, does

confinement server any purpose other than to protect the primary from the outside word? Are there any good references on this subject?

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

As far as I understood years ago, the definition of a high explosive includes the fact it can detonate without confinement. Sure a bit more pressure

can be build up with a solid confinement, but that shouldn't matter as the detonator of choice should be able to reliably set of the secondary charge.

Detonators, in my opinion, should contain enough of the primary, but while handling it as little as possible . If this means direct contact between

the primary and secondary in the detonator, you should go for two who are perfectly fine with being in contact. Otherwise you shouldn't use the two in

combination anyway.

The part where you can go for optimizing performance is the secondary (in the secondary charge). Press it to your likes. Just don't go crazy on the

detonator side. it should be safe to make, better to use a little more primary than to press it. The only time I pressed a primary was in my TATP

days, and I did it with a two meter long pole.

If you prefer having your indexes and hands, go for a safe overkill detonator. E.g. PETN is set of (very) easily and as little as 500 mg can set of

ANNM. If you can make a reliable 500 mg PETN plastic straw detonator, why would you risk pressing primaries?

|

|

|

wessonsmith

Hazard to Others

Posts: 203

Registered: 15-2-2018

Location: elsewhere

Member Is Offline

|

|

The short answer, no, the case doesn't contribute to the quality of detonation for primaries that don't require confinement to detonate.

The robustness of the case does help when dealing with primaries that are very sensitive to friction. Placing those types of primaries in a paper

case is dangerous due to the possibility of squeezing the shell, possibly causing a detonation. A metal case significantly reduces that possibility.

Primaries that require some confinement will need a metal tube to allow them to DDT reliably. NHN and CHP come to mind.

Of course, you had better know what types of material your chosen primary can play with.

[Edited on 14-8-2019 by wessonsmith]

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Quote: Originally posted by wessonsmith  | The short answer, no, the case doesn't contribute to the quality of detonation for primaries that don't require confinement to detonate.

The robustness of the case does help when dealing with primaries that are very sensitive to friction. Placing those types of primaries in a paper

case is dangerous due to the possibility of squeezing the shell, possibly causing a detonation. A metal case significantly reduces that possibility.

Primaries that require some confinement will need a metal tube to allow them to DDT reliably. NHN and CHP come to mind.

Of course, you had better know what types of material your chosen primary can play with.

[Edited on 14-8-2019 by wessonsmith] |

I wouldn't risk limbs over "easiness" of handling.

[Edited on 14-8-2019 by Tsjerk]

I just think manipulating primaries is a no go and should be avoided as much as possible.

[Edited on 14-8-2019 by Tsjerk]

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

The tube does mater in that it guides and focuses the shock wave, this has more an effect on critical diameter but not so much so as the materials we

will generally be handling.

The higher confinement comes into play as to the amount of material required to be used, with high density pressed primaries as little as 50mg of

azide/styphnate will effectively initiate TNT/ and RDX

The rigidity is more pertinent to preventing this compressed material from being broken up and the befor mentions guidance of the shock wave ensuring

effective transmission and continuation of the detonation wave

For effective det you want the shock wave to over take the expansion wave (The hot gasses expanding of the tube) rigidity comes to this.

The fact metal offers an additional layer of safety is another bonus, but the main purpose is to protect the materials from the environment and keep

them from becoming de laminated.

In the vast majority the primary pellet is directly pressed to the secondary, some configurations use a re-enforcing cap others do not, and depending

if delay elements are implemented

Attachment: Efficiency of detonators.pdf (759kB)

This file has been downloaded 464 times

[Edited on 14-8-2019 by XeonTheMGPony]

Attachment: Initial_priming_substances_for_high_expl.pdf (1.5MB)

This file has been downloaded 473 times

[Edited on 14-8-2019 by XeonTheMGPony]

Attachment: Critical diameter of fulminated mercury and Pb Azide Naval report.pdf (3.7MB)

This file has been downloaded 509 times

|

|

|

twelti

Hazard to Others

Posts: 217

Registered: 20-2-2019

Member Is Offline

|

|

Good points, and references. I'm thinking more about the interaction of the secondary in the det to the main charge, not so much between the primary

and secondary. So, in a commercial detonator, the entire primary and secondary charge is fully encased in metal. For the secondary to initiate the

main charge the det is inserted into, it must transfer the energy through the casing. Does this happen everywhere the same along the length of it, or

more at the end (I have heard it mentioned that there is a focusing effect of the cylindrical confinement and the det wave moving along it)? What

actually impacts the main charge is not the det wave passing from one EM to another, the it is impinging on the metal casing and THAT is impinging on

the main charge. So would it be better to have a thicker walled det casing but with an open end such that the secondary directly touched the main

charge at the end of the det, or use a thinner walled det casing with closed end (like normal) and fully insert it in the main charge?

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

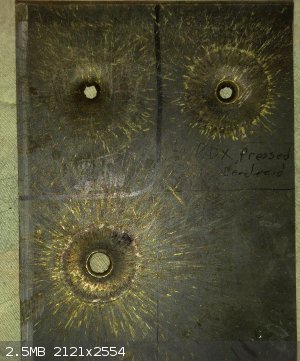

the accelerating wave is down ward with incidental dissipation to the sides, the full force of the shock wave at peak speed will be out the bottom.

Observe the witness plate, see how it is concave then at the epicenter a fine cut hole?, and observe the metal spatter effect on the steel.

You can set a charge off by simply aiming the det at the charge with a paper thick gap for most axially, lesser so parallel.

Now observe the video file carefully, this is a paper shelled cap that got damage during assembly, to dispose of it I did the surface fire, watch the

flame jet shoot out to the left of the kewie fruit (it was rotten)

[Edited on 16-8-2019 by XeonTheMGPony]

Attachment: bad cap Vs Kewie.wmv (7MB)

This file has been downloaded 849 times

|

|

|

twelti

Hazard to Others

Posts: 217

Registered: 20-2-2019

Member Is Offline

|

|

Just got this carbon fiber tube. It is quite thin, strong and light. I'm hoping it will be useful. Has anyone tried CF tube in a det before?

|

|

|

MineMan

International Hazard

Posts: 1012

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

I think CF tubes might be the best material.

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

i believe a papertube externally treated with some hard plastic, really spraypaint might work should be plenty strong, it may also absorb some shock

if dropped which metal would directly transmit this shock

as for shock/friction, in flashpowder graphite decreases such sensitivity, quite significantly. i dont recall the exact numbers but some flashpowders

that could only tolerate 1kg dropweight at 30cm could take around 45cm with graphite added, 5%? i recall seeing one guy saying one very sensitive

organic primary could be stabilized using carbon from thermally decomposed sugar, but also a few other basic chemicals that i dont remember

more effort could be done with initiators by side-fusing it and having a small amount of water above the fuse to tamp it, with this added direction to

the blast you could probably have high success rates simply placing it right ontop of a charge rather than submerging it

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Antiswat  | i believe a papertube externally treated with some hard plastic, really spraypaint might work should be plenty strong, it may also absorb some shock

if dropped which metal would directly transmit this shock

as for shock/friction, in flashpowder graphite decreases such sensitivity, quite significantly. i dont recall the exact numbers but some flashpowders

that could only tolerate 1kg dropweight at 30cm could take around 45cm with graphite added, 5%? i recall seeing one guy saying one very sensitive

organic primary could be stabilized using carbon from thermally decomposed sugar, but also a few other basic chemicals that i dont remember

more effort could be done with initiators by side-fusing it and having a small amount of water above the fuse to tamp it, with this added direction to

the blast you could probably have high success rates simply placing it right ontop of a charge rather than submerging it |

Simpler yet, a good wood glue, dilute with some water to make it a bit runnier, paint on, roll tube leave to dry.

If you did your cap well enough it can be a couple mm from the charge and set it off! most of the time I just press mine to the side if need be (Main

reason I even bother making plastic bonded is as a means to afix the dets to solid charges.

[Edited on 3-9-2019 by XeonTheMGPony]

|

|

|

Mr.Greeenix

Harmless

Posts: 40

Registered: 8-4-2015

Member Is Offline

Mood: No Mood

|

|

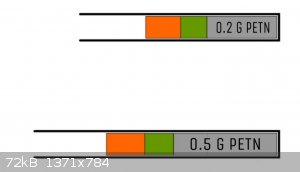

I recently succeded in synthesizing some nickel aminoguanidin perchlorat. It works perfectly, 0,08g can realibly detonate 0,2g PETN. It is really a

superb material !

But i am having a problem with my detonators i am not sure i should have

I am currently testing two kinds of Detonators, one small one and one big one. The small one is with [0,1g NHP, 0,2g PETN] and the big one is with

[0,1g NHP, 0,5g PETN]. All materials are handpressed into a thick reusable plastic straw with an inner diameter of 5,5mm.

I have 10/10 for the [0,1g NHP, 0,2g PETN] blasting cap and 0/3 for the [0,1g NHP, 0,5g PETN] blasting cap.

But how can i detonate 0,2g and not 0,5g?? I dont understand how this would work if the diameter is the same every time. If i understand correctly the

acceleration wave produced by the NHP 'ignites' the PETN at the top and then it 'burns' with its Detonation velocity to the bottom.

How can it matter if there is a little more PETN pressed into the straw ?

|

|

|

Praxichys

International Hazard

Posts: 1063

Registered: 31-7-2013

Location: Detroit, Michigan, USA

Member Is Offline

Mood: Coprecipitated

|

|

I use these as detonator cases and they are cheap and work extremely well:

Vials

They are perfectly sized, chemically inert, and available in many lengths. I use a piece of pegboard (into which they are an interference fit) as a

holder to melt cast the primary. 500-1000mg (depending on the power I want) of well neutralized and recrystallized ETN powder is charged into each

vial, then they are suspended in hot water over a bread loaf pan using the pegboard. Once everything is cool, the bottom of the vial contains a solid

block of ETN. I place 100-150mg SADS (or more recently, lead azide) on this, then visco fuse, then a cotton plug to keep the primary in place, then

seal them by filling the space above the cotton with about 6mm of 30 minute clear epoxy. When cured, I spray the visco with scotch guard to improve

its waterproofing and the unit is done. Swap out the visco for an eBay electric match if you want an electric version.

The result is a highly reliable, powerful, compact, long lasting detonator. (Although they should never be stored - that is illegal in my area without

an inspected magazine and dangerous to boot)

Edited to fix hyperlink.

[Edited on 27-9-2019 by Praxichys]

|

|

|

twelti

Hazard to Others

Posts: 217

Registered: 20-2-2019

Member Is Offline

|

|

Yes, but you didn't answer Greenix's question. Why the larger amount of ETN is not detonating. Could it be chance? Doesn't seem likely but... I'm

using the same primary and ETN now, in amounts of around 80mg of ANP and maybe 700 mg of ETN and always works. Maybe a stronger tube. I'm using

something like:

https://pyrodirect.com/index.php?app=ecom&ns=prodshow&am...

You could also use the tubes you have and add a few wraps of fiberglass strapping tape around it. That stuff is mongo strong! TUbe is bettter though,

since more rigid.

|

|

|

MineMan

International Hazard

Posts: 1012

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Mr.Greeenix  | I recently succeded in synthesizing some nickel aminoguanidin perchlorat. It works perfectly, 0,08g can realibly detonate 0,2g PETN. It is really a

superb material !

But i am having a problem with my detonators i am not sure i should have

I am currently testing two kinds of Detonators, one small one and one big one. The small one is with [0,1g NHP, 0,2g PETN] and the big one is with

[0,1g NHP, 0,5g PETN]. All materials are handpressed into a thick reusable plastic straw with an innerp diameter of 5,5mm.

I have 10/10 for the [0,1g NHP, 0,2g PETN] blasting cap and 0/3 for the [0,1g NHP, 0,5g PETN] blasting cap.

But how can i detonate 0,2g and not 0,5g?? I dont understand how this would work if the diameter is the same every time. If i understand correctly the

acceleration wave produced by the NHP 'ignites' the PETN at the top and then it 'burns' with its Detonation velocity to the bottom.

How can it matter if there is a little more PETN pressed into the straw ?

|

Try pressing .4g of ETN then lightly press .1g ETN on top of it and lightly press the AGNP.... I think in your case having a layer of more loose ETN

is better then pressed primary.

Also. How are you sealing both ends. Seal both well!

|

|

|

sodium_stearate

Hazard to Others

Posts: 255

Registered: 22-4-2011

Location: guard duty at the checkpoint

Member Is Offline

Mood: No mask.

|

|

fascinating!

I've just got to say this:

Great reading and pics! Very interesting stuff for sure.

But I always find myself looking at my intact and working

hands and fingers after reading these threads here.

Then I become thankful that I still have them all, and that

they all still are working right.

"Opportunity is missed by most people

because it is dressed in overalls and it

looks like work" T.A. Edison

|

|

|