nimgoldman

Hazard to Others

Posts: 303

Registered: 11-6-2018

Member Is Offline

|

|

Mercuric Chloride Synthesis Success?

I finally decided to prepare mercuric chloride (HgCl2) since this compound is hard to get by an amateur. I'd like to share the process here for a

critical review.

The procedure has been already discussed here and performed by Nile Red. So there goes the credits. Here I just added photos and comments about the procedure. The general procedure goes like this:

Hg ->(nitric acid)-> Hg(NO3)2 ->(heat or base)-> HgO ->(hydrochloric acid)-> HgCl

I did one modification to the procedure, which is obtaining mercuric oxide by precipitation from solution instead of heat decomposition. This makes

the procedure more messy, but it is quicker and I believe also removes the guesswork of mercuric nitrate being fully decomposed to oxide.

First, I dissolved about 50.2 grams (0.25 mol) of elemental mercury in 1.14 mol nitric acid (I used 90 mL, 59% HNO3):

Note the tissue paper added on top to prevent liquid droplets escaping the flask. Unfortunately, the reaction became too vigorous and I had to quickly

transfer everything to a 250 mL Erlenmeyer flask (the 150 mL was too small). It would be also safer to add the mercury by parts and not all at once to

prevent frothing and thermal runaway. Maybe cooling the flask would help (I am used to dissolve silver which does not react as readily as mercury).

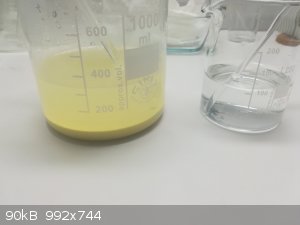

When everything dissolved, I started adding 25% sodium hydroxide to precipitate mercuric oxide (HgO). At first, a tan-brown precipitate apperead which

turned to pumpkin colour and more precipitattion happened as I added excess hydroxide:

Now for the filtration part. At first I tried a sintered funnel but the HgO powder is so fine it went through. I had a hard time later to clean the

sinter (using hot nitric acid), so using the sintered funnel for this is a no no:

I then used Buchner funnel with two stacked filter papers with great success, though small amount of solids still went through (might be solved by

re-filtering over the bed of solids from the first filtration). I washed the beaker several times with water to remove all the mercuric oxide from it.

One messy part is to get all the HgO off the filter into a clean container. I used standard cellulose filter paper but finer type of filter would work

better, such as glass fiber filter.

I washed the solids on filter with distilled water to remove any sodium hydroxide in it.

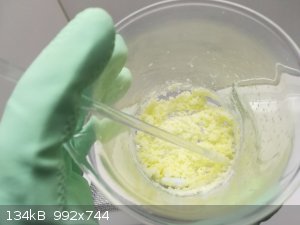

I then transferred most of the material to a beaker (using spatula) and poured about 52 mL of 36.5% HCl over it. The solids blackened first (is it

mercury(I) oxide?) but then dissolved when stirred:

I must note the solution heated up a lot so it would be safer to use more dilute acid, cool the container in an ice bath or do the addition more

slowly. Cooling might be preferred as there will be less water to evaporate. Also use as little acid as possible to minimize amount of corrosive

fumes.

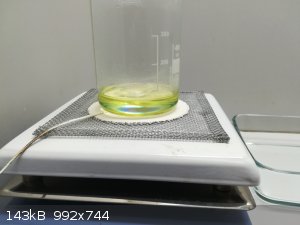

Once everything dissolved, I filtered the supposed mercuric chloride solution once more (optional) and started evaporating the water. Here is the

setup I used:

There is a wire gauze added between the beaker and the hotplate to avoid overheating and smooth out the temperature changes. I then stuck a

thermocouple probe between the beaker and the ceramic plate to monitor actual temperature under the beaker and never allowed it to exceed 150 °C. The

probe is all metal and protected by glass fibers so it is safe to use it that way.

Finally, the solution was slowly magnetically stirred and a fan was blowing air over the beaker to promote evaporation. The fume hood was being vented

at maximum speed.

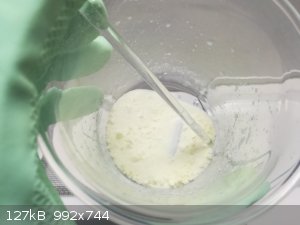

This process took several hours and I ended up with a moist powder resebling scrambled eggs mixed with sand:

I continued heating but this time ran at lower temperature (around 100 °C) to prevent the dry mercuric chloride to vaporise (I found in text it

sublimes at elevated temperatures since it does not form a tightly held ionic structure like most salts).

I also monitored the HCl vapours by a pH paper:

I stopped the drying process once the paper had not turned substantially red even when held over the powder for prolonged time.

Here is the result, a free flowing bright yellow powder:

The yield was 95.6% (about 65 grams of HgCl2) which makes sense provided there were losses during the filtration. It could be greatly improved with

technique though.

However, I doubt the purity of my mercuric chloride provided it is yellowish and not white (presence of oxides?). There could be metal impurities from

the original mercury sample (not much but enough to color the product perhaps).

Cleanup

I washed all the glassware twice with conc. nitric acid (dilute might be sufficient) then once with deionised water.

All the washings were collected in a large beaker and there is about 1 100 mL of water containing mostly nitric acid, mercuric nitrate and mercuric

chloride.

I plan to precipitate mercury as sulfide (using sodium sulfide) and perform more cleanup of the liquid part if necessary. I can use mercury test

strips for the liquid to see whether the liquid is safe to discard.

The solid mercury sulfide will be stored for making elemental mercury later.

[Edited on 20-5-2019 by nimgoldman]

[Edited on 20-5-2019 by nimgoldman]

|

|

|

woelen

Super Administrator

Posts: 8015

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

This is a nice synthesis. Your product must be quite pure. The yellow color is not strong and a tiny amount of impurity can give a strong coloring.

Is a solution of the HgCl2 in distilled water completely clear? If not, then you might have some basic chloride or oxide in it. Keep in mind that

HgCl2 does not dissolve that well in cold water. You need quite a lot of water to dissolve a small amount.

One remark about the prevention of small droplets getting airborne. I would take more paper tissues and make a loose ball of it and press this in the

open end of the erlenmeyer such that it fits loosely. Then I would take another piece of larger paper tissues, put the ball in that in the center,

press that into the opening of the erlenmeyer and fold the rest of the outer tissue around the rim, downwards. In this way you still have more than

sufficient space for the gas to escape, but you have 100% capture of droplets. Of course your liquid must not frothe so much that it reached the

tissue ball, so you should use a sufficiently large flask.

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Yellow colouring can occur from hardware store grade HCl.its full of heavy metal impurities.is this the same mercury chloride you get by gassing

elemental Hg with chlorine gas if is there still an oxygen in there as in mercury oxychloride?

|

|

|

DavidJR

National Hazard

Posts: 908

Registered: 1-1-2018

Location: Scotland

Member Is Offline

Mood: Tired

|

|

If you want mercuric chloride as a catalyst or for preparing aluminium amalgam etc, I'd advocate doing the whole prep in the flask you're going to use

it in. This minimizes the amount toxic crap getting everywhere. Basically, just add the weighed amount of mercury metal to your reaction flask,

dissolve in nitric acid, boil off the excess acid and thermally decompose the nitrate, add conc HCl, if necessary evaporate off excess HCl/H2O. Then

add all of the other reactants to the flask and do whatever you were going to do with it.

|

|

|

fusso

International Hazard

Posts: 1922

Registered: 23-6-2017

Location: 4 ∥ universes ahead of you

Member Is Offline

|

|

Why not just react Hg, HNO3 and HCl all together in the same step, like how chloroplatinic/auric acids are made? You can use less HNO3 if you do it

like this.

Hg + 2 HCl + 2 HNO3 = HgCl2 + 2 NO2 + 2 H2O

3 Hg + 6 HCl + 2 HNO3 = 3 HgCl2 + 2 NO + 4 H2O

|

|

|

woelen

Super Administrator

Posts: 8015

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

This does not work well. HgCl2 is only sparingly soluble. It may prevent complete dissolution of all Hg.

Another issue is that you need quite some excess HNO3/HCl if you want all Hg to dissolve. How do you want to separate the nitrate and acid from the

HgCl2 (provided everything does dissolve)? Getting pure HgCl2, free from nitrate, will be hard. Hg forms a complex HgCl4(2-) at high concentration of

chloride and this is not easily isolated.

With gold and platinum things are different. These metals do not form stable nitrates and on careful evaporation of the acid mix, only the acid

chloro-complex (e.g. H[AuCl4] as complex acid) remains behind.

|

|

|

nimgoldman

Hazard to Others

Posts: 303

Registered: 11-6-2018

Member Is Offline

|

|

Thanks for the inputs.

The hydrochloric acid is not from hardware store but an assayed reagent grade HCl form a chem supplier:

| Quote: | HCl....................................min. 35%

SO2 ash.....................max. 0,001%

H2SO3....................max. 0,001%

SO4.........................................max. 0,0002%

free Cl2................................max. 0,0002%

heavy metals (Pb)..................max. 0,0003%

Fe...........................................max. 0,0001%

As...........................................max. 0,00001% |

So no heavy metals there. Wikipedia says HgCl2 could be slightly yellow colored - the discoloration was heaviest when the powder was still wet and as

it dried, it lost most of the colored impurities - I am not sure what that is, probably has something to do with chlorine being still around plus the

small amount of base. Next time I will certainly use as little base and as little acid as needed.

Yes there are certainly cleaner methods to make HgCl2 but I didn't want to play with chlorine gas.

The amount of waste is bigger then one-pot synthesis or preparation as needed, but I wanted a stock HgCl2 so I don't have ot make it for a long time.

[Edited on 22-5-2019 by nimgoldman]

|

|

|

Keras

National Hazard

Posts: 909

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Did you try passing your mercury chloride over activated charcoal?

|

|

|

nimgoldman

Hazard to Others

Posts: 303

Registered: 11-6-2018

Member Is Offline

|

|

No but I need only catalytic amounts for reductions (the product will be worked up and purified later anyway) so I guess high purity is not critical

here.

The purification procedure from Armarego et al.:

| Quote: | Mercuric chloride [7487-94-7] M 271.5, m 276o, b 304o, d 4 20 5.6. Crystallise it twice from distilled water,

dry it at 70o and sublime it under high vacuum. Its solubility in H2O is 4.3% at ~0o, 6.6% at ~10o and 54% at

~100o. It is soluble in EtOH and is extracted into Et2O from an aqueous solution. It is very POISONOUS and

0.2-0.4g is fatal. The antidote is immediate administration of white of egg as an emetic. |

So it seems extraction from aqueous solution might suffice to remove discoloration from polar impurities.

Crystallization from water would definitely purify it, but due to its high toxiciy, I don't like to play much with concentrated solutions.

There would also be a little waste water with Hg ions in it from recrystallization that needs to be further processed.

|

|

|

ZetekitoxinAB

Harmless

Posts: 19

Registered: 31-7-2019

Member Is Offline

Mood: Omberacetam

|

|

I am almost sure you could easily get HgCl2 by reacting Hg with conc. HCl to which you add dropwise 30% hydrogen peroxide. Apply heat if necessary; I

would much rather just crystallize the salt out instead of boiling it to dryness. You may loose some product but you get pure HgCl2.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Good luck with that and IMHO it's best to keep HgCl2 as separate containers of HgO suspended in water (it's yellow from alkali IME) and HCl. The Pb3O4

color may explain the black precipitate and maybe the yellowness too. Doesn't carbonate give a brownish color? Isn't the nitrate supposed to give HgO

of that color, but by heating the dry salt?

BTW it's been said that the sulfate crystallizes nicely from the hot excess acid that some mercury was dissolved in, and readily precipitates equally

nice HgO from pure dilute alkali after being dissolved in conc. NaCl.

There does not seem to be much need for dry HgCl2. Old school corrosive sublimate sounds like a fun experiment though, if one takes HgCl2 seriously.

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

If I wanted this compound, especially in small quantities, I would first try a photolysis approach involving the direct combination of elements under

UV light.

My speculation is based on this reported photolysis: "Reactions of Metal Atoms. I. The Combination of Mercury and Chlorine Atoms and the Dimerization

of HgCl", in J. Chem. Phys. 48, 4758 (1968); https://doi.org/10.1063/1.1668058 . To quote the first sentence of the abstract:

"The combination reaction of mercury atoms with chlorine atoms from the mercury‐sensitized flash photolysis of CF3Cl has been studied."

I would instead try the UV photolysis of Cl2 (also a source of •Cl) with Hg, as per Wiki on Hg2Cl2 (see

https://en.wikipedia.org/wiki/Mercury(I)_chloride#Preparation_and_reactions):

"Photochemistry

Mercurous chloride decomposes into mercury(II) chloride and elemental mercury upon exposure to UV light.

Hg2Cl2 → HgCl2 + Hg

The formation of Hg can be used to calculate the number of photons in the light beam, by the technique of actinometry."

As such, my speculated direct reaction under UV light:

Cl2 + hv = •Cl + •Cl

Hg + •Cl = •HgCl

•HgCl + •HgCl = Hg2Cl2

And finally, per Wiki above with UV:

Hg2Cl2 + hv → HgCl2 + Hg

The application of heat may be required to increase yield (as if the experiment was not already dangerously toxic).

----------------------------------------------------------------

Found a path to organomercury halides, to quote:

"Relatively few organic halides react directly with metallic mercury to afford the corresponding organomercury halides. Among the simple alkyl halides

only methyl iodide produces good yields (Equation (1)).12 These reactions appear to be free radical in nature since they are usually promoted by light

or photolysis"

Link: https://www.sciencedirect.com/topics/chemistry/organomercury...

CAUTION: Toxicity concerns/issues prevent me from performing any of these experiments.

[Edited on 11-8-2019 by AJKOER]

|

|

|