RogueRose

International Hazard

Posts: 1594

Registered: 16-6-2014

Member Is Offline

|

|

Grinding/powdering glass in a blender - with water in blender?

I need to make some glass frit and I've found it is MUCH more difficult than i thought it would be. I have a "pestle" I made from a 1 cup stainless

steel measuring cup that I filled with lead and placed a 30" 3/4" piece of rebar into the lead. There are also 3 5/8" bolts going into the sides of

the pestle that were used to center the rebar before the lead was poured to fill the cup. This works great for a lot of things and I've tried to use

it with broken pieces of lab glassware (all borosilicate) and have all the glass broken up to max size of about 1/4" max size in any direction.

I use an old soup can which the SS cup fit's inside to hold the glass (with just enough water so there is no dust) and then smash the glass with an up

and down force and a little rotational grinding. Even though I used a wire wheel to remove any rust from the exterior bolt heads, it seems that there

is a fair amount of rust getting into the glass powder (it looks sand colored, you would think it WAS sand). I run the smashed glass through some

strainers/sifters with decreasing size ending with a plastic (LDPE??) coffee filter mesh, which still allows a fair amount to pass through. The finest

parts are the ones that looked sand colored, the rest have been washed with clean water (and a little HCl + H2O2 - which give crystal clear glass)..

I was wondering if i could use an old blender (ti is very thick glass to grind up the larger pieces of glass that remain. I'm only about 10% done

with all the glass after about 2 hours.

I figured that I would add water with the glass pieces, that way it should keep the glass down towards the bottom instead of on the sides. There are

different speed settings, pulses etc. I'm open to sharpening the blades as they are currently rounded a little bit (from wear or came that way..?)

and trying different settings.

I'm just worried about something building up at the bottom and causing the blades to lock up and stripping the coupling gear on the base of the

blender. This happened with aluminum when I tried grinding some (not even a whole lot - it was a different blender, a much more expensive one... it

was dry & maybe it caused the Al to melt in that case??)

The only other option would be to use a coffee grinder, though I don't have any decent ones ATM and IDK if they can be used with a little water to

keep the nasty dust down.

I guess a ball mill could be used, IF I has a working one, but ATM I don't - I really need to get one up and running.

|

|

|

Sulaiman

International Hazard

Posts: 3698

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

On the Mohs scale of hardness, lead = 1.5, glass = 5.5 https://en.wikipedia.org/wiki/Mohs_scale_of_mineral_hardness

so lead is a poor choice as a pestle for crushing glass.

Put the glass in a cloth bag on a rock and smash with a hammer ?

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

RogueRose

International Hazard

Posts: 1594

Registered: 16-6-2014

Member Is Offline

|

|

The lead was melted and poured inside of the stainless cup (lf 1 cup in size - about 220ml or so??), so the outer side of the pestle is stainless

steel. It handles the glass pretty well, only very slight scratches. I tried this with a brass mortar and pestle (for only a couple "poundings) and

stopped b/c it was causing damage).

As far as the cloth bag, the glass would shred the bag very quickly.

In addition, the can I use to hold the glass is a steel (tinned I think) soup can, and it has held up remarkably well with all the pounding it took.

|

|

|

Gearhead_Shem_Tov

Hazard to Others

Posts: 167

Registered: 22-8-2008

Location: Adelaide, South Australia

Member Is Offline

Mood: No Mood

|

|

The "standard" way of doing this is to use black iron plumbing pipe nipple with a cap screwed on the bottom. Put your glass shards in, then use a

steel bar a touch smaller diameter than the inside diameter of the nipple and pound away.

Screen the finer particles out, resume pounding the larger ones, etc.

|

|

|

RogueRose

International Hazard

Posts: 1594

Registered: 16-6-2014

Member Is Offline

|

|

Well, "It will blend!!!" I got a cheap $2.99 blender (which was interchangable with a nice Sears base/motor), but the cheap one had a polycarbonate

"blending vessel (can't think of name)

Strange, I couldn't add any pics except one at a time (had to edit the post and add another image once the first one was posted).

The next 3 are just pictures of the 8lb pestle I made from a stainless steel measuring cup into which I poured hot lead - there are standard steel

bolts on the side, which rust. I think I need to cut those off to give more room for clearance. This works REALLY well when breaking up

crystals/powders, things that seem like they are rock hard, this does a great job!

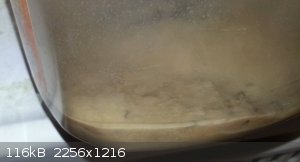

This is what the glass looked like after using the pestele - I think it was from the rust from the bolts on the sides and in the can

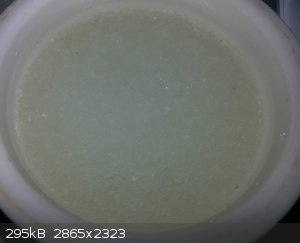

This is the sifted glass (through tea and or coffee filter) after it has soaked in a little HCl and H2O2 (35%)

[Edited on 3-2-2019 by RogueRose]

[Edited on 3-2-2019 by RogueRose]

|

|

|

crystal grower

Hazard to Others

Posts: 474

Registered: 3-1-2016

Location: Os Petrosum

Member Is Offline

Mood: Puzzled

|

|

You can make very fine SiO2 powder by mixing liquid glass and H2SO4

[Edited on 2-3-2019 by crystal grower]

|

|

|

RogueRose

International Hazard

Posts: 1594

Registered: 16-6-2014

Member Is Offline

|

|

Thanks for the tip! Is that sodium metasillicate or sodium sillicate? I actually came across a gallon of some of the metasillicate (it's VERY

heavy). I kind of wish I knew that before, but I'm wondering if the SiO2 from that method wouldn't make too pure a compound because it is

essentially quartz (pure SiO2) which has a much higher MP than soda lime glass and even borosillicate.

I'm not sure I could get the pure SiO2 to reach the glass transition point, where borosillicate looks to be around 1200-1250F and SiO2 is about

400-500F higher IIRC.

As far as the colors of my ground glass, the grey is from the metal blade wearing away and the HCl + H2O2 has cleaned it up beautifully, just as it

has the brown, sand looking glass. I'm not done processing it yet but I'll post some pics when I'm done.

I was really surprised when the cheapo Proctor Silex blender chopped up the glass. The pieces weren't too big, I had smashed them a little with that

pestle so there weren't any pieces longer than 1/2" (and they were thin like beakers). I'm wondering how much harder the glass is to ice b/c it

really sounded like I was making a daiquiri, lol

I was thinking of using the metasillicate as a binder with some clays and maybe some CaO or Ca(OH)2 & some sand to make a refractory for a kiln or

forge. IDK if it is worth it to use the metasillicate in place of water, but it supposedly increases the temperature handling of the material.

|

|

|

crystal grower

Hazard to Others

Posts: 474

Registered: 3-1-2016

Location: Os Petrosum

Member Is Offline

Mood: Puzzled

|

|

I think it's the metasilicate but it shouldnt really matter.

I don't remember exactly how I did the experiment but anyway, after mixing the water glass and sulfuric acid, you get a gel-like precipitate of

silicic acid which needs to be dehydrated using heat. Make sure to keep stirring it during the whole process.

I won't help you with the glass transition point, you'll have to try it yourself.

I'm also suprised the blender did such a good job, can the blades be even considered as blades anymore?

|

|

|

RogueRose

International Hazard

Posts: 1594

Registered: 16-6-2014

Member Is Offline

|

|

Quote: Originally posted by crystal grower  | I think it's the metasilicate but it shouldnt really matter.

I don't remember exactly how I did the experiment but anyway, after mixing the water glass and sulfuric acid, you get a gel-like precipitate of

silicic acid which needs to be dehydrated using heat. Make sure to keep stirring it during the whole process.

I won't help you with the glass transition point, you'll have to try it yourself.

I'm also suprised the blender did such a good job, can the blades be even considered as blades anymore? |

Yeah, they are still in pretty good shape. I'd guess they lost about 1-2% of their surface tip. The edges got a little dulled. I'll take a pic and

post b/c I was pretty impressed as well. I can't believe this worked and when I tried Al foil of loosely balled foil and about 1/5 - 1/4th full in

the blender. IT was a really expensive Kitchen Aid ($200+) blender and it destroyed the coupling 4 times and I couldn't grind anything with it. I'd

try to do it again but I'm afraid it will break it again.

|

|

|

wg48temp9

National Hazard

Posts: 784

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Its simperler and probably cheaper to buy silica gel as cat litter than make it.

The silica gel is very friable so it quickly (compared to glass) blends to a fine powder with a significant air float fraction.

I would guess that blending in water reduces the grinding efficiency of turning the small particles to finer ones.

The powdered silica gel can also be used to make a sodium silicate solution as it readily dissolves exothermically in sodium hydroxide solution.

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

Endo

Hazard to Others

Posts: 124

Registered: 5-1-2006

Location: USA

Member Is Offline

Mood: Cold

|

|

There are also some cleaning/polishing products out there that are labeled as the only ingredient is quartz powder. I picked some up in the clearance

section at the grocery store for 50 cents/ bottle the other day. I will take a pic when I get home and post it for the product details.

|

|

|