| Pages:

1

2 |

aonomus

Hazard to Others

Posts: 361

Registered: 18-10-2009

Location: Toronto, Canada

Member Is Offline

Mood: Refluxing

|

|

Homebuilt recirculating evaporative cooler

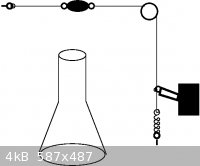

So I'm sure we all have the same problem, how to cool our condensers without wasting lots of water. I've seen alot of people that use buckets of water

with pumps in them to recirculate, and by sheer mass alone, the water doesn't increase in temperature much, however this wasn't good enough for me

So what I did was I built an evaporative water cooler based off of how power plant cooling towers work: shower of water downwards with airflow upwards

(forced or convection).

So water is pumped out of the sump at the bottom (bottom closed by pipe cap, unit is fully enclosed), to the condenser, and back to the top of the

unit, where it pumps into a regular shower head aimed downward. A fan pushes air in at the wye fitting, travelling upwards, cooling the water by

evaporation as it passes.

With water 10 degC above ambient, it reaches ambient in approximately 10 minutes. I want to do other tests with even warmer water, but I haven't had

time just yet. Because of the heat exchange, it gets more efficient as the temperature difference between water and air increases. The unit can keep

water at ambient, or just a hair below ambient temperature under sustained usage, I've distilled with water and methanol for 3-4 hours continuous with

no rise in temperature.

A safety feature is that because of the extremely low volume of water ever contained in the system at any one point in time (about 1.5-2L), you will

never really be able to flood your workspace should a hose fitting come loose. The bilge pump doesn't even reach down to the bottom, so the real

volume of water that could be pumped out is probably closer to 1L.

One downside is that you get a fine water spray out the top of the unit, which rains down on nearby objects. While this isn't a problem, it just means

you have to refill from time to time. The only other downside I can see to this is if you have a very low boiling solvent, or you are distilling a low

boiling solvent under vacuum. You cannot add ice to this unit (any water below ambient would just get warmed up anyway), so you are essentially

limited by air temperature.

An improvement I may make is to merge the top stack with a bucket so that ice can be added, and the fan/shower be enabled/disabled to give the best of

both worlds.

And just a nice looking picture of a distillation going (orange peels to see if I could get orange oil out of them, didn't work out well, but the

cooler did!)

|

|

|

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

That cooler is nice. Mind you, it's true that in every distillation I've done, it would have been easier to just start with somewhat more water than

to build a whole setup like this - but with this you could run something for 24 hours if you had to.

Are the orange peels in that boiling flask in big chunks (it looks like it)? I would recommend turning them into tiny bits in a food processor and/or

macerating them before doing distillation. Not that I had much better luck when I tried to get limonene from lemon peel, but my problems were later on

when I tried to isolate from the distillate -

|

|

|

aonomus

Hazard to Others

Posts: 361

Registered: 18-10-2009

Location: Toronto, Canada

Member Is Offline

Mood: Refluxing

|

|

Yes, with a setup like this I could run it happily unattended (if it wasn't for the heat/fire hazard), but other safety features would be necessary

(low water, low flow alarms, fire alarm, etc).

And the orange peels in that picture were larger chunks, but I did a second run with 500mL peels instead of 100mL approx, and with smaller sized (cut

up with scissors). I only got about 0.5mL...

But otherwise, the cooler works!

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aonomus  | | Yes, with a setup like this I could run it happily unattended (if it wasn't for the heat/fire hazard), but other safety features would be necessary

(low water, low flow alarms, fire alarm, etc). |

A float valve hooked up to a water supply would provide you

continuous water. Put the float in the sump at the bottom. You could likely use a float valve from a toilet tank, with a little plumbing effort.

For a foolproof system, you'd still want a low-water alarm. With a refilling device, though, it wouldn't go off in ordinary operation.

|

|

|

aonomus

Hazard to Others

Posts: 361

Registered: 18-10-2009

Location: Toronto, Canada

Member Is Offline

Mood: Refluxing

|

|

Unfortunately the sump is only 4" in diam, and even smaller after taking the pump into account. I most certainly will want to do a revisit to this

build when this one dies or becomes enough of a problem.

I would probably substitute the bottom cap fitting with a flange fitting, and bolt it to the lid of a sturdy bucket. This would allow for regular

fountain pumps to be used over a noisy bilge pump, give space for a float valve, and space to add ice in if you wanted cooling below ambient.

I could see this being quite handy for lengthy soxhlet extractions or refluxing reactions.

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

I like it aonomus good thinking.

I was woundering what is inside of the cooling tower? Does the water just drop thru it or is there some sort of heat exchanger in there? Might I

suggest rolled up corregated cardboard inside of the tube to create a pretty efficient unit.

I may have to make something simular sometime just to play with thanks for sharing.

BTW as for the float valve there are sensors you can get for pans that go under airconditioners which are an electric version of a float valve and

they will send a signal down the line when the water is up. Something of this sort could be worked into the unit with ease.

A fire alarm would be as simple as placing a thin piece of wire above the most likely area of fire the distilling flask. If theres a fire it breaks

cutting current and triggering an alarm. These circuits are very basic and can be made with ease for about 5-10$ at the very most.

[Edited on 20-11-2009 by Sedit]

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

Quote: Originally posted by Sedit  | I like it aonomus good thinking.

I was woundering what is inside of the cooling tower? Does the water just drop thru it or is there some sort of heat exchanger in there? Might I

suggest rolled up corregated cardboard inside of the tube to create a pretty efficient unit. |

I'd suggest glass wool to prevent mold & rot.

A loose glass wool plug at the top would catch a lot of the spray and return it to

the system.

Quote: Originally posted by Sedit  |

BTW as for the float valve there are sensors you can get for pans that go under airconditioners which are an electric version of a float valve and

they will send a signal down the line when the water is up. Something of this sort could be worked into the unit with ease.

A fire alarm would be as simple as placing a thin piece of wire above the most likely area of fire the distilling flask. If theres a fire it breaks

cutting current and triggering an alarm. These circuits are very basic and can be made with ease for about 5-10$ at the very most.

[Edited on 20-11-2009 by Sedit] |

Velleman &c. sell water sensor kits which can activate relays.

There are fusible links, low melting alloy chunks, sold to be put over house furnaces and oil storage tanks. They are normally used with steel braided

wires and a spring to forcibly shut off valves and switches in case of overheating. The spring is set to force the switch off. The wire and link hold

the switch open. If the link melts, the spring is free. The nice thing is that they last indefinitely (decades), are inexpensive, and operate at about

60-80C, well below temperatures which might start a fire.

|

|

|

mr.crow

National Hazard

Posts: 884

Registered: 9-9-2009

Location: Canada

Member Is Offline

Mood: 0xFF

|

|

Wow good work! Everyone needs a bong cooler

What did you use for the water on top? Looks like a pipe with holes in it.

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

Just a thought but what effects would you get out of other liquids that evaporate easier or less so. It would have to be non toxic, have a higher

vapor pressure and non flamible but it could provide alternatives to the temperatures currently created in the system.

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

entropy51

Gone, but not forgotten

Posts: 1612

Registered: 30-5-2009

Member Is Offline

Mood: Fissile

|

|

Well, its interesting. | Quote: | | The unit can keep water at ambient, or just a hair below ambient temperature |

But since it only cools to

ambient, why not just use an air condenser (without a jacket) and direct the air blast from a fan onto that? It will cool the condenser to ambient

temperature without any plumbing and you wouldn't have the water mist to contend with.

Its not evaporative cooling because if it were it would reduce the temperatoure to less than ambient due to removal of the latent heat of evaporation.

Its convective cooling. It's a heat exchanger using ambient air as the cooling medium.

The reason this design is not actually giving evaporative cooling is that the drops of water falling through the tower don't have a large enough

surface area exposed to the counter-current air flow to evaporate a significant amount of water and thus cool the water by removing the latent heat of

evaporation. Cooling towers normally contain some form of filling over which the water flows, thus giving a large surface area for evaporation.

Sedit has also pointed this out.

I suppose some people with little understanding of heat transfer will toss out some equations which have nothing to do with evaporative cooling. But

the real engineers among us will not be fooled by a couple of equations.

If you could put your heat exchanger outside during cold weather then you could cool below the ambient (inside) air temperature.

[Edited on 22-11-2009 by entropy51]

|

|

|

aonomus

Hazard to Others

Posts: 361

Registered: 18-10-2009

Location: Toronto, Canada

Member Is Offline

Mood: Refluxing

|

|

@ mr.crow:

The water spray from the top is via a shower head, I used a 1/2" NPT tee with a end cap and short segment on each end to create the mount for it.

As for the internal packing, I could increase the surface area and decrease the flow rate by using something like glass wool, or even scotch brite

scouring pads, and also probably something like that on the output to cut down on the misting.

I only had a low flow computer fan handy, so its only really a heat exchanger currently, and maybe just a little bit of an evaporative cooler. If I

added packing material, and a more powerful fan, it would become an evaporative cooler and kick the pants off the average bucket + pump. I only

MacGyvered it from parts sitting around, so if someone wants to build a better version with a more efficient method for distributing the water and

keeping it in the packing to be evaporated, then please do, I want to see how far this can be taken...

@ Sedit:

Liquids that evaporate poorly (eg: oil) would just make the unit act as a heat exchanger, because of the higher surface area in contact with air as it

rains down, vs just sitting in a sump. Liquids that evaporate faster (eg: a water-IPA mix) would evaporate off and cool down below ambient, but you

would breathe in whatever you put in there.

NB: Because its a recirculating system, one would prefer to add in some sort of biocide, but because its evaporative, you would breathe in whatever

biocide you add to the sump! If anyone has any suggestion for a non-human-toxic biocide that is effective, and won't leave a big mess, please

make suggestions.

As for the fire sensor, because I have a lab jack, chances are that if I ever do design such a elaborate system, I'd rig a motor to drop the heating

device/bath down, a solid state relay to shut down the heating, and possibly a medium flow CO2 or N2 deluge system (nothing that would overwhelm the

fume hood that it would be situated in).

|

|

|

User

Hazard to Others

Posts: 339

Registered: 7-11-2008

Location: Earth

Member Is Offline

Mood: Passionate

|

|

For a biocide my 65L water reservoir contains a small amount of hypochlorite (bleach), don't know how much just poured some in.

Before my water started to feel fatty , i don't have this problem no more.

It must have been a year ago when I poured it in and it still works.

Simple and effective.

Even thought of taking one of the hoses and let them go through the wall let them contact cold outside air and returning them.

I solved the warming cooling water by just using a huge cement mixing bucket.

[Edited on 21-11-2009 by User]

What a fine day for chemistry this is.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

This device is essentially the same as a swamp cooler,

useful for moderate cooling in climates where the summer is relatively dry. The packing used for a swamp cooler could be used off the shelf, the only

modification needed would be to cut to shape. Likewise, the pumps used for a swamp cooler have the right kind of flow rate. If you live in an

appropriate part of the country, all this is available at any local big box hardware store.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by entropy51  | | But since it only cools to ambient, why not just use an air condenser (without a jacket) and direct the air blast from a fan onto that? It will cool

the condenser to ambient temperature without any plumbing. |

The reason not to do this boils down to the fact

that heat capacity of water is much greater than that of air. Even though air flows faster, the mass flow × heat capacity product is higher

with water. And then, after that, the use of a recirculation system increases the surface area for reject heat to the environment, which is what

turning the cooling medium into droplets gets you. The heat rejection rate of this device is far higher than using a simple air system. Using a

complicated air system is going to have the same kind of construction cost, and then not work as well because of the difference in heat capacities

between air and water and/or the need to deal with high air flow volumes and attendant pressures, not at all suitable for use with glass.

|

|

|

gsd

National Hazard

Posts: 847

Registered: 18-8-2005

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by watson.fawkes  | Quote: Originally posted by entropy51  | | But since it only cools to ambient, why not just use an air condenser (without a jacket) and direct the air blast from a fan onto that? It will cool

the condenser to ambient temperature without any plumbing. |

The reason not to do this boils down to the fact

that heat capacity of water is much greater than that of air. Even though air flows faster, the mass flow × heat capacity product is higher

with water........ |

Yes W.F. this is a correct argument and there is one more compelling reason for not doing this.

The operating equations here are:

Heat rejected in the condenser = Heat taken by out side fluid (water or air)

= mass X Specific heat X Temperature rise of cooling medium

This is a heat balance equation the significance of which is explained by you.

Also

Heat rejected in the condenser = Heat transfer coefficient X Area of Condenser X Log Mean Temp. difference (Between inside and outside)

This is a heat transfer equation.

As per the 2nd equation the controlling factor is the HTC which is about 2 orders of magnitude higher for water than that for air (roughly for water

if it is 250 kcal/hr.m2.C then that for air will be 10) So technically you will need about 25 times more surface area for air to compensate for this

difference. In order to overcome this deficit, where air cooling is indispensable ( as in car radiators or room AC) the surface area is enhanced by

using "Finned Tubes" which of course in impracticable in case of glass condensers.

Also somebody has commented upthread that this is not evaporative cooling because in that case the water temperature should drop below ambient

temperature.

Well the device aonomus has built is an evaporative cooler. The reason why it is operating as a convective cooler is probably the outlet temperature

of water ex condenser is very marginally higher than the inlet water temperature. So the amount of air he is pumping is able to remove this heat

"sensibly".

gsd

|

|

|

aonomus

Hazard to Others

Posts: 361

Registered: 18-10-2009

Location: Toronto, Canada

Member Is Offline

Mood: Refluxing

|

|

I should try running the unit with really hot water and plot temperature vs time to see how it all works out...

Happy to see though that people like the idea, this is the beta version, hopefully I'll come up with a better one in good time. Upon further thought,

I'd probably want a higher flow unit as well, simply because of the need for multiple condensers simultaneously (eg: a soxhlet extraction running in

the background while a distillation or reflux is running).

How have peoples experiences with impeller drive fountain pumps been? How is the pressure and flow control available? What happens if a valve is used

and is shut off momentarily or closed partially, will the pump react badly to the increased backpressure?

[Edited on 22-11-2009 by aonomus]

|

|

|

User

Hazard to Others

Posts: 339

Registered: 7-11-2008

Location: Earth

Member Is Offline

Mood: Passionate

|

|

Well I have bullied my fountain pump a couple of times and it didnt scream or anything.

But I think if this is done repeatedly the pump will suffer trauma.

These things consisting out of plastic and simple carbon brush motors are not built for this purpose.

I dont think it will live long if it is repeated.

Makes me wonder to, is it possible to use a dimmer to slow down the pump action?

What a fine day for chemistry this is.

|

|

|

aonomus

Hazard to Others

Posts: 361

Registered: 18-10-2009

Location: Toronto, Canada

Member Is Offline

Mood: Refluxing

|

|

As far as I know, AC line fountain pumps are magnetic inductance based, and are fully sealed. They have a impeller with a magnet attached to it, and

they sit on a small needle bearing (self centered by magnetic field).

Dimmers are not rated for inductive loads, so you will probably explode it. There are special ones rated for fans and other motors though.

If you feel ambitious, look at phase-angle controllers (technical name for a dimmer).

The bilge pump is plastic and carbon brush motor based, so its not destined to last, plus the water keeps weakening the caulk and I have to let it dry

out for a few days before I can use it again. I think the hassle might be worth a revisit....

|

|

|

blazter

Hazard to Self

Posts: 71

Registered: 3-9-2002

Member Is Offline

Mood: No Mood

|

|

The theoretical lowest temperature that an evaporative cooling device can reach is the dewpoint of the ambient air. Naturally, you will never get

there because of inefficient mixing of the air and the water. The better your packing media is and evenness of liquid/air flow is, the closer you

get.

It is possible to model/estimate cooling tower performance but you will need to have a good idea of your air flow rate, water flow rate, packing

surface area, inlet temperature, and outlet temperature. The following links should get you started with what you need to know:

http://www.cheresources.com/ctowerszz.shtml

http://www.jalal.com.pk/papers/Cooling%20Tower%20Theory.pdf

Of course Perry's is the ultimate authority, as referenced in both those links.

|

|

|

aonomus

Hazard to Others

Posts: 361

Registered: 18-10-2009

Location: Toronto, Canada

Member Is Offline

Mood: Refluxing

|

|

New parts acquired, version two in progress....

I'll be using a fountain pump, bucket, and the cooler stack will be mounted to the lid. It should disassemble for easy transport as well. Large water

volume, easy to clean from any potential bacterial growth, switch between evaporative or ice-in-bucket modes. Possibly adding a float valve of some

sort to make volume maintenance easy.

For the method of distributing water, I may abandon the shower head, instead substituting a coil of copper pipe with regularly spaced holes, and

plastic dish scrubbing pads used as packing material.

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

Scratch the plastic dish pads perhaps. They would be a fine packing material but why not use something with a higher heat transfer rate like copper

scrubbing pads? Perhaps it will be best as well to place the inlet of the water maybe 1/4 of the way down with packing on top so that fine spray is

stopped and more efficient cooling is aquired.

Just my thoughts at the moment. Right now Im just an interested annoying arm chair scientist

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

aonomus

Hazard to Others

Posts: 361

Registered: 18-10-2009

Location: Toronto, Canada

Member Is Offline

Mood: Refluxing

|

|

Plastic is cheaper than copper. For a university student with a total number for his student loan thats a little scary... yeah.

Plastic should do fine, with a surface area many many times that of whats found with a shower head spray.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

The heat transfer that's

relevant here is that between the air and water. This is a boundary process, where the limiting factor is the surface area of contact between these

two. The material of the mechanical support for the water doesn't affect the surface area.

On the other hand, the effect of a heat conductor as packing material is to equalize the temperature gradient within the column. Specifically, what it

does is to set up a second heat transfer process within the cooling water. This tends to flatten the temperature profile of the cooling water,

lowering the total heat removal capacity of the device. It's not at all obvious that this is so. The essence of it is that the total heat capacity is

related to the convexity of the temperature profile of the cooling water. Equalizing the temperature lowers that convexity. (Incidentally, a

concurrent flow heat exchanger has convexity of the opposite sign, even worse, which is why countercurrent heat exchangers are the norm.) The upshot

is that a heat-insulating packing material performs better.

|

|

|

gsd

National Hazard

Posts: 847

Registered: 18-8-2005

Member Is Offline

Mood: No Mood

|

|

The most desired property of the packing material in this cooler is its ability to "get wet". Which will promote formation of high surface area of

water and hence better contact and heat transfer. The packing material plays the role of facilitator not that of Medium.

gsd

|

|

|

Mr. Wizard

International Hazard

Posts: 1042

Registered: 30-3-2003

Member Is Offline

Mood: No Mood

|

|

The evaporative, 'swamp' coolers, or cooling towers do work well, when the air is dry enough. Unless you have very high humidity they will function,

cooling the water toward the dew point limit. Be aware they will raise the humidity of their local air space. Fresh dry air keeps them working best.

You can obtain the new air by putting the unit in a hood that pulls the humid air away, putting it outdoors, or putting the tower in a room equipped

with a vent fan, such as a bathroom.

Special cooler pads are quite available and cheap in the springtime here in the US. The cheaper ones consist of excelsior or wood turnings. The more

expensive ones are a plastic coated fiber. They usually only are replaced because of lime build up. The purpose is to increase the surface area of the

water, without restricting air flow. Loose packing is most important to the air flow, and to the maximum temperature differential.

|

|

|

| Pages:

1

2 |