| Pages:

1

..

4

5

6

7

8

..

24 |

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

You assume Nd sulphate is soluble in alcohol, or at least alcohol/water mixtures. Any evidence you've come across for that?

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

I know I read some of the other lanthanide sulfates are alcohol soluable- To what degree, I dont know. But I do know Lanthanium and Cerium both have

similar soluability curve in water, with respect to temperature. I'll just do some experimentation, and get back to you on that!

http://chemicalland21.com/industrialchem/inorganic/LANTHANUM...

"Lanthanum sulfate is a white crystals. It is slightly soluble in water, soluble in alcohol" down the page a bit.

This could have some interesting data, if I could view it...

http://www.springerlink.com/content/rm1567257x822731/

[Edited on 11-15-2011 by Wizzard]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

So in a sense, assuming reasonably that this applies also to others in the 'cerium group' (as they were once called), you're risking to acually

increase solubility!

But it's always, always, always worth a shot...

[Edited on 16-11-2011 by blogfast25]

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

Oh, yes- I'm looking to increase solubility below 0*C to push ever more ferrous sulfate out of solution.

Just reading through some other threads, came across a gas chemistry link, this may be of interest to this thread- I think it may be applied to Nd2O3

to possibly generate Nd metal!

http://mattson.creighton.edu/PipetteRxn/index.html

[Edited on 11-16-2011 by Wizzard]

[Edited on 11-16-2011 by Wizzard]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Unfortunately, the reduction of Nd2O3 with hydrogen is far from possible. It is possible with the oxides of Fe, Co, Ni and a few others but not with

the REs.

Allow me to explain. Take a generic reduction by hydrogen:

MO<sub>n</sub> + n H<sub>2</sub> === > M + n H<sub>2</sub>O

This can only proceed if the change in Gibbs Free Energy, ΔG = ΔH - T ΔS is negative (< 0): systems seek a state of minimal Free

Energy. Assuming for argument’s sake that the entropic effects for this reaction are small (so T ΔS ≈ 0), then ΔG ≈ ΔH

< 0.

ΔH can be found by adding the Heats of Formation of the reaction products and subtracting from this the sum of the Heats of Formation of the

reagents. In the cases of Fe2O3, CoO and NiO this ΔH is indeed negative and these reactions can proceed.

But in the case of Nd2O3 its HoF is too large and ΔH > 0 (in reality we should take the entropic effects into account). It’s also for this

reason that Nd2O3 cannot be reduced by aluminium or magnesium, both far stronger reducing agents than hydrogen.

REs are generally produced by electrolysis. But reduction of the trifluorides with magnesium is also possible (for the same reason: ΔH < 0).

It’s this latter reaction Mr Home Scientist and me will endeavour to produce Nd metal. If we ever get round to making enough

NdF<sub>3</sub>, that is!

[Edited on 16-11-2011 by blogfast25]

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

Well then I learn something every day! Thanks for the write-up.

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

In the midst of all this talk about separation and purification, I wanted to get back on track with the final step of this process to obtain Nd metal.

I have a few crops of NdF3 already made, so I wanted to try one out to see how it went.

These are my samples of NdF3 (under fluorescent lighting), each vial from a different batch of magnets. The one on the left is the one I showed in a

previous post (distinctly green), the middle one is a very nice white, and the righthand sample is a bit more brown. The rightmost one is what I used

in this experiment - since it's a bit more contaminated it was a good candidate for initial experimentation.

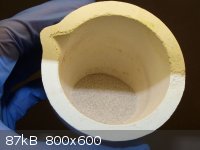

That righthand vial contained 7.1g of NdF3. I mixed this with 1.4g of Mg powder - somewhat more than the stoichiometric amount, but I wanted it in

excess. I placed this in a fused silica crucible in which the reaction was to take place.

Since the total mass of the reactants was only 8.5g, I decided that normal thermite procedures wouldn't be sufficient (as per an earlier suggestion).

So, I placed this crucible on a ring stand and heated it from below with a propane torch. I was hoping to get to the initiation heat just from this,

but after about 15 minutes of blasting the bottom of the crucible with the torch there was no change. So, to get things started I grabbed a small

strip of Mg ribbon with tongs, lit this with the torch, and dropped it into the hot crucible. This did the trick! The whole interior lit up with a

nice orange glow and a good amount of smoke as the reaction took place. It reminded me of chromium thermite I've done in the past - lots of light and

smoke but no sparks. I was very excited to see something happen  Here's what it

looked like shortly after the smoking stopped. You can see the ring stand and blue propane bottle beneath it. Here's what it

looked like shortly after the smoking stopped. You can see the ring stand and blue propane bottle beneath it.

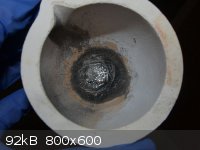

I waited about an hour to let this cool, then took it inside to see what I could find. Disappointingly, I didn't find much at all.  The vast majority was just a dark grey powder. The vast majority was just a dark grey powder.

Clockwise from top left, here's what each pile is.

Top left (TL): crust from top of the reaction. It's mostly white MgO.

TR: Bulk of the material below that. It's pretty uniformly grey.

Bottom right (BR): Much blacker material from the bottom of the reaction products.

BL: A small amount of scrapings from stuff stuck to the bottom of the crucible.

Now here's where things get interesting.

In scraping away the black material from the bottom, I revealed an extremely thin layer of a very shiny metal!

I scraped some of this out and picked out some of the larger pieces to put in a vial to see them better. "Larger" of course meaning extremely tiny.

This can't be more than 50mg. There were more shiny dots in the bottom left pile of the previous picture.

What's encouraging is that these flakes are not attracted to a strong magnet! That means they can't be iron, so I tentatively think that

these are actual (miniscule) chips of Nd metal!

Some of the rest of the reaction material did seem to be affected by a magnet, so as I suspected there's certainly some iron contamination in this

batch. Magnetite could explain some of the black coloration.

Now to test this metal, I placed a small amount of the black powder with shiny chips in a test tube and added a few drops of sulfuric (battery) acid.

It immediately produced a good amount of gas and a large amount of heat. Some of the black material didn't dissolve. I was hoping to get a pink

solution to confirm Nd, but it still looks colorless to me. It was such a tiny amount though I bet it'd be impossible to see if it was there anyways.

I'd think testing with oxalate should show me something, even at low concentrations. I have yet to try this. It's hard to say if I actually made Nd

metal because it's nearly impossible to separate the shiny bits for testing alone since they are so tiny. What's in the vial is by far the best of

what I could collect.

So I suppose this confirms the difficulty of getting this reaction to work at small scales. I imagine the whole mess didn't get hot enough, despite my

additional propane torch heating, to react all the way or produce molten metals. Something obviously happened to the reaction mixture, but it

just didn't make an appreciable amount of metal. Just a lot of grey and black powdery garbage, plus that promising tiny amount of shiny metal.

|

|

|

Chemistry Alchemist

Hazard to Others

Posts: 403

Registered: 2-8-2011

Location: Australia

Member Is Offline

Mood: No Mood

|

|

Could the Nd that formed be from the heating with he torch? im sure if it was the thermite reaction, Nd metal will be spread through out the mixture

but if it was only at the bottom, could that be from heating?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Mr Home Scientist:

Wow! Much to talk about here, especially since I was going to U2U you advising NOT to proceed: much more about that later on.

You seem indeed to have obtained reaction and Nd metal.

Some comments.

Igniting the mixture by just heating would probably have required at least 800 C (my estimate). The high initial temperature might be what saved this

reaction though. It was definitely the right idea to heat externally.

You claim to see MgO but the main reaction product should be MgF2 of course. I suggest in any case to grind down the slag and treat it with strong

HCl. If the reaction took place then the dark material is likely caused by fine Nd metal dispersed through sintered MgF2. It should still react with

strong acid though. With an MP of 1263 C your orange glow may have been just a little short of melting the MgF2 down.

One possibility is that the metal you found is unreacted Mg (Fe seems unlikely, as it was only a contaminant) and the only way to prove it is

neodymium would be to try and dissolve it in as little H2SO4 as possible and see if you get a precipitate at BP, or by saturating the solution with

K2SO4. If you go Nd2(SO4)3, it can be tested with oxalic acid (redissolve it in iced water first). MgSO4 is of course highly soluble over a wide range

of temps. But it’s unlikely to be Mg, IMHO…

And here’s the strange news that I was going to U2U about.

Getting much closer to producing NdF3 now (I took receipt of the NH4HF2 this morning), I decided to do a full thermochemical calculation for NdF3 +

3/2 Mg === > Nd + 3/2 MgF2 (1), last night, with a view of estimating potential end temperatures. Well, that didn’t take very long! For some

years I’ve been convinced that this reaction would be thermodynamically favourable (ΔG < 0) and with more than enough reaction enthalpy

(ΔH << 0) to spare but that must have been based on an erroneous calculation or datapoint!

Wolfram Alpha coughed up a value for the standard heat of formation of NdF3 of - 1657 kJ/mol (which ‘sounds right’) and for MgF2 of - 1124 kJ/mol.

Immediately it becomes apparent that the Standard Heat of Reaction for (1) = 1657 - 1.5 x 1124 = - 29 kJ/mol which really is

negligibly small, almost ΔG ≈ 0. No entropic effects are taken into account but for reactions involving only solids these are usually

small.

It really means that if the reaction proceeds AT ALL, strong external heating would be needed to get the metal and slag to melt and separate (whereas

various thermite-like reactions generate enough heat to achieve this)

But it seems to me you’ve provided invaluable evidence that the reaction does proceed, albeit w/o generating much extra heat, otherwise you’d have

obtained a neat slag puddle with the metal at the bottom.

The other point is that I found two literature references claiming NdF3 is purple/violet. I looked at your procedure again and believe your product(s)

are relatively pure samples of neodymium trifluoride and that your colour is the right one, bar maybe slight distortion by FeF3. But that should have

stayed in solution because it’s soluble though, bar a little occlusion/co-precipitation…

All in all, a big ‘thumbs up!’

[Edited on 17-11-2011 by blogfast25]

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

Second-round extraction and recrystallization of my magnet sulfate soup produced 5.45g of neodymum sulfate, plus .50g in 2 large single crystals- pics

attached

The small one is 7x4x3mm, the large one is 9x6x6mm.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Nice whoppers, Wizzard!

Are you gonna attempt some really giant ones?

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

You know it! I'm going to go a real nice writeup with at least 150g of magnet material, and walk-through the whole process, step by step... With the

help of my new scale and other measuring devices. There's even still more Nd to be extracted from my soup. Noy much, but maybe another 3g or so I'd

guess. 2nd round was very successful, though. I wish I had more hot plates...

|

|

|

Poppy

Hazard to Others

Posts: 294

Registered: 3-11-2011

Member Is Offline

Mood: † chemical zombie

|

|

I'm jealous of your crystals

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Thou Shall't not Coveth another Man's Crystals!

Wizz, I bet you could sell these, especially even larger ones, to the 'alternative medecine' crowd, you know? 'Astral spectrum changes', a bit of

'quantum this' and 'quantum that' and some good pics and hop: 20 bucks a pop!

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

Quite possibly. I dont take advantage of other people ignorance, however  Plus I

dont know if this sulfate is toxic or not. Plus I

dont know if this sulfate is toxic or not.

|

|

|

Poppy

Hazard to Others

Posts: 294

Registered: 3-11-2011

Member Is Offline

Mood: † chemical zombie

|

|

Quote: Originally posted by Wizzard  | Quite possibly. I dont take advantage of other people ignorance, however  Plus I

dont know if this sulfate is toxic or not. Plus I

dont know if this sulfate is toxic or not. |

Yes every crystal really just filters incoming radiation and gives off specific ones of their kind, that could be useful if you manage to deal with

some divine spectrometric relationship.

I was even planning on polishing a "ambient temperature thermal lens" crystal haha

Back on the neodimium issue, the sulphate method is trustworthy. My final powder was assumed to contain neodimium sulphate, but it dissolved so slowly

in water you couldn't know. But diluting this with some hydrochloric acid gave a yellow brown solution under a tungsten lamp, and a green solutoin

under a fluorescent lamp. There might just be some iron contaminants, but the sulphate method gives neodimium as the prevailing component of its

admitted double salt.

|

|

|

Poppy

Hazard to Others

Posts: 294

Registered: 3-11-2011

Member Is Offline

Mood: † chemical zombie

|

|

All products are going into a rebatch to see what happens in a schikorr like reaction with Nd hydroxide.

This product will then be slowly crystalised hopefully reaching wizzard's one quality.

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

@Chemistry Alchemist: Yeah I was thinking the same thing too - since that's where the torch was hitting it was definitely hotter at the bottom. That,

I think, fits well with blogfast's comments about this reaction needing a bit more heat to get results.

Quote: Originally posted by blogfast25  | | You claim to see MgO but the main reaction product should be MgF2 of course. I suggest in any case to grind down the slag and treat it with strong

HCl. If the reaction took place then the dark material is likely caused by fine Nd metal dispersed through sintered MgF2. It should still react with

strong acid though. With an MP of 1263 C your orange glow may have been just a little short of melting the MgF2 down. |

Indeed. I think just the top layer of white is MgO from the burning magnesium strip reacting with air. That's why the white is only on top but not

further down. In the second to last picture you can see a lot of white powder on the sides of the crucible from this.

So you're thinking react all the products with acid, and it will leave behind the MgF2? Or dissolve everything and test with oxalate? MgOx appears to

also be rather insoluble.

Quote: Originally posted by blogfast25  | | One possibility is that the metal you found is unreacted Mg (Fe seems unlikely, as it was only a contaminant) and the only way to prove it is

neodymium would be to try and dissolve it in as little H2SO4 as possible and see if you get a precipitate at BP, or by saturating the solution with

K2SO4. If you go Nd2(SO4)3, it can be tested with oxalic acid (redissolve it in iced water first). MgSO4 is of course highly soluble over a wide range

of temps. But it’s unlikely to be Mg, IMHO… |

Right, I would think that any Mg metal down there would have been heated enough to react away. I thought that it might be Fe because the fluoride

looked fairly contaminated, plus my recovered metal was such a tiny amount anyway.

Quote: Originally posted by blogfast25  | | The other point is that I found two literature references claiming NdF3 is purple/violet. I looked at your procedure again and believe your product(s)

are relatively pure samples of neodymium trifluoride and that your colour is the right one, bar maybe slight distortion by FeF3. But that should have

stayed in solution because it’s soluble though, bar a little occlusion/co-precipitation… |

I think that last bit is pretty likely. When making the fluoride I used a fairly concentrated solution of the sulfate. I can see why more dilute is

better, and I'll make sure to do this next time. I've got another batch of sulfate ready to recrystallize and convert to the fluoride.

Quote: Originally posted by blogfast25  | And here’s the strange news that I was going to U2U about.

...

It really means that if the reaction proceeds AT ALL, strong external heating would be needed to get the metal and slag to melt and separate (whereas

various thermite-like reactions generate enough heat to achieve this)

But it seems to me you’ve provided invaluable evidence that the reaction does proceed, albeit w/o generating much extra heat, otherwise you’d have

obtained a neat slag puddle with the metal at the bottom. |

That's quite interesting. It's good that you rechecked the theory! I think that is definitely going to be the way to go with this - heat the crucible

up high enough, then initiate the reaction as I did before. To this end, I just ordered some fire bricks from Home Depot's website and I'm going to

build a (crude) furnace around the crucible to keep the heat in. Hopefully this will be enough to get me to the melting points. Exciting times ahead!

[Edited on 11-18-2011 by MrHomeScientist]

|

|

|

Endimion17

International Hazard

Posts: 1468

Registered: 17-7-2011

Location: shores of a solar sea

Member Is Offline

Mood: speeding through time at the rate of 1 second per second

|

|

If you're about to try that melting scenario, consider argon, because if you don't use it, you will fail miserably, meaning the yield will be

dreadfuly small, and you'll end up with your precious starting batch heavily contaminated.

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

Argon may work well. Just don't try nitrogen or CO2  Speaking of which, anybody

know anything about lanthanide nitrides? Speaking of which, anybody

know anything about lanthanide nitrides?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Endimion17  | | If you're about to try that melting scenario, consider argon, because if you don't use it, you will fail miserably, meaning the yield will be

dreadfuly small, and you'll end up with your precious starting batch heavily contaminated. |

Nope. Failure is by no means guaranteed w/o argon. See aluminothermic reactions of which I carried out more than a dozen on different metal oxides

(Fe, Cu, Si, Ti, Cr, Mn, V, Nb and combined ones as well): despite end temperatures of around 3000 K, you usually get good quality metal (if you get

everything right! - they’re not as easy as you might think) because the once molten slag (alumina) forms a perfect protective barrier for the metal

regulus. No need for argon here neither, assuming you can get the MgF2 to actually melt (1263 C, not even that hard).

@Mr Home Scientist:

Yes, I suggest trying to recover as much Nd by extracting it from the slag. Nd and Mg should be easily separable with the saturated K2SO4 method.

Careful not to use too strong acid (32 % HCl will be OK) or your MgF2 will start acting like fluorite: a HF generator!

Way to go with the furnace. I’m thinking of carrying out my reaction with my dinky toy charcoal furnace: that melts copper but only just…

There is however another ‘theoretical’ aspect that I haven’t touched upon.

Assume we heat a stoichiometric mix of NdF3 and Mg to above the MP of MgF2 and reaction occurs. Now we hold the crucible there at that temperature: in

the melt the equilibrium 2 NdF3 + 3 Mg < === > 2 Nd + 3 MgF2 rules.

The equilibrium constant is given by Nernst:

ΔG = - RT lnK with ΔG the change in Free Energy (at temperature T) and K the equilibrium constant (at T):

K = ( a<sub>Nd</sub><sup>2</sup> x a <sub>MgF2</sub><sup>3</sup> / ( a<sub>NdF3</sub><sup>2</sup> x a <sub>Mg</sub><sup>3</sup> / ( a<sub>NdF3</sub><sup>2</sup> x a <sub>Mg</sub><sup>3</sup>

With each a the activity of each species (we cannot use concentrations here)

We would have to calculate ΔG (at T) from the Standard change of Free Energy, ΔG<sup>298 K</sup> but examples with similar

reactions show that the temperature correction, even for T > 1000 K, is usually small.

Although we don’t know the exact ΔG, we know from the above that it is likely to be quite small. Well, from Nernst we know that if ΔG

≈ 0, then K ≈ 1 or in plain English: there should be considerable free Mg in the metal phase. I thus predict that obtaining high purity Nd

with this method is probably impossible.

In practical news, I’ve finally finished precipitating, filtering and washing the first batch of NdF3. Tomorrow it will be dried. So far it is very

clearly lavender coloured.

And another 25 g of magnet material has been dissolved in HCl. I’m going the ‘sat. K2SO4’ route again, just to explore that a bit more. The

double salt has been precipitated and will be further processed, hopefully tomorrow…

[Edited on 18-11-2011 by blogfast25]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

After filtering and drying (on a hot plate), I obtained a disappointing 6.3 g NdF3. TY should have been about 20, I was hoping for about 10 g and got

6. On the bright side, the product is clearly pink/lanender in tungsten light and switches quite dramatically to this eerie green under TL. With what

I’ve made today I should have about 10 g or more, enough for an ‘all in’ attempt.

So with the last magnet (28 g) I revisited the K2SO4/Nd sulphate double salt method, to try and clear a few things up.

Everything was uneventful at first. I set the first filtrate (after precipitation of the Nd double salt) but before any washing, aside as ‘Filtrate

A’, then washed with cold, saturated K2SO4 and obtained this ‘pretty in pink’: the NdK double sulphate (hydrate):

But it was during washing I stumbled on a mistake I made in the previous runs and which explains I found a lot of iron in the washed double sulphate:

without controlling the pH in the washing solution iron becomes oxidised to Fe3+ and at the higher pH (4 - 5 or above) starts dropping out. That then

get caught in the filter cake and there’s your contamination! Remedy: simply acidify the washing solution of sat. K2SO4 slightly.

The liquid obtained from washing was labelled ‘Filtrate B’.

I then proceeded to test both A and B for presence of Nd with oxalate. Obviously this can’t be done in the presence of ferrous material because FeOx

is poorly soluble (and there’s a lot of Fe). Therefore 50 ml of both solutions were oxidised on ice bath with 9 % H2O2, simmered to destroy any

excess H2O2, then calculated amounts of oxalic acid dehydrate were added. This complexes the Fe3+ to soluble trioxaloferrate (III)

(FeOx<sub>3</sub><sup>3-</sup>. This for instance is B after that treatment: the trioxaloferrate complex is emerald green:

What is very interesting is that in neither the cases of A nor B after treatment does any insoluble neodymium oxalate precipitate, none whatsoever,

indicating the separation is complete.

The double sulphate was then converted to Nd(OH)3 with KOH, filtered and washed and dissolved in 10 ml of glacial acetic acid and 50 ml water, chosen

because my HCl contains traces of Fe3+. The hydroxide dissolved well in that solvent but needed a little heat. And that caused precipitation! First I

thought Fe(OH)3 but it’s whitish. Remnants of Nd sulphate? A hydrolysis product of Nd acetate? To be figured out tomorrow…

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

Here's a video I made of the last round of separation by evaporation of the ferrous sulfate form the neodymium sulfate.

http://youtu.be/UoWkqdHnEQc

Play it at high resolution, and if you look close at the lighted side, you'll see the crystals form and grow before being covered in the green iron

sulfate.

This is how I separate the two, but this sample was not run hot enough, and was not stopped once the iron sulfate crust forms- Simply stopping

evaporation at a certain point and filtering out the precipitated crystals of neodymium sulfate from the solution of (almost pure) ferrous sulfate is

my process. This video was more a time-lapse demo- I have rehydrated the mess, and I am already recrystallizing.

[Edited on 11-22-2011 by Wizzard]

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

A slightly better video:

http://youtu.be/hY51xRO7SjA

Anybody else still working on this? I've accumulated almost 10g of Nd2(SO4)3

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Oh yes. Now drying another batch of hopefully 10 g of NdF3.

|

|

|

| Pages:

1

..

4

5

6

7

8

..

24 |