| Pages:

1

..

6

7

8

9

10

11 |

Aqua_Fortis_100%

Hazard to Others

Posts: 302

Registered: 24-12-2006

Location: Brazil

Member Is Offline

Mood: †

|

|

@ Tim and Xenoid, thank you guys.. I'm away from my house this week, so when I return I will visit the eletronics supply store and report my own

adventures

Xenoid , this cell you've did really seems to be a very good cell to massive prodution of chlorates..with very high currents.. sure, this is the good

and mad science in pure form

@hashashan, also thanks to present us with the good job you've did.. what is your spected yield of chlorate ? Did you notice fast rates of corrosion

on graphites used as cathodes?

A little doubt ocurred now , all peoples says that is much better using linseed oil treated gouging rods , but I never had heard about the

quantitative comparation on using treated gouging rods and no treated ones.. So How fast is the erosion of these two types operating at same

conditions (temperature, current density, chloride conc. , etc)?

In the first cell I did (described above) , I tried to treat the pieces of gouging rods with a weird kind of brownish 'linseed oil' ("óleo de

linhaça") .. I tried to mix this with acetone (60% the only OTC here) , but these compounds didn't have mixed ! It separated in two layers.. But

anyway I put this in a glass pickle jar with the gouging rods and let some time(without vacuum).. after I have removed the gouging rods ., I let the

rods 'curing' at about 4 weeks, but when I've used it in electrolysis, in short space of time (less than a minute) they had set free a weird mini

immiscible bubbles which stay at the surface of the brine.. back to drawing board

"The secret of freedom lies in educating people, whereas the secret of tyranny is in keeping them ignorant."

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Linseed oil (or any other varnish) has to be baked to really cure it in porous materials.

Tim

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

| Quote: | Originally posted by Aqua_Fortis_100%

A little doubt ocurred now , all peoples says that is much better using linseed oil treated gouging rods , but I never had heard about the

quantitative comparation on using treated gouging rods and no treated ones.. So How fast is the erosion of these two types operating at same

conditions (temperature, current density, chloride conc. , etc)?

|

There is a short thread here, you may already have seen it;

http://www.sciencemadness.org/talk/viewthread.php?tid=9184

I used "boiled linseed oil" which is brown, rather than "raw linseed oil" which is pale yellow. From my point of view, I think the main benefit of the

linseed oil (or any waxy impregnation) is preventing the salt solution and chlorine, etc. migrating up the rods and corroding the electrical

connections.

@ Tim - I wasn't aware of the baking, I've just left mine in a warm place for a week or so, they get a plastic like coat. Does the baking at what -

100 - 150 oC. produce a hard coat?

Something I thought about trying is shellac (varnish - golden flakes), dissolve in alcohol and let rods soak in it! As I said in the other thread -

plenty of scope for simple experiments here.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

It's my understanding that varnishes cure best in the 150C range. Stick it in the oven at cookie-baking temperatures while the S.O. is out with a wad

of money at the mall.

I wonder if the common polyurethane stuff would hold up very well.

For that matter, I wonder why linseed oil would work well. It's heavily crosslinked (well, supposed to be anyway), but those bonds might be

vulnerable to attack. Certainly, any remaining -enes will be chlorinated rapidly. Urethane might survive better for its aromatic content, but worse

for its functional content (O's and N's). I'm not sure what lacquer usually is these days, but I would think if it dissolves in alcohol, it wouldn't

seem to be a very robust material.

Really serious processing here, I wonder what graphite vacuum-impregnated with glass would do.

Tim

|

|

|

hashashan

Hazard to Others

Posts: 255

Registered: 10-10-2006

Member Is Offline

Mood: No Mood

|

|

Well its a 5+ liter tank .. I think that 2 Kg will be there for sure. And I still didnt start running it. However from previous runs I can tell you

that the cathodes hardly erode at all.

|

|

|

Aqua_Fortis_100%

Hazard to Others

Posts: 302

Registered: 24-12-2006

Location: Brazil

Member Is Offline

Mood: †

|

|

| Quote: | Originally posted by Xenoid:

I used "boiled linseed oil" which is brown, rather than "raw linseed oil" which is pale yellow. From my point of view, I think the main benefit of the

linseed oil (or any waxy impregnation) is preventing the salt solution and chlorine, etc. migrating up the rods and corroding the electrical

connections.

|

Wow, that's seems the same stuff I've used..but was strange the fact that this linseed oil haven't mixed with my acetone..(that's maybe because of the

acetone concentration - 60%, being the rest ethanol and some water), but anyway it touched and, I think, penetrated in some extent the rod pieces. Can

I replace the acetone by ethanol ? (Because I have about 2 L of absolute ethanol and some more of common 95% grade)

| Quote: | Originally posted by Xenoid Here :

I think I've mentioned it at least twice in other threads, to get a good connection to a gouging rod, leave about 2-3 cm of the copper on the end of

the rod that you are going to make the electrical connection. You can then solder your wires onto the copper, or make small stainless steel clips to

clamp onto the copper. |

Yes, in your cell (some posts above) this is show also.. that's seems to be good in a eletrical connection..But I'm worried: what happens if , in some

way, the green mess of copper get a way into the electrolyte ? I need to descart the whole batch because of Cu contamination ?

| Quote: | Originally posted by Xenoid:

I used "boiled linseed oil" which is brown, rather than "raw linseed oil" which is pale yellow. From my point of view, I think the main benefit of the

linseed oil (or any waxy impregnation) is preventing the salt solution and chlorine, etc. migrating up the rods and corroding the electrical

connections.

|

Any waxy substance ? Why I can't just rub on the gouging rods some paraffin ? (that's because of the poorer adering (or any other) properties and/or

because of the waxy making electric isolation ?)

Also, why the formed chlorine does not appear to react with the hardened linseed oil at grapithe and making more mess (any substance formed ?) in the

cell?

@ Tim, I still don't understand : You say that is best to put the linseed oil at 150*C , but , you say to baking the oil alone or baking it when on

the gouging rods ?

(if in latter case, is present some risk of damaging the gouging rods? )

| Quote: | Originally posted by Tim:

Really serious processing here, I wonder what graphite vacuum-impregnated with glass would do.

|

Wow, I like your idea of glass on gouging rods.. But , is there risk of some sort of electric isolating the graphite?

Also what about using a sodium silicate solution instead of the linseed oil and then passing in a HCl solution ?

@hashashan, my gouging rods are somewhat expensive ... So I will hardly use it as cathode..but seems to be good in using a chlorate cell in which the

product will be used in a perchlorate cell as you have said before..

(recently I acquired also some Ni electrodes..Can anyone tell me if this can be a useful cathode?)

thanks

[Edited on 13-12-2007 by Aqua_Fortis_100%]

"The secret of freedom lies in educating people, whereas the secret of tyranny is in keeping them ignorant."

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by Aqua_Fortis_100%

But I'm worried: what happens if , in some way, the green mess of copper get a way into the electrolyte ? I need to descart the whole batch because of

Cu contamination ? |

Copper is insoluble and unreactive in chlorate solution.

| Quote: | | Any waxy substance ? Why I can't just rub on the gouging rods some paraffin ? (that's because of the poorer adering (or any other) properties and/or

because of the waxy making electric isolation ?) |

I doubt that would be very effective. Certainly, just rubbing it on isn't going to do a damn thing.

| Quote: |

@ Tim, I still don't understand : You say that is best to put the linseed oil at 150*C , but , you say to baking the oil alone or baking it when on

the gouging rods ? |

You tell me. What good is it to cure a block of solidified linseed oil? Sounds pretty stupid eh? Baking the rods to cure the oil inside them sounds

like a much better idea.

(if in latter case, is present some risk of damaging the gouging rods? )

| Quote: | | Also what about using a sodium silicate solution instead of the linseed oil and then passing in a HCl solution ? |

Hmm, a possibility.

| Quote: | | (recently I acquired also some Ni electrodes..Can anyone tell me if this can be a useful cathode?) |

As good as any other metal for cathode.

Tim

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

@ Aqua_Fortis_100%

As I stated elsewhere, there is plenty of scope for amateur experimentation in treating gouging rods, I use a siloxane concrete treatment with about

10% linseed oil, it works OK but it's not perfect, it penetrates very well! I played around with candle wax dissolved in PURE acetone and in hexane

camping fuel, and some others, I don't remember!

Sodium silicate? - Go for it, it's used as a concrete sealant after all, like the siloxane, and could work well in this application. Experiment,

that's what this forum is about, after all...

Copper contamination? - I've never observed it, sure there is some green corrosion, but movement is always OUT of the cell, not into it!

|

|

|

chloric1

International Hazard

Posts: 1141

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

| Quote: | Originally posted by Xenoid

Hashashan - I see you are still using "old fashioned" graphite (gouging rods), haven't you switched over to the "new - fangled" Co oxide (spinel)

anodes yet.....

The cell is sealed and the lid has 12 (9.5mm) gouging rods mounted through it. The rods are held in place using waterproof cable glands and "o" rings.

One advantage of this design is that the used gouging rods can easily be removed and replaced, by unscrewing the gland. The "o" ring seals in gasses

and fumes and prevents corrosion of the electrode electrical connections

The vent tube is 6mm ID PVC tubing fitted similarly to the gouging rods, but using the next size down cable gland.

Image 1: Main components, SS cathode, plastic pail, lid with gouging rod anode assembly.

Image 2: Details of anode electrode connections and mountings.

Image 3: Close up, showing cable gland, gouging rod and "o" ring.

Image 4: SS cathode, in position and wired up.

[Edited on 11-12-2007 by Xenoid] |

I have notice simular anode hookups in the cobalt spinel section. I really need to go to the hardware store soon and look around. The water proof

cable thingies are in the electrical dept?? Also, what are those metal tabs that you circle around your rods? I have been looking for those becuase

my old cell was ugly and I need to connect several anodes so I can lower the current density on each one to get maximum life out of them.

I am not too far from messing around with cobalt spinel but I need a heat gun and cash is modest. Maybe this weekend. I need to try to contribute

especially since I am going to try selling anodes so I can financially support my hobby with a net gain to boot!

Fellow molecular manipulator

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

Have used Nickle in a Perchlorate cell myself. They corroded. The cell had a LD anode that was let run and run. There was a black mess due to Ni

corrosion.

Indusry used Ni. It needs Chromate to protect if from the cell invironment. (Not good/possible with LD).

Dann2

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

| Quote: | Originally posted by chloric1

I have notice simular anode hookups in the cobalt spinel section. I really need to go to the hardware store soon and look around. The water proof

cable thingies are in the electrical dept?? Also, what are those metal tabs that you circle around your rods? I have been looking for those becuase

my old cell was ugly and I need to connect several anodes so I can lower the current density on each one to get maximum life out of them.

|

Chloric - sorry to take so long in replying, I kept forgetting about your post, with all the anode excitement...

I bought the cable glands from a specialist electronics company called Jaycar, here in NZ and Australia. They have an IP68 rating which is the highest

possible for dust and water sealing. They have a built in rubber and plastic sealing mechanism, however I bought the next size smaller than would

normally be used, because it was cheaper and also they took up less room (this was when I was trying to fit 10 of them on top of a pickle jar). Size

was not so important in my latest "bucket" cell. You can use the correct size glands "as is". If you use the smaller, cheaper ones, you have to cut

off the sealing part and drill them out to 9.5 mm. Just get a small "O" ring that fits tightly around the rod, and put a bit of silicone grease on the

assembly!

The clips are made from stainless steel. I picked up a whole lot of scrap at a recycling centre. I cut strips 6 cm long and about 1, 1.5 or 2 cm wide,

(I made a range of sizes). The rods are 9.5 mm or 3/8" so you have to preform the clips around drill bits which are a bit smaller than the rods.

Here's where it becomes a bit hazy, as I made a large batch several months ago and haven't made any since!

I used an 8 or 8.5 mm drill and bent the strips into a "U" shape around it, then squeeze the ends in a vice as tightly up to the drill as possible.

You'll end up with something roughly the right shape. Next force this around a drill (9.0 mm) and do the same thing, you may have to do a bit of

hammering at this stage. You should get nice tight bends where the tag starts to go around the rod. Don't try to form them around something the same

size as the rods, otherwise they will never be tight or look nice. I'm sorry I can't be more specific, it's a bit of trial and error. I got quite good

at it and even threw away my first few attempts, because they were not "up to standard" Drill 3.5 mm holes ( say 1/8") in the tags, after you make

them. All I used were two drill bits, the vice, a hammer and some metal snips.

[Edited on 14-12-2007 by Xenoid]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

That old iron tin nitrate hydrogel , or the chromium or aluminum analogues , might make for an interesting

baked on coating and sealer for even lowly gouging rods .

http://www.sciencemadness.org/talk/viewthread.php?action=att...

A mixture of zinc and cobalt nitrates , perhaps with

manganese and lead and bismuth nitrates baked on top ,

might even yield a perchlorate anode .

[Edited on 14-12-2007 by Rosco Bodine]

|

|

|

chloric1

International Hazard

Posts: 1141

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Reply

I know your seriously multitasking, so I was not expecting a rapid reply anyway. You explained enough to me, I understand that the drill form must be

smaller than the rod I will use, its like drilling holes smaller than your tap bit before you tap otherwise the bit won't remove material and make

your wonderfull threads.

Copper may be easier to fab, I might want to nickel plate copper strips. If solution does not "wick" up your anode then copper connection would be

fine IMHO. Especially if your doiong O-ring seals and want not. Just don't repeat the 1986 Challenger errors and use the wrong size O-rings.

Fellow molecular manipulator

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

I copper plated the anodes I used in my eight month run. Having stripped the copper from the graphite nubs left, I have two chunks of graphite, about

6" long, good and solid, if impregnated with what have you.

The main obstacle is height and porosity. The first bar I used had a vein of low density that wicked chlorine right up to the copper, continuously

corroding that side much faster than anywhere else. I stripped, cleaned and replated it halfway through. The second lasted its whole lifetime with

one plating, showing no tendency to devour the copper.

The copper surface was always mildly tarnished of course, due to chlorine in the area. Most of the gas, steam and salt fume stayed in the cell due to

the packing I placed on top. The height above the liquid level was the other major factor keeping the copper metallic.

Tim

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

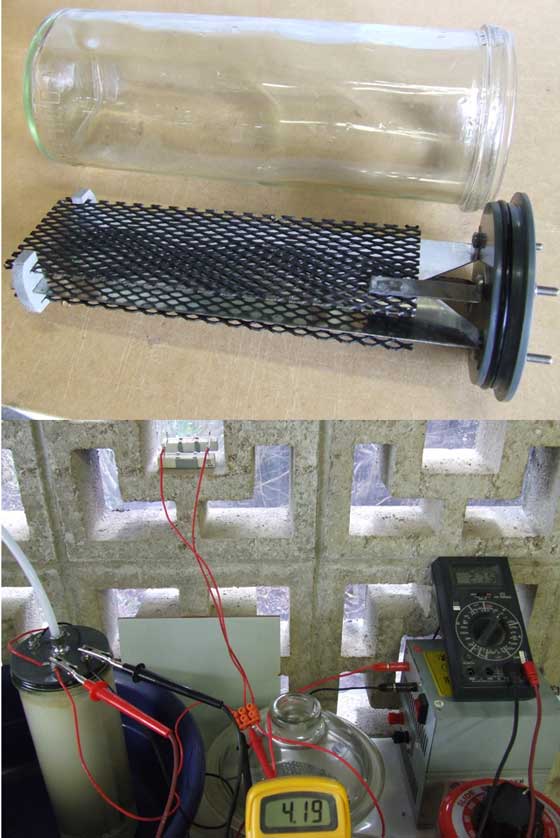

Chlorinator Electrode Chlorate Cell

I've finally got around to putting together a chlorate cell based on the chlorinator cell electrodes I rescued from a skip (see "Cobalt Oxide Anodes"

thread, pp 2,4,6,7).

http://www.sciencemadness.org/talk/viewthread.php?tid=9572&a...

The cell is based around a tall fruit bottling jar I got from a recycling place for 50 cents. The cell is only about 1.1 litres but it fits the

chlorinator anodes very well. The cell uses the two outer electrodes of the original chlorinator because thes were the least worn. It has a central SS

cathode, with the 2 multi metal oxide (RuO2/TiO2) coated Ti mesh anodes on either side. Electrode spacing is 10mm. The cell was filled with saturated

NaCl, about 350g.

The cell is running of a 5 volt computer supply, and at the moment is operating at 2.75 volts and 4.19 amps. A pair of 0.8 ohm 20 watt resistors in

parallel are used to control the current. The ~4 amp current is quite conservative as I want to see how they behave, I may increase it later. The cell

voltage is an amazing 2.75 volts, I've never had a cell running at a voltage of less than about 3.2 volts before! I guess it's due to the large

surface area flat sheet electrodes, the close spacing, and the efficient MMO coating.

Needless to say the cell electrolyte is clear (Yay!!!) although a little orangey-brown scum formed initially, it has mostly faded!

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

Cell looks very tidy. Your bench is respectible too, would not show mine in a photo, I can tell ya!!!!!!!!!!!

The MMO in industrial Chlorate production are not run at low Chloride conc. as it erodes/damages them. Perhaps the type of MMO on the pool

chlorination andodes are different than the industrial anodes for Chlorate as the pool anode will ALWAYS be sitting in water with little Chloride

present. The pool andoes suit the home maker better than the 'real macoy' of industry. Hope the presence of Chlorate does not do any damage though.

2c later,

Dann2

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

@ Dann2

Yes, a tidy cell but as it turns out, a flawed design. BTW you should see the rest of the garage - an utter pig sty! What do you think about the low

operating voltage (2.75 volts), I was quite surprised!

The orangey - brown scum actually got worse, much worse! When I came down to check it this morning (after 16 hours operation) it was full of brown and

orange particles and so cloudy I couldn't see the electrodes. Fearing that the anodes had disintegrated, I switched the mutimeters on, and was

relieved to see the electrical parameters were essentially unchanged.

I dismantled the cell, and immediately saw the problem. I had used two SS screws to attach the 2 Ti anodes to the PVC lid and also act as electrical

terminals. I have always used this procedure in the past for SS cathodes, so used it for the anodes without thinking! I should have known better, SS

is useless in anodic saline conditions.

The screw heads had about 5 - 10% corroded away...

In doing so they had contaminated the cell with Cr and copious amounts of reddish-brown colloidal iron hydroxide - just what I was trying to avoid, as

this is a major problem with gouging rods!

After careful cleaning I have now coated the screw heads with hot glue. Epoxy would have been better, but I think the hot glue should hold up. I've

filtered the solution, lucky I have a pressure filter....

http://www.sciencemadness.org/talk/viewthread.php?tid=9630

and put the cell back together, albeit with an orangey coloured electrolyte!

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

My Chlorate Cell

Your cell looks pretty good there, Xenoid.

Attached is a picture of mine.

The container is a 4L PET jar from Wal-Mart. The lid is PP. (I would have preferred PVC but it's kind of hard to find).

The studs that connect the electrode assembly to the lid are titanium, with titanium washers and viton o-rings.

The electrode assembly is a solid plate type, rated at 20 amps.

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

@ jpsmith123

We've been waiting a long time!

When are you going to fire up that baby...  .. it looks really good! It will be

sooo.. nice to have a clear solution to work with. .. it looks really good! It will be

sooo.. nice to have a clear solution to work with.

Did you have much trouble adapting the original chlorinator cell lid to your jar. As you would have seen in the other thread my chlorinator had an

epoxy sealed top and no terminals. I think they are starting to make them all like that now!

That's a long exhaust pipe, are you planning on feeding it over to the neighbours place...

With that large capacity, it would probably benefit from a bit of magnetic stirring.

Be sure to let us know how you get on. I'm impressed with these electrodes so far, but its only early days. These chlorinators are supposed to last 5

-6 years in pool use, I wonder how long in a chlorate cell...!!!!

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Goddammit!!!...

I just can't get this chlorinator electrode chlorate cell right.

This morning I noticed more orange-brown gunk floating around in the cell. Thinking the hot glue had lifted off the anode screws, I was already to

replace it with epoxy. But, no, this time its the SS cathode that's starting to corrode badly along the edges. I haven't really had this problem

before, just some minor cathode corrosion. Must be the relatively small cathode to anode surface area ratio, usually I have big cathode surfaces

compared to gouging rods.

Moral of story, if you want a nice clean running cell use TITANIUM cathodes.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Funny, with all the graphite shit I had, I didn't give a rat's ass about the rusting "stainless" steel cathode I've been using. Methinks you should

point your nose down away from the clouds!

Tim

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

| Quote: | Originally posted by 12AX7

Methinks you should point your nose down away from the clouds!

Tim |

Well, I'd just like to get away from filtering and defloccing etc. all together. Ti sheet is now pretty cheap, no reason not to use it for cathodes.

Theoretically a chlorate cell should be perfectly clean, just boil and crystallise, or if you use KCl just dig out the crystals!

A chlorate cell can be as "low tech" as you want, I prefer to head the other way!

|

|

|

Aqua_Fortis_100%

Hazard to Others

Posts: 302

Registered: 24-12-2006

Location: Brazil

Member Is Offline

Mood: †

|

|

Developments in my cell

I invested some money to get my PC PSU to do a good job in chlorate cell and I'm think to be probably close to achieve that..

In a prior attempt I tried to connect a 0,22ohm/5W resistor between the +5V lines.. But was too simple and the resistor heated like hell in a few

seconds !

Yesterday I constructed and tested a circuit that my friend did , tested and did the upload here to control and to stabilize current (the photo was

his test , using a lamp and the schematic is in portuguese (also)) :

http://www.4shared.com/file/32991572/7dcdf563/Regulador_0_a_...

It gives a max. and smooth 4,4 - 4,5 A running in my cell .. He said that with this I can control the current to even 8 A , but the connections and

the cell design (anode -cathode distance , cell materials connections,etc) will afect it at all..And so the low current I got...

What I can do to improve the connections? Can I solder the wires direct to the rest of copper plating on anodes (as Xenoid advised to let some of the

copper unpeeled)?

Thanks!

[Edited on 3-1-2008 by Aqua_Fortis_100%]

[Edited on 3-1-2008 by Aqua_Fortis_100%]

"The secret of freedom lies in educating people, whereas the secret of tyranny is in keeping them ignorant."

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

| Quote: | Originally posted by Aqua_Fortis_100%

In a prior attempt I tried to connect a 0,22ohm/5W resistor between the +5V lines.. But was too simple and the resistor heated like hell in a few

seconds !

What I can do to improve the connections? Can I solder the wires direct to the rest of copper plating on anodes (as Xenoid advised to let some of the

copper unpeeled)?

|

What do you mean, you "connected the .22 ohm resistor BETWEEN the +5V lines" The resistor goes in series with your cell to drop the voltage and limit

the current. Wattage for that resistor at 4 amps should be W=I^2xR, W= 16 x .22, W= 3.52, 5W should be adequate. At 4 amps that resistor will drop

the voltage by E=IR, E=4 x .22, E= .88 volts.

If you connect that .22 resistor BETWEEN +5v and 0V (earth) you will get I=E/R, I=5/.22, I=22.7 amps - that's probably at the PSU limit! That would be

113.4 watts that poor old 5W resistor would be trying to dissipate!

Mind you, even in series it will get warm, or even hot when running at 3.52W

That circuit should be OK, I've used something similar for constant current charging of NiCad cells in battery packs for caving lights. It's

effectively using the power transistor as a variable resistor.

Yes, for you, the best thing is to solder directly to the remaining copper! You'll need a fairly heavy duty soldering iron. A lightweight electronic

iron doesn't develop enough heat, well mine doesn't anyway. Put silicone grease on your connections, make sure no electrolyte gets on them...

[Edited on 3-1-2008 by Xenoid]

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

| Quote: | Originally posted by Xenoid

Well, I'd just like to get away from filtering and defloccing etc. all together. Ti sheet is now pretty cheap, no reason not to use it for cathodes.

Theoretically a chlorate cell should be perfectly clean, just boil and crystallise, or if you use KCl just dig out the crystals!

|

After various experiments and disasters over the last few weeks, I now realise that the SS cathode corrosion occurs almost wholly in the headspace

area of a cell, and is particularly pronounced at metal junctions (needless to say). Any SS within the electrolyte and even metal juctions within the

electrolyte are little corroded.

Colloidal Fe hydroxide and Cr contamination from the headspace area can be avoided. I have found glue lined heatshrink tubing or even a silicone

grease coating, overlain with ordinary heatshrink will protect the SS in the headspace area. Screw connections to the outside world can be covered in

hot glue.

The 10L, 12 rod cell I described in an earlier post, now has 5mm threaded rod cathode connections. These are covered in heatshrink and rise directly

up through small waterproof cable glands on the lid. The entire electrode assembly is now mounted directly to the lid, and is completely gas and odour

free.

So if protected correctly SS makes perfectly good, contamination free, cathodes. Ti cathode(s) for a large cell would work out to be quite expensive

and I now realise it is not justified. Perhaps Tim is right, and I should get my head down out of the clouds, it's just that making these cells is

such damn fun!...

|

|

|

| Pages:

1

..

6

7

8

9

10

11 |